A Strategy for Research and Development

Research and development (R & D) needs to be carefully planned and managed to succeed. It is easy to waste money on developing ideas that go nowhere, but getting it right can lead to business stability, security and long-term profits.

Planning

R & D should be included in your overall business plan. The plan should illustrate the direction you want the business to take and how R & D fits in with your other business activities. Set out clear objectives, time frames and budgets. A clear plan can prevent the project straying from your business goals and wasting valuable resources and money.

You may need to involve staff with specific skills to draw up the plan, for example finance staff to set up budgets. You may also need outside help.

Your plan should set out the steps that need to be taken from the inception of the ideas to the product launch. You should allocate the necessary resources to the project, including funding, staff and time. You might decide to set up a specific team to work on the project.

Management

Good management is vital to reduce risk of failure and realize as many ideas as possible.

To manage R & D projects effectively you should:

" Make sure staff involved in R & D understand the business' overall strategy;

" Ensure these employees understand what is commercially realistic;

" Assess the changing risks and potential of projects as they progress, continually developing a rigorous business case;

" Ensure that intellectual property ownership issues are resolved;

" Recognize when a project isn't going to work; and

" Understand the relative importance of different projects to your business.

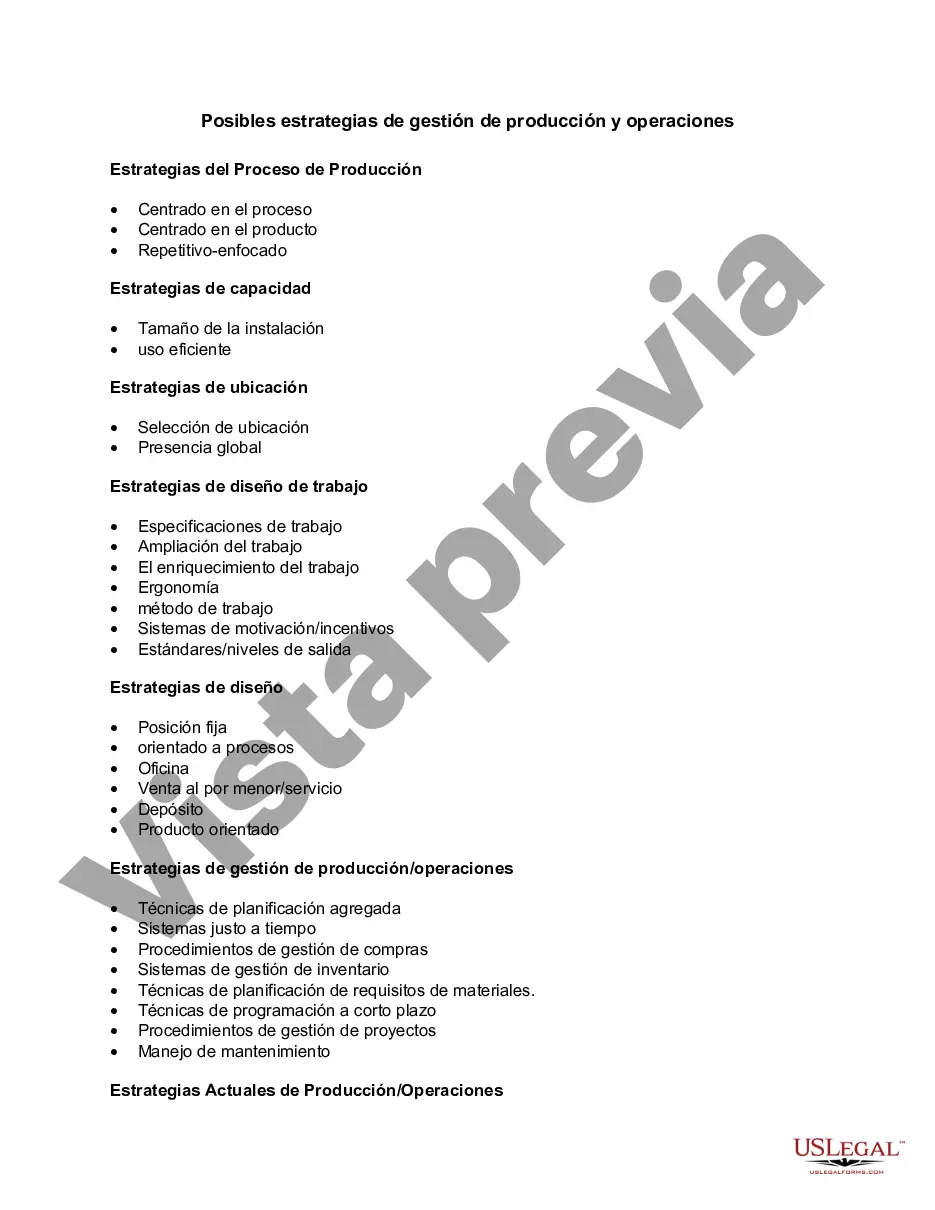

California Possible Production and Operations Management Strategies are innovative methodologies aimed at enhancing productivity, efficiency, and profitability within California-based businesses. These strategies rely on a combination of advanced technologies, streamlined processes, and effective decision-making to optimize production and operations, ultimately leading to growth and competitive advantage in the market. One prominent approach to California Possible Production and Operations Management Strategies is lean manufacturing. Lean manufacturing emphasizes minimizing waste, increasing efficiency, and maximizing customer value. This methodology entails continuous improvements, eliminating non-value-added activities, optimizing flow, and ensuring quality at every step of the production process. By adopting lean manufacturing, California businesses can reduce costs, improve delivery times, and enhance overall customer satisfaction. Another vital strategy in California Possible Production and Operations Management is agility. With rapidly changing market conditions, businesses need to be adaptable and responsive to stay ahead of their competition. Agile strategies involve maintaining flexibility and quick responding capabilities to unforeseen events or customer demands. This approach helps businesses adjust production and operations in real-time, ensuring effective resource allocation, reduced lead times, and enhanced customer satisfaction. Furthermore, California Possible Production and Operations Management Strategies encompass environmental sustainability practices. Given the state's commitment to eco-friendly initiatives, many businesses in California focus on reducing their environmental impacts. Implementing sustainable manufacturing processes, adopting energy-efficient technologies, and reducing waste generation not only aligns with the state's objectives but also improves brand image and attracts environmentally conscious customers. In addition to these strategies, California Possible Production and Operations Management also includes just-in-time (JIT) manufacturing and total quality management (TQM). JIT, an inventory management approach, aims to minimize inventory levels while ensuring the availability of materials as needed. TQM emphasizes the consistent delivery of high-quality products or services through continuous improvement, employee empowerment, and customer-focused practices. In summary, California Possible Production and Operations Management Strategies encompass a range of methodologies focused on enhancing productivity, efficiency, and environmental sustainability of businesses in California. These strategies include lean manufacturing, agility, environmental sustainability practices, JIT manufacturing, and TQM. By implementing these strategies, businesses can anticipate cost reduction, improved profitability, enhanced customer satisfaction, and a competitive edge in the California market.

Para su conveniencia, debajo del texto en español le brindamos la versión completa de este formulario en inglés. For your convenience, the complete English version of this form is attached below the Spanish version.