A Strategy for Research and Development

Research and development (R & D) needs to be carefully planned and managed to succeed. It is easy to waste money on developing ideas that go nowhere, but getting it right can lead to business stability, security and long-term profits.

Planning

R & D should be included in your overall business plan. The plan should illustrate the direction you want the business to take and how R & D fits in with your other business activities. Set out clear objectives, time frames and budgets. A clear plan can prevent the project straying from your business goals and wasting valuable resources and money.

You may need to involve staff with specific skills to draw up the plan, for example finance staff to set up budgets. You may also need outside help.

Your plan should set out the steps that need to be taken from the inception of the ideas to the product launch. You should allocate the necessary resources to the project, including funding, staff and time. You might decide to set up a specific team to work on the project.

Management

Good management is vital to reduce risk of failure and realize as many ideas as possible.

To manage R & D projects effectively you should:

" Make sure staff involved in R & D understand the business' overall strategy;

" Ensure these employees understand what is commercially realistic;

" Assess the changing risks and potential of projects as they progress, continually developing a rigorous business case;

" Ensure that intellectual property ownership issues are resolved;

" Recognize when a project isn't going to work; and

" Understand the relative importance of different projects to your business.

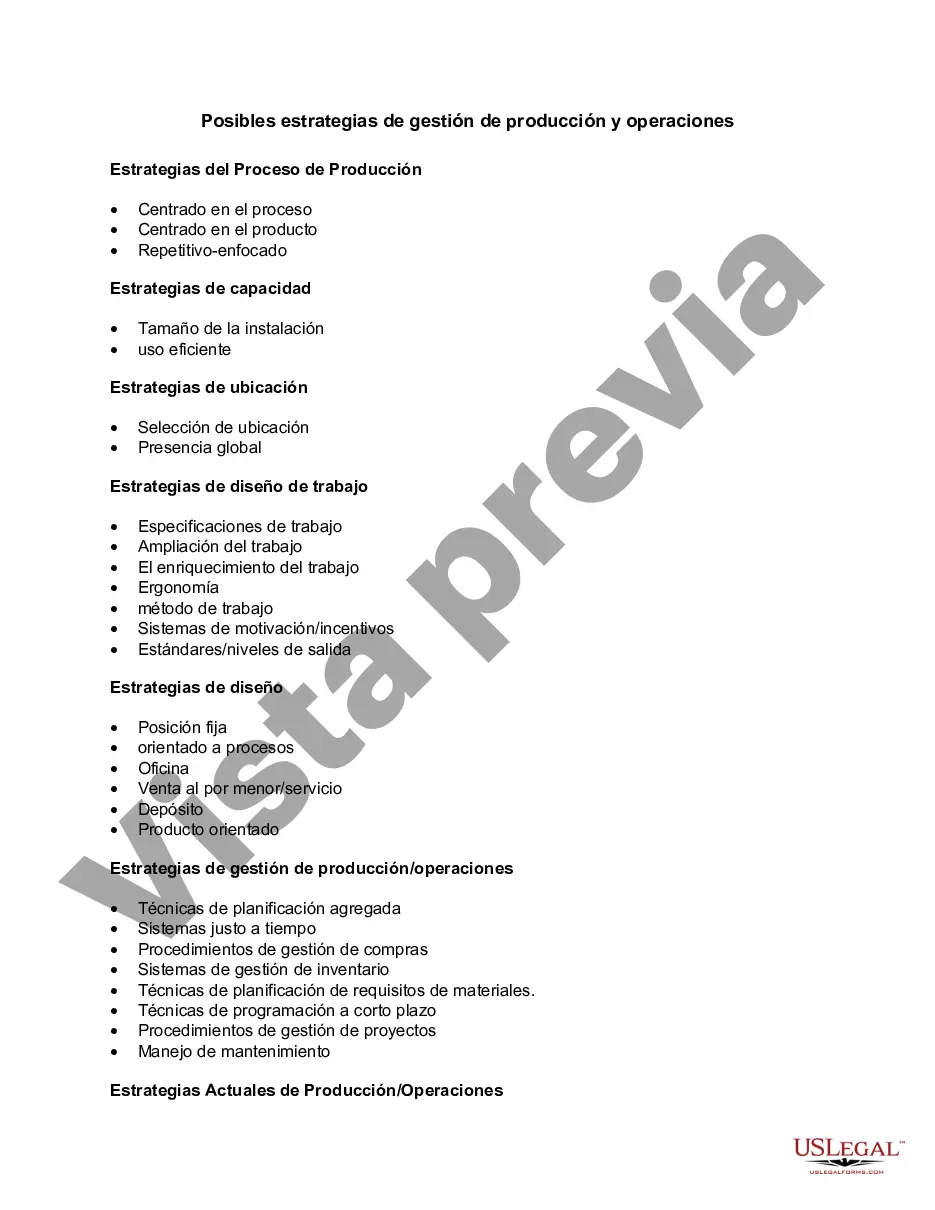

Indiana Possible Production and Operations Management Strategies are various methodologies implemented by organizations in Indiana to optimize their production and operational processes. These strategies aim to improve efficiency, reduce costs, increase productivity, and deliver quality products and services to customers. Below, we will explore some key production and operations management strategies commonly employed in Indiana: 1. Lean Manufacturing: Lean manufacturing focuses on minimizing waste and maximizing value in manufacturing processes. It involves streamlining operations, reducing inventory, and enhancing employee involvement to achieve cost savings and better customer satisfaction. 2. Six Sigma: Six Sigma is a data-driven approach that aims to improve process quality by identifying and eliminating defects or errors. It involves utilizing statistical tools and techniques to measure performance, analyze data, and implement process improvements to achieve near-perfect levels of quality. 3. Just-In-Time (JIT): JIT strategy emphasizes producing and delivering products or services just when they are needed. It focuses on minimizing inventory levels, reducing lead times, and improving overall efficiency through closer coordination with suppliers and customers. 4. Total Quality Management (TQM): TQM is a comprehensive approach that focuses on continuous improvement, customer satisfaction, and employee involvement. It involves establishing a quality-oriented culture, implementing quality control processes, and continuously monitoring performance to identify and address problems at all levels of the organization. 5. Supply Chain Management: Supply chain management encompasses the coordination and optimization of all activities involved in delivering products and services to customers. It includes managing suppliers, inventory, logistics, and distribution channels to ensure smooth operations, minimize costs, and meet customer demands. 6. Agile Manufacturing: Agile manufacturing emphasizes flexibility, adaptability, and quick response to customer demands. It involves leveraging technology, efficient communication channels, and cross-functional teams to enable rapid product development, production, and delivery. 7. Business Process Reengineering (BPR): BPR involves rethinking and redesigning business processes to achieve significant improvements in efficiency, quality, and customer satisfaction. It often requires radical changes, such as the integration of technology and reorganization of workflows, to enable dramatic performance improvements. Overall, Indiana Possible Production and Operations Management Strategies encompass a wide range of methodologies aimed at optimizing production and operational processes. By implementing these strategies, organizations in Indiana can drive competitive advantage, improve customer satisfaction, and achieve sustainable growth in today's dynamic business environment.

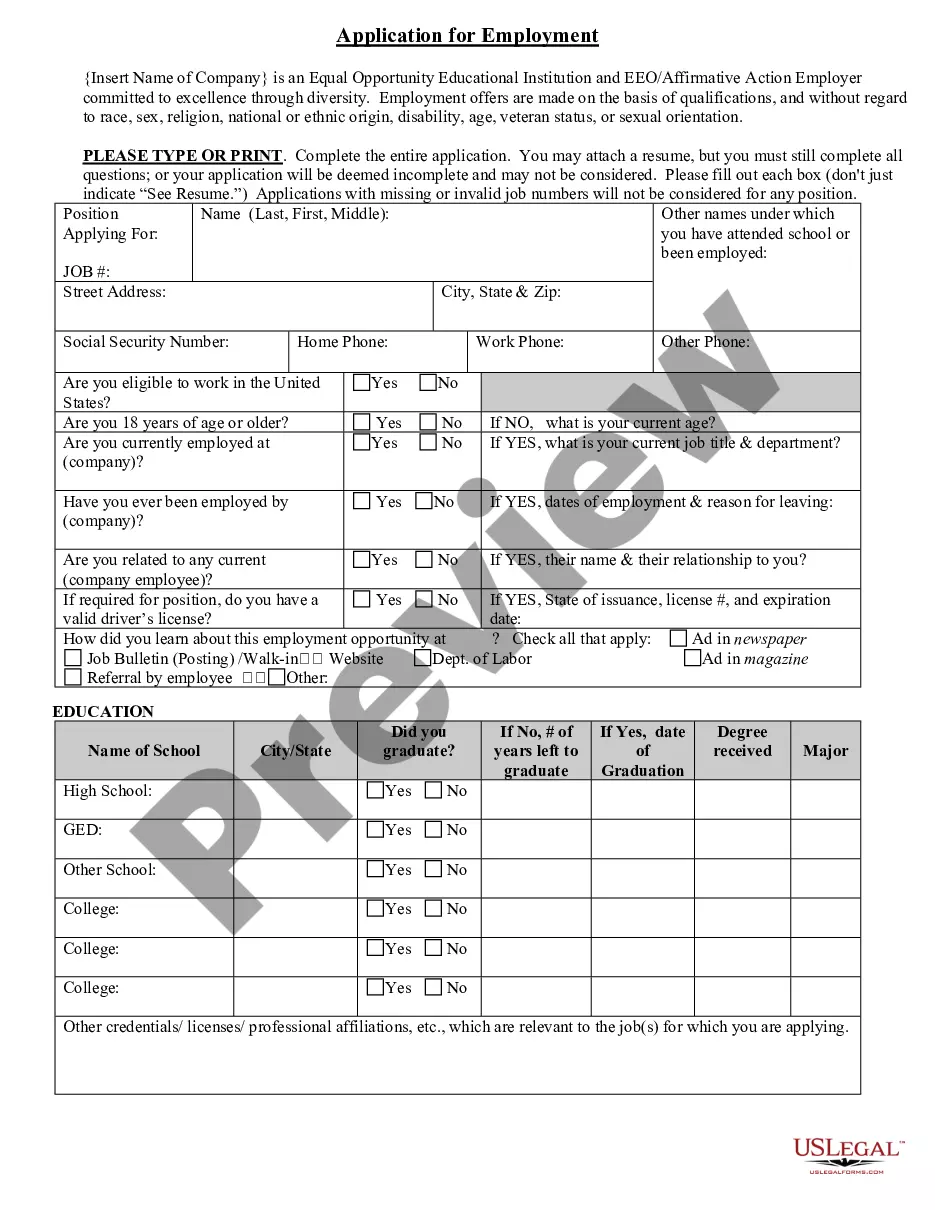

Para su conveniencia, debajo del texto en español le brindamos la versión completa de este formulario en inglés. For your convenience, the complete English version of this form is attached below the Spanish version.