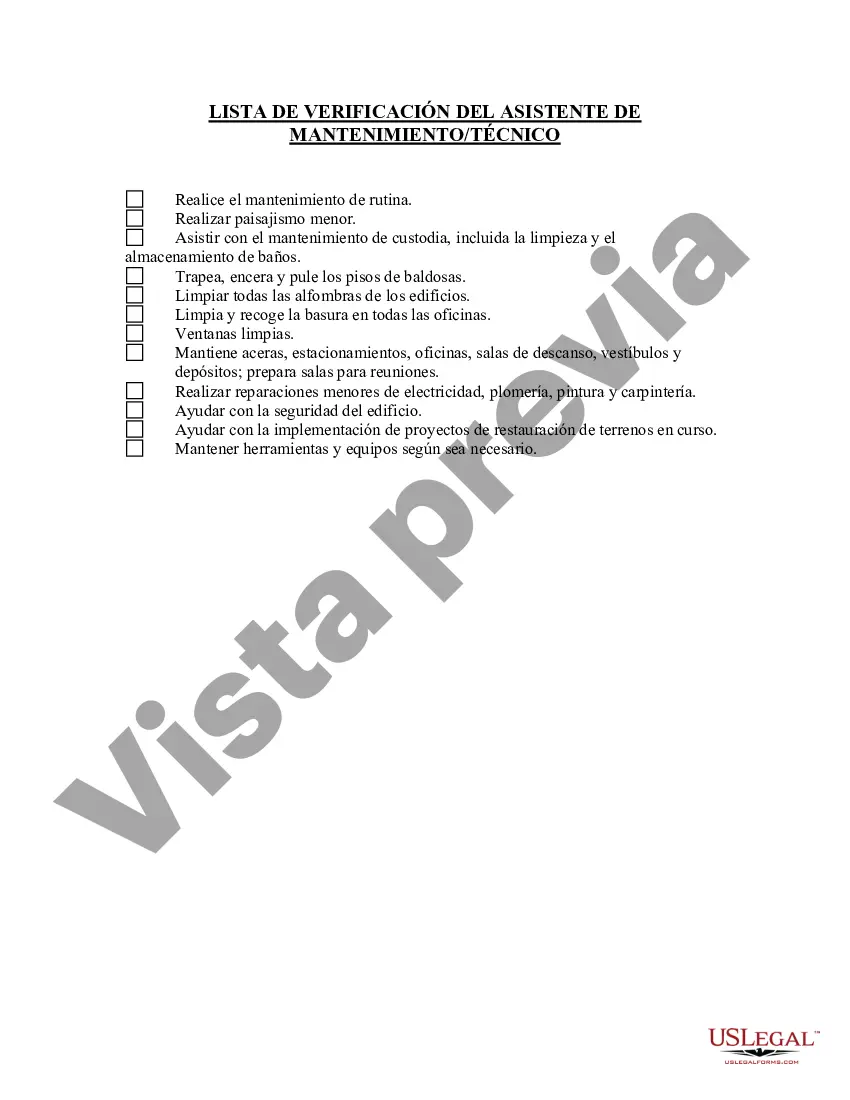

Description: The Michigan Maintenance Assistance — Technician Checklist is a comprehensive guide that outlines the essential tasks and considerations for technicians carrying out maintenance and repair work in Michigan. This checklist serves as a helpful tool to ensure that all necessary steps are taken to maintain equipment, facilities, or systems in optimal working condition. It encompasses various types of maintenance, including preventive, corrective, and predictive, covering a wide range of industries such as manufacturing, automotive, healthcare, and more. The checklist includes key components and areas that technicians need to inspect, evaluate, and address during a maintenance assignment. It begins with an initial assessment to identify the scope of work required, followed by a thorough evaluation of equipment or systems, identifying potential issues or areas of improvement. The checklist highlights specific maintenance tasks, such as cleaning, lubricating, adjusting, and replacing components as necessary. Key sections of the Michigan Maintenance Assistance — Technician Checklist may include: 1. Environmental Health and Safety: — Verify compliance with safety regulations and protocols. — Inspect and maintain safety equipment like fire extinguishers and emergency exits. — Evaluate and address any hazardous materials or potential risks. 2. Equipment or System Inspection: — Check for wear and tear, leaks, or signs of damage. — Test functionality of components and verify proper operation. — Review equipment manuals and specifications for reference. 3. Preventive Maintenance: — Perform routine cleaning, lubrication, and calibration of equipment. — Identify and address potential issues before they cause significant problems. — Record maintenance activities and schedule future service intervals. 4. Corrective Maintenance: — Address identified issues promptly to prevent further damage or downtime. — Repair or replace faulty components or systems. — Collaborate with other teams or specialists if required. 5. Predictive Maintenance: — Utilize advanced diagnostic tools and techniques to assess equipment condition. — Analyze data trends and performance indicators to predict potential failures. — Implement proactive measures to minimize downtime and extend equipment lifespan. Different types of Michigan Maintenance Assistance — Technician Checklists may be tailored to specific industries or sectors. For instance: 1. Manufacturing Maintenance Assistance — Technician Checklist— - Focuses on the maintenance needs of production machinery, assembly lines, and manufacturing facilities. 2. Automotive Maintenance Assistance — Technician Checklist— - Covers maintenance procedures for vehicles, including routine inspections, fluid changes, brake servicing, and more. 3. Healthcare Facility Maintenance Assistance — Technician Checklist— - Tailored to the unique maintenance requirements of hospitals, clinics, and healthcare facilities, emphasizing cleanliness, sterilization, and medical equipment maintenance. By utilizing the Michigan Maintenance Assistance — Technician Checklist, technicians can ensure thorough and standardized maintenance procedures, resulting in improved efficiency, enhanced safety, and prolonged lifespan of equipment and systems.

Para su conveniencia, debajo del texto en español le brindamos la versión completa de este formulario en inglés. For your convenience, the complete English version of this form is attached below the Spanish version.Michigan Asistencia de mantenimiento - Lista de verificación del técnico - Maintenance Assistance - Technician Checklist

Description

How to fill out Michigan Asistencia De Mantenimiento - Lista De Verificación Del Técnico?

Are you currently in a position in which you require paperwork for either company or individual uses virtually every day time? There are a variety of authorized document templates available on the net, but finding ones you can trust is not easy. US Legal Forms provides a huge number of kind templates, much like the Michigan Maintenance Assistance - Technician Checklist, which are composed in order to meet state and federal demands.

When you are already knowledgeable about US Legal Forms web site and get an account, just log in. Following that, you can download the Michigan Maintenance Assistance - Technician Checklist format.

If you do not come with an accounts and need to begin to use US Legal Forms, follow these steps:

- Obtain the kind you want and ensure it is for the right city/state.

- Utilize the Preview key to analyze the form.

- Read the information to ensure that you have chosen the proper kind.

- When the kind is not what you are searching for, use the Lookup area to discover the kind that meets your needs and demands.

- When you discover the right kind, just click Purchase now.

- Choose the rates program you desire, fill in the specified information and facts to make your account, and pay for an order utilizing your PayPal or charge card.

- Decide on a handy paper format and download your backup.

Discover each of the document templates you may have bought in the My Forms food selection. You can obtain a extra backup of Michigan Maintenance Assistance - Technician Checklist at any time, if possible. Just click the essential kind to download or print out the document format.

Use US Legal Forms, the most substantial selection of authorized kinds, to save lots of time and steer clear of errors. The support provides appropriately made authorized document templates which can be used for an array of uses. Produce an account on US Legal Forms and commence creating your life easier.