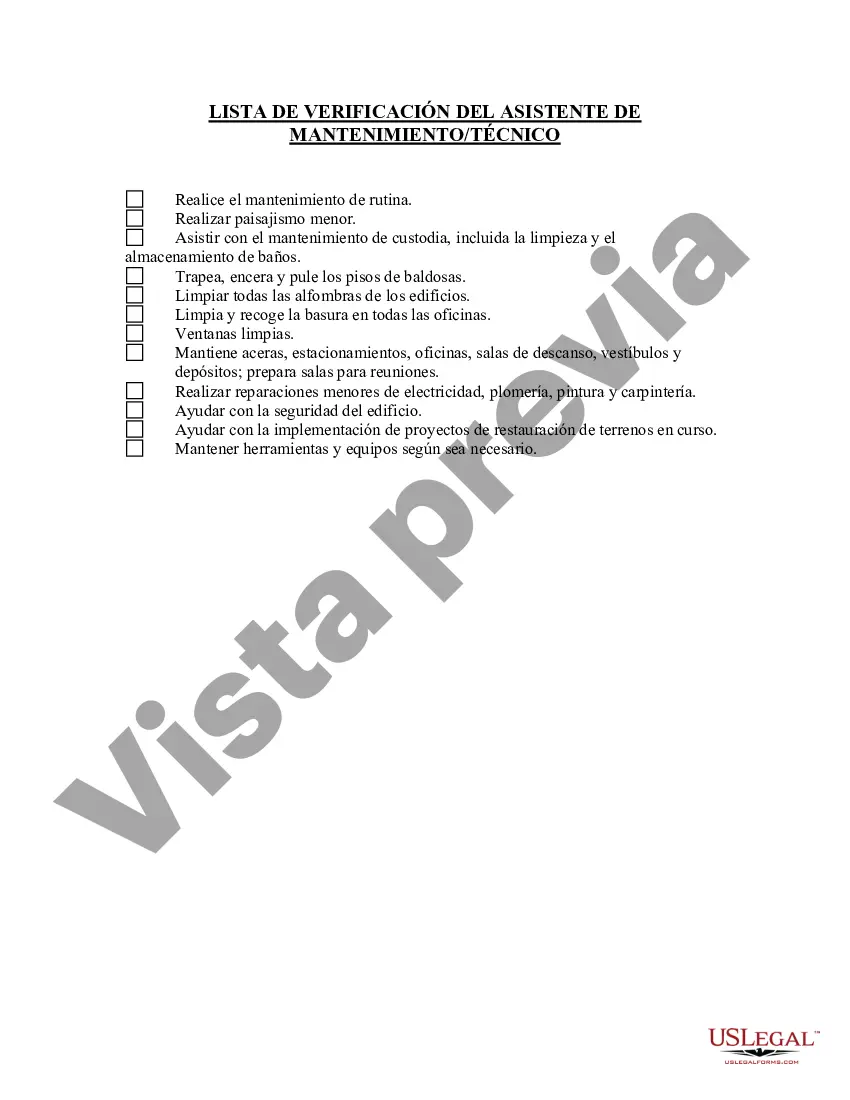

Missouri Maintenance Assistance is a program designed to provide support and guidance to technicians in conducting efficient and effective maintenance activities. The Missouri Maintenance Assistance — Technician Checklist is an essential tool used in this program to ensure all necessary tasks are completed and standards are met. This checklist contains a comprehensive list of items that technicians need to review, inspect, and address to maintain the optimal functionality of equipment, machinery, or facilities. The Missouri Maintenance Assistance — Technician Checklist covers different areas of maintenance, including equipment inspection, troubleshooting, repairs, and preventive maintenance tasks. It is specifically tailored to meet the requirements of various industries such as manufacturing, construction, healthcare, or transportation. The checklist includes relevant keywords such as equipment maintenance, inspection, repair, troubleshooting, and preventive maintenance to ensure that all essential aspects of maintenance are addressed. By following this checklist, technicians can identify potential issues, perform necessary repairs, and prevent breakdowns or malfunctions, thus minimizing costly downtime. Additionally, the Missouri Maintenance Assistance program offers different types of checklists based on specific maintenance needs. Some different types of Missouri Maintenance Assistance — Technician Checklists include: 1. Equipment Maintenance Checklist: This checklist focuses on the inspection, lubrication, calibration, and maintenance of specific equipment or machinery. It ensures that each component and system of the equipment is in optimal condition to prevent failures or malfunctions. 2. Facility Maintenance Checklist: This checklist is designed to cover various aspects of facility maintenance, such as electrical systems, HVAC systems, plumbing, safety equipment, lighting, and general cleanliness. It ensures that the facility is well-maintained, safe, and complies with relevant regulations. 3. Preventive Maintenance Checklist: This type of checklist emphasizes routine maintenance tasks aimed at preventing potential failures or breakdowns. It includes activities like filter replacements, lubrication, cleaning, and inspections. 4. Troubleshooting Checklist: In case of equipment malfunction or failure, this checklist assists technicians in systematically identifying the root cause of the problem. It provides a step-by-step guide to diagnose and resolve issues efficiently. These different types of Missouri Maintenance Assistance — Technician Checklists help technicians streamline their maintenance activities, promoting a proactive approach to equipment and facility management. By using these checklists, technicians can maintain equipment longevity, reduce downtime, and ensure optimal performance, ultimately enhancing productivity and profitability.

Para su conveniencia, debajo del texto en español le brindamos la versión completa de este formulario en inglés. For your convenience, the complete English version of this form is attached below the Spanish version.Missouri Asistencia de mantenimiento - Lista de verificación del técnico - Maintenance Assistance - Technician Checklist

Description

How to fill out Missouri Asistencia De Mantenimiento - Lista De Verificación Del Técnico?

Are you presently in a place where you need to have paperwork for both organization or person purposes virtually every day? There are a lot of legal document templates accessible on the Internet, but getting kinds you can rely on is not simple. US Legal Forms offers 1000s of develop templates, like the Missouri Maintenance Assistance - Technician Checklist, which are composed to satisfy state and federal needs.

In case you are currently familiar with US Legal Forms site and possess your account, basically log in. After that, you may acquire the Missouri Maintenance Assistance - Technician Checklist template.

If you do not provide an accounts and want to start using US Legal Forms, abide by these steps:

- Find the develop you need and ensure it is to the right metropolis/state.

- Use the Review option to examine the form.

- Browse the description to actually have chosen the right develop.

- If the develop is not what you are searching for, take advantage of the Search industry to obtain the develop that fits your needs and needs.

- Whenever you get the right develop, just click Acquire now.

- Pick the prices plan you need, fill out the required information and facts to generate your bank account, and pay for the transaction making use of your PayPal or charge card.

- Choose a practical document format and acquire your version.

Discover all the document templates you might have bought in the My Forms food list. You can obtain a more version of Missouri Maintenance Assistance - Technician Checklist whenever, if needed. Just go through the needed develop to acquire or print the document template.

Use US Legal Forms, the most considerable selection of legal forms, to save lots of efforts and stay away from blunders. The service offers professionally made legal document templates which you can use for an array of purposes. Make your account on US Legal Forms and commence producing your life a little easier.

Form popularity

FAQ

The purpose of maintenance is to ensure the maximum efficiency and availability of production equipment, utilities and related facilities at optimal cost and under satisfactory conditions of quality, safety and protection for the environment.

An effective preventative maintenance schedule avoids equipment failure, which can represent not only decreased productivity but also workplace safety risks to employees. In addition, a preventive maintenance checklist reduces human errors and contains important safety instructions that minimize the chance of injury.

Simply put, maintenance performed on a regular basis to reduce the likelihood of failure is preventive maintenance. Also called planned or preventative maintenance, PM is conducted throughout an asset's normal operating conditions.

Six Tips for Creating a PM ChecklistInvolve the Right People in the Process. When planning the assets to maintain and creating PMs for each one, it helps to have the right types of expertise on board.Be Detailed, but Concise.Include Pictures.Include Safety Measures.Make Your Checklists Mobile.Update as Needed.

The primary objective of planned maintenance is to maximize equipment performance by keeping equipment running safely for as long as possible, without that equipment deteriorating or having unplanned outages. Planned maintenance activities include any maintenance work scheduled in advance.

A preventive maintenance checklist is an itemized list of written tasks that guide technicians through a process of asset's preventive maintenance (PM).

A preventive maintenance plan can save a company money because it will managers and staff to focus on preventing equipment failure rather than reacting in case of emergencies. Preventive maintenance checklists can help you to monitor your assets based on maintenance goals, expected needs and past performance.

By identifying components or parts that are wearing out and repairing or replacing them before they fail, an effective preventive maintenance program can help limit production downtime and extend the service life of equipment and facilities.

For example: performing regular business and equipment inspections, cleaning and lubricating essential equipment, and tidying your business's grounds are all examples of preventive maintenance. The goal of preventive maintenance is to prevent equipment failure before it occurs, and to reduce the risk of accidents.