South Dakota Maintenance Engineer Checklist

Category:

State:

Multi-State

Control #:

US-381EM

Format:

Word;

Rich Text

Instant download

Description

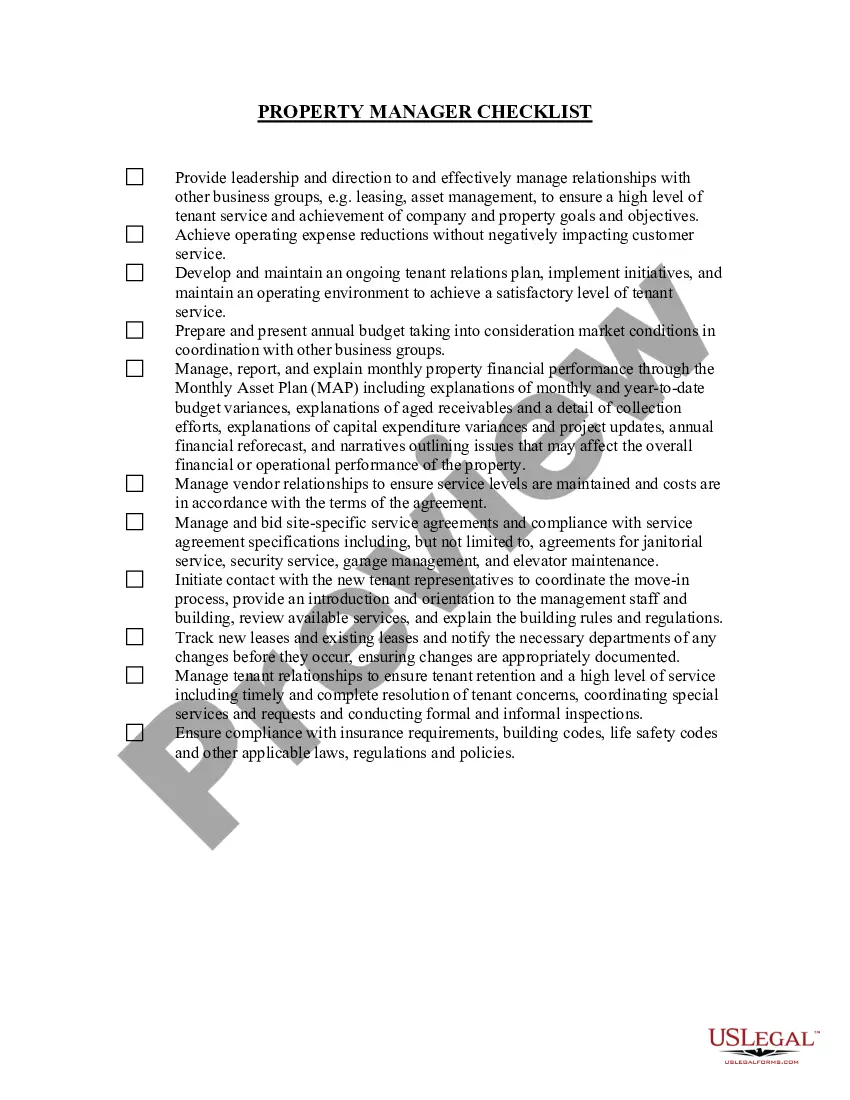

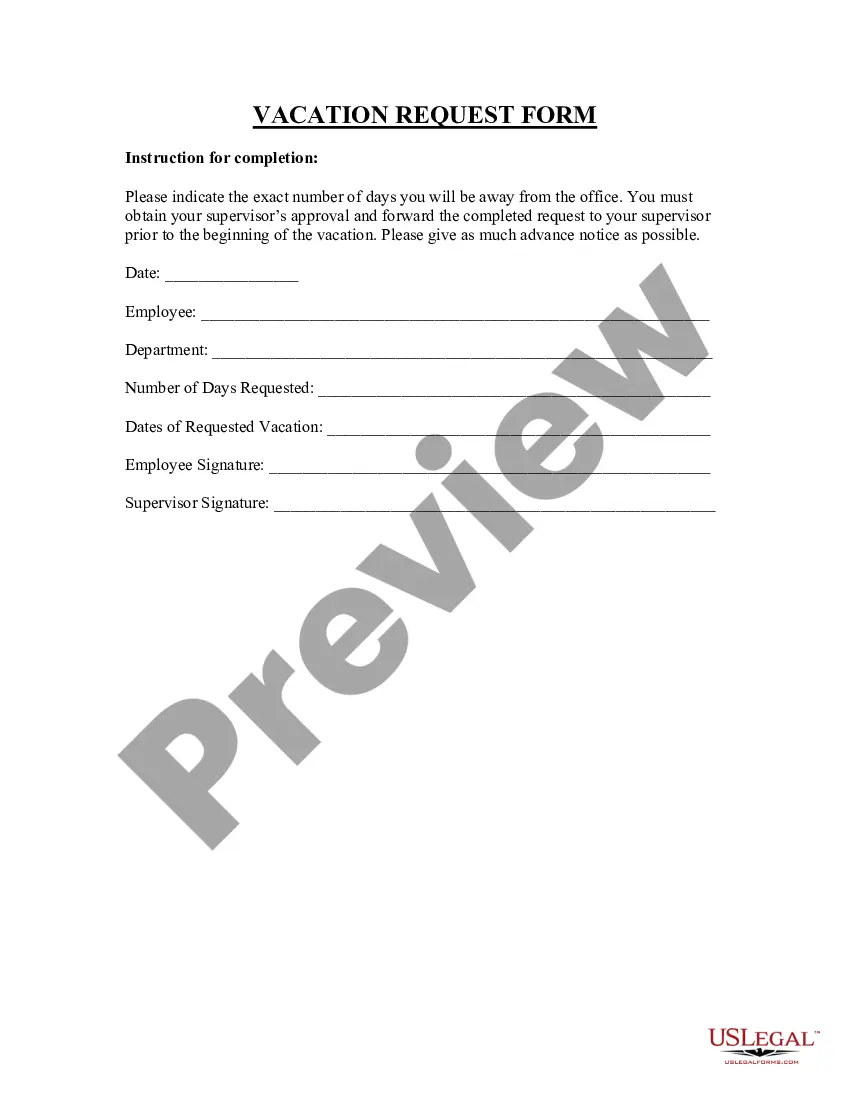

This form is used to list the potential duties of a maintenance engineer.

Free preview

How to fill out Maintenance Engineer Checklist?

If you want to finish, download, or create valid document templates, use US Legal Forms, the largest array of legal forms, available online.

Utilize the website's simple and user-friendly search to find the documents you need.

Various templates for business and personal purposes are grouped by types and states, or keywords.

Step 4. Once you have found the form you need, click the Get now button. Choose the pricing plan you prefer and enter your details to register for an account.

Step 5. Complete the transaction. You can use your credit card or PayPal account to finalize the transaction.

- Use US Legal Forms to acquire the South Dakota Maintenance Engineer Checklist with just a few clicks.

- If you are already a US Legal Forms customer, Log In to your account and click the Download button for the South Dakota Maintenance Engineer Checklist.

- You can also access forms you previously obtained in the My documents tab of your account.

- If you are using US Legal Forms for the first time, follow the instructions below.

- Step 1. Make sure you have chosen the form for the correct city/state.

- Step 2. Use the Preview option to review the form's content. Don't forget to read the information.

- Step 3. If you are not satisfied with the type, use the Search section at the top of the screen to find other versions of the legal form template.