Title: Understanding the Vermont Shipping Order for Warehoused Goods: Types and Process Explained Keywords: Vermont shipping order, warehoused goods, types, process, inventory management, logistics, distribution, warehouse shipments, shipping documents Introduction: The Vermont shipping order for warehoused goods plays a crucial role in facilitating efficient inventory management, logistics, and distribution processes. In this article, we will delve into the details of the Vermont Shipping Order for Warehoused Goods, shedding light on its types and the step-by-step process involved in issuing and tracking these orders. Types of Vermont Shipping Order for Warehoused Goods: 1. Outbound Shipping Order: This type of Vermont Shipping Order is utilized when goods are ready to be shipped from a warehouse to their intended destinations. It involves creating a detailed order, specifying the items, quantities, shipping methods, and delivery instructions. 2. Inbound Shipping Order: Within the realm of Vermont Shipping Orders for Warehoused Goods, the inbound shipment order is employed when items are expected to arrive at a warehouse from suppliers or other locations. It allows warehouses to prepare for incoming goods, ensuring smooth operations and proper inventory management. 3. Inter-Warehouse Shipping Order: When there is a need to transfer goods from one warehouse to another within Vermont, inter-warehouse shipping orders are used. This type of order helps optimize distribution, ensuring that goods reach their destined warehouses efficiently while maintaining accurate inventory records. The Process of Vermont Shipping Order for Warehoused Goods: 1. Order Generation: A Vermont shipping order begins by identifying the need for shipping goods. This can be triggered by various factors such as an outbound customer order, replenishing warehouse stocks, or transferring items between warehouses. 2. Document Preparation: Once the need for shipping is established, the necessary shipping documents are prepared. These typically include a detailed shipping order, packing list, bill of lading, and any other required documentation. 3. Order Authorization: The shipping order must be authorized by relevant personnel within the organization, such as warehouse managers or logistics coordinators. This step ensures accountability and accuracy throughout the process. 4. Goods Packing and Preparation: The warehouse staff gathers the items specified in the shipping order and packs them securely. Each package is labeled appropriately, and necessary transportation preparations, such as palletizing or crating, are done to ensure safe handling during transit. 5. Shipping Carrier Selection: Depending on the requirements and nature of the goods being shipped, a shipping carrier is selected. Various factors considered include cost-effectiveness, delivery timeframes, and the carrier's expertise in handling specific types of goods. 6. Shipment Tracking: To monitor the movement and delivery status of goods as they leave the warehouse, the shipping order includes tracking information. This enables the warehouse, inventory management, and the concerned parties to stay informed about the current status of the shipment. 7. Delivery and Documentation: Once the goods are delivered to their destination, the receiving party provides acknowledgment of receipt, allowing the shipping process to be formally concluded. Additionally, any required paperwork, such as delivery receipts or proof of delivery, is collected and filed for record-keeping purposes. Conclusion: Efficiently managing Vermont shipping orders for warehoused goods is crucial for smooth inventory management, logistics, and distribution processes. By understanding the different types of shipping orders and following a standardized process, businesses can ensure reliable and streamlined shipment operations, resulting in enhanced customer satisfaction and improved overall supply chain performance.

Para su conveniencia, debajo del texto en español le brindamos la versión completa de este formulario en inglés. For your convenience, the complete English version of this form is attached below the Spanish version.Vermont Orden de envío para mercancías almacenadas - Shipping Order for Warehoused Goods

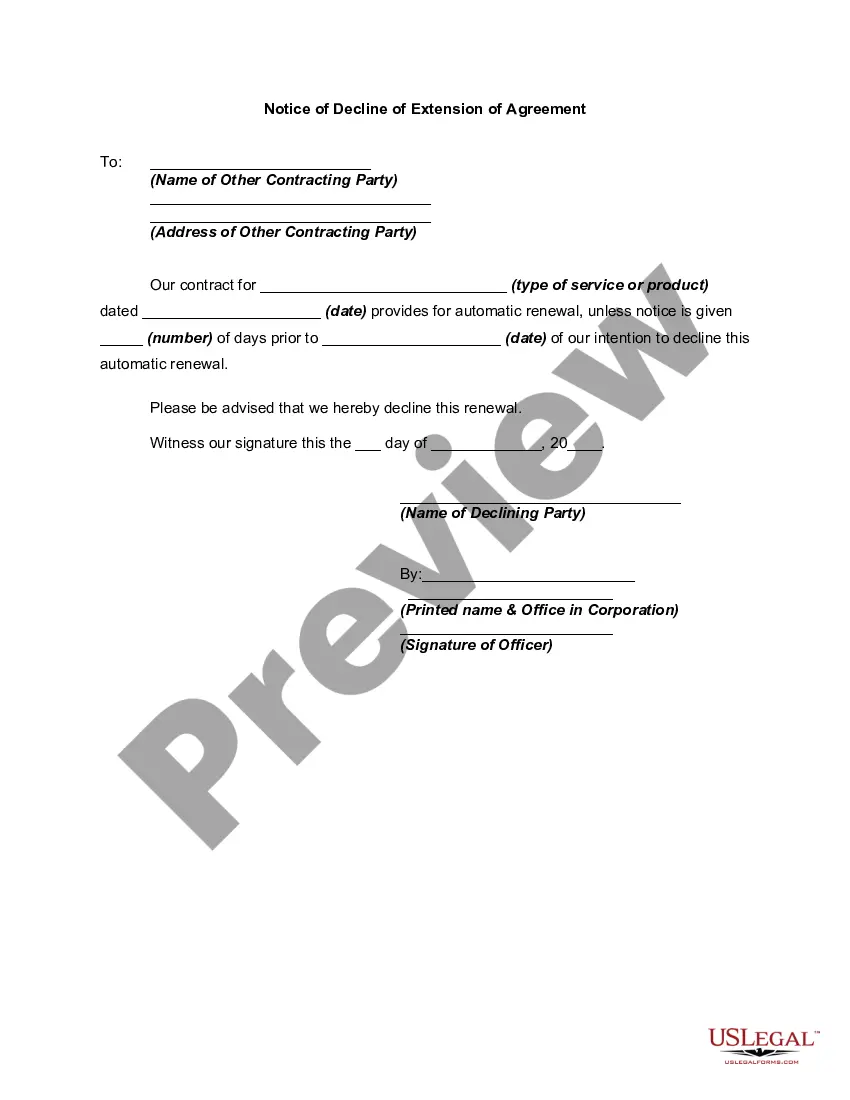

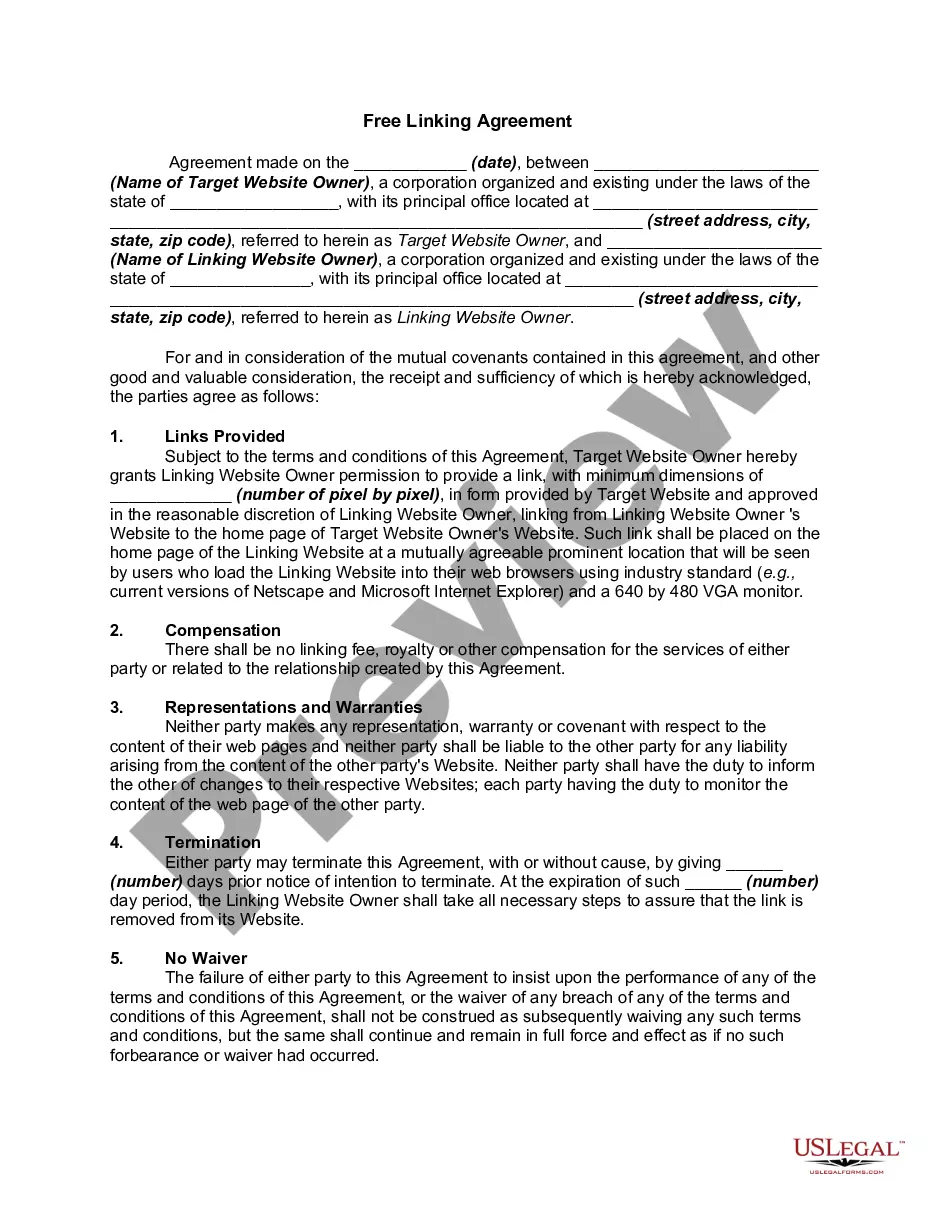

Description

How to fill out Vermont Orden De Envío Para Mercancías Almacenadas?

US Legal Forms - one of many most significant libraries of legal types in the United States - provides a variety of legal papers templates you may down load or produce. Utilizing the site, you will get a huge number of types for business and specific uses, sorted by categories, says, or search phrases.You will discover the newest versions of types such as the Vermont Shipping Order for Warehoused Goods in seconds.

If you already have a subscription, log in and down load Vermont Shipping Order for Warehoused Goods from your US Legal Forms library. The Down load option will show up on each and every form you view. You have accessibility to all in the past acquired types inside the My Forms tab of your own profile.

In order to use US Legal Forms for the first time, here are easy recommendations to get you started:

- Be sure you have chosen the proper form for your personal area/county. Go through the Review option to examine the form`s content. Read the form description to ensure that you have selected the appropriate form.

- When the form doesn`t match your requirements, use the Look for area near the top of the display screen to find the one which does.

- When you are content with the form, confirm your option by clicking on the Buy now option. Then, opt for the pricing program you like and supply your references to register for the profile.

- Approach the transaction. Utilize your bank card or PayPal profile to finish the transaction.

- Pick the formatting and down load the form on the device.

- Make modifications. Fill out, change and produce and indication the acquired Vermont Shipping Order for Warehoused Goods.

Every single format you added to your money does not have an expiry time and is also the one you have permanently. So, if you would like down load or produce one more duplicate, just go to the My Forms portion and then click around the form you want.

Get access to the Vermont Shipping Order for Warehoused Goods with US Legal Forms, by far the most comprehensive library of legal papers templates. Use a huge number of professional and status-specific templates that fulfill your business or specific requirements and requirements.