A Strategy for Research and Development

Research and development (R & D) needs to be carefully planned and managed to succeed. It is easy to waste money on developing ideas that go nowhere, but getting it right can lead to business stability, security and long-term profits.

Planning

R & D should be included in your overall business plan. The plan should illustrate the direction you want the business to take and how R & D fits in with your other business activities. Set out clear objectives, time frames and budgets. A clear plan can prevent the project straying from your business goals and wasting valuable resources and money.

You may need to involve staff with specific skills to draw up the plan, for example finance staff to set up budgets. You may also need outside help.

Your plan should set out the steps that need to be taken from the inception of the ideas to the product launch. You should allocate the necessary resources to the project, including funding, staff and time. You might decide to set up a specific team to work on the project.

Management

Good management is vital to reduce risk of failure and realize as many ideas as possible.

To manage R & D projects effectively you should:

" Make sure staff involved in R & D understand the business' overall strategy;

" Ensure these employees understand what is commercially realistic;

" Assess the changing risks and potential of projects as they progress, continually developing a rigorous business case;

" Ensure that intellectual property ownership issues are resolved;

" Recognize when a project isn't going to work; and

" Understand the relative importance of different projects to your business.

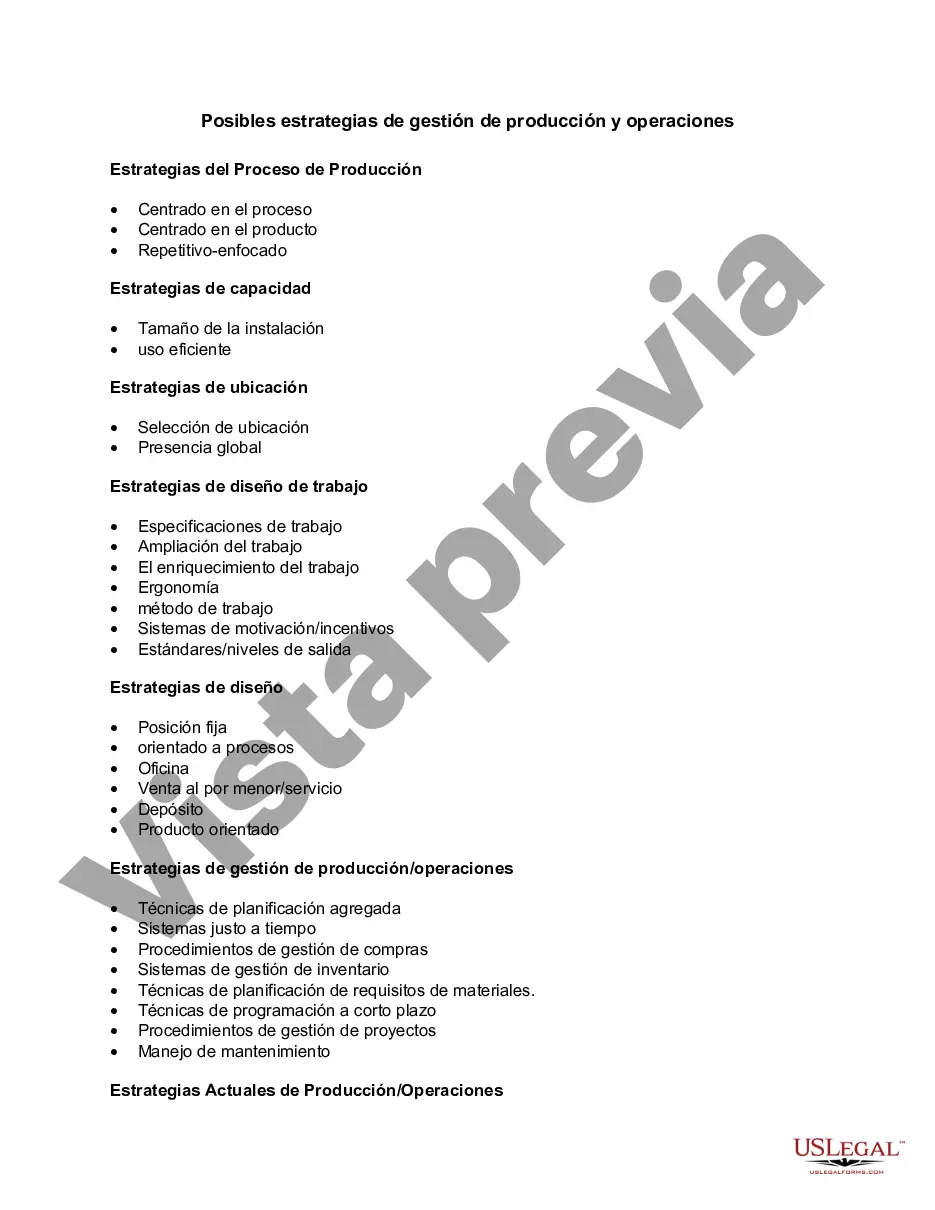

Orange, California, is a vibrant city located in Orange County, renowned for its rich history, diverse culture, and thriving business community. One crucial aspect of successful businesses in Orange, California, is effective production and operations management strategies. In this article, we will explore various possible strategies and approaches that organizations in this region can implement to maximize efficiency, reduce costs, and contribute to their overall success. 1. Lean Manufacturing Strategy: The lean manufacturing strategy focuses on eliminating waste and optimizing production processes. Companies in Orange, California, can adopt lean principles such as just-in-time (JIT) manufacturing, continuous improvement, and value stream mapping to minimize inventory holding costs, reduce lead times, and enhance product quality. 2. Six Sigma Quality Strategy: Employing Six Sigma, businesses in Orange, California, can minimize defects and errors in their production processes. By rigorously measuring, analyzing, and improving the quality of their output, companies can enhance customer satisfaction, reduce rework, and enhance overall operational efficiency. 3. Total Quality Management (TQM) Strategy: TQM emphasizes continuous improvement, customer-focused strategies, and employee involvement. Organizations in Orange, California, can implement TQM principles such as benchmarking, employee empowerment, and customer feedback to enhance quality, productivity, and innovation. 4. Agile Manufacturing Strategy: Agile manufacturing focuses on rapid adaptation and flexibility in response to market demands. Organizations in Orange, California, can adopt agile manufacturing techniques like cross-training employees, implementing modular production systems, and fostering collaboration to enable quick product changes, shorten lead times, and respond effectively to customer preferences. 5. Sustainable Operations Strategy: Sustainability is a growing concern across various industries. By adopting sustainable operations practices, companies in Orange, California, can reduce their environmental footprint while improving brand image and attracting environmentally conscious customers. Strategies may include energy-efficient manufacturing processes, waste reduction, recycling initiatives, and responsible supply chain management. 6. Capacity Planning Strategy: Optimizing production capacities is crucial for businesses in Orange, California. Companies can implement capacity planning strategies, such as demand forecasting, layout optimization, and process redesign, to ensure optimal resource allocation, minimize idle time, and maintain competitive advantage. 7. Outsourcing Strategy: When it aligns with their business goals, companies in Orange, California, can consider outsourcing certain non-core activities to specialized firms. By focusing on core competencies and leveraging the expertise of external partners, organizations can streamline operations, reduce costs, and enhance overall efficiency. 8. Supply Chain Management Strategy: Efficient supply chain management is key to meeting customer demands and maintaining competitiveness. Organizations in Orange, California, can adopt supply chain strategies such as just-in-time inventory management, vendor managed inventory, and collaborative forecasting to improve reliability, reduce lead times, and enhance overall coordination within the supply chain. By implementing these various production and operations management strategies, businesses in Orange, California, can optimize their processes, improve product quality, reduce costs, and gain a competitive edge in the dynamic marketplace. These strategies provide a glimpse into the diverse approaches available, allowing organizations to tailor their management strategies to suit their specific needs and drive sustained success.

Para su conveniencia, debajo del texto en español le brindamos la versión completa de este formulario en inglés. For your convenience, the complete English version of this form is attached below the Spanish version.