A Strategy for Research and Development

Research and development (R & D) needs to be carefully planned and managed to succeed. It is easy to waste money on developing ideas that go nowhere, but getting it right can lead to business stability, security and long-term profits.

Planning

R & D should be included in your overall business plan. The plan should illustrate the direction you want the business to take and how R & D fits in with your other business activities. Set out clear objectives, time frames and budgets. A clear plan can prevent the project straying from your business goals and wasting valuable resources and money.

You may need to involve staff with specific skills to draw up the plan, for example finance staff to set up budgets. You may also need outside help.

Your plan should set out the steps that need to be taken from the inception of the ideas to the product launch. You should allocate the necessary resources to the project, including funding, staff and time. You might decide to set up a specific team to work on the project.

Management

Good management is vital to reduce risk of failure and realize as many ideas as possible.

To manage R & D projects effectively you should:

" Make sure staff involved in R & D understand the business' overall strategy;

" Ensure these employees understand what is commercially realistic;

" Assess the changing risks and potential of projects as they progress, continually developing a rigorous business case;

" Ensure that intellectual property ownership issues are resolved;

" Recognize when a project isn't going to work; and

" Understand the relative importance of different projects to your business.

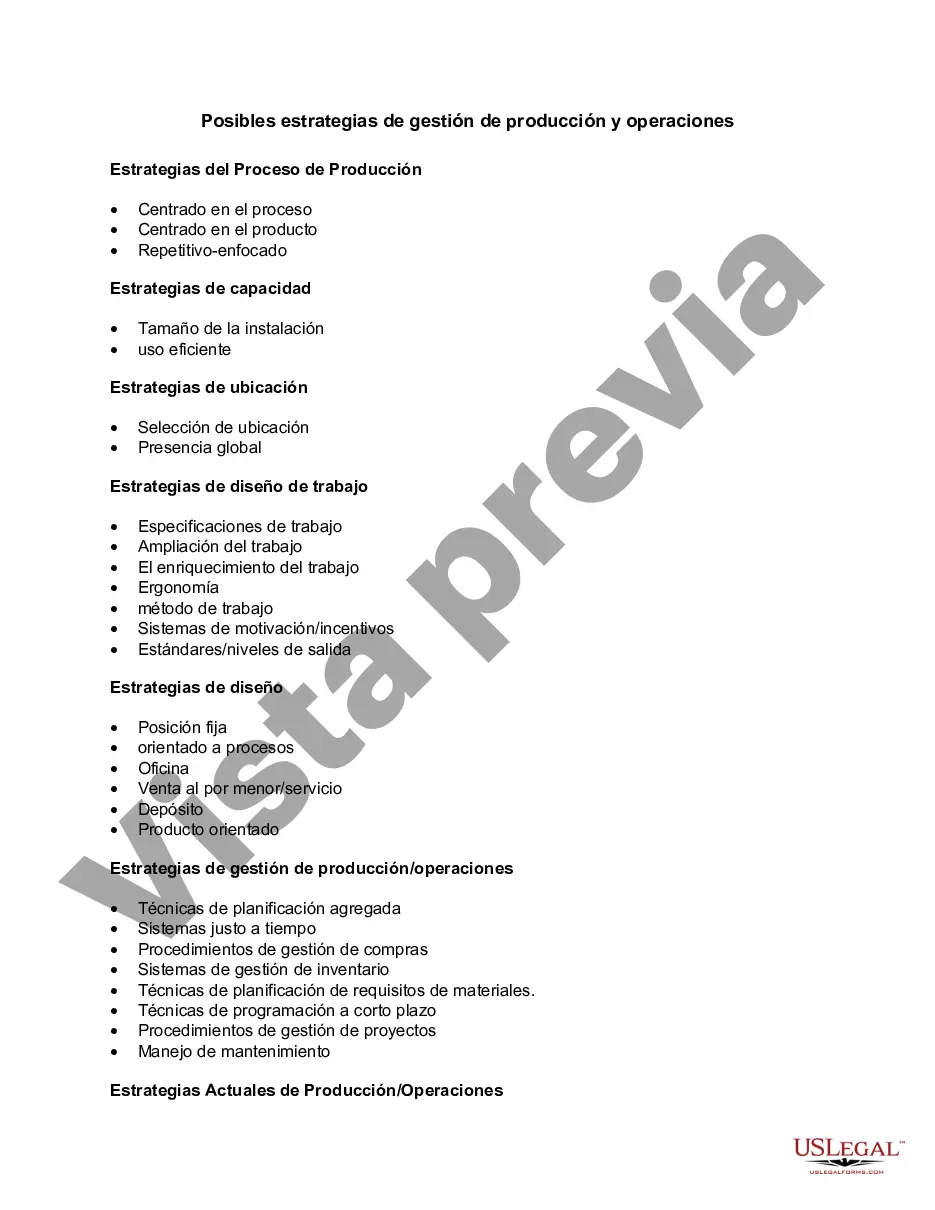

San Antonio, located in Texas, is a vibrant city known for its rich history, diverse culture, and growing economy. With a population of over 1.5 million people and a thriving business community, the city offers various production and operations management strategies for businesses looking to establish or expand their operations. 1. Lean Manufacturing: Lean manufacturing is a popular production strategy in San Antonio, focused on reducing waste, optimizing processes, and maximizing efficiency. Local businesses often implement practices like continuous improvement, just-in-time inventory, and value stream mapping to streamline operations and reduce costs. 2. Six Sigma: Six Sigma is a data-driven approach used to improve quality, eliminate defects, and enhance efficiency. Many organizations in San Antonio employ Six Sigma techniques to analyze and improve their operational processes, resulting in reduced errors, better customer satisfaction, and increased productivity. 3. Supply Chain Management: Due to its strategic location and strong transportation infrastructure, San Antonio is an ideal hub for supply chain operations. Many companies in the region focus on optimizing their supply chain management by leveraging technologies, employing cross-functional teams, and establishing strong supplier relationships to enhance overall efficiency and responsiveness. 4. Agile Project Management: Agile project management methodologies are increasingly adopted in San Antonio to enhance collaboration, flexibility, and adaptability in production and operations management. Companies often use Agile frameworks like Scrum or Kanban to improve communication, achieve faster time-to-market, and adapt quickly to changing customer demands. 5. Technology Integration: San Antonio is home to a growing technology sector, attracting businesses that incorporate advanced technologies into their production and operations processes. Companies leverage automation, artificial intelligence, big data analytics, and other emerging technologies to optimize processes, enhance productivity, and gain a competitive edge in the market. 6. Sustainable Operations: In recent years, there has been an increasing focus on sustainability in San Antonio, with businesses adopting eco-friendly practices and environmentally conscious operations. Implementing strategies like energy-efficient manufacturing processes, waste reduction initiatives, and recycling programs not only contribute to environmental conservation but also improve overall brand reputation. 7. Quality Management Systems: Quality management systems, such as ISO 9001, are widely embraced by organizations in San Antonio to ensure consistent quality, streamline processes, and enhance customer satisfaction. Strict adherence to quality standards helps companies meet regulatory requirements, reduce defects, and maintain a competitive advantage. 8. Outsourcing and Offshoring: In some cases, businesses in San Antonio opt for production and operations management strategies that involve outsourcing certain tasks or offshoring operations to countries with lower labor costs. This strategy can help reduce expenses, take advantage of specialized skills, and focus on core competencies. By implementing these various production and operations management strategies, businesses in San Antonio can achieve operational excellence, improve efficiency, reduce costs, and ultimately drive growth in a highly competitive market.

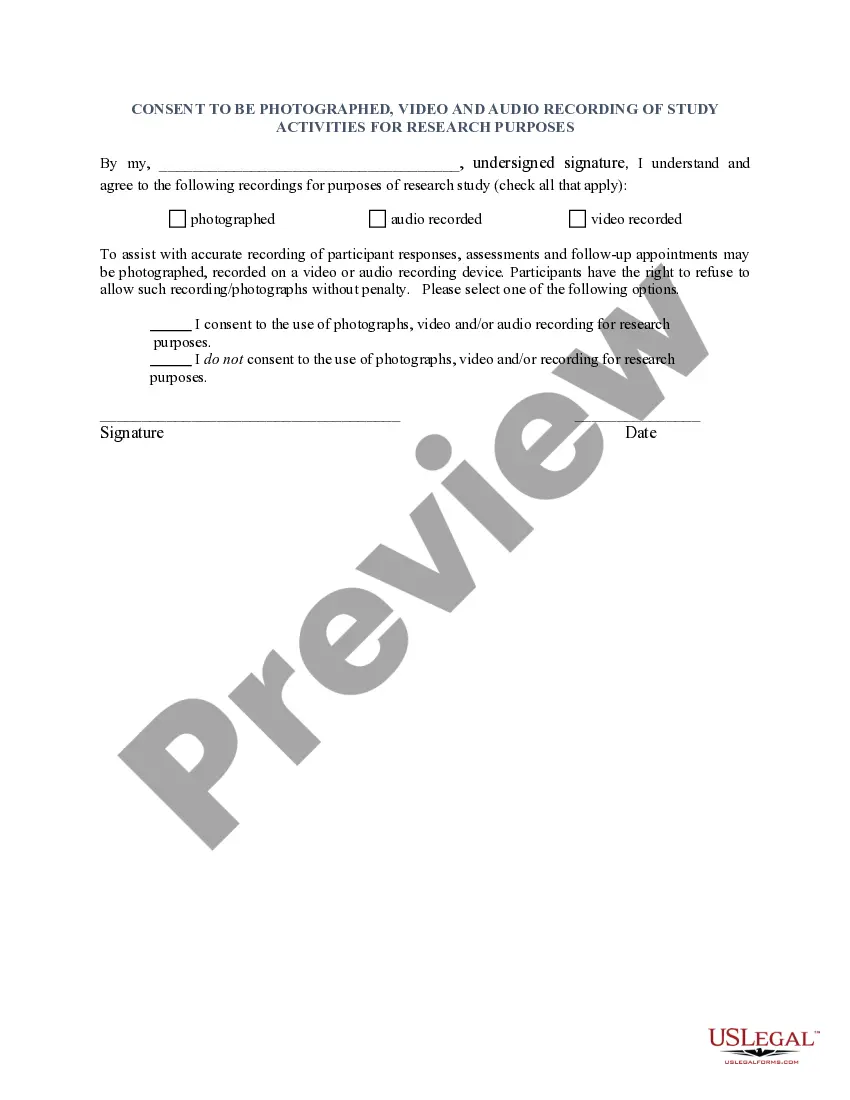

Para su conveniencia, debajo del texto en español le brindamos la versión completa de este formulario en inglés. For your convenience, the complete English version of this form is attached below the Spanish version.