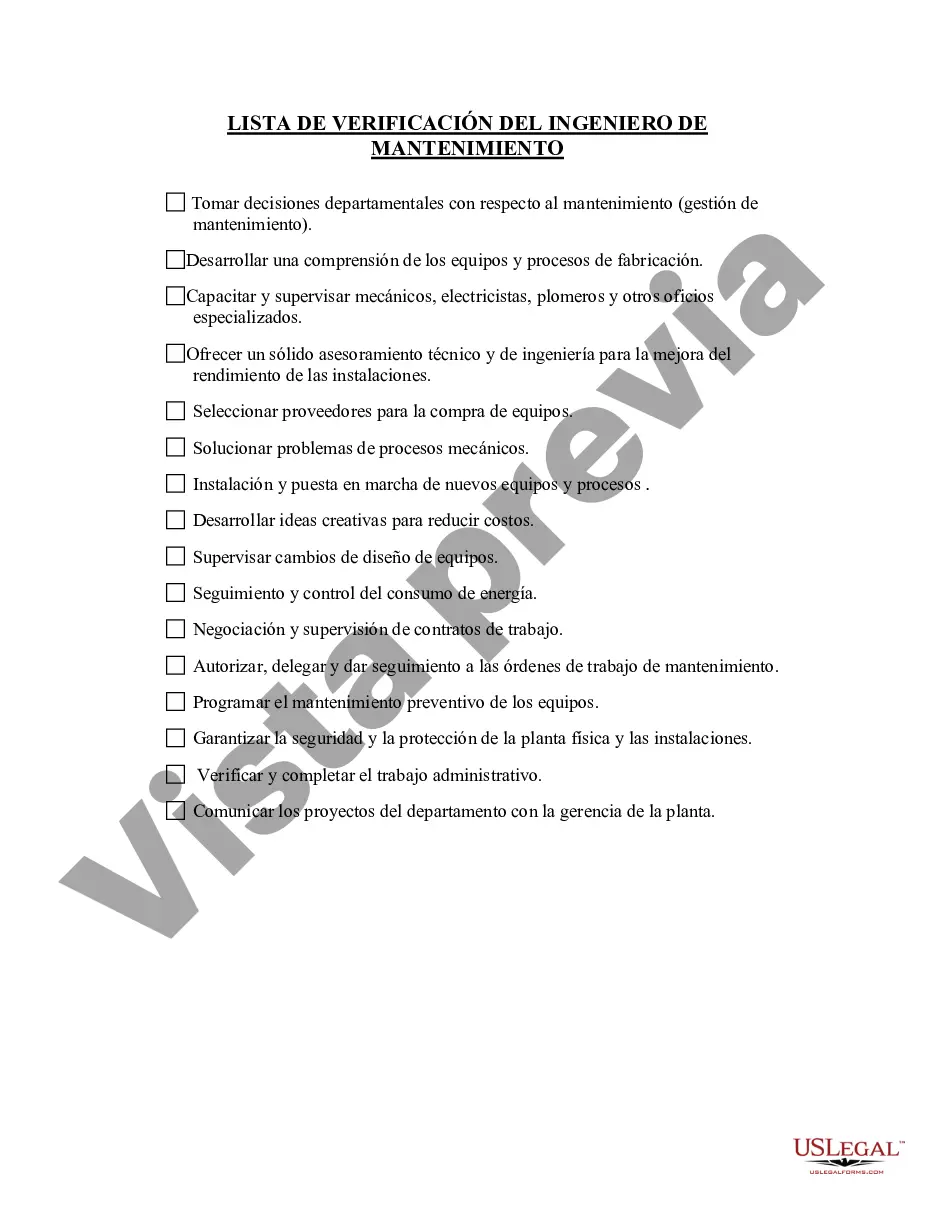

Keywords: Allegheny Pennsylvania, maintenance engineer, checklist, types The Allegheny Pennsylvania Maintenance Engineer Checklist is a comprehensive tool used by maintenance engineers in the Allegheny Pennsylvania area to ensure the effective management, organization, and execution of maintenance tasks. It helps maintenance engineers streamline their daily activities and address potential issues proactively. This checklist acts as a guideline and reference for the various responsibilities they undertake and helps ensure the smooth functioning of equipment, machinery, and facilities in Allegheny. The checklist includes a variety of tasks that maintenance engineers in Allegheny Pennsylvania may need to perform. Some common items on this checklist include: 1. Equipment inspections: Maintenance engineers are tasked with regularly inspecting all machinery and equipment to identify potential maintenance or repair needs. They examine for worn-out parts, faulty wiring, leaks, or other signs of wear and tear. 2. Lubrication and fluid checks: The checklist prompts maintenance engineers to check the lubrication and fluid levels of different equipment, ensuring they are adequately maintained to prevent breakdowns or malfunctions. 3. Preventive maintenance: The checklist also emphasizes the importance of preventive maintenance. Engineers are prompted to carry out scheduled inspections, cleanings, and replacements of parts to avoid unexpected downtime or costly repairs. 4. Cleaning and sanitation: Maintenance engineers must ensure cleanliness and sanitation in various areas of a facility, including workshops, storage spaces, and common areas. The checklist helps them keep track of regular cleaning routines and ensure compliance with health and safety standards. 5. Safety inspections: Safety is a top priority for maintenance engineers. The Allegheny Pennsylvania Maintenance Engineer Checklist includes tasks that ensure all safety measures, such as proper signage, protective equipment availability, and emergency exits, are in place and functional. 6. Documentation and record-keeping: The checklist emphasizes maintenance engineers' responsibility to maintain accurate records of all inspections, repairs, and maintenance activities performed. This documentation helps track equipment history, identify patterns or recurring issues, and plan future maintenance schedules effectively. While there might not be specific types of Allegheny Pennsylvania Maintenance Engineer Checklists, this checklist can be tailored to meet the specific needs and requirements of different industries or facilities within Allegheny Pennsylvania. For example, there may be checklists specific to manufacturing plants, commercial buildings, hospitals, or educational institutions. These checklists can include industry-specific tasks relevant to the maintenance engineer's role in that particular environment. In conclusion, the Allegheny Pennsylvania Maintenance Engineer Checklist is a vital tool that facilitates efficient maintenance management. It ensures that maintenance engineers in Allegheny Pennsylvania can fulfill their responsibilities effectively, minimize downtime, and keep equipment and facilities running smoothly.

Para su conveniencia, debajo del texto en español le brindamos la versión completa de este formulario en inglés. For your convenience, the complete English version of this form is attached below the Spanish version.Allegheny Pennsylvania Lista de verificación del ingeniero de mantenimiento - Maintenance Engineer Checklist

Description

How to fill out Allegheny Pennsylvania Lista De Verificación Del Ingeniero De Mantenimiento?

How much time does it normally take you to draw up a legal document? Because every state has its laws and regulations for every life sphere, finding a Allegheny Maintenance Engineer Checklist suiting all regional requirements can be tiring, and ordering it from a professional lawyer is often costly. Many web services offer the most common state-specific documents for download, but using the US Legal Forms library is most advantegeous.

US Legal Forms is the most extensive web catalog of templates, gathered by states and areas of use. Aside from the Allegheny Maintenance Engineer Checklist, here you can get any specific document to run your business or personal deeds, complying with your regional requirements. Specialists verify all samples for their validity, so you can be sure to prepare your documentation properly.

Using the service is fairly easy. If you already have an account on the platform and your subscription is valid, you only need to log in, opt for the required form, and download it. You can retain the document in your profile at any time later on. Otherwise, if you are new to the platform, there will be some extra actions to complete before you obtain your Allegheny Maintenance Engineer Checklist:

- Check the content of the page you’re on.

- Read the description of the template or Preview it (if available).

- Look for another document utilizing the related option in the header.

- Click Buy Now once you’re certain in the chosen document.

- Decide on the subscription plan that suits you most.

- Register for an account on the platform or log in to proceed to payment options.

- Pay via PalPal or with your credit card.

- Change the file format if necessary.

- Click Download to save the Allegheny Maintenance Engineer Checklist.

- Print the sample or use any preferred online editor to complete it electronically.

No matter how many times you need to use the acquired template, you can find all the files you’ve ever downloaded in your profile by opening the My Forms tab. Try it out!