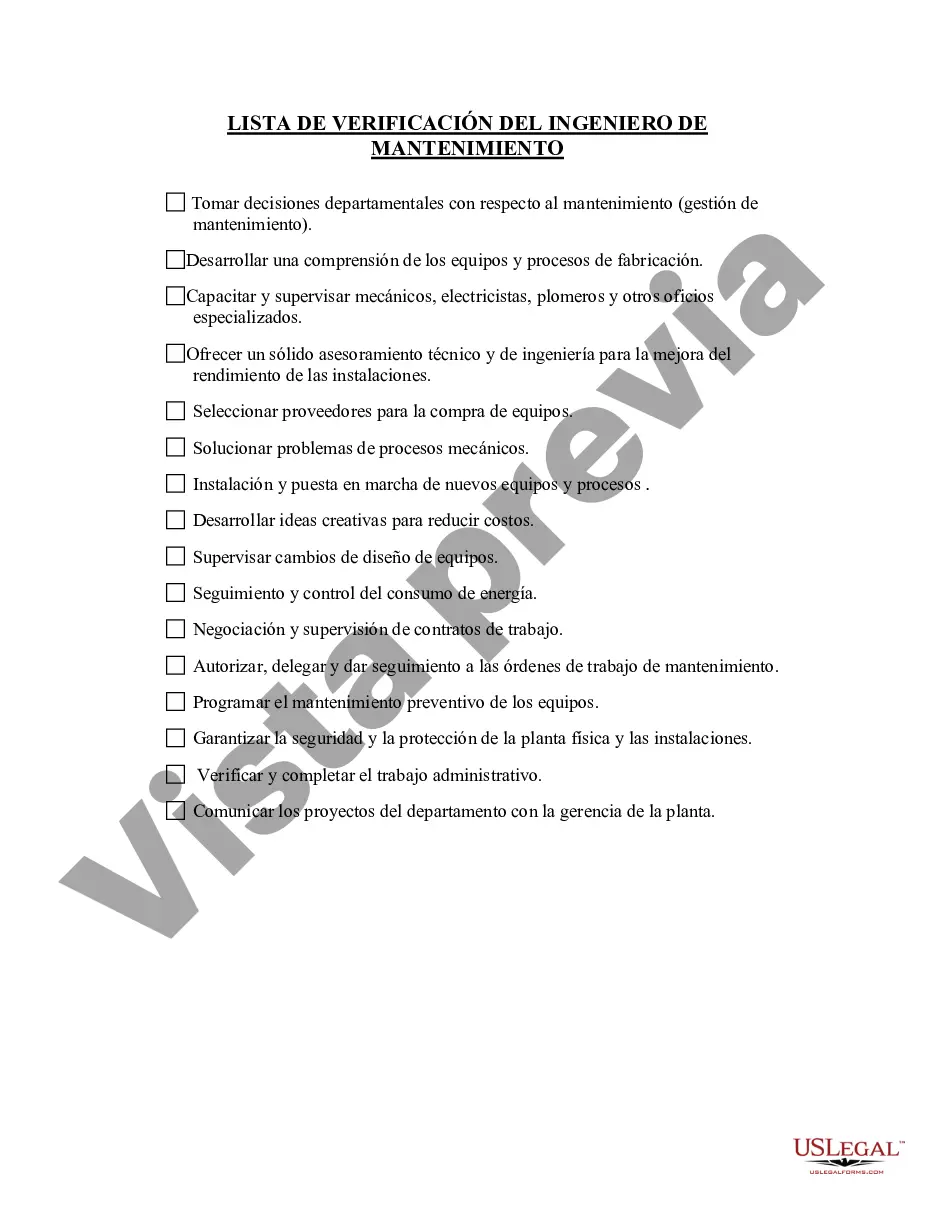

Cuyahoga Ohio Maintenance Engineer Checklist is a comprehensive list of tasks, guidelines, and procedures that maintenance engineers in Cuyahoga, Ohio, follow to ensure the smooth functioning and optimal performance of equipment, systems, and facilities. These checklists often serve as a valuable tool for maintenance engineers to keep track of routine maintenance tasks, identify potential issues, and mitigate any risks associated with the maintenance process. They are essential to maintain the integrity, reliability, and safety of various infrastructure components in Cuyahoga, Ohio. Keywords: Cuyahoga Ohio, maintenance engineer, checklist, tasks, guidelines, procedures, smooth functioning, optimal performance, equipment, systems, facilities, routine maintenance, potential issues, risks, integrity, reliability, safety, infrastructure components. Different Types of Cuyahoga Ohio Maintenance Engineer Checklists: 1. Equipment Maintenance Checklist: This checklist covers routine maintenance procedures for specific equipment used in various industries, including but not limited to machinery, electrical systems, HVAC systems, plumbing systems, and other essential infrastructure components. 2. Facility Maintenance Checklist: This type of checklist focuses on maintaining the overall condition of buildings, premises, and facilities. It includes tasks related to cleaning, landscaping, structural maintenance, fire safety measures, and compliance with building codes and regulations. 3. Preventive Maintenance Checklist: This checklist emphasizes proactive measures to prevent potential issues and breakdowns. It typically includes tasks such as lubrication, filter replacements, calibration, inspection, and testing. Preventive maintenance checklists are crucial for ensuring the longevity and optimal performance of equipment or systems. 4. Safety Inspection Checklist: This checklist aims to ensure compliance with safety regulations and identifies potential hazards or risks. It covers inspections of safety equipment, emergency preparedness, electrical safety, fire safety measures, and proper handling of hazardous materials. 5. Energy Efficiency Checklist: This checklist focuses on reducing energy consumption and promoting energy-efficient practices. It includes tasks such as energy audits, equipment optimization, insulation checks, and the implementation of energy-saving measures. 6. Compliance Checklist: This type of checklist ensures that maintenance activities adhere to relevant industry standards, legal requirements, and best practices. It covers tasks related to permits, licenses, documentation, reporting, and environmental regulations. By utilizing these various Cuyahoga Ohio Maintenance Engineer Checklists, professionals can effectively manage and prioritize maintenance tasks, minimize downtime and costly repairs, enhance safety standards, and ultimately achieve optimal performance and reliability of equipment and facilities.

Para su conveniencia, debajo del texto en español le brindamos la versión completa de este formulario en inglés. For your convenience, the complete English version of this form is attached below the Spanish version.Cuyahoga Ohio Lista de verificación del ingeniero de mantenimiento - Maintenance Engineer Checklist

Description

How to fill out Cuyahoga Ohio Lista De Verificación Del Ingeniero De Mantenimiento?

Creating forms, like Cuyahoga Maintenance Engineer Checklist, to take care of your legal affairs is a difficult and time-consumming process. Many situations require an attorney’s participation, which also makes this task expensive. Nevertheless, you can consider your legal matters into your own hands and deal with them yourself. US Legal Forms is here to save the day. Our website comes with more than 85,000 legal documents intended for different cases and life circumstances. We make sure each document is in adherence with the laws of each state, so you don’t have to be concerned about potential legal problems associated with compliance.

If you're already aware of our website and have a subscription with US, you know how straightforward it is to get the Cuyahoga Maintenance Engineer Checklist template. Simply log in to your account, download the form, and personalize it to your requirements. Have you lost your document? No worries. You can get it in the My Forms tab in your account - on desktop or mobile.

The onboarding flow of new users is fairly simple! Here’s what you need to do before downloading Cuyahoga Maintenance Engineer Checklist:

- Ensure that your template is compliant with your state/county since the rules for creating legal documents may differ from one state another.

- Find out more about the form by previewing it or going through a quick description. If the Cuyahoga Maintenance Engineer Checklist isn’t something you were hoping to find, then use the header to find another one.

- Log in or register an account to start using our service and download the document.

- Everything looks great on your side? Hit the Buy now button and choose the subscription option.

- Select the payment gateway and enter your payment details.

- Your form is ready to go. You can try and download it.

It’s an easy task to find and purchase the appropriate document with US Legal Forms. Thousands of organizations and individuals are already benefiting from our rich library. Subscribe to it now if you want to check what other perks you can get with US Legal Forms!