Travis Texas Maintenance Engineer Checklist: A Comprehensive Guide for Efficient Maintenance Operations Keywords: Travis Texas, Maintenance Engineer, Checklist, Efficient, Operations Description: The Travis Texas Maintenance Engineer Checklist is an indispensable tool that helps ensure smooth and effective maintenance operations in various settings throughout the Travis Texas region. This comprehensive checklist acts as a roadmap, providing maintenance engineers with a detailed list of tasks and procedures to follow, ultimately enhancing the overall functioning and longevity of a facility or system. The Travis Texas Maintenance Engineer Checklist covers a wide range of maintenance aspects, encompassing both preventative and corrective maintenance practices. By diligently adhering to this checklist, engineers can minimize downtime, identify potential issues before they escalate, and maximize the efficiency of repair and maintenance procedures. There are different types of Travis Texas Maintenance Engineer Checklists that cater to diverse sectors and industries: 1. Building Maintenance Checklist: This variant focuses on the upkeep and repair of commercial, residential, and industrial buildings. It includes tasks such as inspecting electrical systems, plumbing, HVAC units, fire safety equipment, elevators, and general structural maintenance. 2. Manufacturing Facility Maintenance Checklist: Tailored for manufacturing units, this checklist emphasizes the regular inspection, cleaning, and calibration of machinery and equipment, ensuring optimal productivity and minimizing machinery breakdowns. 3. Vehicle Maintenance Checklist: Addressing the needs of fleet maintenance engineers, this checklist includes regular inspections, fluid checks, tire maintenance, and monitoring of vehicle systems to keep the transportation operations functioning smoothly. 4. Facility Systems Maintenance Checklist: Aimed at maintenance engineers overseeing utility systems, this checklist encompasses tasks related to electrical panels, backup generators, water supply and treatment systems, waste management systems, and other critical components of facility infrastructure. 5. Equipment Maintenance Checklist: Primarily designed for maintenance engineers working with specialized equipment, this checklist focuses on calibration, lubrication, routine inspection, and other upkeep tasks needed for optimal performance. Travis Texas Maintenance Engineer Checklist is continuously updated to reflect industry-specific best practices and evolving technological advancements. It acts as a framework for maintenance engineers, ensuring that crucial maintenance activities are not overlooked, thereby fostering safe and reliable operations while optimizing resource allocation.

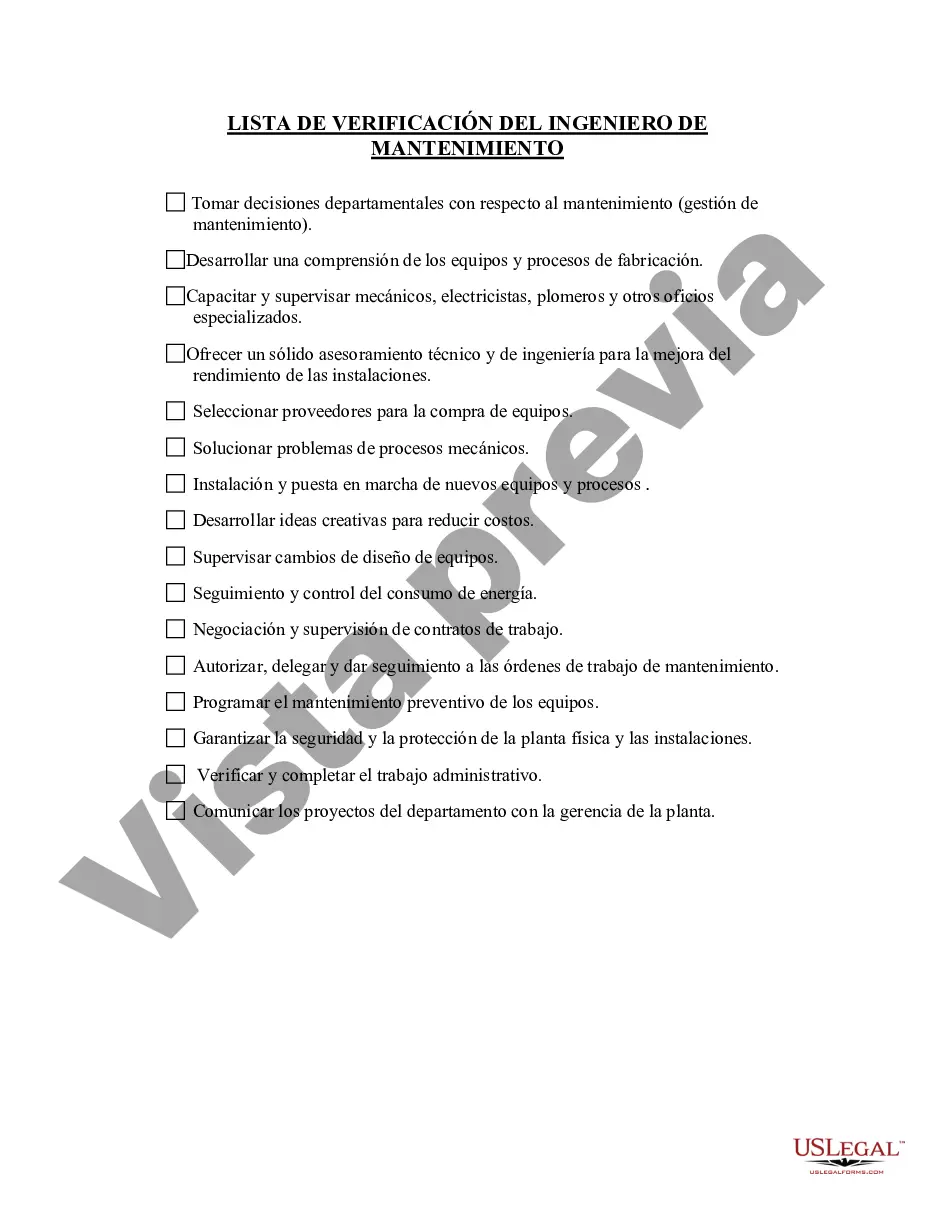

Para su conveniencia, debajo del texto en español le brindamos la versión completa de este formulario en inglés. For your convenience, the complete English version of this form is attached below the Spanish version.Travis Texas Lista de verificación del ingeniero de mantenimiento - Maintenance Engineer Checklist

Description

How to fill out Travis Texas Lista De Verificación Del Ingeniero De Mantenimiento?

Laws and regulations in every sphere vary from state to state. If you're not a lawyer, it's easy to get lost in countless norms when it comes to drafting legal documents. To avoid expensive legal assistance when preparing the Travis Maintenance Engineer Checklist, you need a verified template valid for your county. That's when using the US Legal Forms platform is so advantageous.

US Legal Forms is a trusted by millions web collection of more than 85,000 state-specific legal templates. It's an excellent solution for professionals and individuals looking for do-it-yourself templates for different life and business scenarios. All the forms can be used multiple times: once you purchase a sample, it remains available in your profile for future use. Therefore, when you have an account with a valid subscription, you can just log in and re-download the Travis Maintenance Engineer Checklist from the My Forms tab.

For new users, it's necessary to make a few more steps to get the Travis Maintenance Engineer Checklist:

- Take a look at the page content to make sure you found the correct sample.

- Take advantage of the Preview option or read the form description if available.

- Look for another doc if there are inconsistencies with any of your requirements.

- Utilize the Buy Now button to get the document when you find the right one.

- Opt for one of the subscription plans and log in or create an account.

- Choose how you prefer to pay for your subscription (with a credit card or PayPal).

- Select the format you want to save the document in and click Download.

- Complete and sign the document in writing after printing it or do it all electronically.

That's the simplest and most affordable way to get up-to-date templates for any legal reasons. Locate them all in clicks and keep your documentation in order with the US Legal Forms!