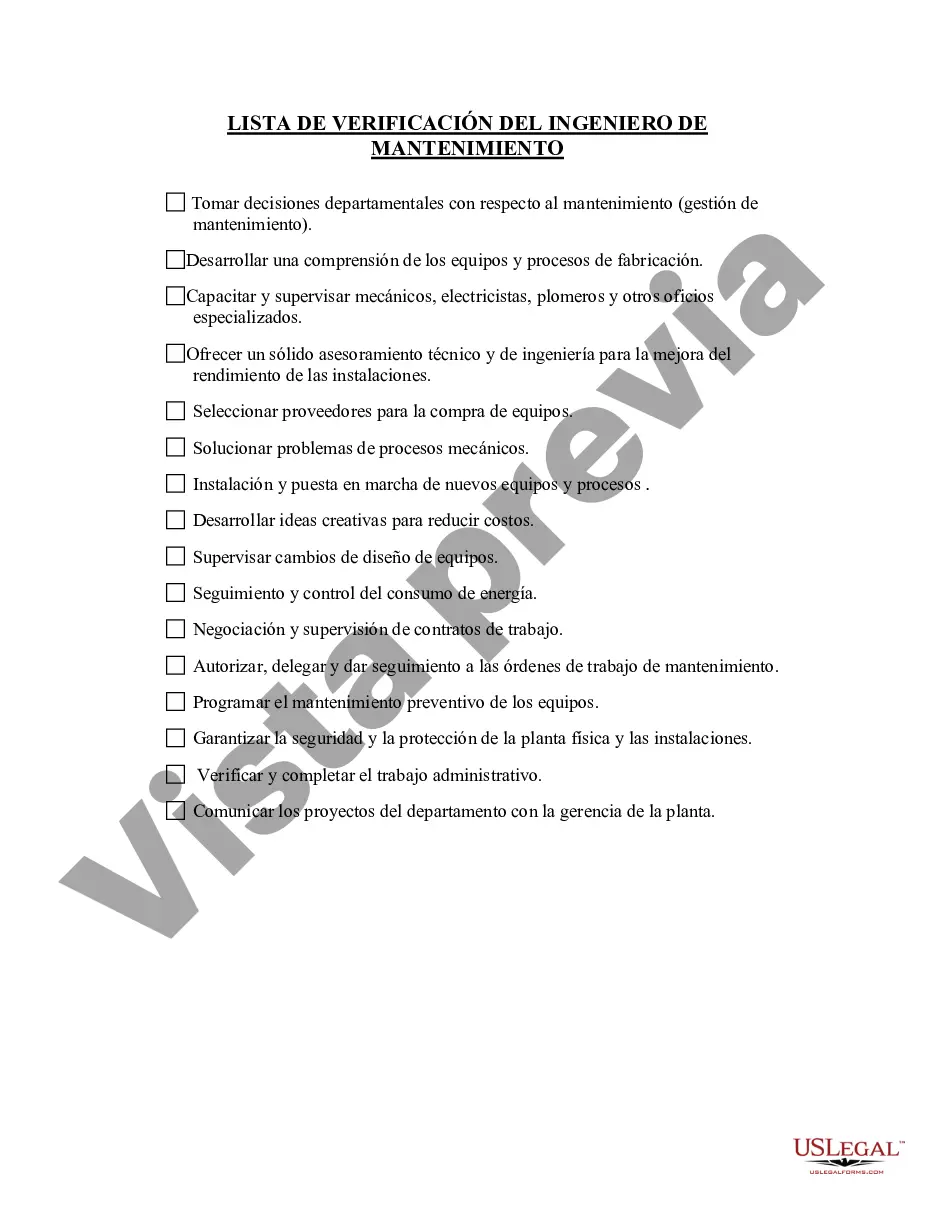

Wayne Michigan Maintenance Engineer Checklist: Ensuring Smooth Operations with Precision and Efficiency Keywords: Wayne Michigan, maintenance engineer, checklist, smooth operations, precision, efficiency Description: A Wayne Michigan Maintenance Engineer Checklist serves as an indispensable tool for maintenance engineers responsible for the efficient functioning and reliability of various systems and equipment in industrial or commercial settings. These checklists comprise detailed guidelines and steps to follow, aimed at ensuring smooth operations, maintaining precision, and enhancing overall efficiency. Different Types of Wayne Michigan Maintenance Engineer Checklists: 1. Preventive Maintenance Checklist: This type of checklist focuses on carrying out routine inspections, servicing, and preventive maintenance tasks on machinery, equipment, and systems to prevent potential breakdowns or failures. It includes tasks such as lubrication, calibration, filter replacements, testing, and overall system monitoring. 2. Electrical Systems Checklist: Specifically designed for maintenance engineers working with electrical systems, this checklist covers various elements such as power distribution units, wiring checks, circuit breaker examination, voltage measurements, ground fault interrupter testing, and the inspection of electrical panels to ensure safe and seamless functioning. 3. HVAC Maintenance Checklist: This checklist caters to maintenance engineers responsible for heating, ventilation, and air conditioning systems. It includes tasks like filter replacements, cleaning and inspecting air ducts, checking refrigerant levels, examining thermostats, inspecting fan motors and belts, and testing system controls to maintain optimum performance and energy efficiency. 4. Plumbing Systems Checklist: Maintenance engineers dealing with plumbing systems benefit from this checklist. It covers tasks like checking for leaks, inspecting pipelines, evaluating water pressure, testing valves and faucets for proper functioning, and ensuring overall water quality and distribution system integrity. 5. Safety Systems Checklist: Maintenance engineers responsible for safety systems such as fire alarms, emergency lighting, sensory equipment, and security systems can utilize this checklist. It involves tasks like system testing, battery replacements, sensor calibration, siren audibility checks, and ensuring the effectiveness of security measures. 6. Facility Maintenance Checklist: Facility maintenance engineers can utilize this comprehensive checklist to cover a wide range of tasks. It includes inspections of various building elements like roofing, lighting systems, windows, doors, flooring, walls, and general structural integrity. Additionally, it covers fire safety, security, and overall cleanliness to ensure a safe and ideal environment for occupants. By adhering to the Wayne Michigan Maintenance Engineer Checklists, professionals can effectively manage their responsibilities while minimizing downtime, reducing maintenance costs, improving equipment longevity, and enhancing overall operational performance. These checklists serve as invaluable tools to achieve precision, efficiency, and the smooth functioning of various industrial and commercial systems in the Wayne Michigan region.

Para su conveniencia, debajo del texto en español le brindamos la versión completa de este formulario en inglés. For your convenience, the complete English version of this form is attached below the Spanish version.Wayne Michigan Lista de verificación del ingeniero de mantenimiento - Maintenance Engineer Checklist

Description

How to fill out Wayne Michigan Lista De Verificación Del Ingeniero De Mantenimiento?

Creating documents, like Wayne Maintenance Engineer Checklist, to take care of your legal matters is a difficult and time-consumming process. Many situations require an attorney’s involvement, which also makes this task not really affordable. Nevertheless, you can acquire your legal matters into your own hands and take care of them yourself. US Legal Forms is here to the rescue. Our website comes with more than 85,000 legal documents crafted for different scenarios and life situations. We ensure each form is in adherence with the laws of each state, so you don’t have to worry about potential legal pitfalls compliance-wise.

If you're already familiar with our services and have a subscription with US, you know how effortless it is to get the Wayne Maintenance Engineer Checklist form. Go ahead and log in to your account, download the template, and personalize it to your requirements. Have you lost your form? Don’t worry. You can get it in the My Forms folder in your account - on desktop or mobile.

The onboarding flow of new users is fairly straightforward! Here’s what you need to do before getting Wayne Maintenance Engineer Checklist:

- Ensure that your template is compliant with your state/county since the regulations for creating legal paperwork may vary from one state another.

- Find out more about the form by previewing it or reading a quick intro. If the Wayne Maintenance Engineer Checklist isn’t something you were hoping to find, then take advantage of the search bar in the header to find another one.

- Log in or create an account to begin utilizing our service and get the document.

- Everything looks good on your end? Click the Buy now button and choose the subscription plan.

- Pick the payment gateway and enter your payment information.

- Your template is good to go. You can try and download it.

It’s easy to find and purchase the needed document with US Legal Forms. Thousands of businesses and individuals are already taking advantage of our extensive collection. Subscribe to it now if you want to check what other advantages you can get with US Legal Forms!