This lease rider form may be used when you are involved in a lease transaction, and have made the decision to utilize the form of Oil and Gas Lease presented to you by the Lessee, and you want to include additional provisions to that Lease form to address specific concerns you may have, or place limitations on the rights granted the Lessee in the “standard” lease form.

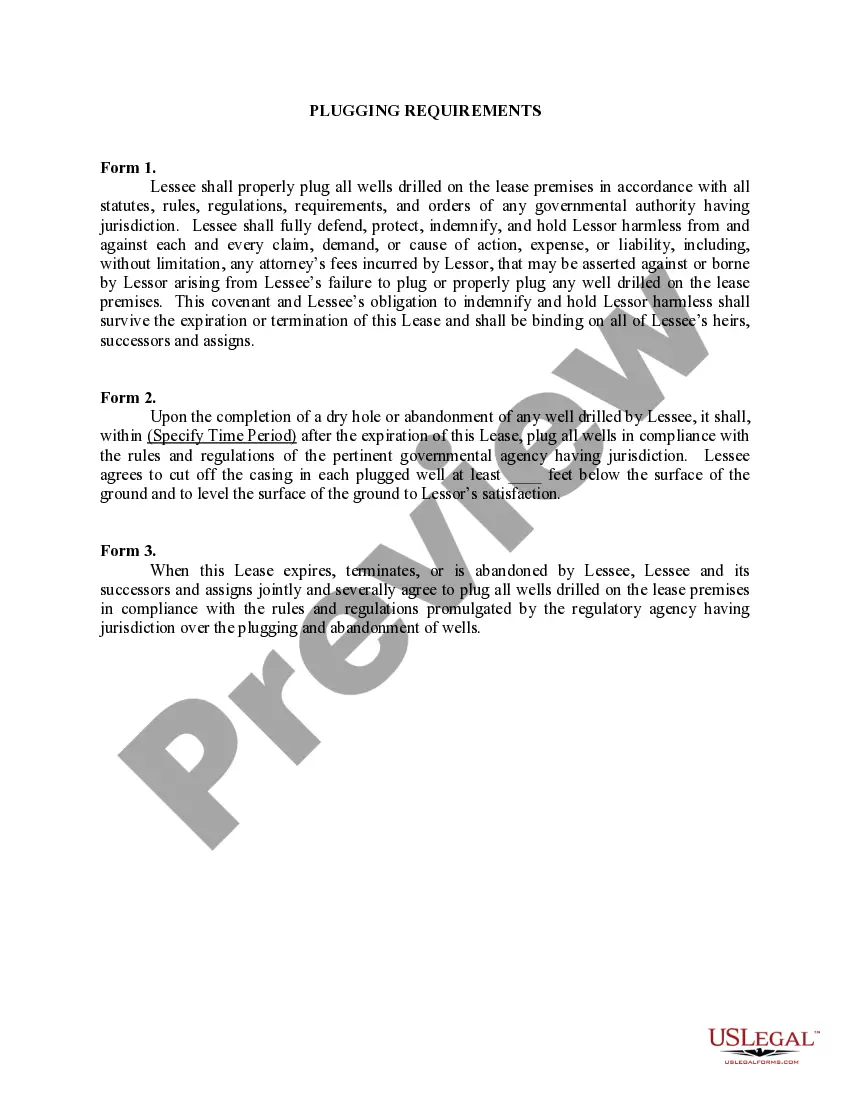

Alaska Plugging Requirements

Description

How to fill out Plugging Requirements?

It is possible to devote time on the web looking for the legal papers format that fits the federal and state specifications you want. US Legal Forms gives 1000s of legal kinds which are examined by professionals. It is possible to download or print out the Alaska Plugging Requirements from the support.

If you already possess a US Legal Forms bank account, you can log in and then click the Acquire key. Afterward, you can total, revise, print out, or sign the Alaska Plugging Requirements. Every legal papers format you purchase is yours eternally. To get one more copy of any obtained kind, go to the My Forms tab and then click the related key.

If you use the US Legal Forms web site for the first time, adhere to the easy guidelines under:

- First, make sure that you have chosen the right papers format to the region/town that you pick. Read the kind information to make sure you have picked out the right kind. If offered, make use of the Review key to check from the papers format too.

- If you want to discover one more version from the kind, make use of the Look for discipline to discover the format that meets your needs and specifications.

- After you have discovered the format you desire, click on Acquire now to carry on.

- Select the costs strategy you desire, type your credentials, and sign up for a merchant account on US Legal Forms.

- Comprehensive the purchase. You should use your Visa or Mastercard or PayPal bank account to purchase the legal kind.

- Select the structure from the papers and download it in your product.

- Make adjustments in your papers if possible. It is possible to total, revise and sign and print out Alaska Plugging Requirements.

Acquire and print out 1000s of papers templates while using US Legal Forms web site, which provides the most important assortment of legal kinds. Use skilled and state-particular templates to handle your company or person requirements.

Form popularity

FAQ

The Alaska Oil and Gas Conservation Act (1955) created the Alaska Oil and Gas Conservation Commission (AOGCC or Commission). The Commission was composed of the Governor of the Territory of Alaska, the Territorial Commissioner of Mines, and the Territorial Highway Engineer.

Area Injection Order (AIO) The AOGCC may issue an area injection order, allowing underground injection of fluids on an area basis, rather than for each well individually.

The oil and gas industry has repeatedly failed to prevent or contain disastrous oil spills on Alaska's coast. The infamous Exxon Valdez oil spill in 1989 poisoned Alaska's beaches and wildlife, and significantly harmed Alaska's Indigenous communities.

The AOGCC approves drilling plans submitted with an application for Permit to Drill. The permit application is reviewed by the Commission's professional staff and the approval process typically takes 5 working days for a routine oil and gas production or injection well.

The entire well construction process ? including hydraulic fracturing ? takes about two or three months.

To own oil or any other mineral coming from your land, you must have mineral rights in addition to your property rights. In other countries, the government has a sovereign claim over all mineral rights. In the United States, private individuals can own mineral rights, unless already reserved by the government.

The Arctic Alaska (onshore) province is endowed with original oil reserves of 16.4 billion barrels and a discovered total of 70 billion barrels of oil in place. The Arctic Alaska (onshore) province produces about 1.5 million barrels per day and accounts for nearly 25 percent of all current U.S. daily oil production.