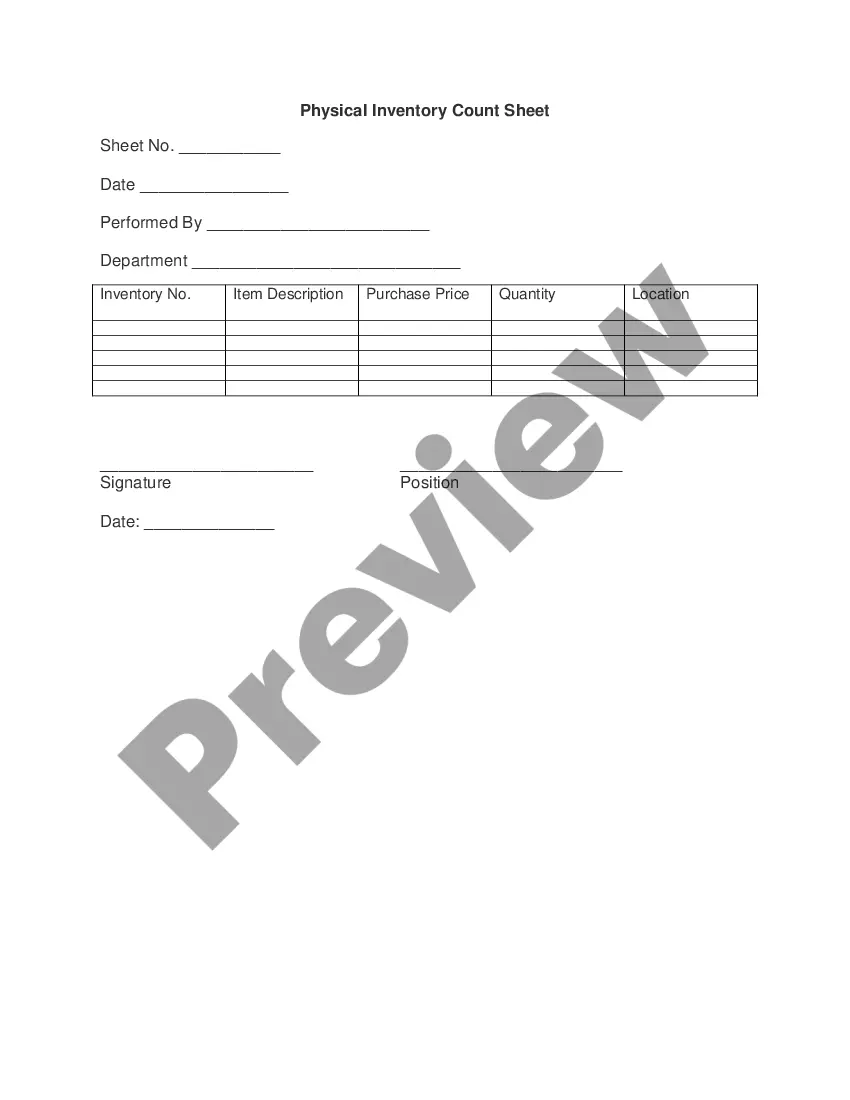

Alabama Physical Inventory Count Sheet

Description

How to fill out Physical Inventory Count Sheet?

US Legal Forms - one of the largest collections of legal documents in the United States - provides a broad assortment of legal form templates that you can download or print. By utilizing the site, you will access numerous forms for both business and personal purposes, organized by categories, states, or keywords.

You can obtain the most recent versions of forms such as the Alabama Physical Inventory Count Sheet in just a few seconds.

If you already have a monthly membership, Log In and retrieve Alabama Physical Inventory Count Sheet from the US Legal Forms library. The Acquire button will be visible on every form you view. You have access to all previously downloaded forms in the My documents section of your account.

Process the transaction. Use a credit card or PayPal account to complete your purchase.

Select the format and download the form to your device. Make modifications. Complete, update, print, and sign the downloaded Alabama Physical Inventory Count Sheet. Each template you save in your account does not expire and is yours permanently. Therefore, if you wish to download or print an additional copy, just navigate to the My documents section and click on the form you need. Access the Alabama Physical Inventory Count Sheet with US Legal Forms, the most extensive collection of legal document templates. Utilize a vast array of professional and state-specific templates that meet your business or personal requirements.

- If this is your first time using US Legal Forms, here are simple steps to help you get started.

- Ensure you have selected the correct form for your city/region.

- Click on the Preview button to review the contents of the form.

- Examine the form details to confirm that you have selected the appropriate form.

- If the form does not meet your requirements, use the Search field at the top of the screen to find one that does.

- Once you are satisfied with the form, finalize your selection by clicking the Buy now button.

- Then, choose the pricing plan that suits you and provide your information to create an account.

Form popularity

FAQ

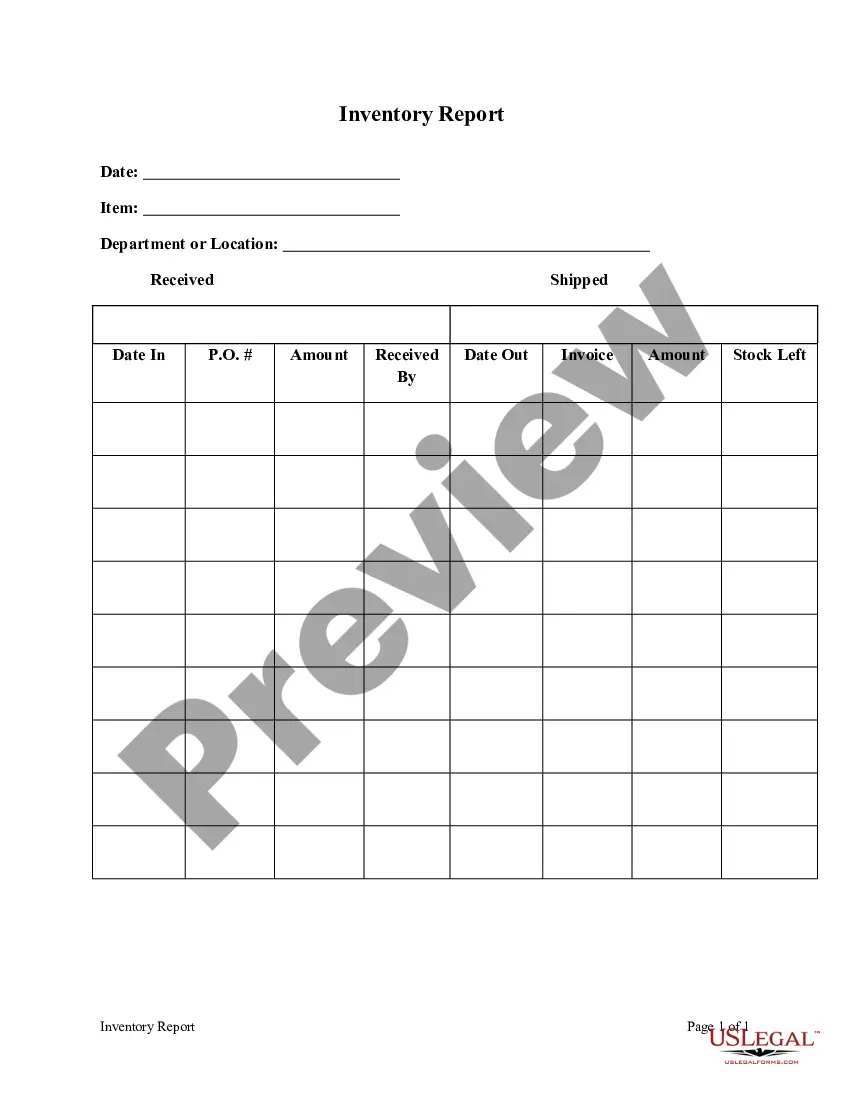

To check physical inventory, begin by using the Alabama Physical Inventory Count Sheet. This sheet helps you systematically document the quantities and conditions of your stock. Ensure you compare the physical counts with your records to identify any discrepancies. Regularly performing this check aids in maintaining accurate inventory records and supports better decision-making for your business.

To perform a physical inventory count, start by preparing an Alabama Physical Inventory Count Sheet ahead of time. Divide your inventory into manageable sections and assign a team to count each section to ensure accuracy. As you count, record the quantities on your sheet and compare with your existing records to identify discrepancies. By following a structured approach, you can achieve a comprehensive and accurate inventory count.

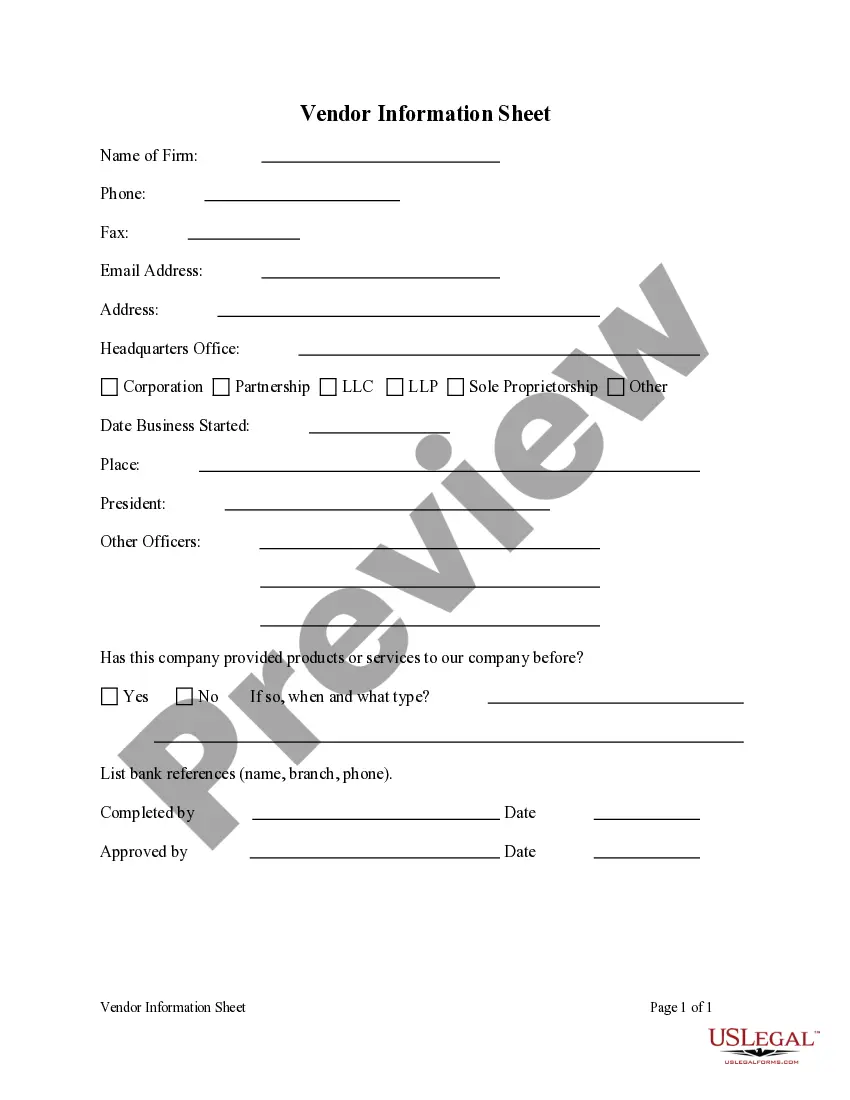

When conducting a physical count of inventory, several factors should be taken into account. First, ensure you have the right tools, such as an Alabama Physical Inventory Count Sheet, to accurately document counts. Additionally, consider factors like stock organization, counting methods, and the timing of your count to minimize disruptions. These aspects can significantly enhance the reliability of your inventory data.

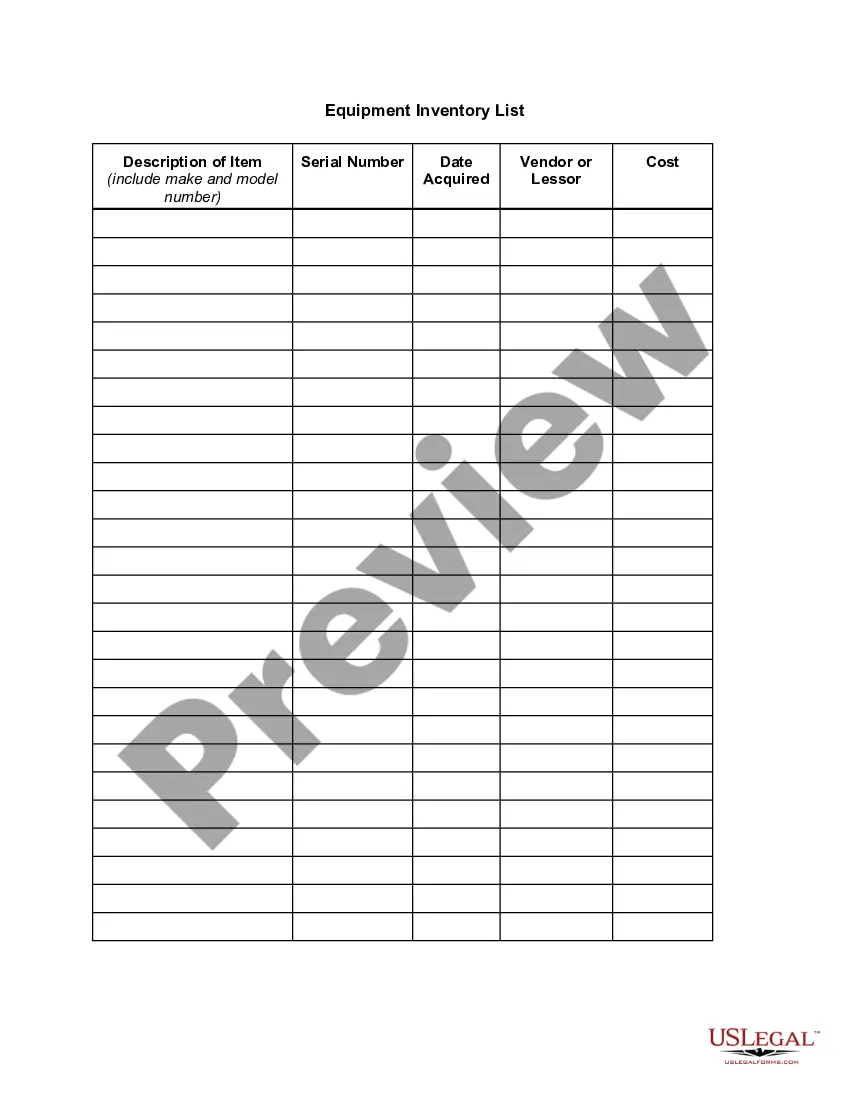

To create a physical inventory document, begin by gathering accurate data on the items in your inventory. You can utilize an Alabama Physical Inventory Count Sheet to record the details of each item, such as quantity, description, and location. Ensure you have a systematic approach, possibly using a spreadsheet or inventory management software, to streamline the creation process. This method helps maintain consistency and capture important information effectively.

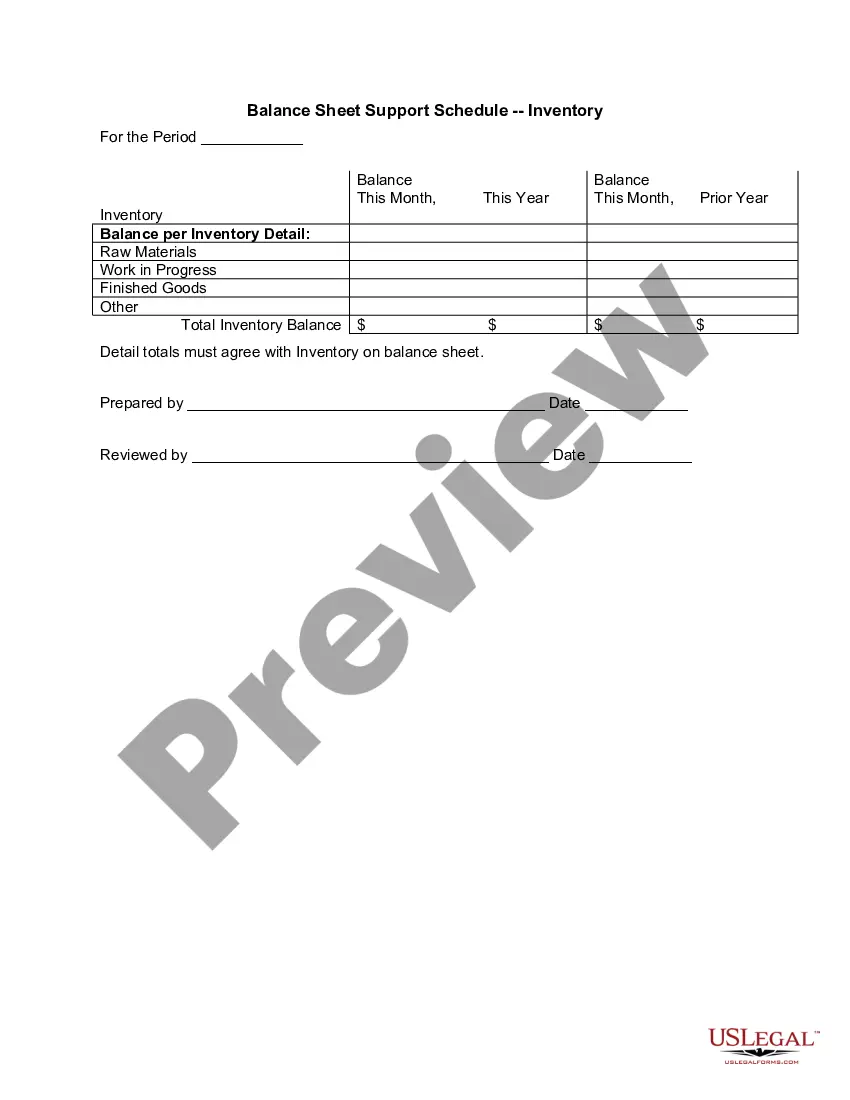

Alabama Personal Property Tax (PPT) must be filed by individuals and businesses that own personal property within the state. This includes various assets such as furniture, machinery, and inventory. If you are managing inventory, using an Alabama Physical Inventory Count Sheet can simplify the process of accurately reporting your assets for PPT.

Yes, inventory is generally considered taxable in Alabama. Business owners must account for their inventory when filing taxes to comply with state regulations. Utilizing an Alabama Physical Inventory Count Sheet can help you track your stock, providing clarity on what assets you own and ensuring you remain compliant with tax obligations.

The 40NR form for Alabama is a tax return specifically designed for non-residents. This form helps non-residents report income earned in Alabama and calculate their tax obligations. If you are managing your inventory in Alabama, understanding how the 40NR form connects with your Alabama Physical Inventory Count Sheet is vital for accurate reporting.

Yes, a physical inventory count is still necessary to ensure accuracy in your inventory records. Regular counts help identify discrepancies and maintain the integrity of your stock levels. Using tools like the Alabama Physical Inventory Count Sheet can facilitate this process and enhance your business operations.

A physical inventory worksheet is a document used to log inventory counts and details during a physical inventory process. The Alabama Physical Inventory Count Sheet serves as an ideal template for this purpose. It helps businesses systematically collect data, ensuring every item is accounted for accurately.

To do a physical inventory count, start by preparing your inventory area and ensuring all items are accessible. Use an Alabama Physical Inventory Count Sheet to aid in organization and accuracy during counting. Involve your team in counting, and consistently verify counts to maintain integrity in your records.