The Alabama Maintenance Supervisor Checklist is an essential tool used by maintenance supervisors in Alabama to ensure the smooth operation and maintenance of various facilities and equipment. This comprehensive checklist covers a wide range of tasks and inspections that supervisors must perform regularly to guarantee the safety, functionality, and longevity of assets under their care. Keywords: Alabama Maintenance Supervisor, Checklist, facilities, equipment, maintenance, tasks, inspections, safety, functionality, longevity, assets. Different types of Alabama Maintenance Supervisor Checklists may vary based on the specific areas of responsibility and industry. Here are a few examples: 1. Alabama Building Maintenance Supervisor Checklist: This checklist focuses on critical aspects related to building maintenance, including HVAC systems, plumbing, electrical systems, fire safety, security systems, and general building upkeep. It ensures compliance with local regulations and optimal facility performance. 2. Alabama Industrial Maintenance Supervisor Checklist: Specifically designed for maintenance supervisors in industrial settings, this checklist covers essential tasks such as machinery inspection, lubrication, equipment calibration, troubleshooting, and preventive maintenance to keep manufacturing processes running smoothly and minimize downtime. 3. Alabama Equipment Maintenance Supervisor Checklist: This checklist caters to supervisors responsible for maintaining specialized equipment or machinery, such as heavy machinery, vehicles, or specialized tools. It includes routine inspections, servicing, replacing worn parts, and adherence to safety guidelines to maximize equipment performance and lifespan. 4. Alabama Grounds Maintenance Supervisor Checklist: For supervisors overseeing landscaping and outdoor maintenance, this checklist focuses on tasks like lawn care, irrigation system checks, tree and shrub maintenance, pest control, and seasonal landscaping activities. It helps maintain a visually appealing outdoor environment. 5. Alabama Facility Safety Maintenance Supervisor Checklist: This checklist places significant emphasis on safety protocols and inspections. It covers areas such as emergency preparedness, safety signage, equipment maintenance, occupational health, and compliance with safety regulations to guarantee a secure work environment for all. These are just a few examples of the various Alabama Maintenance Supervisor Checklists available, and they can be further customized based on specific industry requirements, facility types, and compliance standards.

Alabama Maintenance Supervisor Checklist

Description

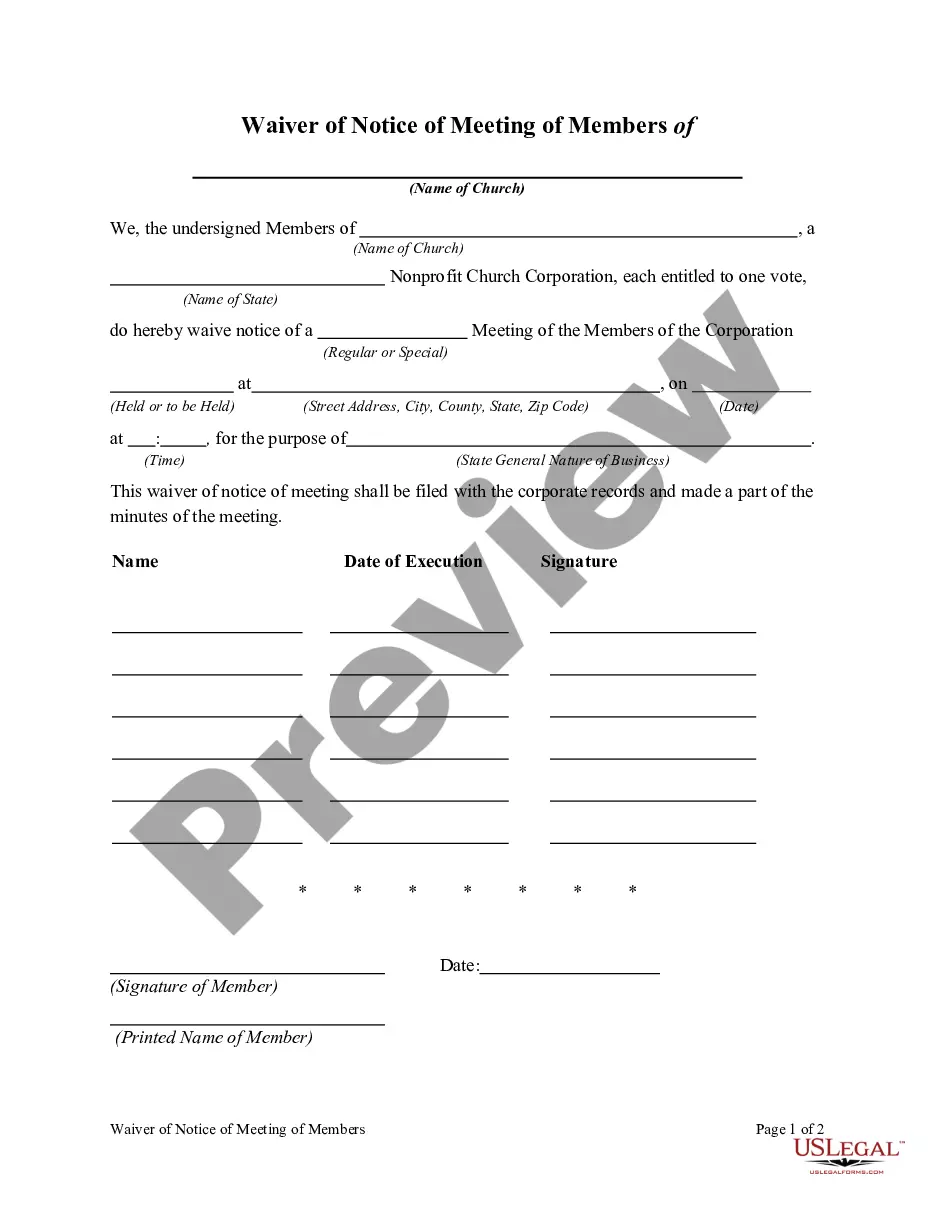

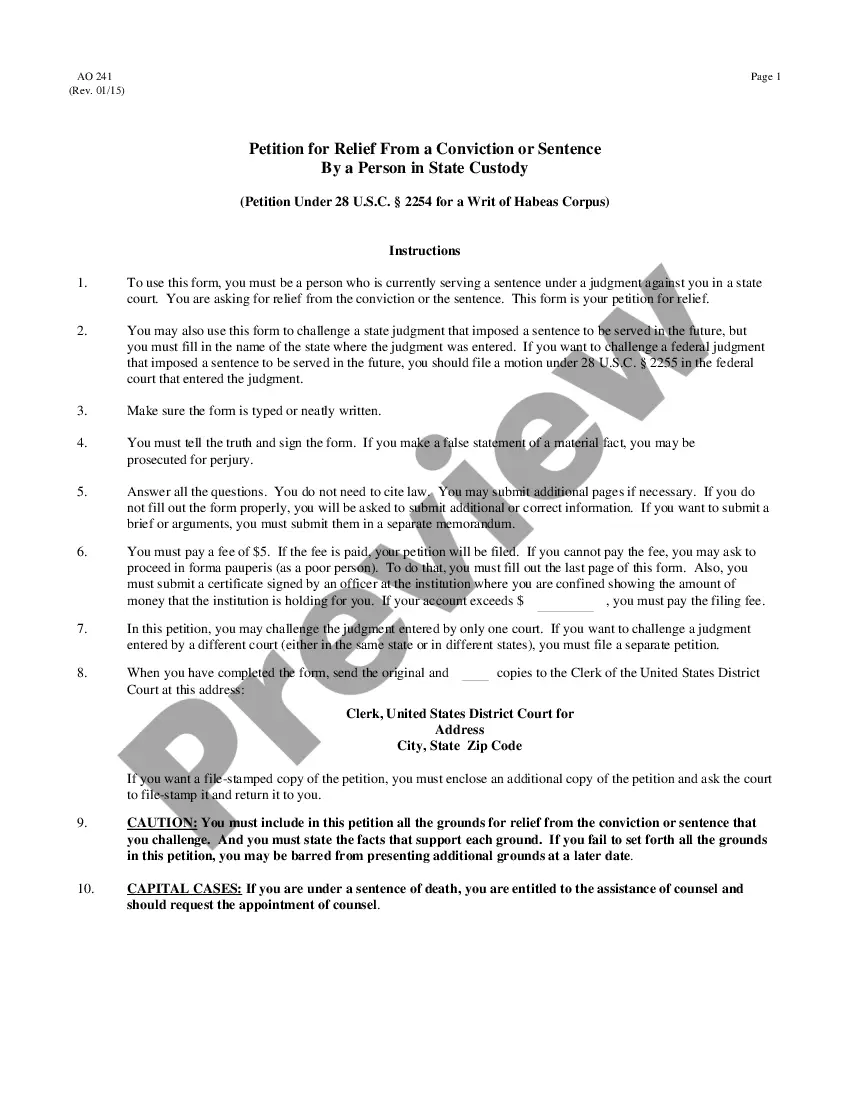

How to fill out Alabama Maintenance Supervisor Checklist?

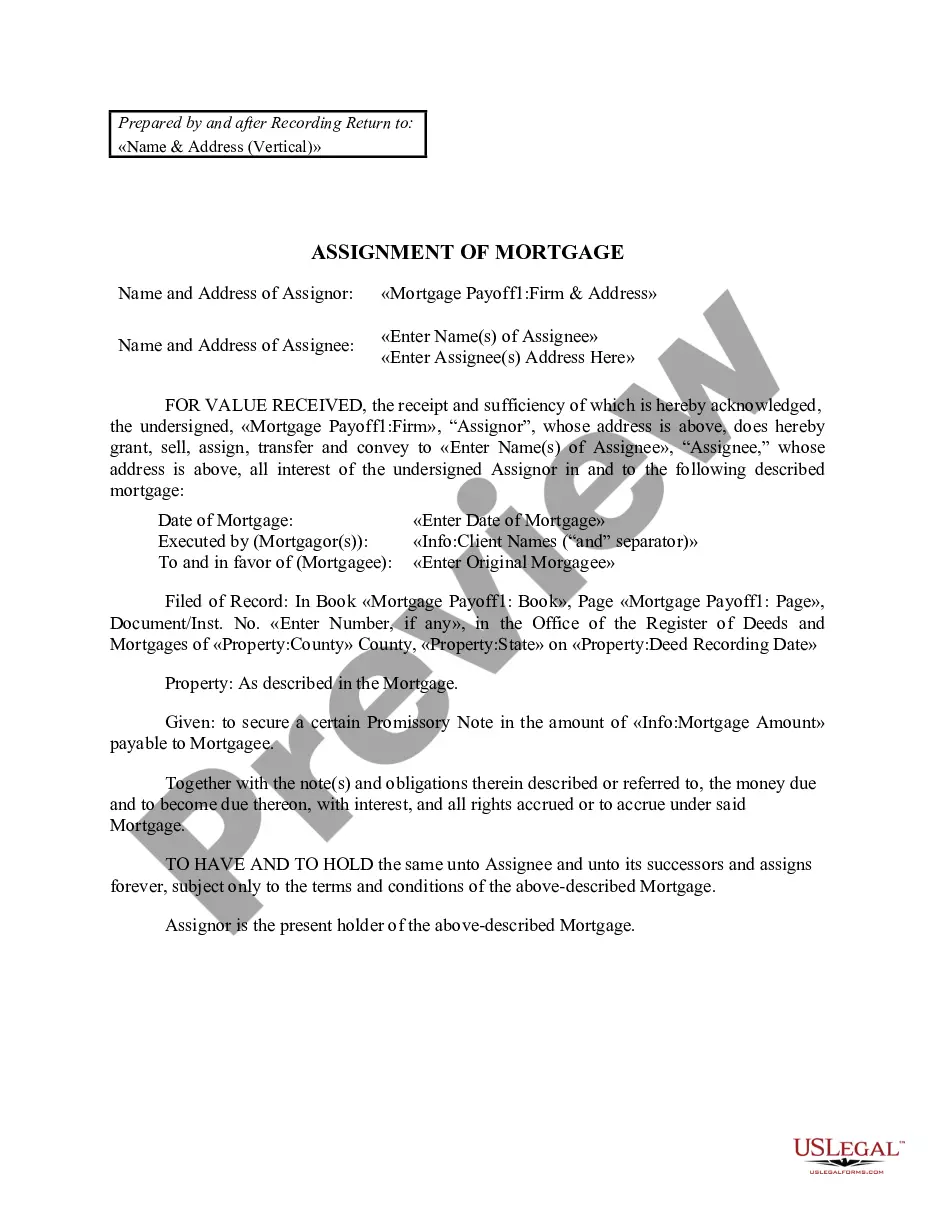

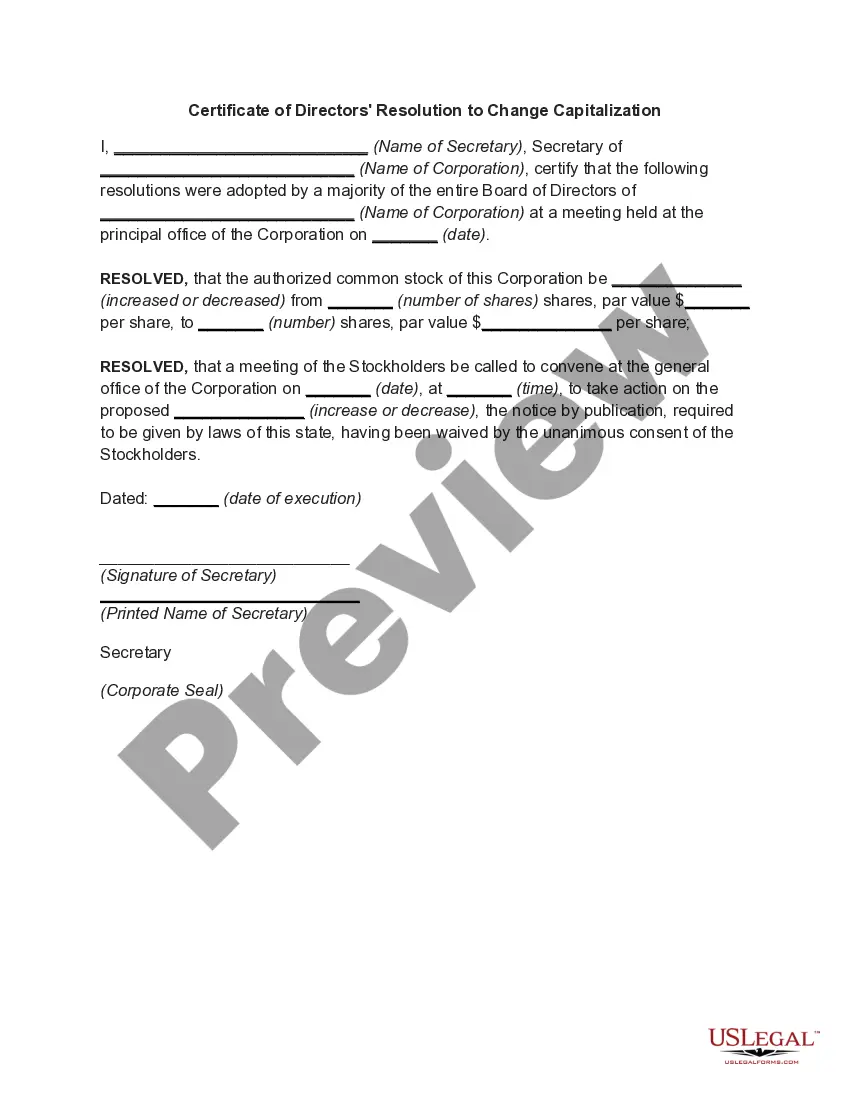

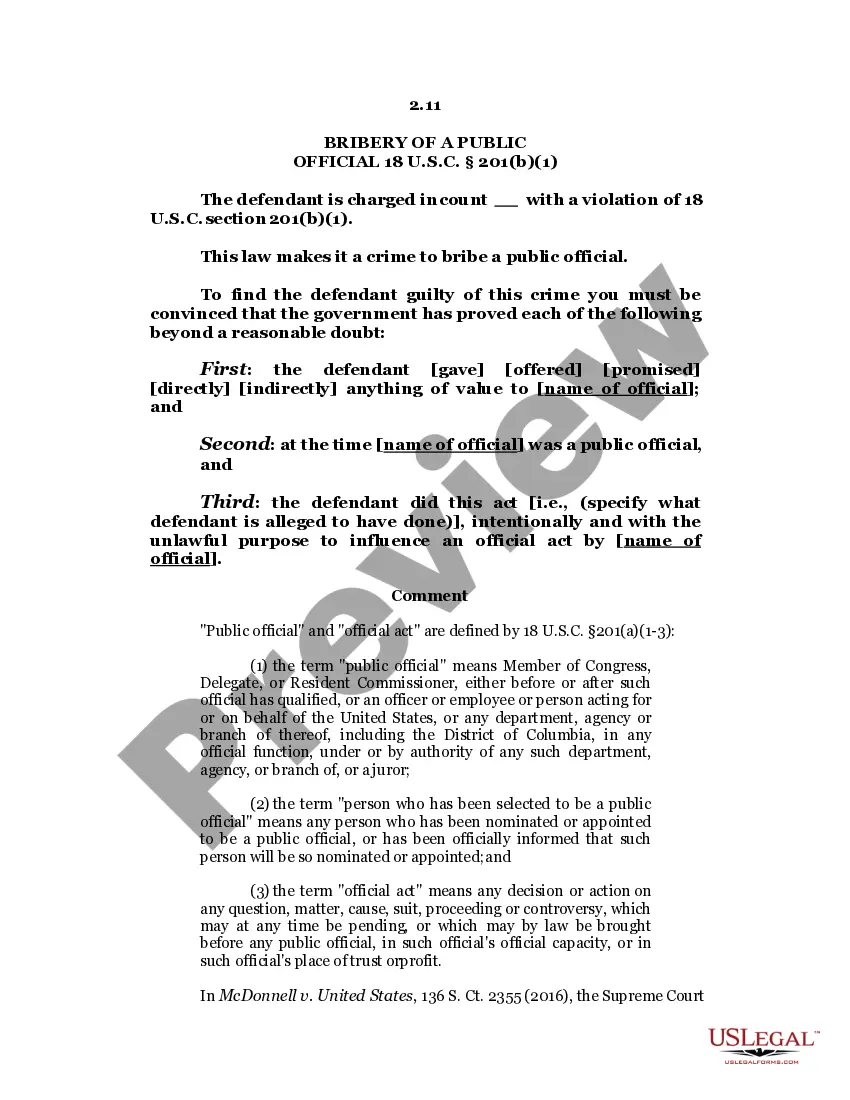

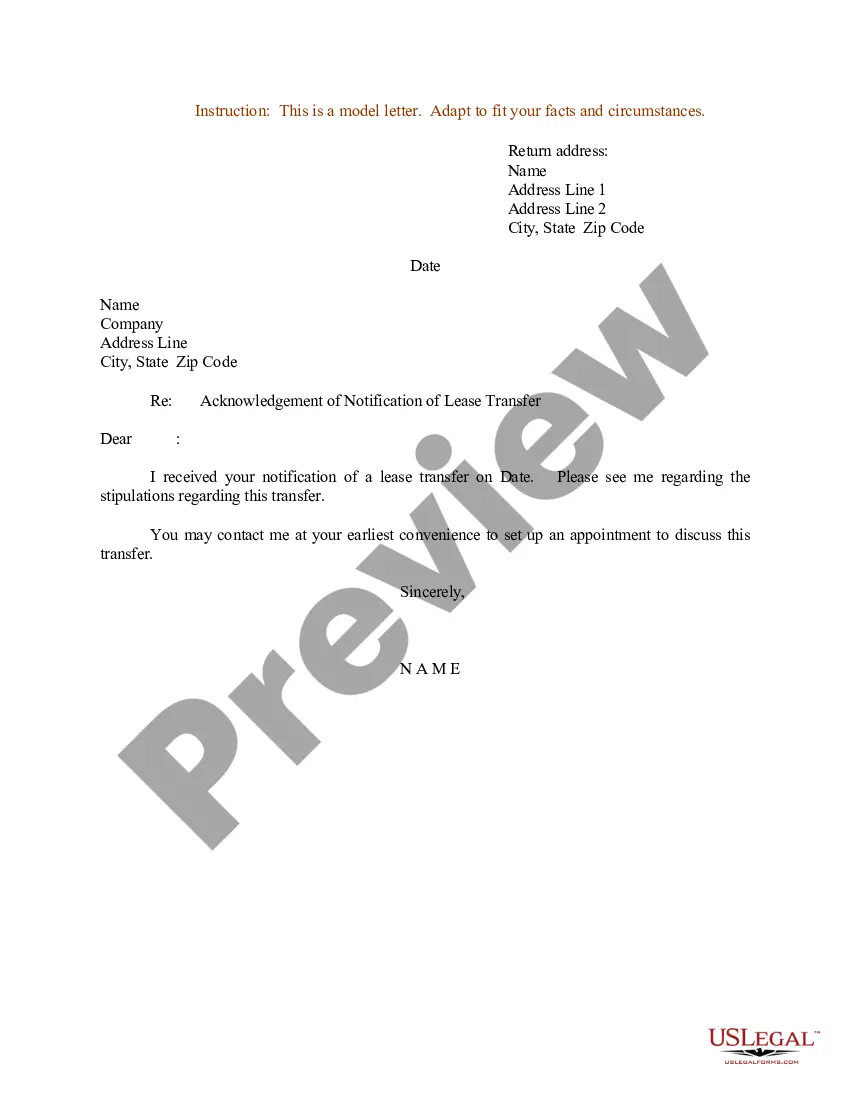

Are you within a situation the place you will need files for sometimes organization or individual reasons nearly every day? There are tons of legitimate papers layouts available online, but finding ones you can rely isn`t simple. US Legal Forms provides thousands of form layouts, like the Alabama Maintenance Supervisor Checklist, that happen to be written in order to meet federal and state demands.

Should you be previously knowledgeable about US Legal Forms internet site and possess your account, simply log in. Afterward, you are able to down load the Alabama Maintenance Supervisor Checklist web template.

Should you not come with an profile and wish to begin using US Legal Forms, abide by these steps:

- Discover the form you need and make sure it is to the correct metropolis/area.

- Take advantage of the Preview button to examine the form.

- See the information to ensure that you have chosen the correct form.

- When the form isn`t what you`re seeking, take advantage of the Search discipline to find the form that fits your needs and demands.

- Once you obtain the correct form, click on Purchase now.

- Pick the pricing strategy you desire, submit the desired details to create your bank account, and purchase the transaction using your PayPal or Visa or Mastercard.

- Choose a handy paper file format and down load your version.

Discover all the papers layouts you have bought in the My Forms menus. You can obtain a additional version of Alabama Maintenance Supervisor Checklist whenever, if possible. Just click on the required form to down load or printing the papers web template.

Use US Legal Forms, by far the most extensive collection of legitimate varieties, to save time as well as avoid faults. The assistance provides professionally made legitimate papers layouts that you can use for an array of reasons. Generate your account on US Legal Forms and begin generating your lifestyle a little easier.

Form popularity

FAQ

On a typical workday, you will find maintenance supervisors working primarily with the technicians and other employees on duty. They must lead and motivate the team and delegate tasks accordingly. They may report to a maintenance manager, facilities manager, maintenance director, or some other executive.

A Maintenance Supervisor is responsible for planning, scheduling and coordinating the installation, maintenance and repair work of equipment and assets in buildings, factories or complexes.

Duties/ Responsibilities:Oversees the day-to-day operations of the maintenance department. Evaluates systems or facilities to determine maintenance or repairs that need to be performed. Assesses building systems to plan work assignments and project schedules. Develops maintenance procedures and schedules.

The five key supervisory roles include Educator, Sponsor, Coach, Counselor, and Director. Each is described below. Note that in your role as a supervisor, you will be using these five roles, in some combination, simultaneously, depending on the needs of the team members.

Maintenance and janitorial skills are those related to repairing and maintaining the function and/or cleanliness of equipment, buildings, and machinery. Such skills are in high demand across the country, ranging from plumbers to carpenters to custodians.

A maintenance supervisor is usually only in charge of the team of people that work under him, while a maintenance manager is in charge of the employees, equipment and often resources allocated to the maintenance faculty of a building or organization.

Important Skills for Maintenance ProfessionalsTechnical Expertise.Interpersonal Skills.Problem Solving and Analytical Skills.Adaptability.Time Management Skills.Teamwork and Collaboration.Ability to Cope with Stress.

Here Are the 8 Skills Every Maintenance Manager Needs to Master to be SuccessfulLeadership. Maintenance managers need to exhibit leadership capability.Good Interpersonal Skills.Time Management.Know How to Groom Individuals.Problem Solving Skills.Flexibility.Team Work.Technical Expertise.

Qualities of a Good Maintenance ManagerDignity and respect for his superiors, team, vendors, and guests. Mentor to his team. Attentive, supportive, and responsive to team needs. Confident in his abilities.