A Strategy for Research and Development

Research and development (R & D) needs to be carefully planned and managed to succeed. It is easy to waste money on developing ideas that go nowhere, but getting it right can lead to business stability, security and long-term profits.

Planning

R & D should be included in your overall business plan. The plan should illustrate the direction you want the business to take and how R & D fits in with your other business activities. Set out clear objectives, time frames and budgets. A clear plan can prevent the project straying from your business goals and wasting valuable resources and money.

You may need to involve staff with specific skills to draw up the plan, for example finance staff to set up budgets. You may also need outside help.

Your plan should set out the steps that need to be taken from the inception of the ideas to the product launch. You should allocate the necessary resources to the project, including funding, staff and time. You might decide to set up a specific team to work on the project.

Management

Good management is vital to reduce risk of failure and realize as many ideas as possible.

To manage R & D projects effectively you should:

" Make sure staff involved in R & D understand the business' overall strategy;

" Ensure these employees understand what is commercially realistic;

" Assess the changing risks and potential of projects as they progress, continually developing a rigorous business case;

" Ensure that intellectual property ownership issues are resolved;

" Recognize when a project isn't going to work; and

" Understand the relative importance of different projects to your business.

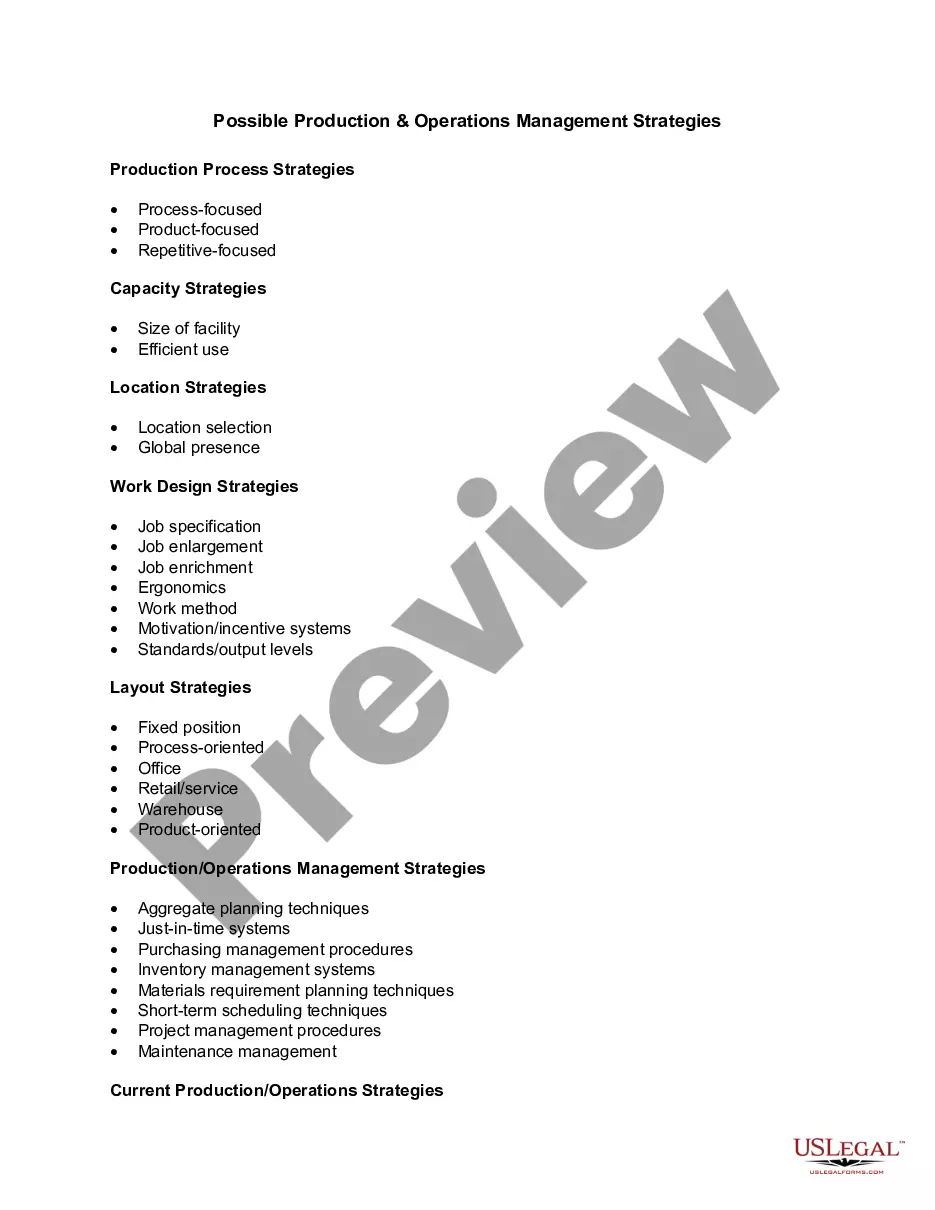

Arkansas Possible Production and Operations Management Strategies: Arkansas, known for its vibrant business climate and diverse industries, is a state that offers various production and operations management strategies to enhance efficiency, productivity, and competitiveness. In this article, we will delve into the details of Arkansas's possible production and operations management strategies and discuss some key examples. 1. Lean Manufacturing Strategy: Lean manufacturing is aimed at reducing waste, improving process flow, and maximizing value while minimizing costs. Arkansas companies adopt this strategy to enhance efficiency, eliminate non-value-added activities, and optimize their supply chain management. Implementing lean principles, such as Just-in-Time (JIT) inventory management and continuous improvement, ensures enhanced productivity and resource utilization. 2. Six Sigma: Six Sigma is a data-driven methodology utilized in Arkansas to improve quality, reduce defects, and streamline operations. By implementing Six Sigma techniques, companies in Arkansas aim to achieve near-perfect processes and operations. This strategy involves identifying defects or opportunities for improvement, setting specific goals, gathering data, and deploying statistical analysis to identify root causes and implement lasting solutions. 3. Total Quality Management (TQM): Total Quality Management focuses on continuously improving product and service quality. Arkansas' businesses adopting TQM strive to enhance customer satisfaction, employee engagement, and operational efficiency. This strategy involves a customer-focused mindset, process improvement teams, regular training and feedback loops, and a culture that encourages quality-oriented thinking at all levels of the organization. 4. Supply Chain Management: Arkansas businesses understand the importance of effective supply chain management to minimize costs, reduce lead times, and meet customer demands. This strategy involves collaborating closely with suppliers, adopting technology-driven solutions like IoT (Internet of Things) for real-time visibility, implementing efficient transportation and logistics practices, and optimizing inventory levels through effective demand forecasting. 5. Automation and Technology Integration: Innovation is a key driver of Arkansas's success in production and operations management. The integration of advanced technologies, such as robotics, artificial intelligence, and big data analytics, enables companies to automate processes, improve accuracy, and enhance productivity. Automation and technology integration strategies empower businesses in Arkansas to meet demanding customer requirements, reduce errors, and stay ahead of the competition. 6. Energy Efficiency and Sustainability: Many Arkansas companies emphasize energy efficiency and sustainable practices to minimize environmental impact, cut costs, and enhance their brand image. Production and operations management strategies in this area involve adopting energy-efficient technologies, implementing recycling programs, optimizing resource allocation, and complying with environmental regulations. In conclusion, Arkansas offers a diverse range of production and operations management strategies for businesses to thrive in today's competitive landscape. Lean manufacturing, Six Sigma, Total Quality Management, supply chain management, automation, technology integration, and sustainability play crucial roles in enhancing productivity, reducing costs, and meeting customer expectations. By embracing these strategies, companies in Arkansas can strengthen their market position and contribute to the state's overall economic growth.