Arkansas Maintenance Assistance - Technician Checklist

Description

How to fill out Maintenance Assistance - Technician Checklist?

If you want to aggregate, download, or create official document templates, utilize US Legal Forms, the largest selection of legal forms available online.

Utilize the site's simple and convenient search feature to locate the documents you require. Numerous templates for business and personal purposes are organized by categories and jurisdictions or keywords.

Use US Legal Forms to find the Arkansas Maintenance Assistance - Technician Checklist in just a few clicks.

Every legal document template you purchase is yours indefinitely. You have access to every form you downloaded in your account. Click the My documents section and select a form to print or download again.

Complete and download, and print the Arkansas Maintenance Assistance - Technician Checklist with US Legal Forms. There are thousands of professional and state-specific forms available for your business or personal needs.

- If you are already a US Legal Forms user, Log In to your account and click the Download button to obtain the Arkansas Maintenance Assistance - Technician Checklist.

- You can also access forms you have previously downloaded in the My documents tab of your account.

- If you are using US Legal Forms for the first time, follow the instructions below.

- Step 1. Ensure you have selected the form for the correct city/state.

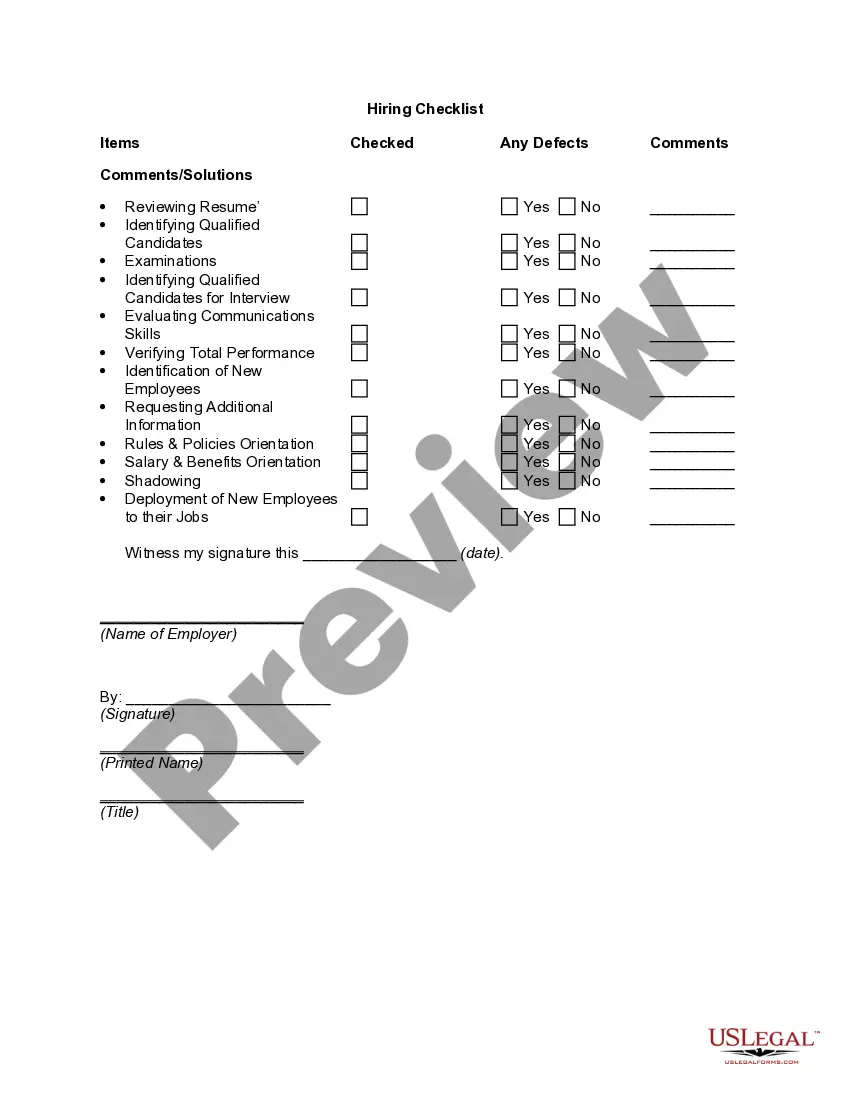

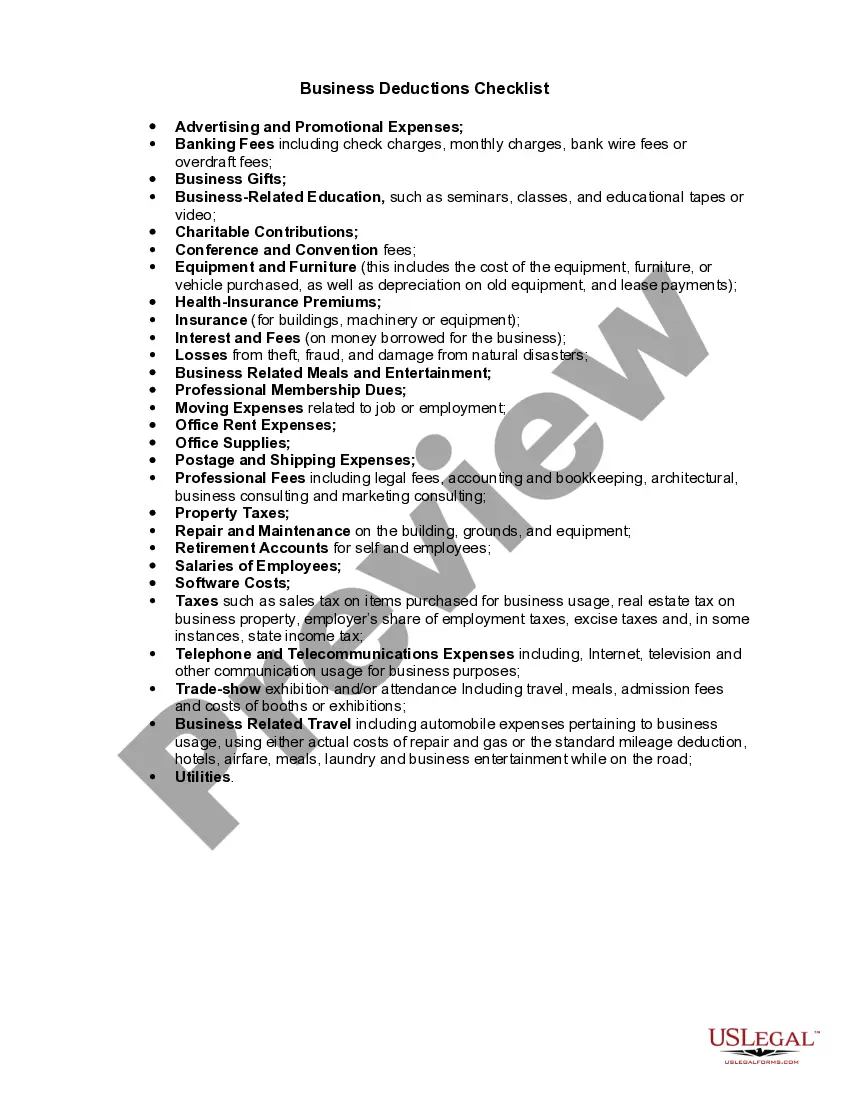

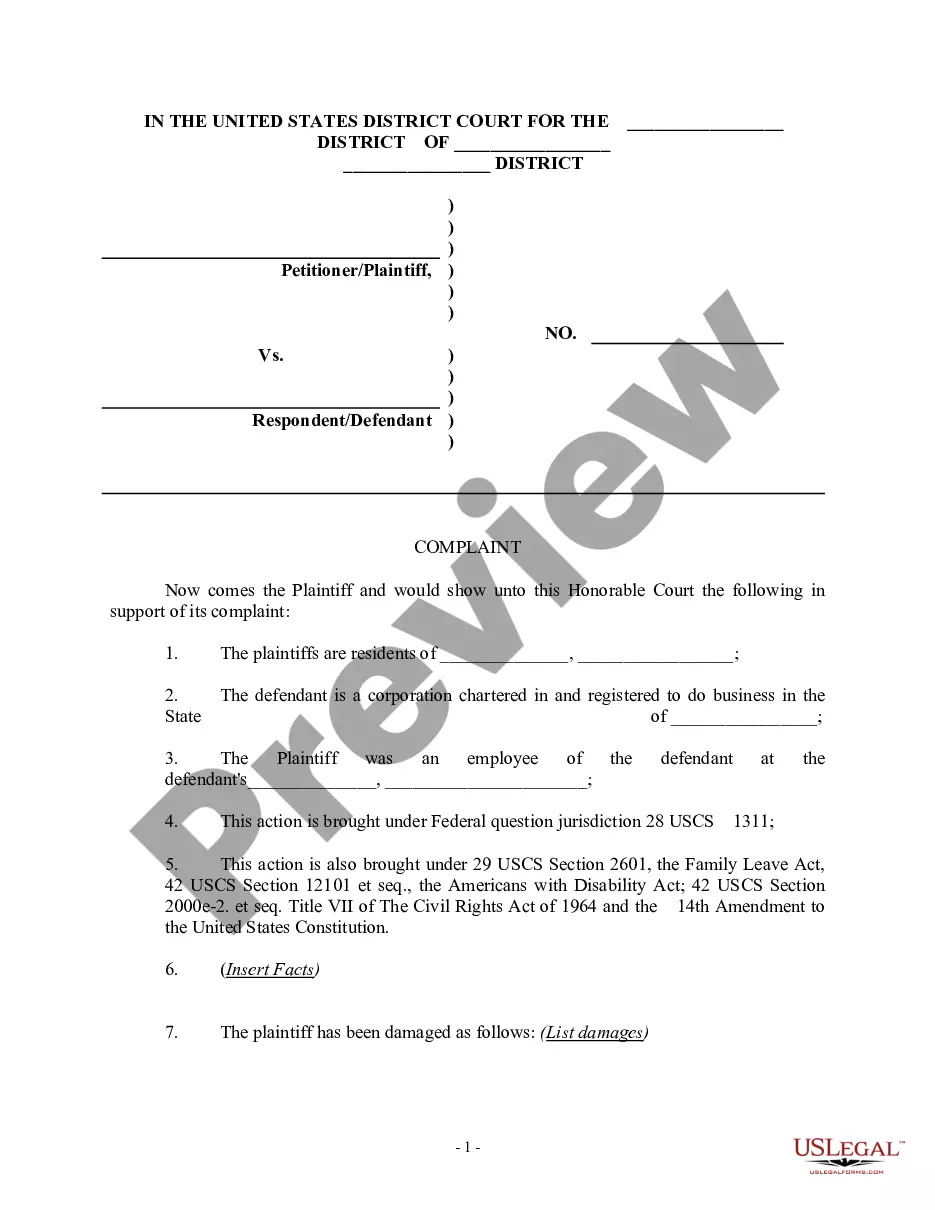

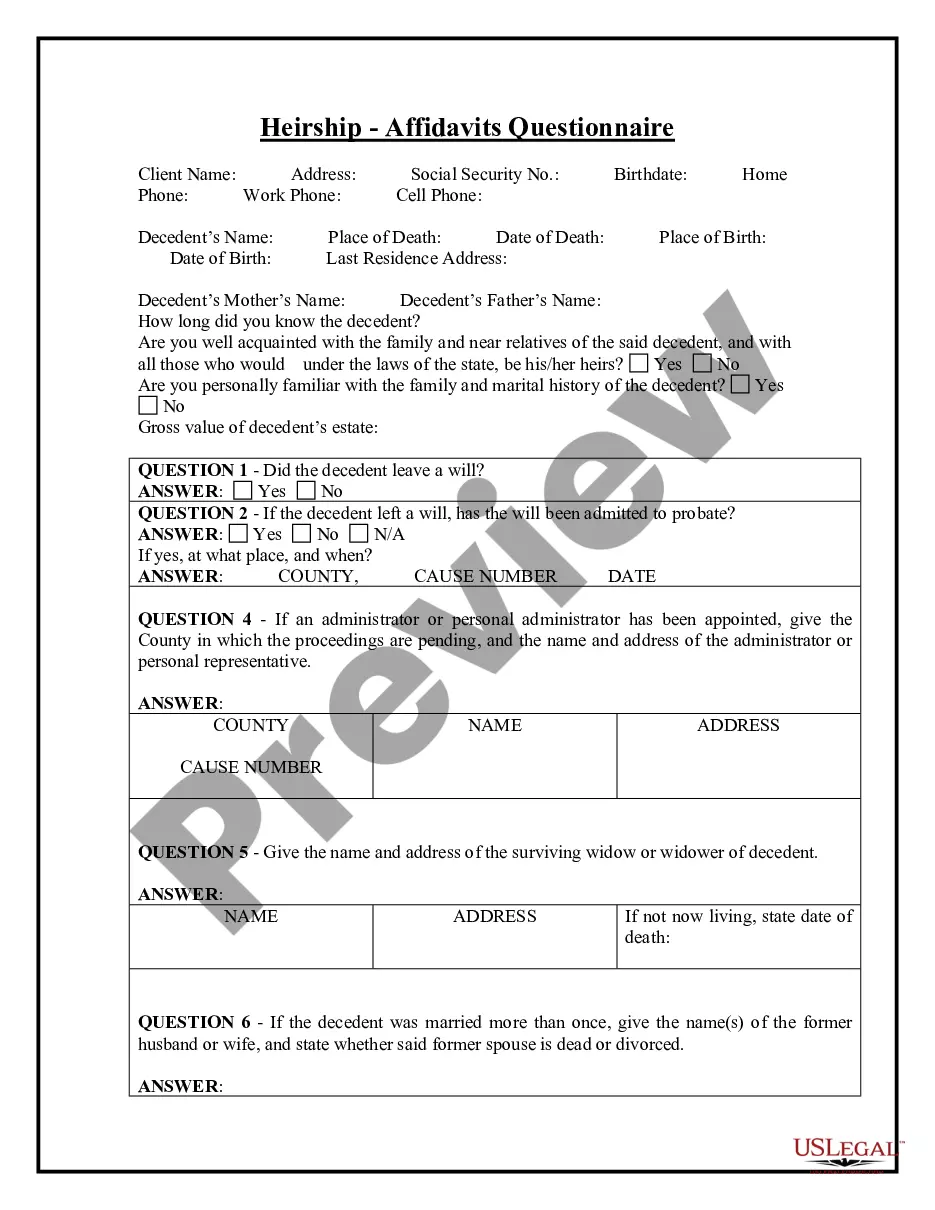

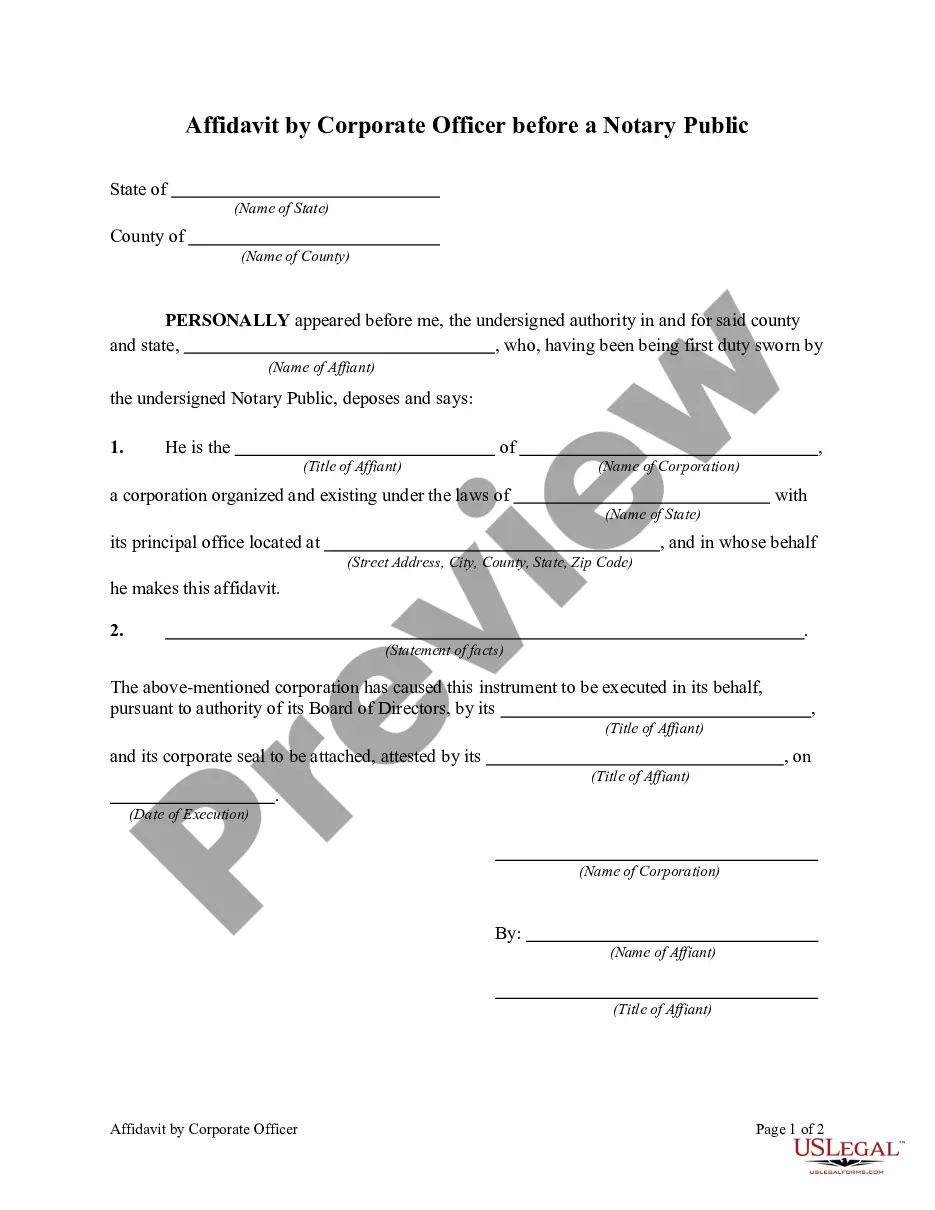

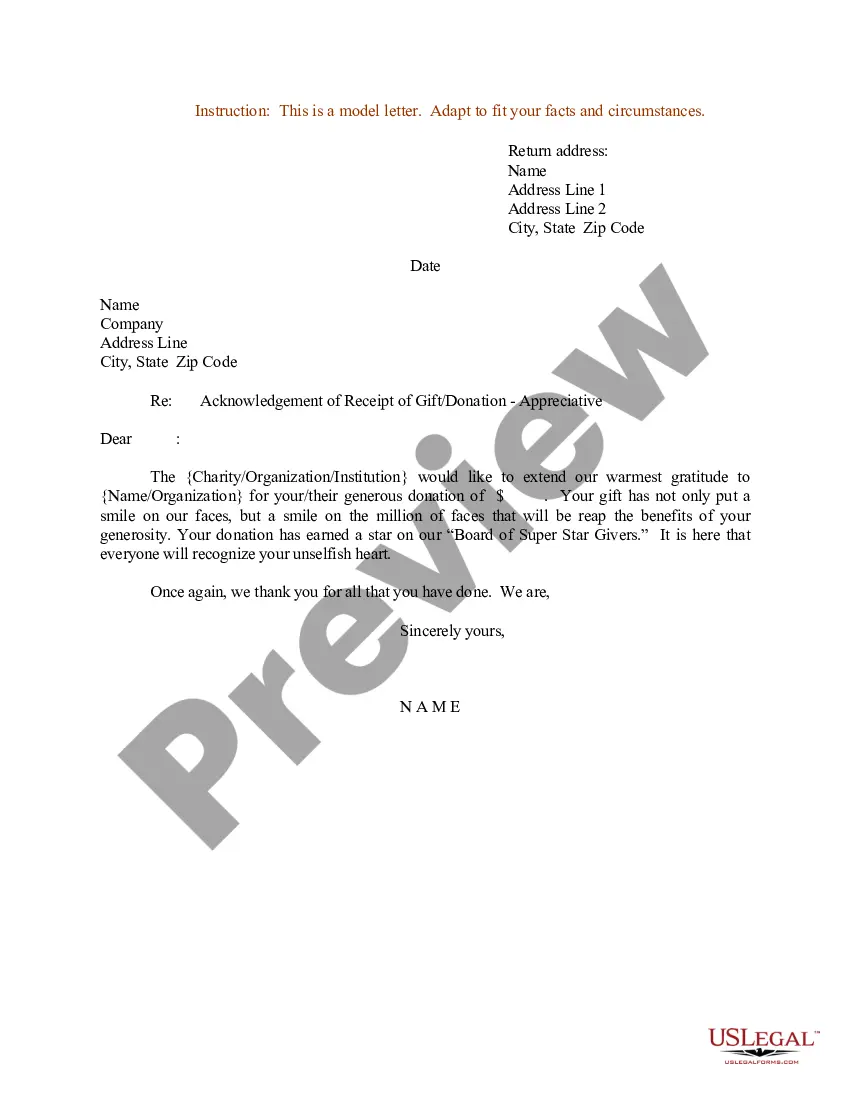

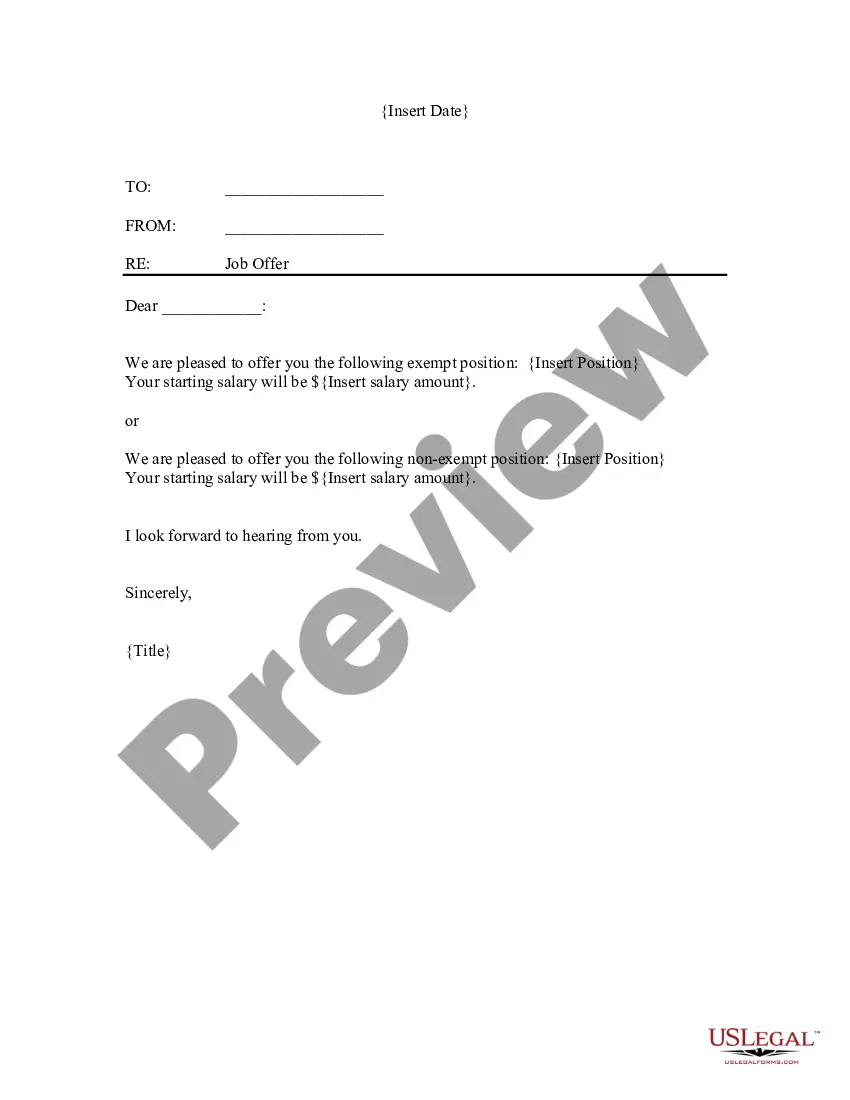

- Step 2. Use the Preview option to review the form's content. Don’t forget to read the description.

- Step 3. If you are not satisfied with the form, use the Search field at the top of the screen to find other versions of the legal form template.

- Step 4. Once you have located the form you need, click the Get Now button. Choose the pricing plan you prefer and enter your details to register for an account.

- Step 5. Complete the payment. You may use your Visa or Mastercard or PayPal account to finalize the transaction.

- Step 6. Select the format of the legal form and download it to your device.

- Step 7. Complete, modify, and print or sign the Arkansas Maintenance Assistance - Technician Checklist.