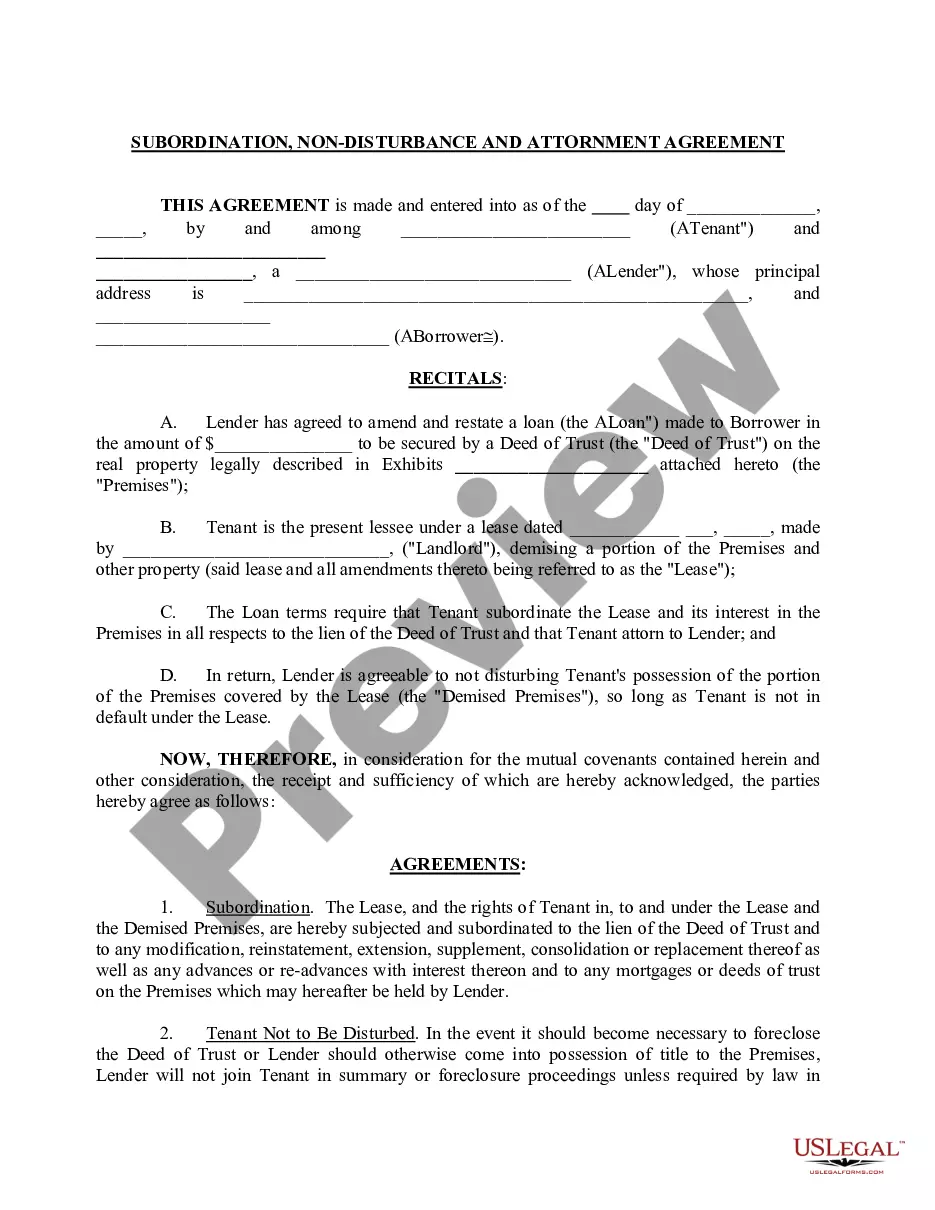

The Plugging of Wells form, the assignee shall plug all wells not capable or no longer capable of producing oil or gas in paying quantities and shall restore the lands around any such well in a manner that meets all requirements of any governmental agency having jurisdiction and the oil and gas lease on which the well is located.

Arkansas Plugging of Wells

Description

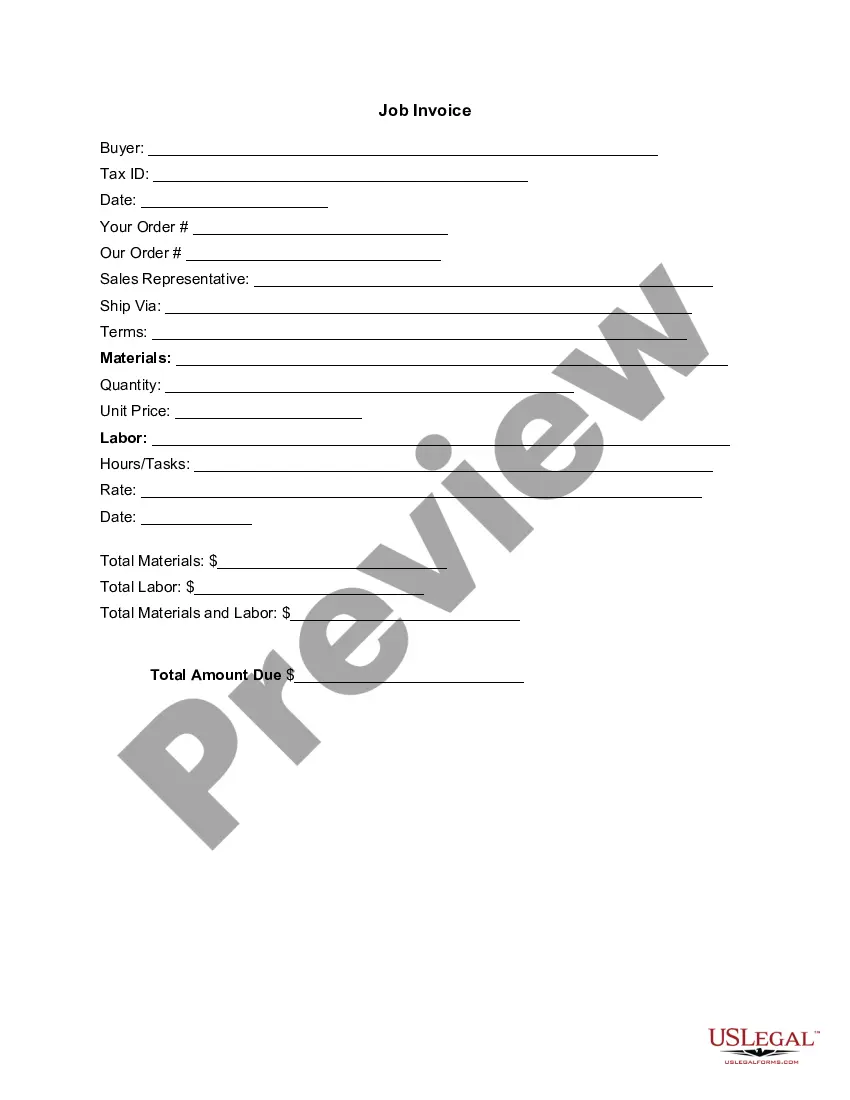

How to fill out Plugging Of Wells?

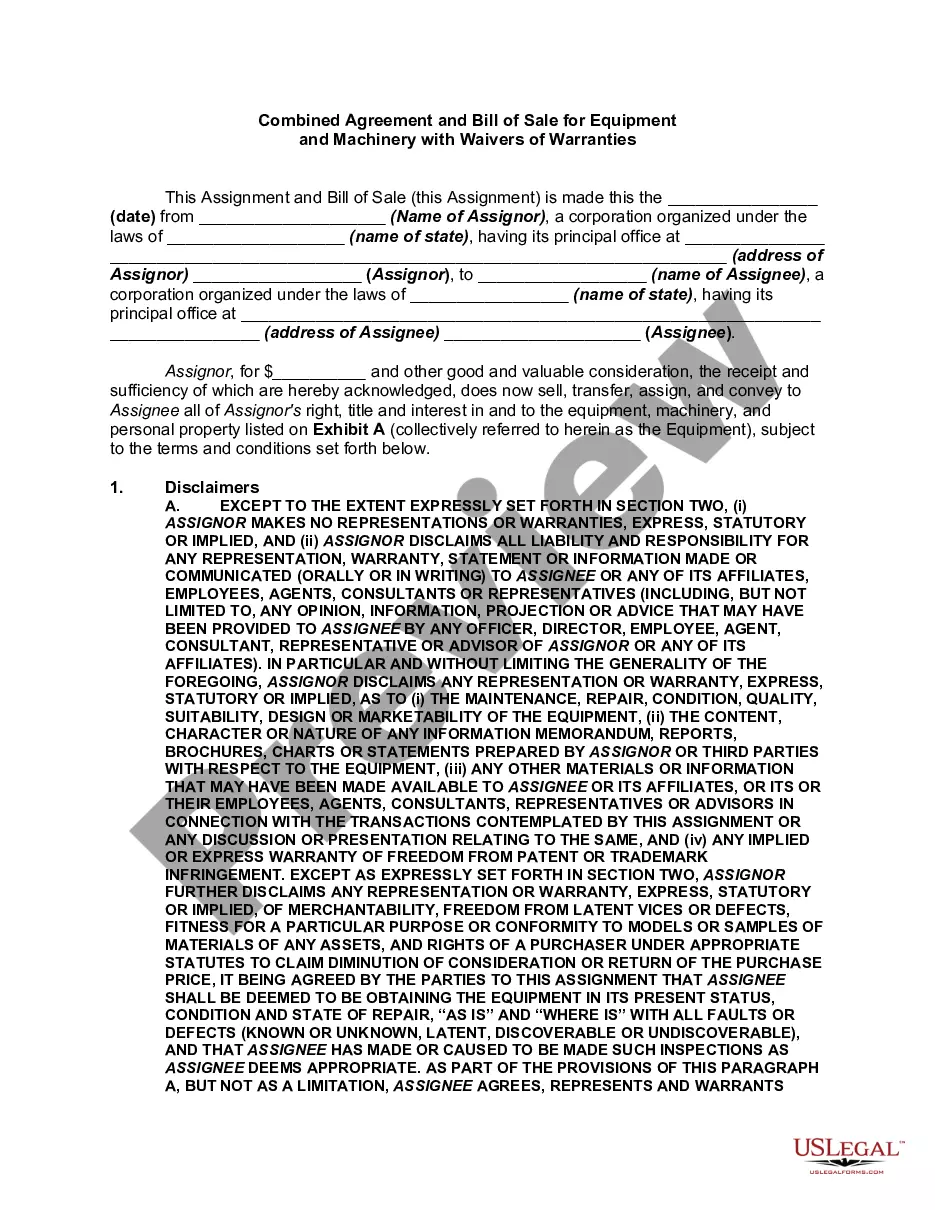

You may invest hours on the Internet attempting to find the legal document template that meets the federal and state specifications you need. US Legal Forms gives a large number of legal varieties which can be reviewed by pros. You can actually down load or print the Arkansas Plugging of Wells from our assistance.

If you already possess a US Legal Forms bank account, you can log in and click on the Obtain switch. After that, you can complete, change, print, or signal the Arkansas Plugging of Wells. Each and every legal document template you get is your own eternally. To get an additional duplicate associated with a obtained develop, proceed to the My Forms tab and click on the related switch.

If you use the US Legal Forms site for the first time, adhere to the basic guidelines beneath:

- Initially, make sure that you have selected the correct document template to the area/metropolis of your choice. See the develop information to make sure you have chosen the appropriate develop. If offered, make use of the Preview switch to appear from the document template at the same time.

- If you want to locate an additional version from the develop, make use of the Search field to find the template that meets your needs and specifications.

- Once you have discovered the template you want, click on Purchase now to proceed.

- Find the rates program you want, type in your references, and sign up for an account on US Legal Forms.

- Comprehensive the deal. You can utilize your bank card or PayPal bank account to purchase the legal develop.

- Find the formatting from the document and down load it to the device.

- Make alterations to the document if necessary. You may complete, change and signal and print Arkansas Plugging of Wells.

Obtain and print a large number of document themes using the US Legal Forms Internet site, which offers the greatest collection of legal varieties. Use expert and state-particular themes to deal with your small business or individual requirements.

Form popularity

FAQ

Fracking has been documented in more than 30 U.S. states and is particularly widespread in North Dakota, Pennsylvania and Texas.

Air pollution and water contamination due to the toxic chemicals used in hydraulic fracturing are the greatest concerns within fracking sites, while the need for wastewater disposal and shrinking water supplies are also pressing issues directly related to the procedure.

All the debris and material need to be removed for successful plugging. Once the well is cleaned out, the plugging process begins by placing cement in the well through the gas and oil-producing zones. These cement plugs, at times, are spaced within the well using bentonite gel spacers (mixtures of clay and water).

As of May 2017, there were 46,973 oil and gas wells in Arkansas ing to the Arkansas Oil and Gas Commission. Of that total, 6,335 wells? 13.5 percent?were hydraulically fractured.

Well plugging involves the placement of cement at discrete depth intervals in a wellbore to seal off hydrocarbon-bearing zones and prevent the pollution of aquifers and surface waters.

BLM is leading the Federal Orphaned Well Program to remediate orphaned wells on Federal Lands. This multi-agency effort includes DOI Land Management Agencies, the U.S. Forest Service (USDA), the U.S. Department of Energy, the Environmental Protection Agency, and the Interstate Oil & Gas Commission Compact.

North Dakota reported the highest spill rate, with 4,453 incidents, followed by Pennsylvania at 1,293, Colorado at 476 and New Mexico at 426. The number of spills reported is partly a reflection of the reporting requirements set by each state.

Natural gas production in the Fayetteville Shale region of north central Arkansas has grown rapidly since horizontal drilling and hydraulic fracturing began in 2004.