This lease rider form may be used when you are involved in a lease transaction, and have made the decision to utilize the form of Oil and Gas Lease presented to you by the Lessee, and you want to include additional provisions to that Lease form to address specific concerns you may have, or place limitations on the rights granted the Lessee in the standard lease form.

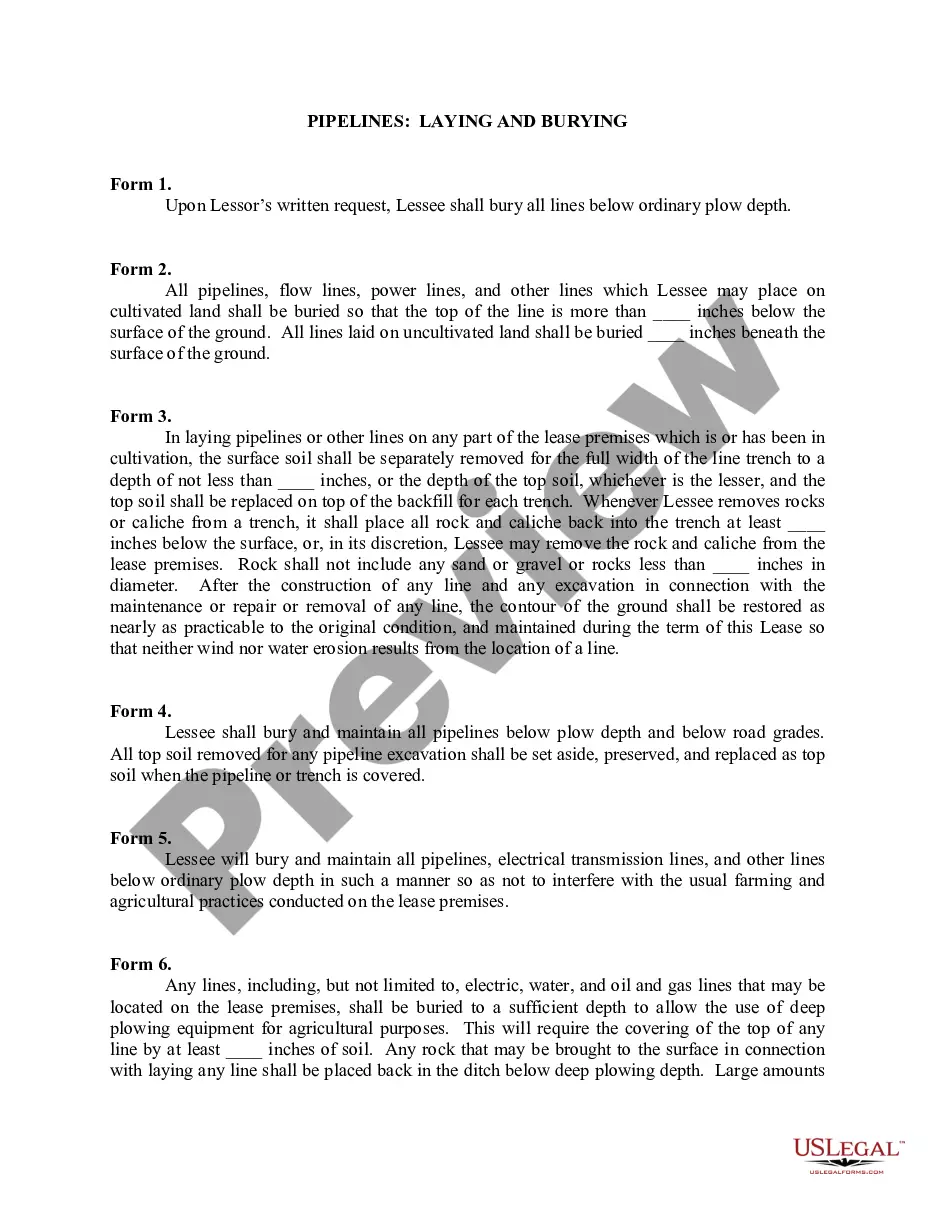

Arkansas Pipelines - Laying and Burying

Description

How to fill out Pipelines - Laying And Burying?

US Legal Forms - among the greatest libraries of authorized types in the USA - delivers a wide range of authorized record web templates you may obtain or print out. Utilizing the website, you can find a huge number of types for company and specific reasons, sorted by classes, states, or key phrases.You can find the most recent types of types much like the Arkansas Pipelines - Laying and Burying within minutes.

If you have a registration, log in and obtain Arkansas Pipelines - Laying and Burying from the US Legal Forms local library. The Acquire key will appear on every form you see. You get access to all earlier acquired types from the My Forms tab of your own accounts.

If you want to use US Legal Forms the first time, listed below are easy instructions to help you started:

- Be sure to have picked out the right form for your area/area. Select the Preview key to check the form`s information. Read the form information to ensure that you have selected the right form.

- In case the form does not satisfy your needs, take advantage of the Research discipline on top of the monitor to find the one which does.

- When you are content with the form, verify your option by clicking on the Purchase now key. Then, pick the pricing strategy you like and offer your credentials to sign up for the accounts.

- Procedure the deal. Utilize your charge card or PayPal accounts to perform the deal.

- Pick the format and obtain the form on the product.

- Make changes. Fill up, revise and print out and sign the acquired Arkansas Pipelines - Laying and Burying.

Each web template you included in your account lacks an expiration time and is also your own eternally. So, in order to obtain or print out an additional version, just proceed to the My Forms segment and then click about the form you need.

Get access to the Arkansas Pipelines - Laying and Burying with US Legal Forms, the most substantial local library of authorized record web templates. Use a huge number of specialist and state-distinct web templates that fulfill your small business or specific requires and needs.

Form popularity

FAQ

Pipeline systems are, in most cases, buried underground. Because they often carry environmentally harmful substances, such as waste or oil, they must be carefully constructed of the materials most appropriate for the substance being transported.

AR ADC 126.05. 2-192.361Arkansas Administrative Code Each buried service line must be installed with at least 12 inches (305 millimeters) of cover in private property and at least 18 inches (457 millimeters) of cover in streets and roads.

While most natural gas pipelines are buried under the ground, there are some that do their work above ground, and these are particularly susceptible to influence and damage from exterior factors.

Gas pipelines transporting natural gas are typically buried just a few feet below the ground, while those carrying liquefied natural gas may be buried up to 100 feet deeper underground.

Within 36 inches of the outer edge of the pipe (on all sides), only hand excavation, air cutting, vacuum excavation, or potholing techniques are permitted.

Federal regulations require that transmission pipelines and regulated type A gathering lines be buried at least 30 inches below the surface in rural areas and deeper (36 inches) in more populated areas.

The depth at which a gas line gets buried varies depending on the country, the town, or the city, but generally should be between 18 and 24 inches deep. Gas pipelines used in commercial areas are typically much deeper than lines used on private property.

Pipelines are generally laid underground because temperature is less variable. Because pipelines are usually metal, this helps to reduce the expansion and shrinkage that can occur with weather changes. However, in some cases it is necessary to cross a valley or a river on a pipeline bridge.