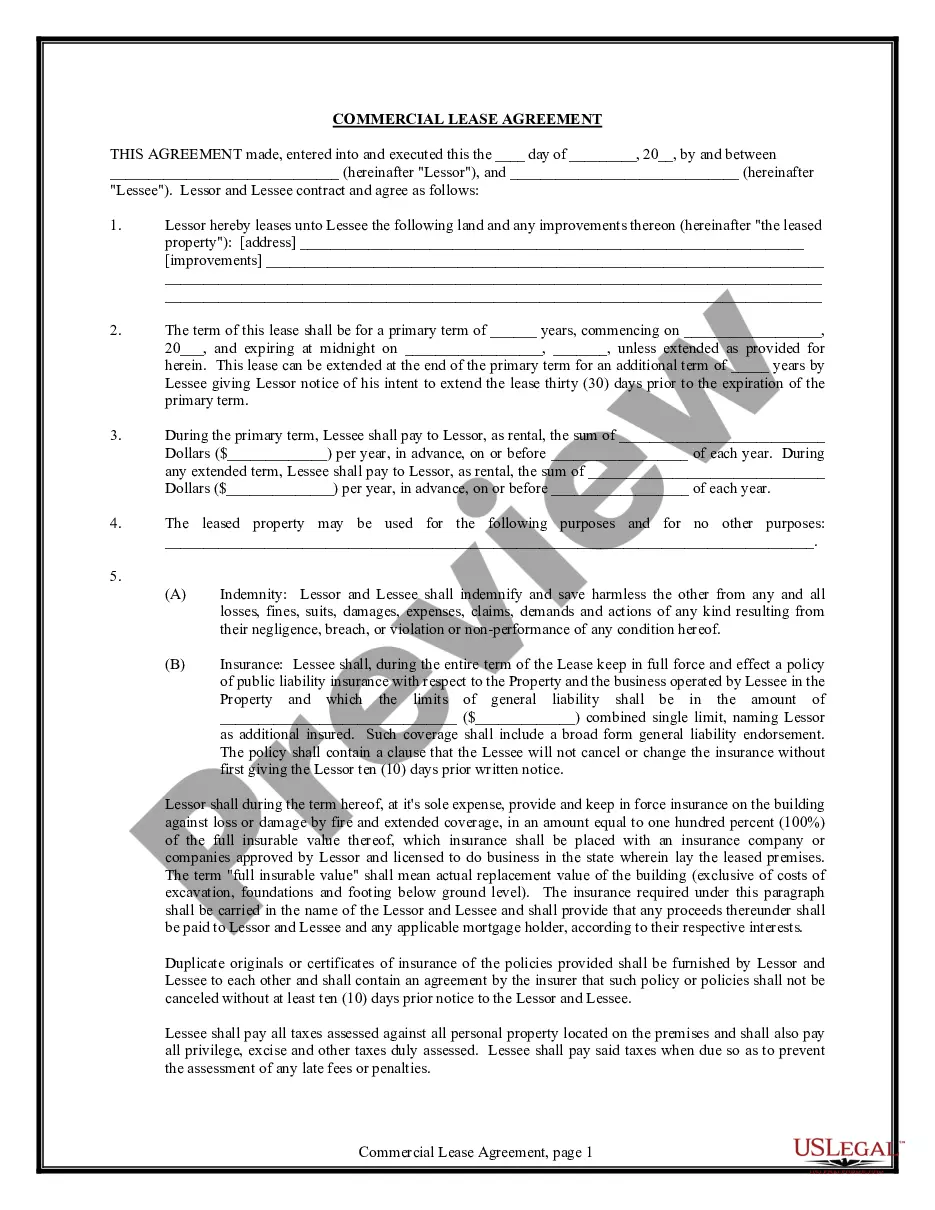

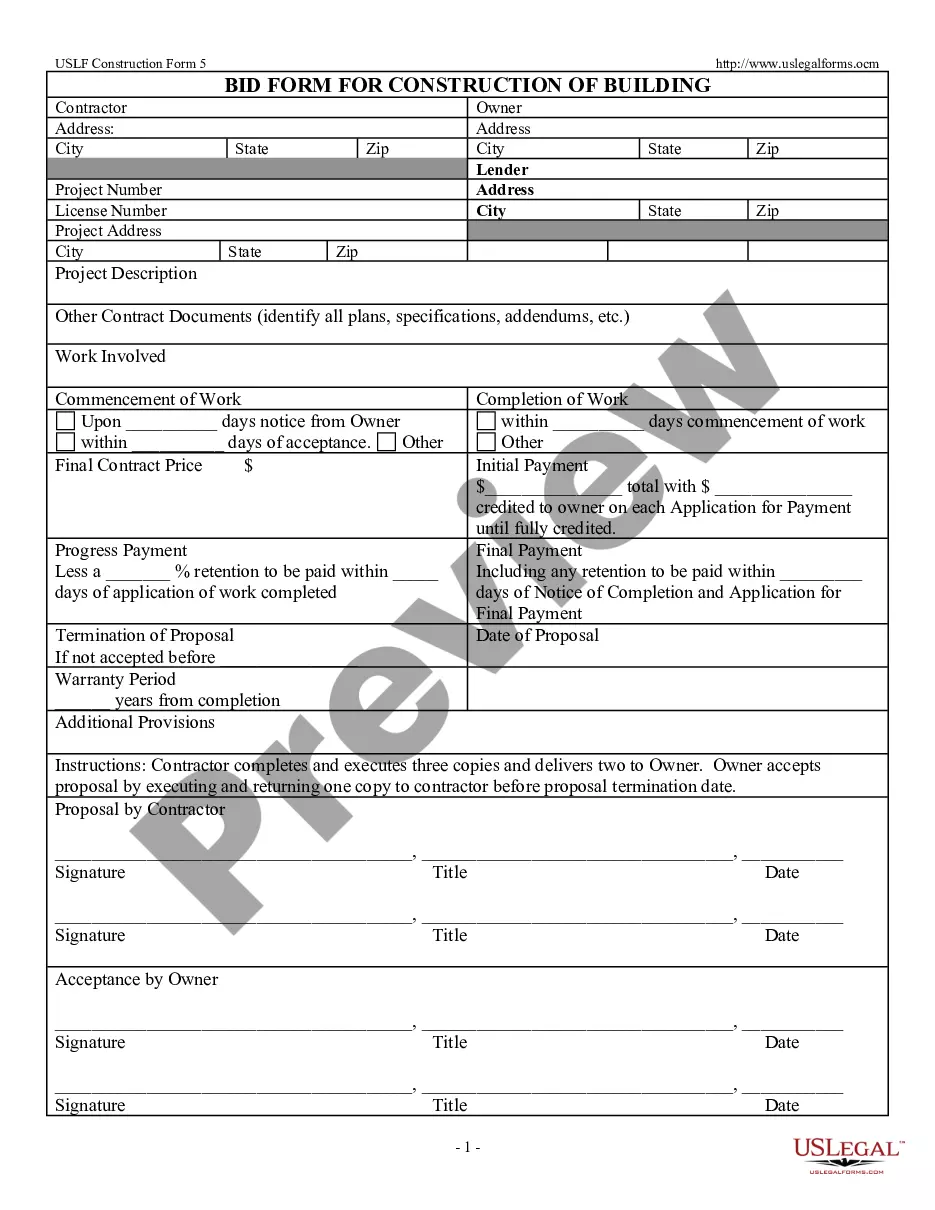

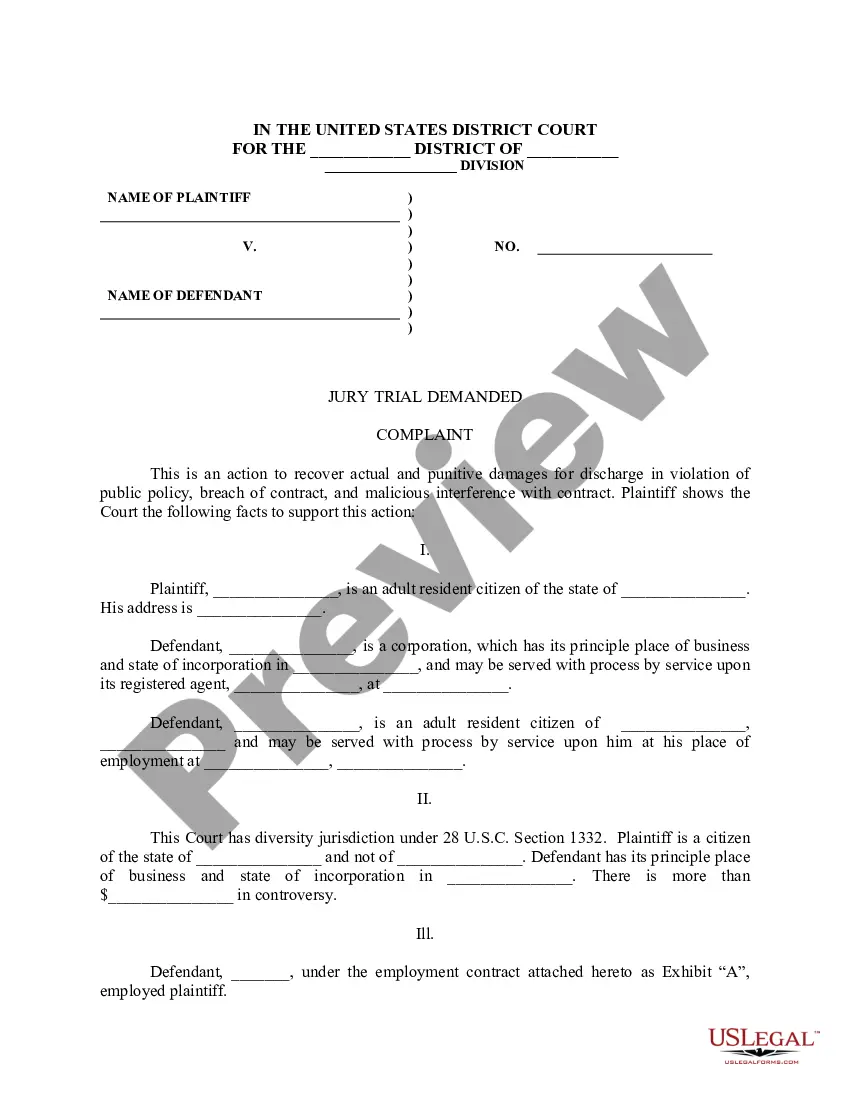

This office lease form states that the landlord shall install a freight elevator that will be adjacent to the tenant's exclusive loading dock. Upon completion of the installation of the tenant's freight elevator, the tenant, at its sole cost and expense, shall maintain the tenant's freight elevator in good working order.

Arkansas Specification for Freight Elevator Service

Description

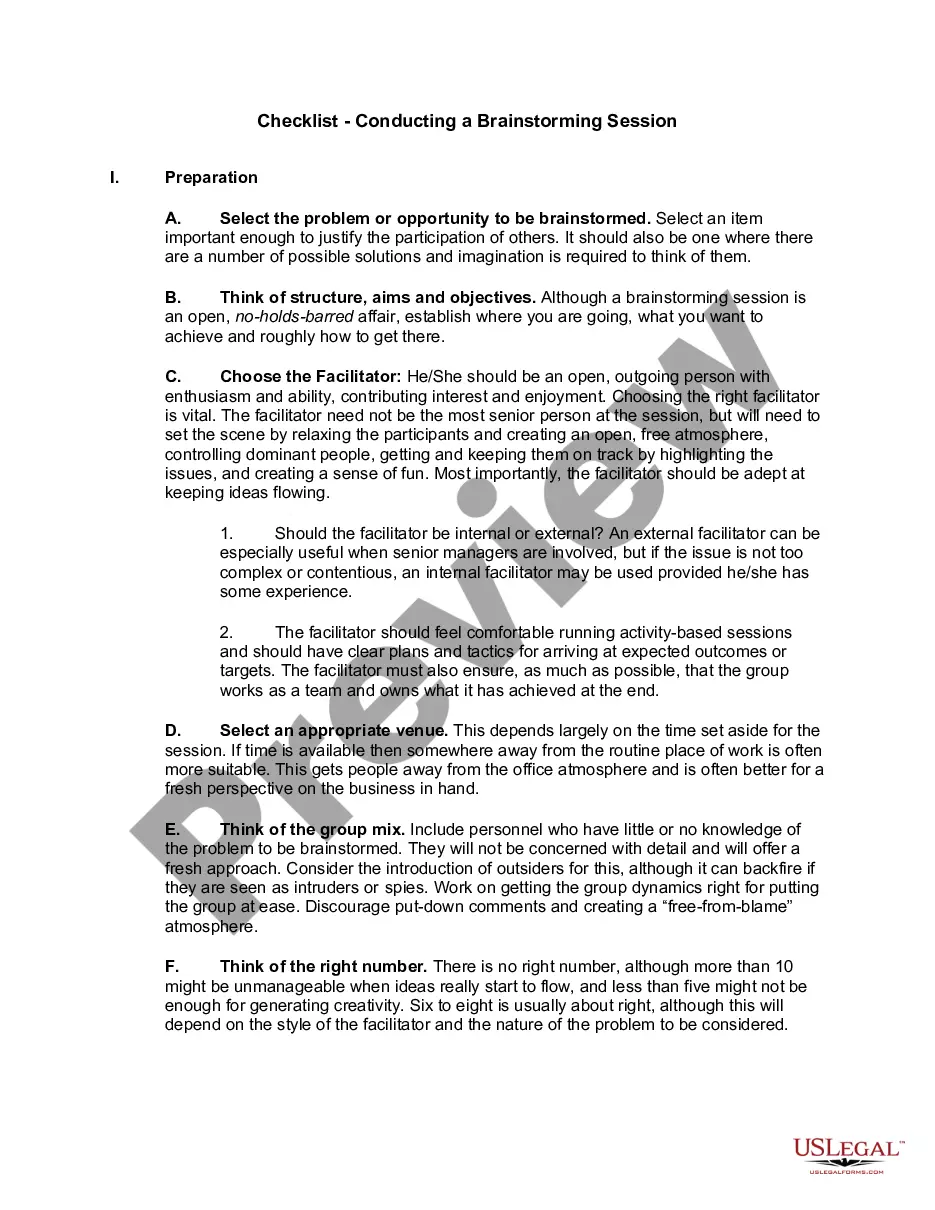

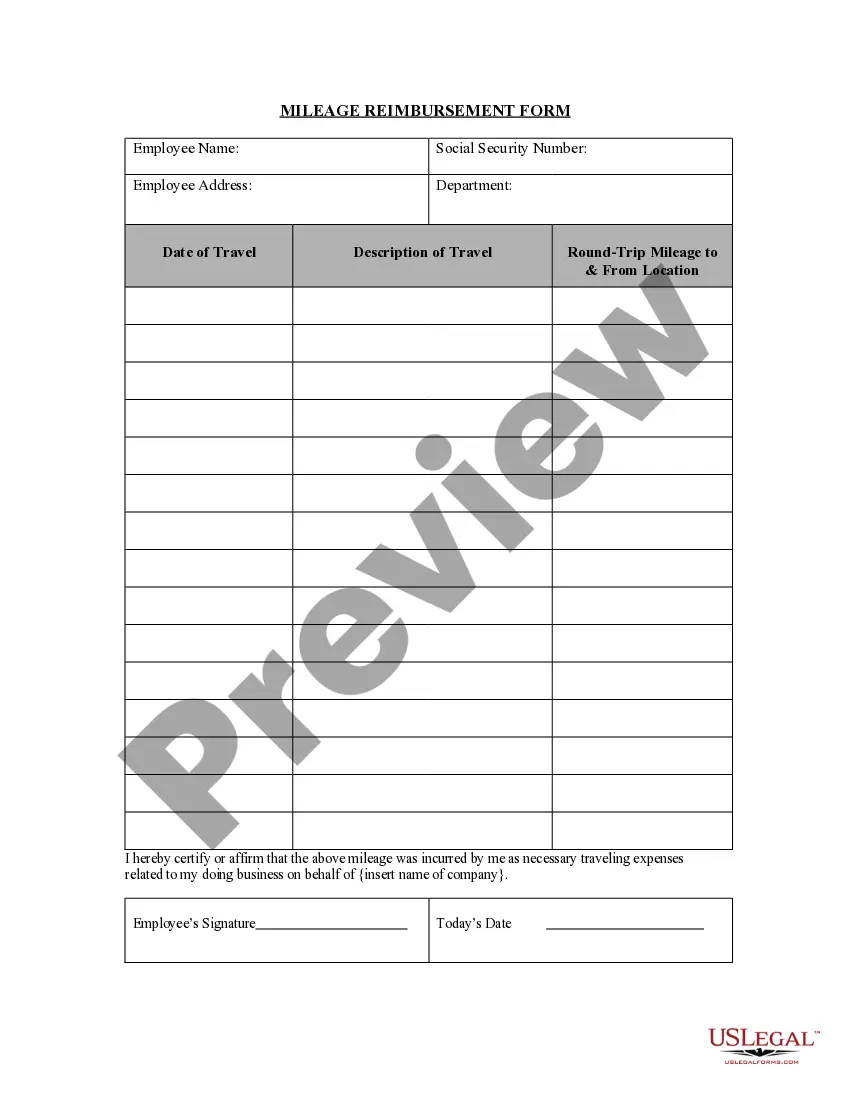

How to fill out Specification For Freight Elevator Service?

It is possible to commit several hours on-line looking for the authorized document format that meets the state and federal demands you require. US Legal Forms gives a large number of authorized kinds which are analyzed by professionals. You can actually down load or produce the Arkansas Specification for Freight Elevator Service from the service.

If you already possess a US Legal Forms account, it is possible to log in and click on the Down load option. Next, it is possible to comprehensive, modify, produce, or sign the Arkansas Specification for Freight Elevator Service. Every authorized document format you acquire is your own property forever. To have yet another copy of the bought develop, visit the My Forms tab and click on the corresponding option.

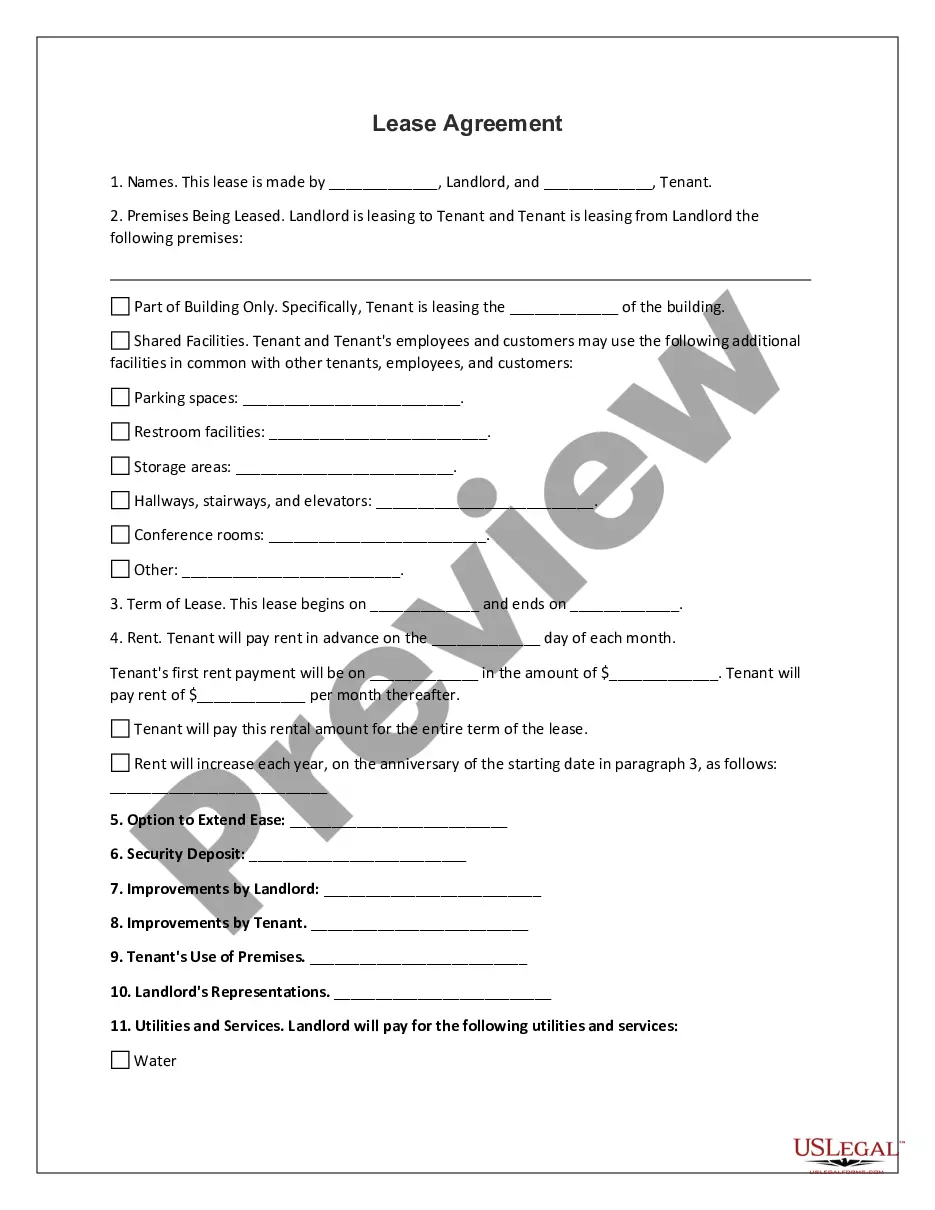

If you work with the US Legal Forms site the very first time, follow the basic instructions below:

- First, make certain you have chosen the best document format for your region/metropolis of your liking. See the develop description to ensure you have chosen the right develop. If available, utilize the Preview option to search with the document format at the same time.

- In order to locate yet another version from the develop, utilize the Lookup industry to find the format that fits your needs and demands.

- After you have discovered the format you need, just click Purchase now to proceed.

- Choose the rates prepare you need, type in your references, and register for a merchant account on US Legal Forms.

- Total the deal. You can use your bank card or PayPal account to cover the authorized develop.

- Choose the structure from the document and down load it to your device.

- Make modifications to your document if necessary. It is possible to comprehensive, modify and sign and produce Arkansas Specification for Freight Elevator Service.

Down load and produce a large number of document web templates making use of the US Legal Forms site, which offers the greatest variety of authorized kinds. Use professional and state-particular web templates to take on your business or person needs.

Form popularity

FAQ

In its simplest definition, lift height is the distance from the floor to the saddle of the hook, when the hook is in its uppermost position. Lift height is a vital measurement in any project because it assures there is enough room to lift or lift and reposition the load you are lifting.

Cable Height Companies that manufacture elevator systems are thus in a race to develop new types of ropes that are both stronger and lighter. With conventional ropes the highest that one elevator car can travel is 500 meters (1640 feet; about 140 floors).

A platform lift is used in any place where you need to move heavy loads from one level to another. They are very popular in warehouses, factories, schools, hospitals, and many others. Platform lifts are also known as scissor lifts or reach lifts.

Freight Elevator Dimensions The cabin of a freight elevator is required to have a minimum height of 8 feet (2.4 m), width of 6 feet (1.8 m), and depth of 5 feet (1.5 m) to accommodate large items.

The Safety Code for Elevators ASME A17. 1-2022, as a code, is intended to provide safety of life and limb and promote public welfare. It covers not only elevators, escalators, moving walks, dumbwaiters, material lifts, and related equipment, but also their associated parts, rooms, spaces, and hoistways.

ADAAG Residential Elevator Size Requirements and Regulations Our models come in 40-by-48-inch, 44-by-54-inch, and 44-by-60-inch floor sizes, with a 96-inch interior cab height. The standard elevator door height can vary depending on your needs, as can the elevator door width.

1. Standard Residential Elevator Sizes. Most home elevators have a cab depth of 36?-60?, width of 48?-60?, and height of at least 80?. Some variation occurs based on architectural features, the layout of your home, and local, state and federal residential building codes.

Most elevators are usually 6.5 to 7 feet wide and 6 feet deep. This is for a standard elevator car. A pneumatic elevator is round and will have completely different dimensions. Their average size is 43 inches in diameter.