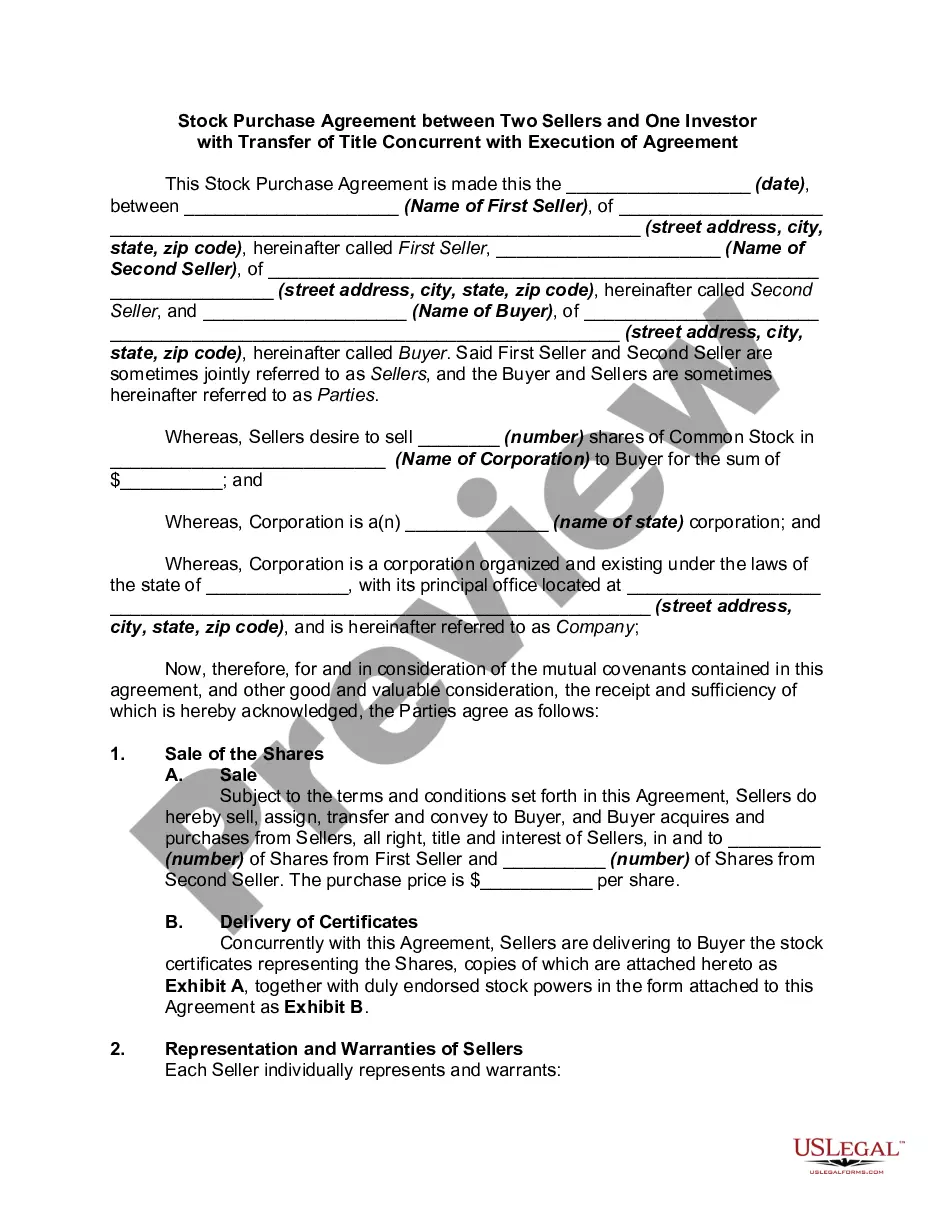

Arizona Maintenance Assistance — Technician Checklist: A Comprehensive Guide to Efficient Maintenance Operations Keywords: Arizona maintenance, assistance, technician checklist, comprehensive guide, efficient maintenance operations Description: The Arizona Maintenance Assistance — Technician Checklist is a crucial tool designed to streamline and enhance maintenance operations across various industries in the state of Arizona. This comprehensive guide provides technicians with a detailed list of tasks and procedures necessary to ensure optimal equipment performance, safety compliance, and operational efficiency. With its focus on efficiency, the Arizona Maintenance Assistance — Technician Checklist encompasses a wide range of maintenance activities, addressing preventive maintenance, equipment inspections, troubleshooting, repairs, and equipment calibration. By utilizing this checklist, technicians can effectively manage their tasks, prioritize actions, and reduce downtime, ultimately contributing to improved productivity and cost savings. Different Types of Arizona Maintenance Assistance — Technician Checklist: 1. Preventive Maintenance Checklist: This type of checklist focuses on routine maintenance tasks to prevent equipment breakdowns and extend the lifespan of machinery. It includes actions such as lubrication, filter replacement, calibration checks, and cleaning routines. 2. Equipment Inspection Checklist: To ensure optimal performance and identify potential issues, technicians employ this checklist to conduct regular inspections. It covers thorough examinations of equipment components, electrical systems, fluid levels, safety features, and overall equipment condition. 3. Troubleshooting Checklist: When faced with equipment malfunctions or performance issues, technicians refer to this checklist to systematically diagnose problems and identify viable solutions. It guides them through a step-by-step process, ensuring efficient troubleshooting and rapid resolution of issues. 4. Repair Checklist: In cases where equipment requires repair, this checklist assists technicians in managing the repair process effectively. It includes tasks such as disassembly, replacement of faulty components, reassembly, and thorough testing to ensure the successful restoration of equipment functionality. 5. Equipment Calibration Checklist: For equipment that requires precise measurements and accuracy, technicians rely on this checklist to perform calibration procedures. It outlines the necessary steps to calibrate instruments, devices, or sensors accurately, ensuring reliable and consistent readings. 6. Safety Compliance Checklist: This specific checklist aims to ensure that all maintenance activities align with safety regulations and protocols. It covers tasks such as inspecting and testing safety features, verifying lockout/ragout procedures, and maintaining proper personal protective equipment (PPE) usage. By using these various types of Arizona Maintenance Assistance — Technician Checklists, maintenance professionals can effectively plan, execute, and document their activities. This equipped approach not only maximizes equipment uptime and performance but also minimizes risks, enhances workplace safety, and helps organizations comply with industry regulations.

Arizona Maintenance Assistance - Technician Checklist

Description

How to fill out Arizona Maintenance Assistance - Technician Checklist?

US Legal Forms - one of many biggest libraries of authorized varieties in the States - offers a variety of authorized record web templates you can down load or print. Utilizing the site, you can find a huge number of varieties for business and individual reasons, sorted by classes, suggests, or keywords.You will discover the most recent models of varieties such as the Arizona Maintenance Assistance - Technician Checklist within minutes.

If you already have a subscription, log in and down load Arizona Maintenance Assistance - Technician Checklist from your US Legal Forms collection. The Obtain key will show up on each develop you view. You get access to all earlier delivered electronically varieties within the My Forms tab of your accounts.

In order to use US Legal Forms the very first time, listed below are easy directions to get you started out:

- Be sure to have picked the best develop for the city/county. Go through the Preview key to review the form`s content material. Browse the develop information to ensure that you have selected the appropriate develop.

- In the event the develop doesn`t fit your demands, make use of the Lookup field at the top of the monitor to discover the one that does.

- Should you be satisfied with the form, affirm your choice by clicking the Get now key. Then, opt for the costs strategy you favor and provide your accreditations to sign up to have an accounts.

- Procedure the deal. Make use of credit card or PayPal accounts to finish the deal.

- Choose the file format and down load the form on the product.

- Make adjustments. Load, edit and print and indication the delivered electronically Arizona Maintenance Assistance - Technician Checklist.

Every single format you put into your money does not have an expiry date and it is your own property for a long time. So, in order to down load or print yet another copy, just check out the My Forms portion and click on the develop you want.

Gain access to the Arizona Maintenance Assistance - Technician Checklist with US Legal Forms, probably the most comprehensive collection of authorized record web templates. Use a huge number of professional and express-certain web templates that satisfy your organization or individual demands and demands.