California Maintenance Assistance — Technician Checklist is a comprehensive document that outlines the necessary tasks and procedures to ensure smooth maintenance and repair operations in various industries within California. This checklist serves as an invaluable tool for technicians and maintenance personnel, enabling them to carry out their work efficiently and effectively. The California Maintenance Assistance — Technician Checklist covers an array of crucial maintenance procedures, emphasizing adherence to safety guidelines and compliance with relevant state regulations. This checklist provides a systematic approach for technicians to follow and helps them avoid any oversight or omission during maintenance tasks. Some key tasks included in the California Maintenance Assistance — Technician Checklist may include: 1. Equipment Inspection: Technicians are required to inspect and evaluate equipment for any signs of wear and tear, damage, or malfunction. This inspection ensures early detection of any potential issues and prevents any unforeseen breakdowns. 2. Routine Maintenance: Regular maintenance tasks such as lubrication, filter replacement, and cleaning are essential for optimal equipment performance. The checklist provides detailed instructions on how to perform these tasks accurately and efficiently. 3. Calibration and Testing: Technicians may need to calibrate and test various instruments and equipment to ensure accuracy and precision. This ensures that the equipment functions properly and produces reliable results. 4. Safety Checks: Safety is of utmost importance in maintenance operations. The checklist includes safety checks to ensure that all safety protocols are followed, such as checking for proper grounding, verifying safety switches, and assessing the overall safety of the work environment. 5. Documentation: Technicians are required to maintain detailed records of all maintenance activities, including the date, time, and details of the tasks performed. The checklist prompts technicians to document their work adequately, facilitating accountability and future reference. California Maintenance Assistance — Technician Checklist can differ based on the industry or sector it is meant for. For example, there may be specific checklists tailored for: 1. Manufacturing Facilities: This checklist may focus on maintenance procedures required for heavy machinery, conveyor systems, and production lines specific to manufacturing environments. 2. Healthcare Facilities: The checklist may cover maintenance tasks related to medical equipment, HVAC systems, and emergency power systems to ensure the smooth operation of healthcare facilities. 3. Transportation Sector: This checklist may emphasize maintenance tasks applicable to vehicles, infrastructure, and systems critical for transportation operations, such as fleet maintenance, roadway maintenance, and transit systems. 4. Energy and Utilities: This checklist may highlight maintenance tasks required for power plants, water treatment plants, and other utilities, with an emphasis on safety protocols and regulatory compliance. 5. Hospitality and Building Maintenance: The checklist may cover maintenance tasks related to HVAC systems, plumbing, electrical systems, fire safety equipment, and general building maintenance procedures for hotels, resorts, or commercial buildings. In conclusion, the California Maintenance Assistance — Technician Checklist serves as a comprehensive guide for technicians and maintenance personnel in various industries within California. It ensures that maintenance tasks are carried out effectively, while also prioritizing safety and regulatory compliance. Different variations of this checklist cater to the specific maintenance needs of different industries.

California Maintenance Assistance - Technician Checklist

Description

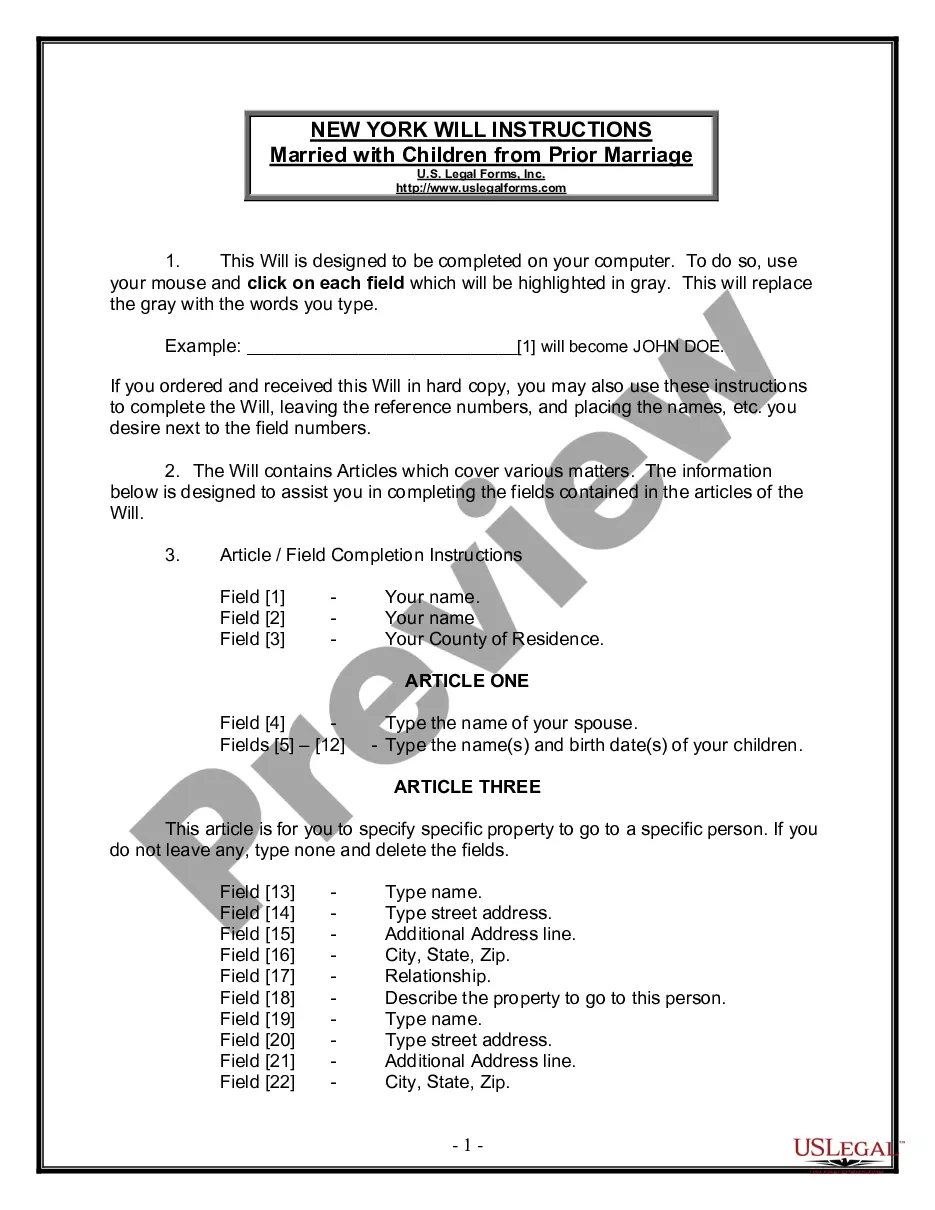

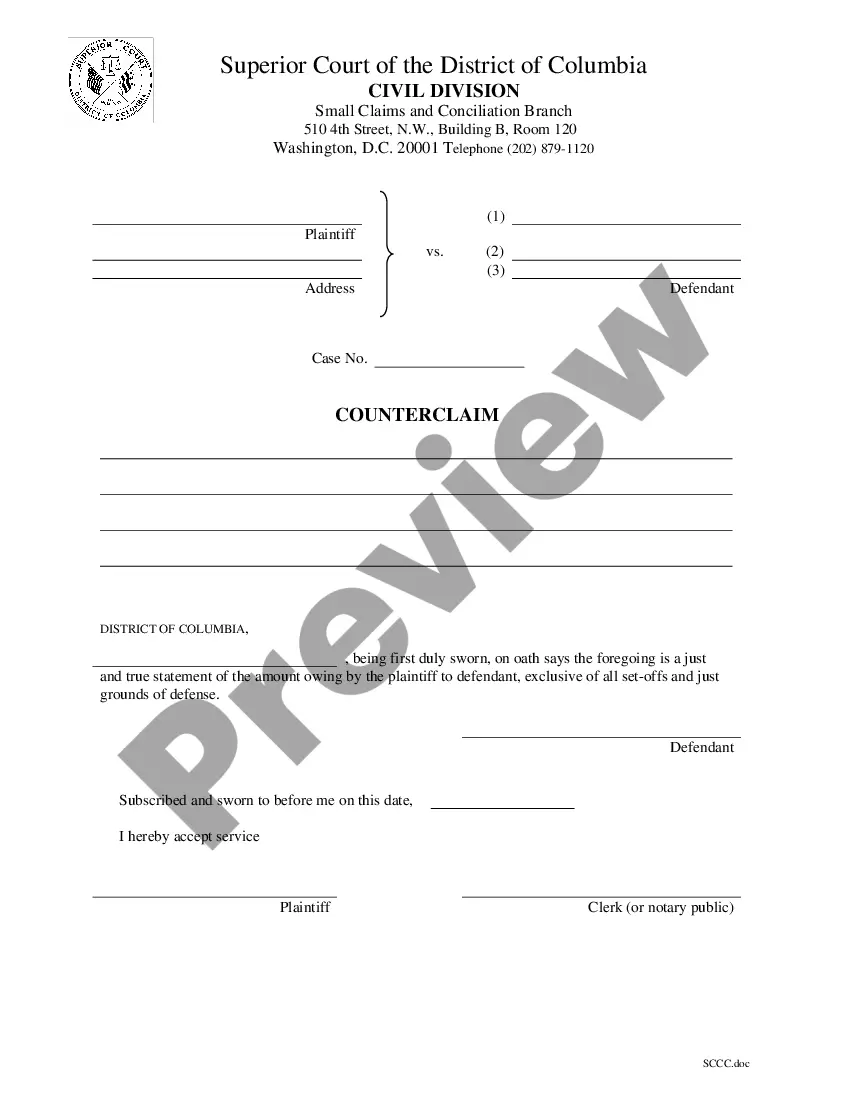

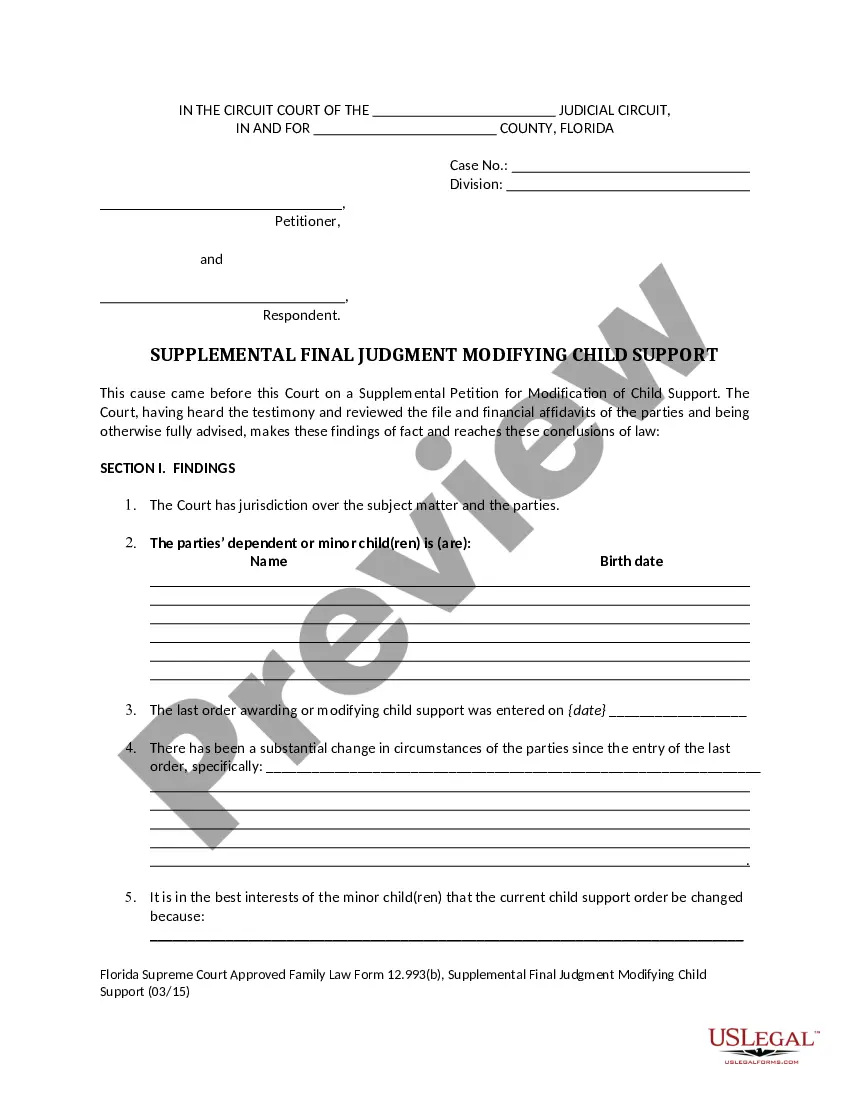

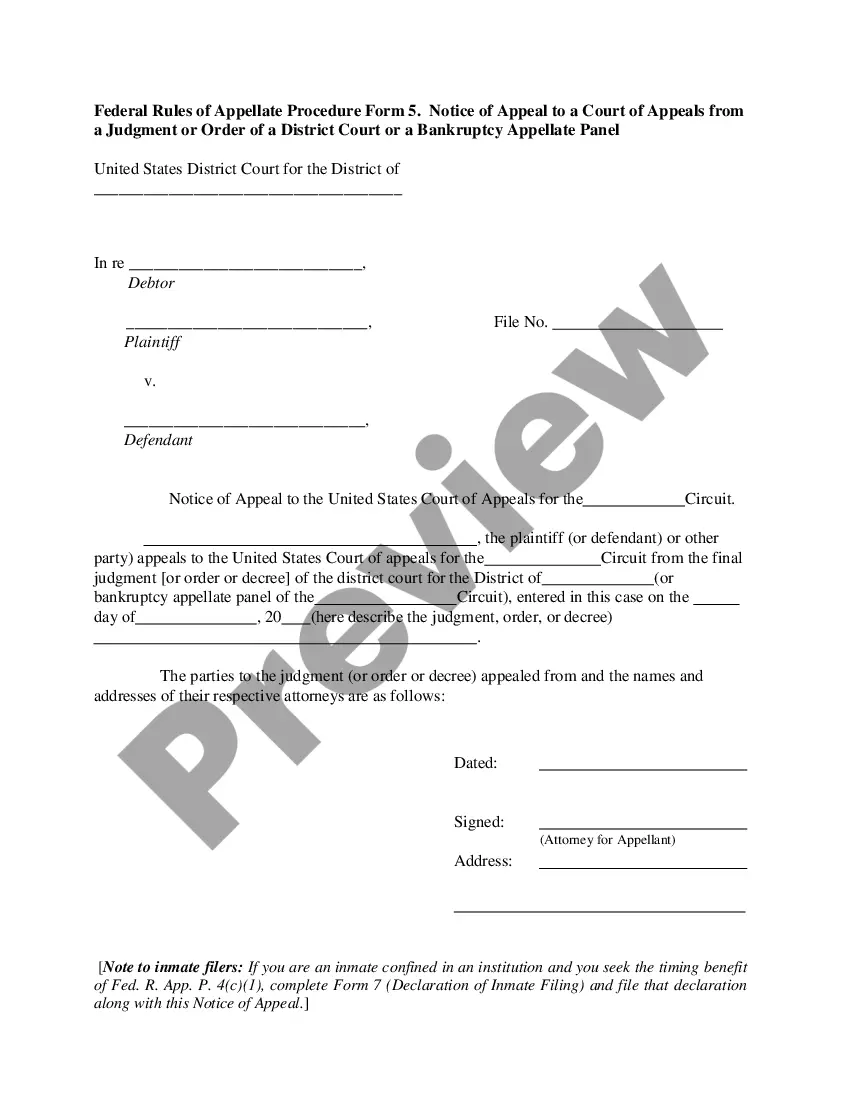

How to fill out California Maintenance Assistance - Technician Checklist?

US Legal Forms - among the biggest libraries of legal varieties in the United States - provides a variety of legal papers web templates you may obtain or print out. Making use of the site, you may get a huge number of varieties for enterprise and individual reasons, sorted by types, states, or keywords.You can find the most recent models of varieties such as the California Maintenance Assistance - Technician Checklist in seconds.

If you already have a monthly subscription, log in and obtain California Maintenance Assistance - Technician Checklist through the US Legal Forms local library. The Down load key will appear on every single type you perspective. You have accessibility to all previously delivered electronically varieties in the My Forms tab of your bank account.

If you want to use US Legal Forms for the first time, here are easy directions to get you began:

- Make sure you have picked out the correct type for the metropolis/area. Go through the Review key to analyze the form`s information. See the type information to actually have selected the proper type.

- In case the type does not fit your demands, utilize the Research industry near the top of the display to get the one that does.

- Should you be content with the form, affirm your option by visiting the Get now key. Then, opt for the rates plan you like and supply your qualifications to register to have an bank account.

- Process the transaction. Make use of charge card or PayPal bank account to finish the transaction.

- Pick the format and obtain the form on your system.

- Make changes. Fill up, change and print out and indicator the delivered electronically California Maintenance Assistance - Technician Checklist.

Every format you included in your bank account lacks an expiration time and is also your own property permanently. So, if you wish to obtain or print out another version, just proceed to the My Forms section and then click in the type you will need.

Obtain access to the California Maintenance Assistance - Technician Checklist with US Legal Forms, by far the most considerable local library of legal papers web templates. Use a huge number of specialist and condition-distinct web templates that meet up with your business or individual needs and demands.