The California Maintenance Engineer Checklist is a comprehensive and essential tool for ensuring the smooth and efficient operation of various facilities and equipment in California. It consists of a detailed set of tasks and responsibilities that maintenance engineers need to perform regularly to maintain the optimal functioning of the infrastructure under their supervision. The checklist encompasses various maintenance aspects, including preventive maintenance, repair works, equipment inspections, safety protocols, and compliance with California regulations. By adhering to this checklist, maintenance engineers can minimize downtime, extend the lifespan of equipment, and uphold the highest standards of safety and performance. Key responsibilities covered in the California Maintenance Engineer Checklist include: 1. Routine and preventive maintenance tasks: — Inspecting and servicing HVAC systems, electrical equipment, plumbing systems, and other infrastructure components. — Lubricating moving parts, replacing filters, and cleaning machines to ensure smooth functioning. — Testing backup systems and emergency generators periodically. — Conducting regular inspections to identify potential issues or signs of wear and tear. 2. Repair and troubleshooting: — Responding promptly to maintenance requests and resolving issues efficiently. — Diagnosing equipment malfunctions and performing necessary repairs. — Ensuring spare parts and tools are readily available for maintenance purposes. — Collaborating with external contractors for specialized repairs if required. 3. Safety management: — Ensuring compliance with safety regulations and codes in California. — Conducting safety inspections and addressing any identified risks or hazards. — Updating safety manuals and guidelines, and training staff on safety protocols. — Maintaining records of safety inspections, incidents, and actions taken. 4. Documentation and record-keeping: — Documenting maintenance activities, including repairs, inspections, and equipment upgrades. — Keeping accurate records of equipment warranties, user manuals, and maintenance logs. — Tracking inventory of spare parts and supplies. — Maintaining a database of contact information for vendors and contractors. Different types of California Maintenance Engineer Checklists may be tailored to various industries and specific facilities. Some examples include: 1. Building Maintenance Engineer Checklist: Primarily applicable to commercial, residential, or institutional buildings, it focuses on maintaining the electrical, HVAC, plumbing, and security systems within the facility. 2. Manufacturing Maintenance Engineer Checklist: Designed for manufacturing plants, it includes tasks like machine maintenance, calibration, minimizing production downtime, and ensuring compliance with environmental regulations. 3. Hotel Maintenance Engineer Checklist: Specific to the hospitality industry, this checklist emphasizes maintenance tasks related to guestrooms, common areas, swimming pools, landscaping, and amenities. 4. Healthcare Facility Maintenance Engineer Checklist: This checklist includes tasks related to medical equipment maintenance, emergency systems, infection control protocols, and compliance with healthcare regulations. These are just a few examples of the numerous types of California Maintenance Engineer Checklists that can be customized to suit different industries and facility requirements.

California Maintenance Engineer Checklist

Description

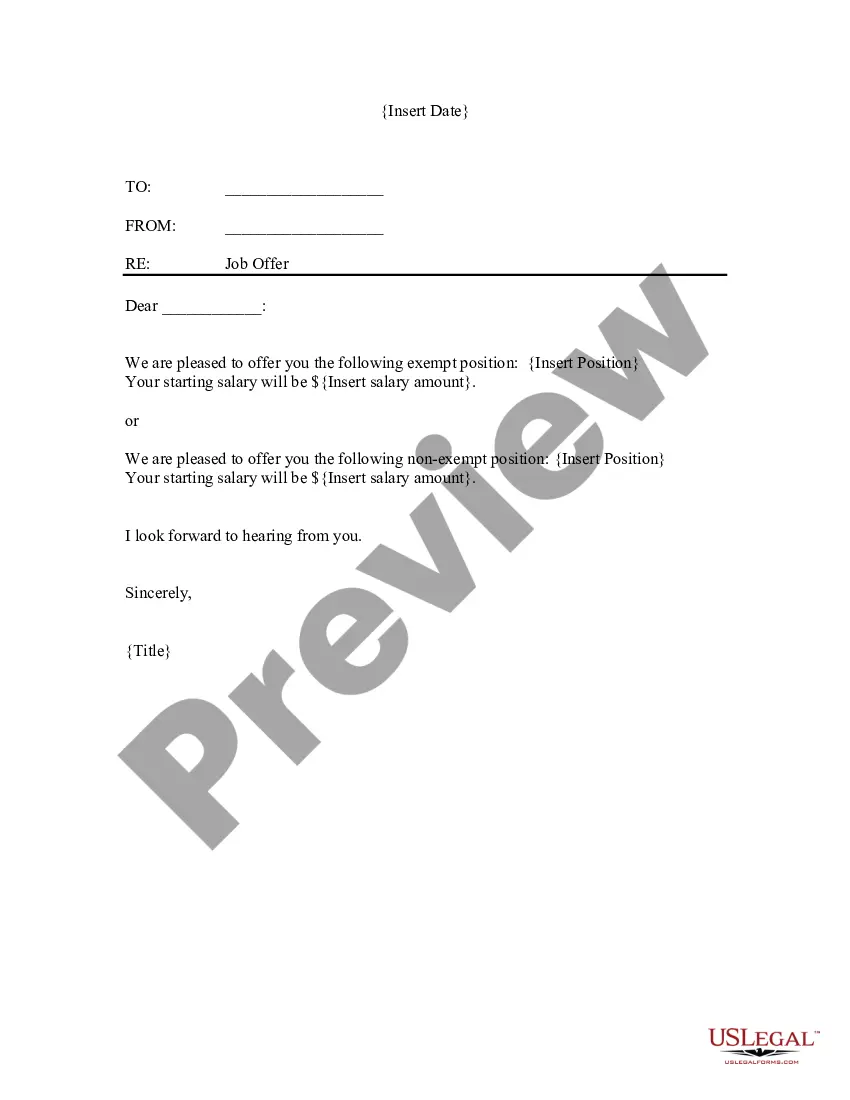

How to fill out California Maintenance Engineer Checklist?

If you wish to comprehensive, download, or print legal document templates, use US Legal Forms, the most important variety of legal forms, that can be found online. Make use of the site`s easy and convenient look for to get the files you want. Different templates for organization and specific purposes are categorized by categories and claims, or keywords. Use US Legal Forms to get the California Maintenance Engineer Checklist in a couple of click throughs.

If you are already a US Legal Forms client, log in for your profile and click on the Obtain option to obtain the California Maintenance Engineer Checklist. You may also gain access to forms you in the past acquired in the My Forms tab of the profile.

Should you use US Legal Forms the very first time, follow the instructions beneath:

- Step 1. Be sure you have chosen the form for your correct city/land.

- Step 2. Utilize the Preview choice to look through the form`s information. Never neglect to read through the information.

- Step 3. If you are unsatisfied together with the develop, make use of the Lookup field on top of the screen to discover other models in the legal develop template.

- Step 4. After you have found the form you want, click on the Purchase now option. Choose the costs prepare you choose and include your references to register to have an profile.

- Step 5. Approach the financial transaction. You may use your charge card or PayPal profile to accomplish the financial transaction.

- Step 6. Choose the format in the legal develop and download it on the product.

- Step 7. Total, edit and print or sign the California Maintenance Engineer Checklist.

Each legal document template you buy is the one you have eternally. You have acces to every develop you acquired inside your acccount. Click the My Forms segment and pick a develop to print or download again.

Be competitive and download, and print the California Maintenance Engineer Checklist with US Legal Forms. There are many professional and status-certain forms you can utilize for your personal organization or specific requirements.