Connecticut Manufacturer Analysis Checklist

Description

How to fill out Manufacturer Analysis Checklist?

Have you ever found yourself in a scenario where you need documentation for either business or personal reasons almost all the time.

There are countless legal document templates available online, but locating forms you can trust is challenging.

US Legal Forms provides thousands of form templates, including the Connecticut Manufacturer Analysis Checklist, designed to meet federal and state requirements.

- If you are already familiar with the US Legal Forms website and have an account, simply Log In.

- Then, you can download the format for the Connecticut Manufacturer Analysis Checklist.

- If you do not have an account and wish to start using US Legal Forms, follow these instructions.

- Obtain the form you need and ensure it corresponds to the correct area/region.

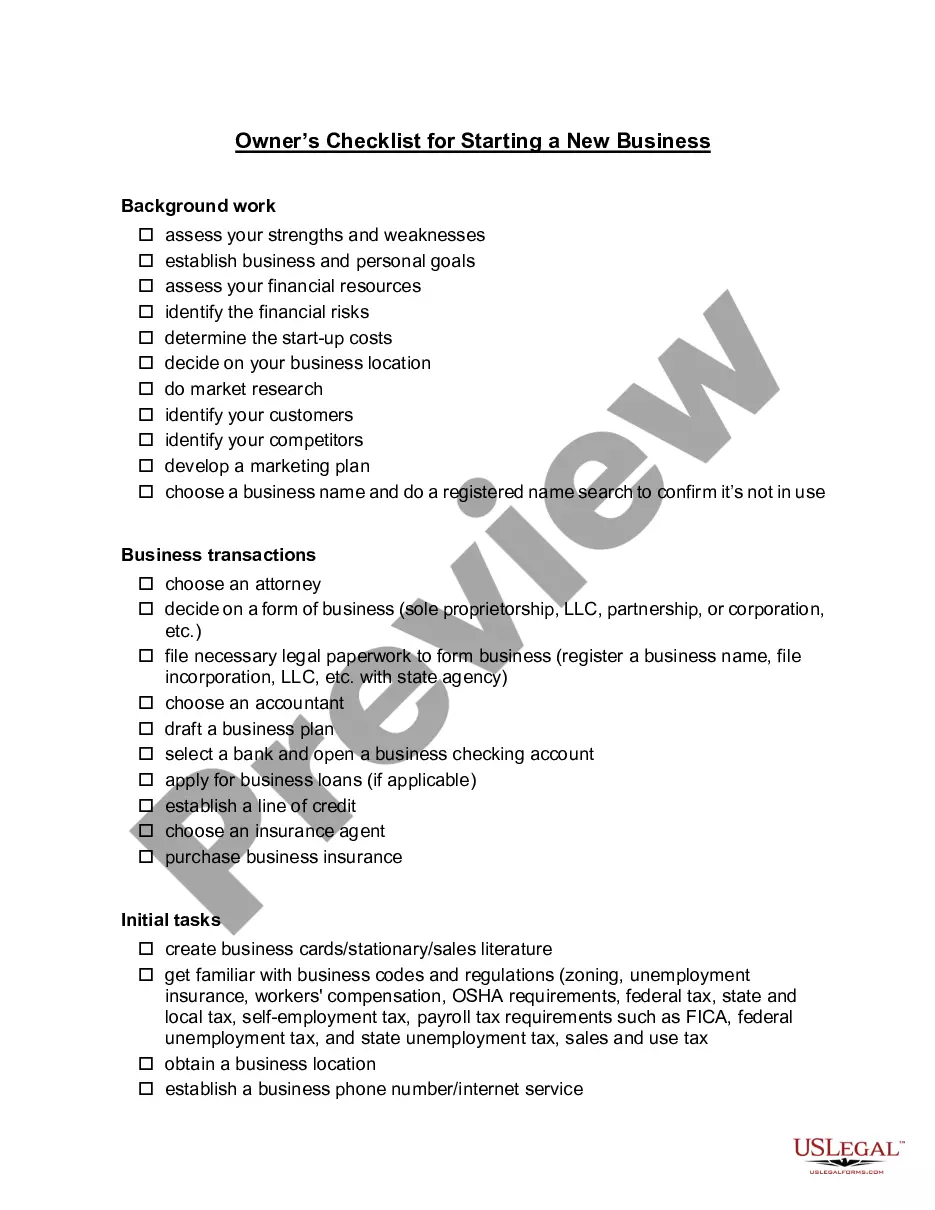

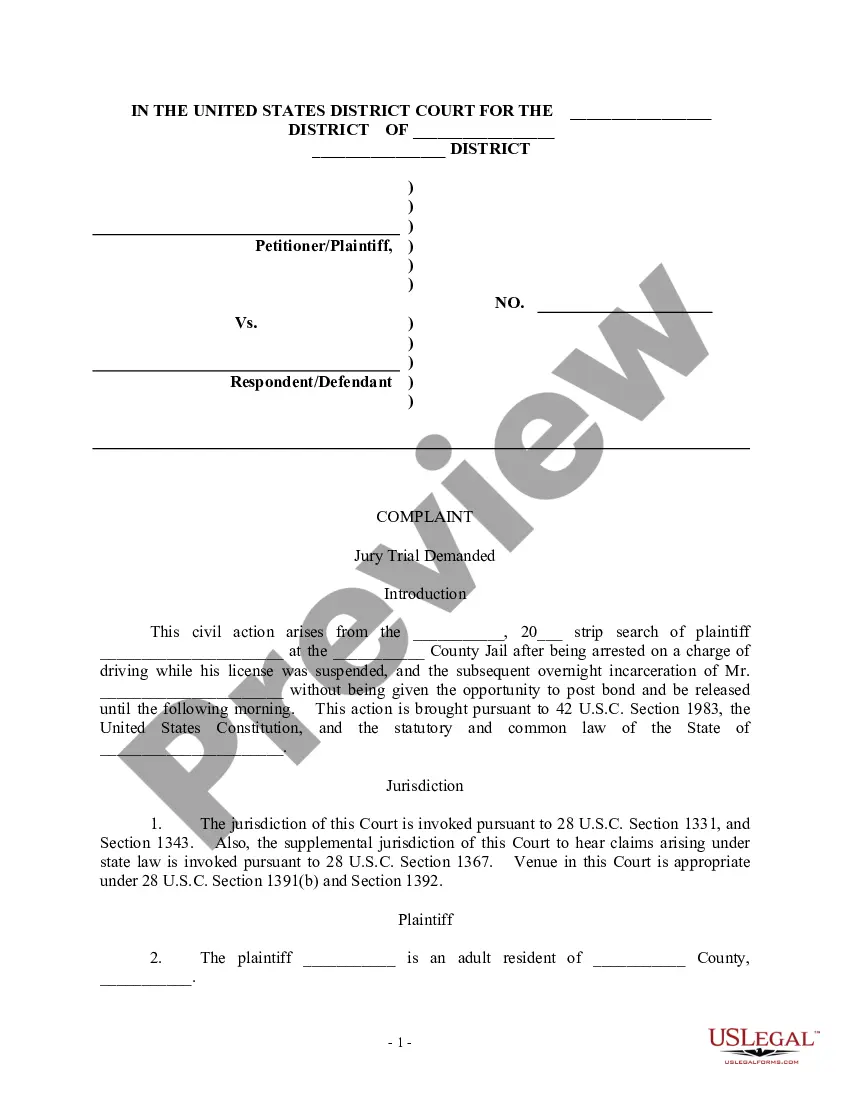

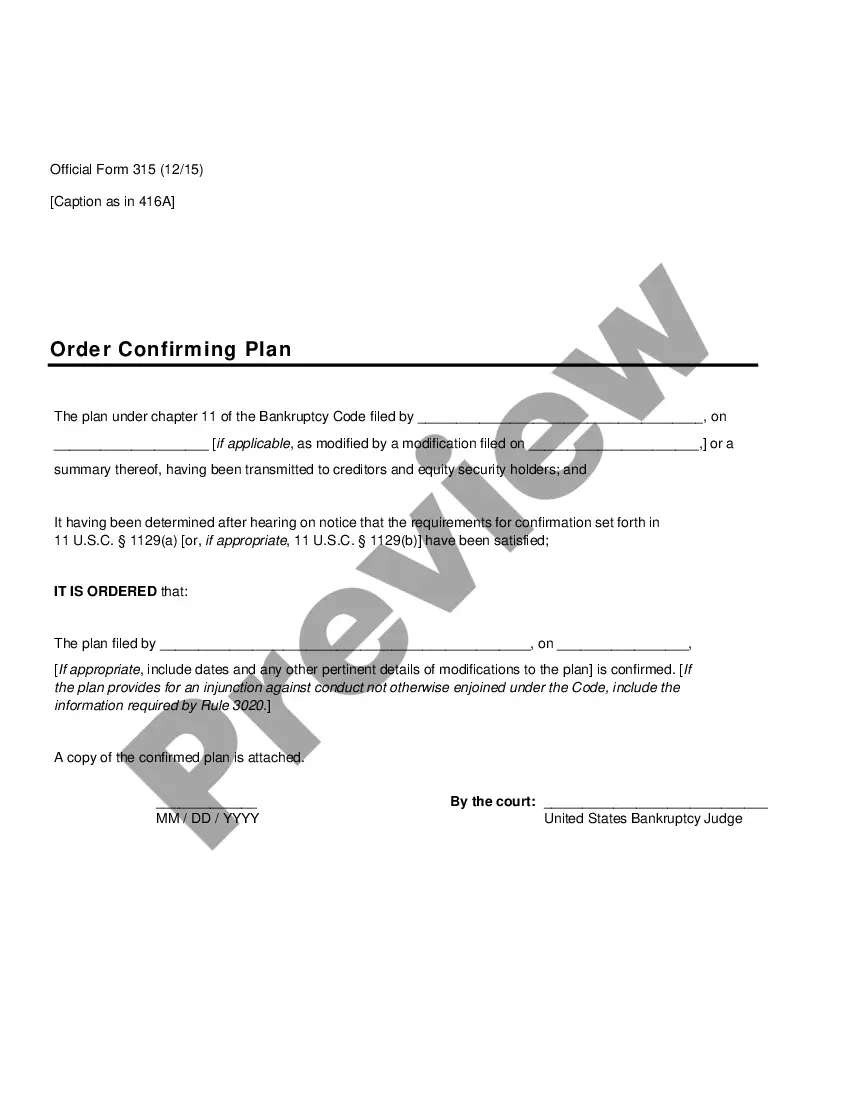

- Utilize the Review button to inspect the document.

- Read the description to confirm that you have selected the appropriate form.

- If the form does not match your needs, use the Search box to find the document that fits your requirements.

- Once you identify the correct form, click Buy now.

- Choose the pricing plan you prefer, enter the necessary information to create your account, and complete the purchase using your PayPal or credit card.

- Select a convenient file format and download your copy.

- Find all the document templates you have purchased in the My documents section.

- You can obtain an additional copy of the Connecticut Manufacturer Analysis Checklist at any time if necessary. Just select the relevant form to download or print the document template.

- Use US Legal Forms, the largest collection of legal forms, to save time and reduce mistakes.

- The service offers professionally crafted legal document templates that you can use for various purposes.

- Create an account on US Legal Forms and start making your life a bit easier.

Form popularity

FAQ

Connecticut is recognized for its diverse manufacturing sector, which includes aerospace, medical devices, and precision instruments. This strong industrial base supports the state's economy and provides numerous opportunities for growth. Including this information in your Connecticut Manufacturer Analysis Checklist can give you insights into the local market.

You can find if a business is registered in Connecticut by visiting the Secretary of State's business search page. Entering the business name or ID will provide you with the registration status and other relevant details. This step is important for your Connecticut Manufacturer Analysis Checklist.

To find the owner of a Limited Liability Company (LLC) in Connecticut, you can search the state’s Secretary of State business database. This database provides details such as the LLC's registered agent and members. Knowing the ownership information can enhance your Connecticut Manufacturer Analysis Checklist.

To determine if a business in Connecticut is licensed and insured, you need to check both the Secretary of State's records and the specific licensing authority relevant to that business type. Many professions require specific licenses, which can usually be confirmed through state websites. This information is crucial when completing your Connecticut Manufacturer Analysis Checklist.

You can search for a business in Connecticut by using the online search portal available on the Secretary of State's website. Simply enter the business name or registration number to find detailed information. This method is effective for addressing inquiries on your Connecticut Manufacturer Analysis Checklist.

The Connecticut Manufacturers Collaborative (CMC) is an initiative aimed at enhancing the manufacturing sector in Connecticut. It focuses on providing resources, networking opportunities, and support for manufacturers in the state. Understanding the CMC can be a valuable addition to your Connecticut Manufacturer Analysis Checklist, as it connects you with industry peers.

To look up a business in Connecticut, you can visit the Connecticut Secretary of State's website. From there, you can access the business search tool, which allows you to input the business name or identification number. Utilizing this tool can help you find the necessary information to complete your Connecticut Manufacturer Analysis Checklist.

An alei number in Connecticut refers to the unique identifier assigned to vehicles registered in the state. This number is crucial for tracking registration information and vehicle history. To better navigate vehicle registrations, the Connecticut Manufacturer Analysis Checklist can provide you with the necessary insights and guidelines.

Connecticut does not issue traditional inspection stickers, but it does require emissions testing for certain vehicles. These tests ensure vehicles meet environmental standards and are safe for road use. For a thorough understanding of your vehicle's requirements, consult the Connecticut Manufacturer Analysis Checklist.

A few states in the U.S. do not require car inspection stickers, including Washington, Oregon, and New Hampshire. Each state has different regulations regarding vehicle safety and emissions. To learn more about vehicle requirements and how they compare with Connecticut, the Connecticut Manufacturer Analysis Checklist is a valuable asset.