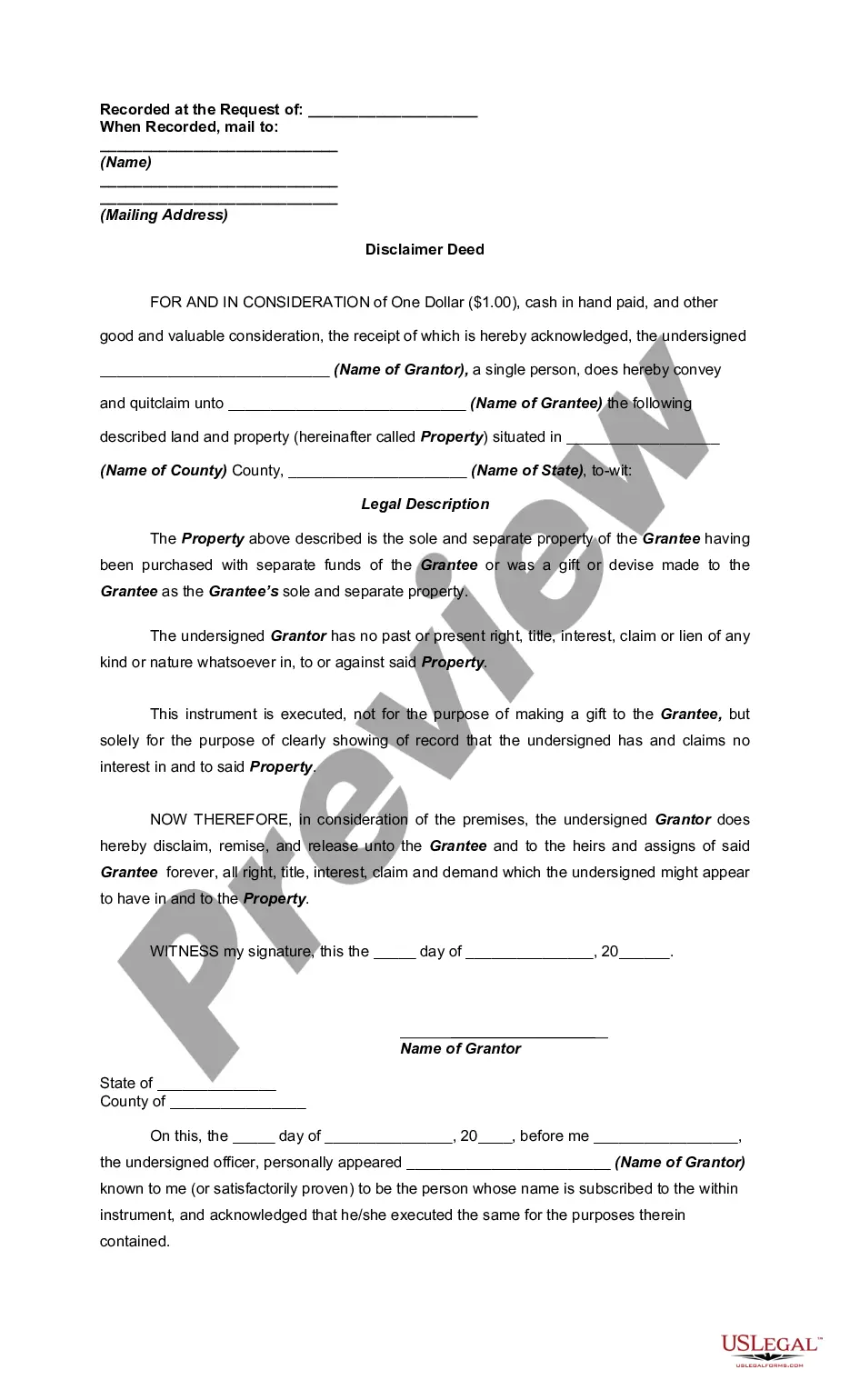

This is a tooling agreement between the buyer and vendor. The document describes the description of tooling, the replacement value of tooling, location of tooling, and the relationship of the parties in all their dealings.

Connecticut Tooling Agreement

Description

How to fill out Tooling Agreement?

US Legal Forms - among the most significant libraries of legitimate types in America - delivers a wide range of legitimate document themes you are able to down load or printing. Using the site, you can find a huge number of types for enterprise and person reasons, categorized by classes, states, or key phrases.You can get the latest types of types such as the Connecticut Tooling Agreement within minutes.

If you already have a registration, log in and down load Connecticut Tooling Agreement from your US Legal Forms local library. The Download option can look on every single develop you look at. You have accessibility to all formerly downloaded types inside the My Forms tab of your respective bank account.

If you want to use US Legal Forms the very first time, listed below are easy guidelines to get you started:

- Be sure to have picked out the proper develop to your town/region. Go through the Preview option to check the form`s information. See the develop outline to ensure that you have chosen the proper develop.

- In the event the develop does not suit your specifications, make use of the Look for discipline at the top of the display to get the one that does.

- Should you be happy with the form, confirm your choice by visiting the Purchase now option. Then, choose the rates strategy you favor and supply your qualifications to register to have an bank account.

- Method the transaction. Utilize your credit card or PayPal bank account to finish the transaction.

- Choose the format and down load the form on your own device.

- Make alterations. Load, modify and printing and signal the downloaded Connecticut Tooling Agreement.

Each template you put into your bank account does not have an expiration particular date and is your own property for a long time. So, if you want to down load or printing an additional copy, just go to the My Forms portion and click about the develop you require.

Get access to the Connecticut Tooling Agreement with US Legal Forms, by far the most substantial local library of legitimate document themes. Use a huge number of expert and express-particular themes that satisfy your business or person demands and specifications.

Form popularity

FAQ

CERT-119. Form & Inst. Certificate for Purchases of Tangible Personal Property and Services by Qualifying Exempt Organizations.

Also exempt are: Food products, including meals, sold through coin-operated vending machines. Meals delivered to persons who are sixty years of age or older, have physical disabilities or are otherwise homebound. Purchases made with supplemental nutrition assistance program benefits.

Tangible products are taxable in Connecticut, with a few exceptions. These exceptions include certain groceries, some clothing, safety gear like firearm locks, child car seats and bike helmets, compact fluorescent bulbs, college textbooks, medical equipment and certain motor vehicles.

Tax-exempt goods Some goods are exempt from sales tax under Connecticut law. Examples include bicycle helmets, most non-prepared food items, medicines, and some medical devices and supplies.

This five-year, 100% property tax exemption is available for eligible machinery and equipment acquired and installed in a manufacturing or biotechnology facility.

This five-year, 100% property tax exemption is available for eligible machinery and equipment acquired and installed in a manufacturing or biotechnology facility.

Exemptions are reductions to the assessment of real estate, personal property, or motor vehicles that have been authorized by Connecticut State Statutes. The Assessor's Office is responsible for administering these exemptions.

General pension and annuity earnings are 100% exempt from income taxes for single filers and married people filing separately with an overall AGI of less than $75,000 a year. Couples filing jointly with an AGI of less than $100,000 a year are fully exempt as well.