District of Columbia Manufacturer Analysis Checklist

Category:

State:

Multi-State

Control #:

US-03083BG

Format:

Word;

Rich Text

Instant download

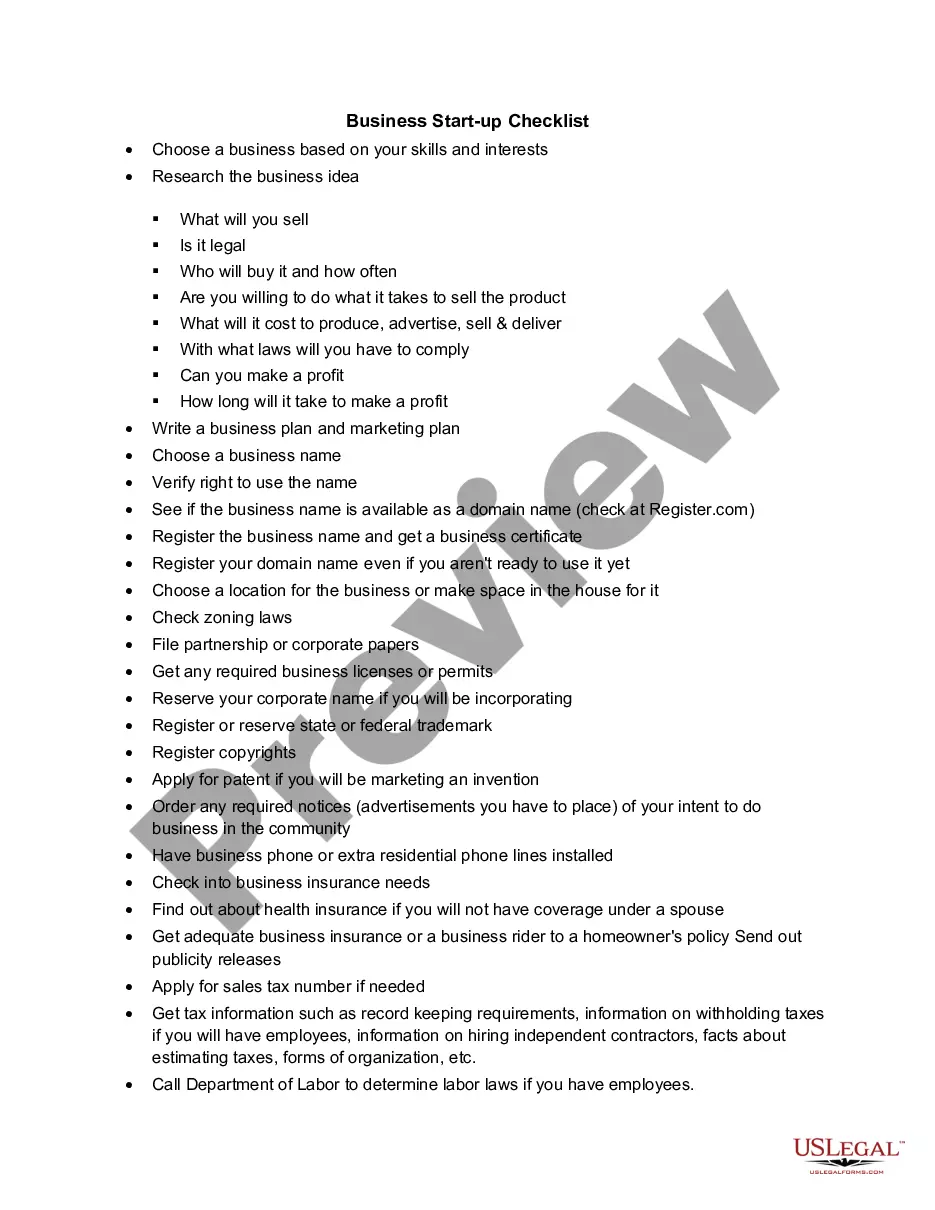

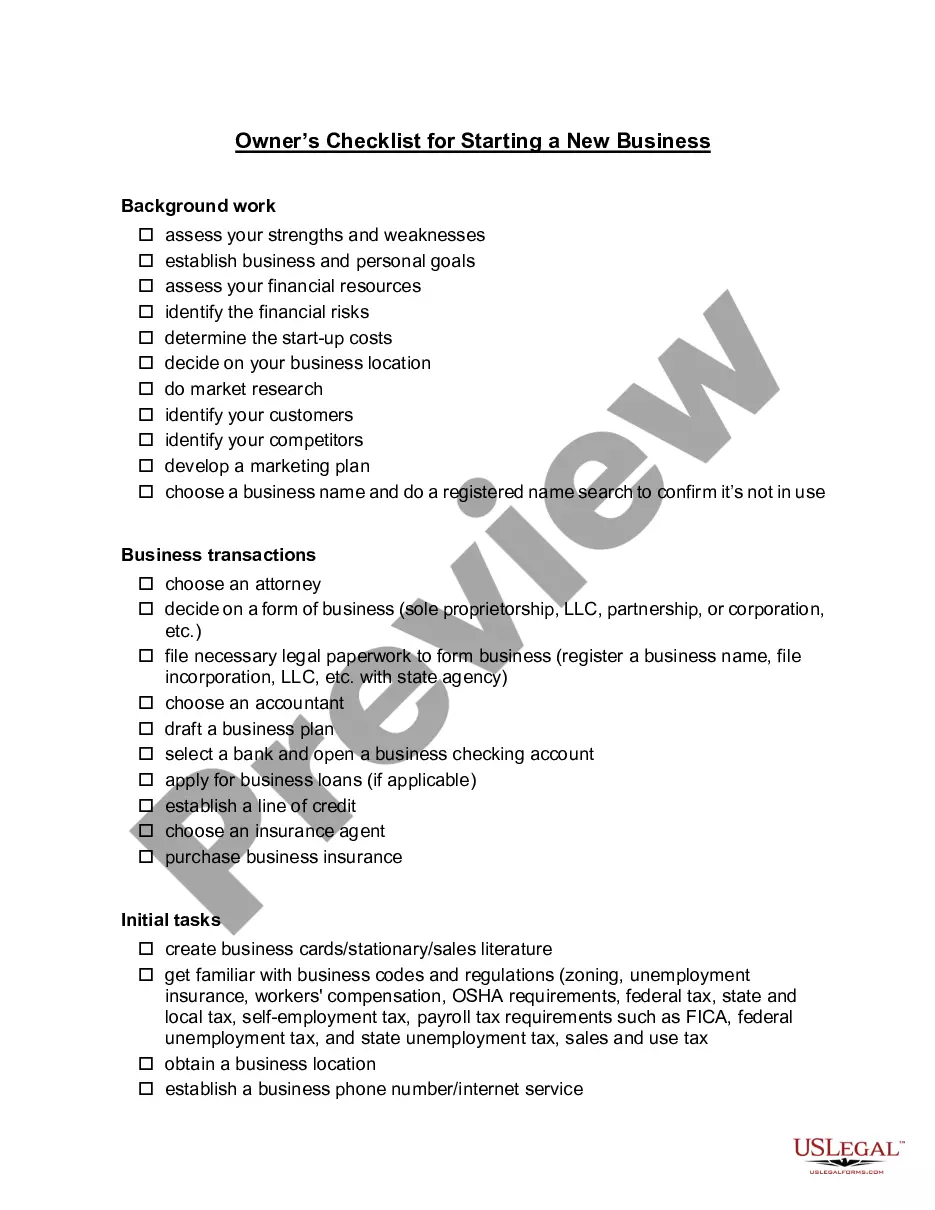

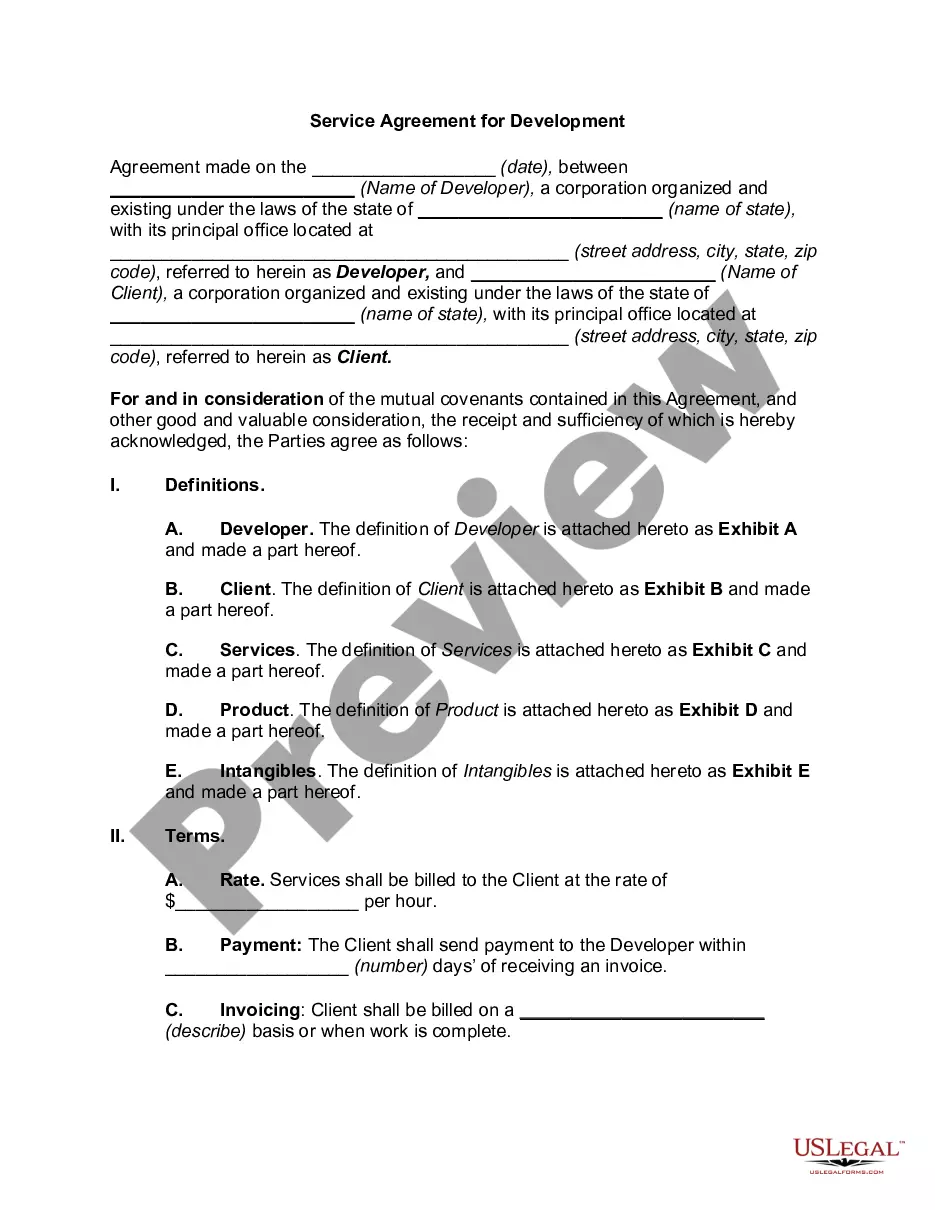

Description

This form can be helpful in planning an efficient layout for your manufacturing site. You must be able to move raw material into the plant and route it through the manufacturing process as efficiently as possible.

How to fill out Manufacturer Analysis Checklist?

Selecting the correct official document template can be a challenge.

Clearly, there are numerous designs accessible online, but how can you find the official form you require.

Utilize the US Legal Forms website. This service offers a vast array of templates, including the District of Columbia Manufacturer Evaluation Checklist, suitable for both business and personal needs.

You can review the form using the Preview option and check the form description to confirm that it is appropriate for you.

- All forms are reviewed by professionals and comply with state and federal regulations.

- If you are already registered, Log In to your account and click on the Download button to obtain the District of Columbia Manufacturer Evaluation Checklist.

- Use your account to explore the legal forms you've previously purchased.

- Visit the My documents section of your account to obtain another copy of the document you require.

- If you are a new user of US Legal Forms, here are simple steps for you to follow.

- First, ensure you have selected the correct form for your locale.