Delaware Maintenance Assistance — Technician Checklist: Ensuring Uninterrupted Operations and Enhanced Efficiency The Delaware Maintenance Assistance — Technician Checklist serves as a comprehensive guide for technicians working in various industries to efficiently execute maintenance tasks and ensure smooth operations. This checklist is designed to maximize productivity, minimize downtime, and prevent equipment failures. Keywords: Delaware Maintenance Assistance, technician checklist, uninterrupted operations, enhanced efficiency, comprehensive guide, maintenance tasks, smooth operations, maximize productivity, minimize downtime, equipment failures. Types of Delaware Maintenance Assistance — Technician Checklists: 1. General Maintenance Checklist: This checklist includes routine maintenance tasks applicable across different industries. It includes essential tasks such as inspecting and cleaning equipment, lubrication, calibration, and checking for wear and tear. The checklist also covers safety inspections and compliance with industry standards. Keywords: general maintenance, routine maintenance tasks, inspecting equipment, cleaning equipment, lubrication, calibration, wear and tear, safety inspections, industry standards. 2. Electrical Maintenance Checklist: Designed specifically for technicians involved in electrical systems' maintenance, this checklist covers tasks related to safety, electrical testing, equipment inspection, and troubleshooting. It ensures that electrical systems are in optimal condition, reducing the risk of electrical outages, hazards, and equipment malfunctions. Keywords: electrical maintenance, safety, electrical testing, equipment inspection, troubleshooting, optimal condition, electrical outages, hazards, equipment malfunctions. 3. HVAC Maintenance Checklist: This checklist caters to technicians responsible for maintaining heating, ventilation, and air conditioning systems. It provides a systematic approach to inspecting, cleaning, and servicing HVAC components. This includes filter replacement, refrigeration system checks, fan belt inspections, and temperature calibration. Following this checklist helps prevent energy inefficiencies, system failures, and compromised indoor air quality. Keywords: HVAC maintenance, heating, ventilation, air conditioning systems, inspecting HVAC components, cleaning HVAC components, filter replacement, refrigeration system checks, fan belt inspections, temperature calibration, energy inefficiencies, system failures, indoor air quality. 4. Vehicle Maintenance Checklist: Technicians working in transportation or fleet management benefit from this checklist. It encompasses tasks such as fluid checks, tire inspections, brake system examination, engine component inspection, and regular servicing. Adhering to this checklist ensures road worthiness, improves fuel economy, and prolongs vehicle lifespan. Keywords: vehicle maintenance, transportation, fleet management, fluid checks, tire inspections, brake system examination, engine component inspection, regular servicing, road worthiness, fuel economy, vehicle lifespan. These different types of Delaware Maintenance Assistance — Technician Checklists encapsulate the specific maintenance requirements of various industries. Each checklist aims to streamline maintenance processes, boost productivity, and minimize downtime to enhance overall efficiency. By adopting these checklists, technicians ensure the longevity of equipment, reduce operational risks, and promote a safer working environment.

Delaware Maintenance Assistance - Technician Checklist

Description

How to fill out Delaware Maintenance Assistance - Technician Checklist?

Are you presently within a position where you need to have documents for either enterprise or specific functions just about every day? There are a lot of authorized file web templates available online, but locating versions you can depend on isn`t easy. US Legal Forms delivers a large number of type web templates, just like the Delaware Maintenance Assistance - Technician Checklist, which can be published to fulfill federal and state requirements.

If you are previously knowledgeable about US Legal Forms site and also have an account, merely log in. Afterward, you are able to acquire the Delaware Maintenance Assistance - Technician Checklist format.

If you do not provide an accounts and need to begin using US Legal Forms, abide by these steps:

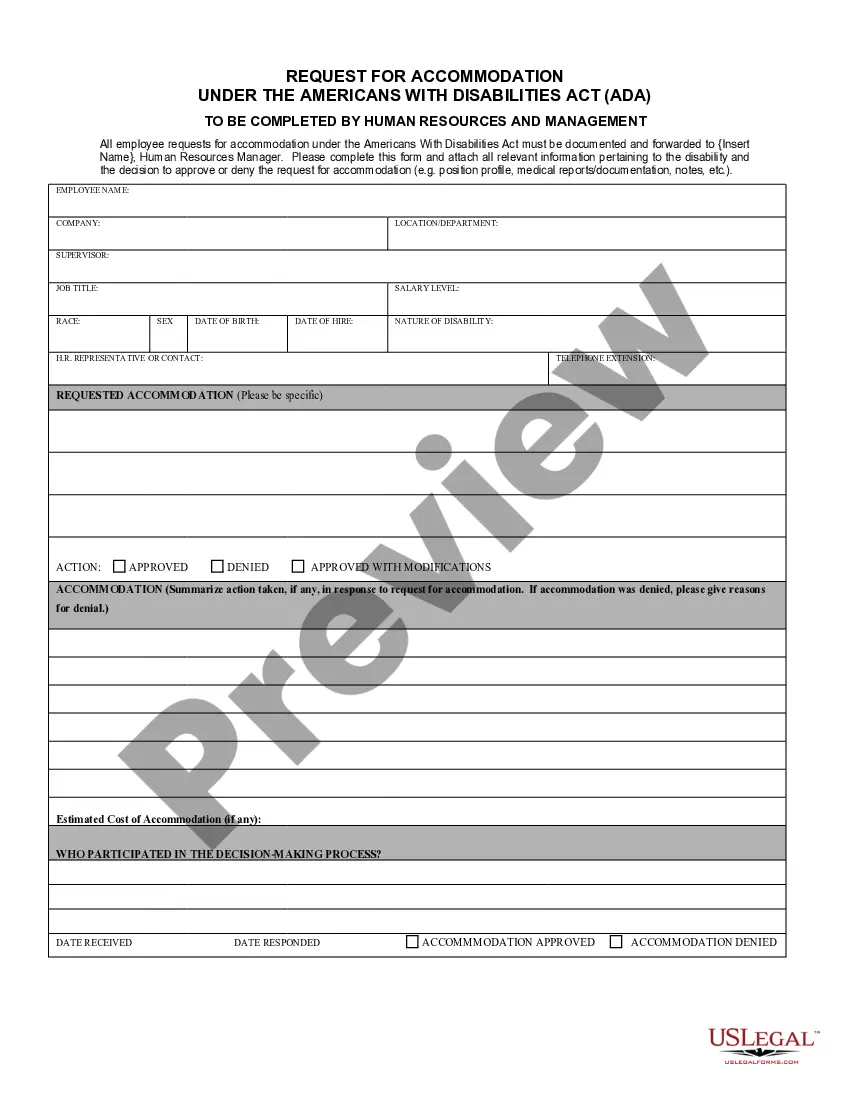

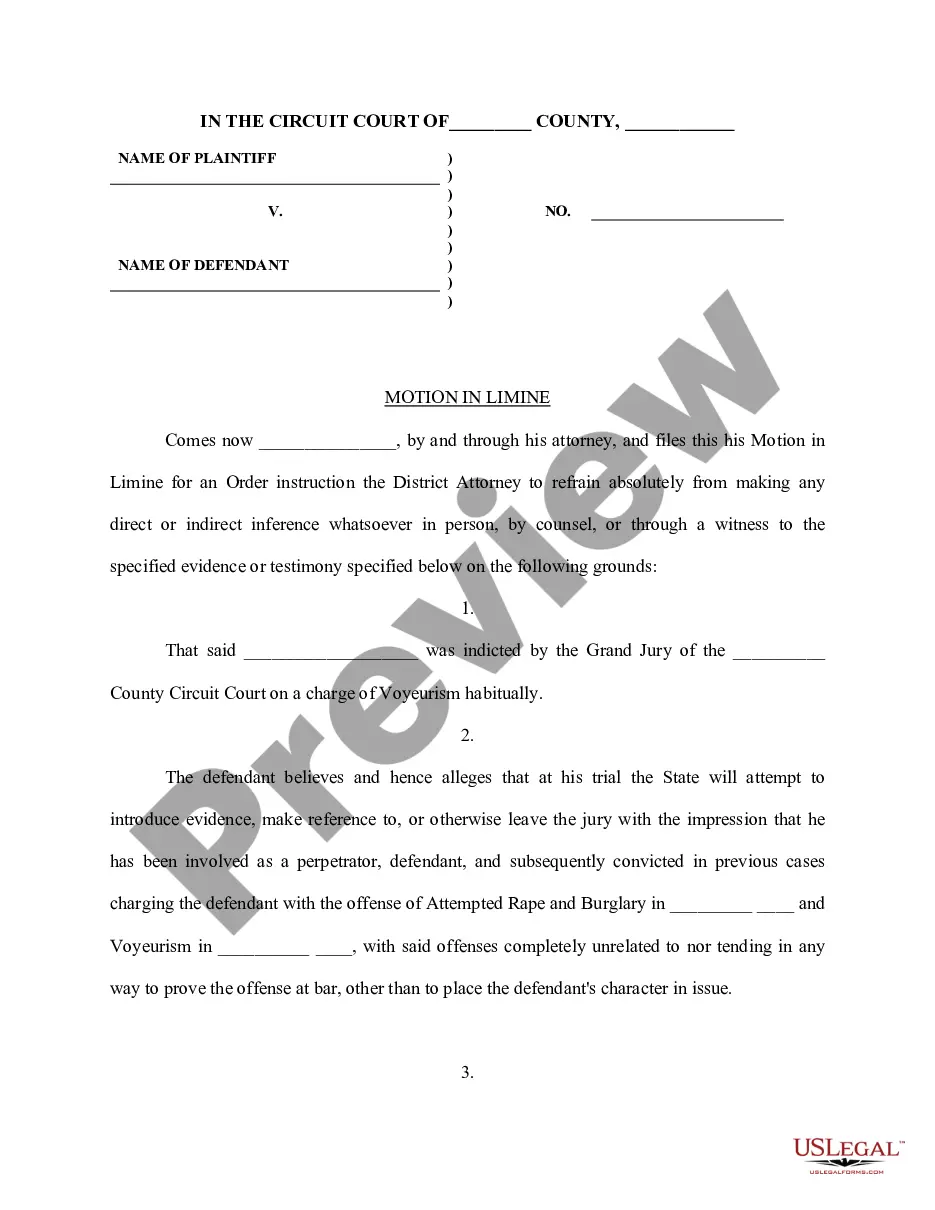

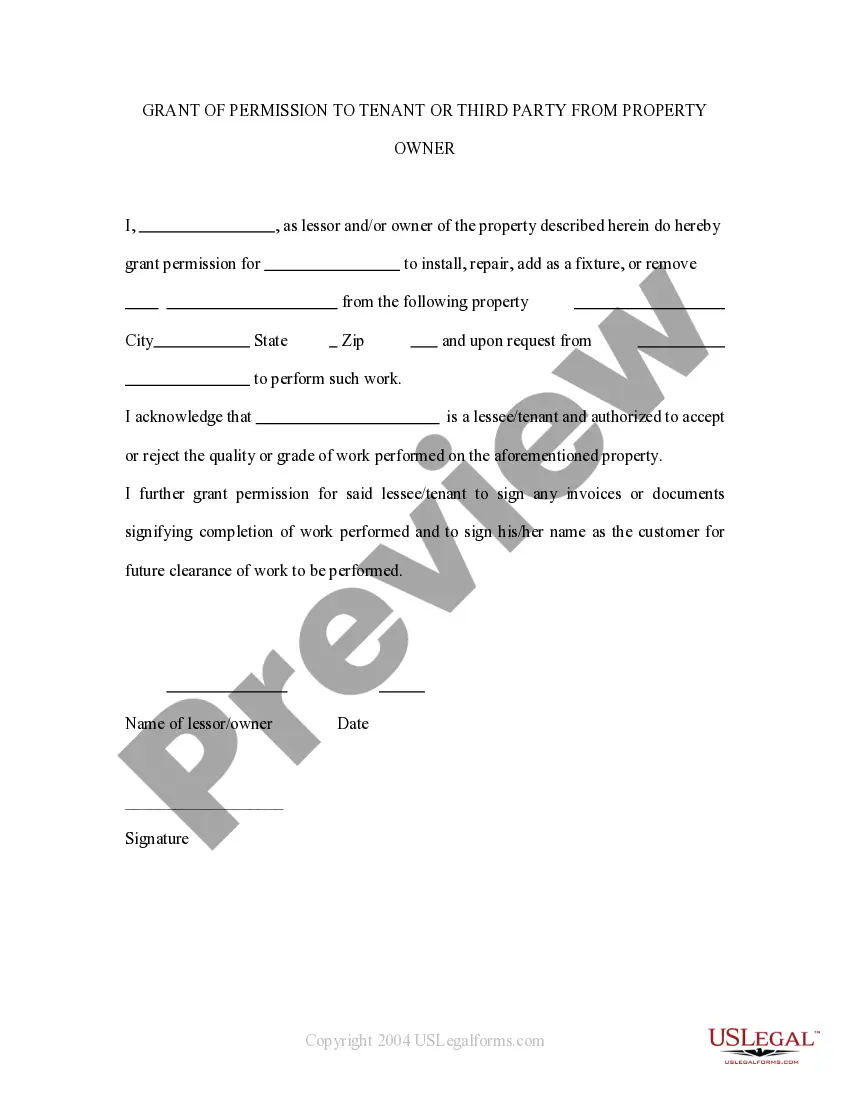

- Get the type you need and ensure it is for that proper city/area.

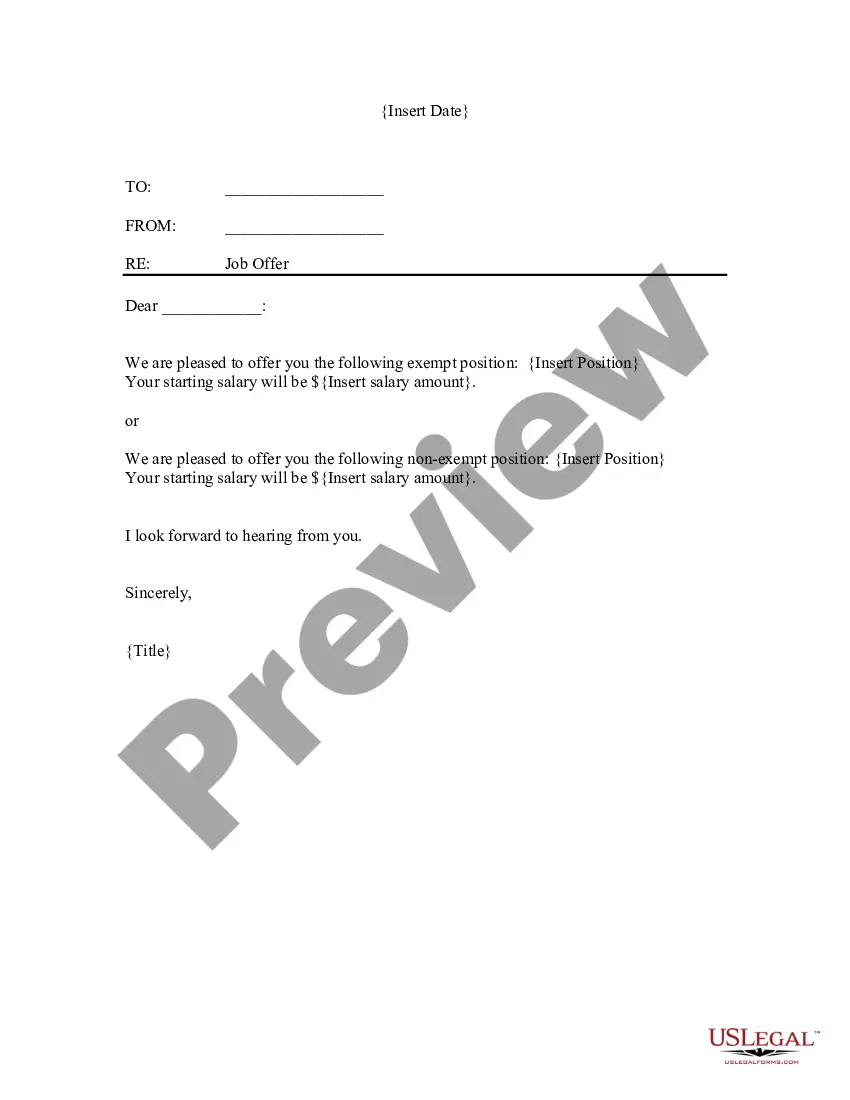

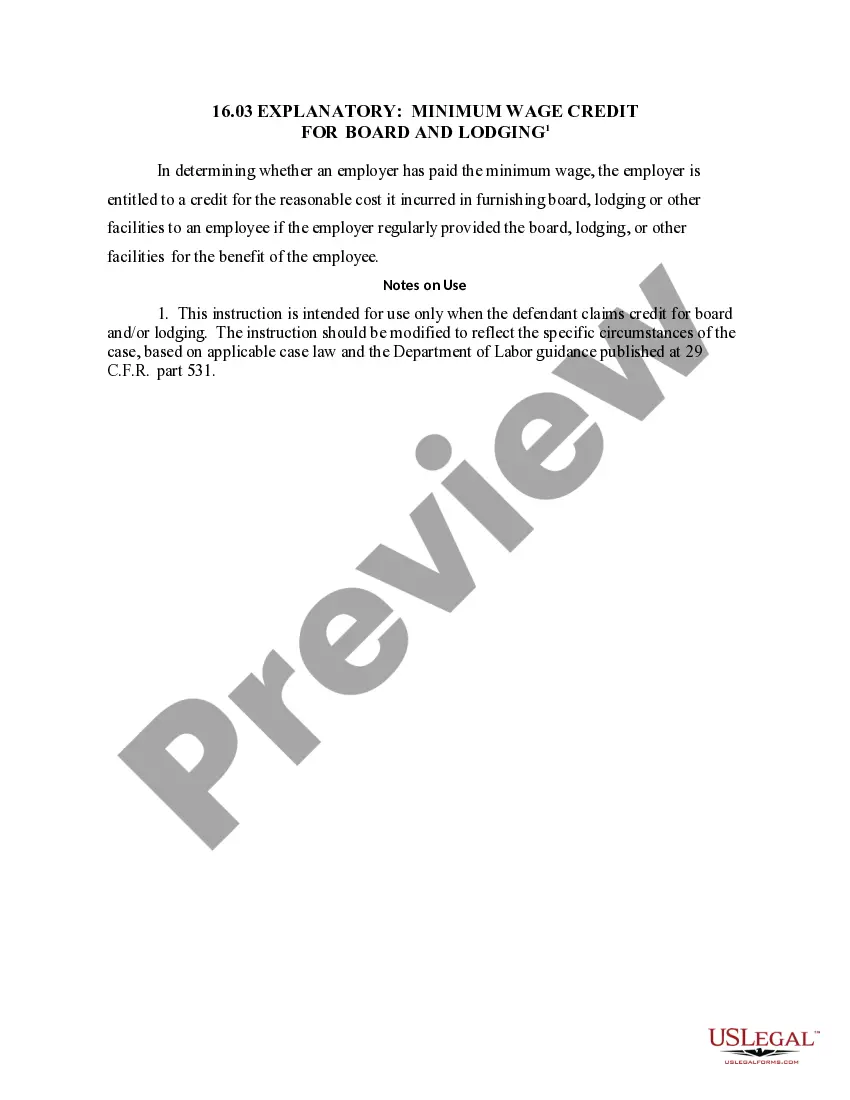

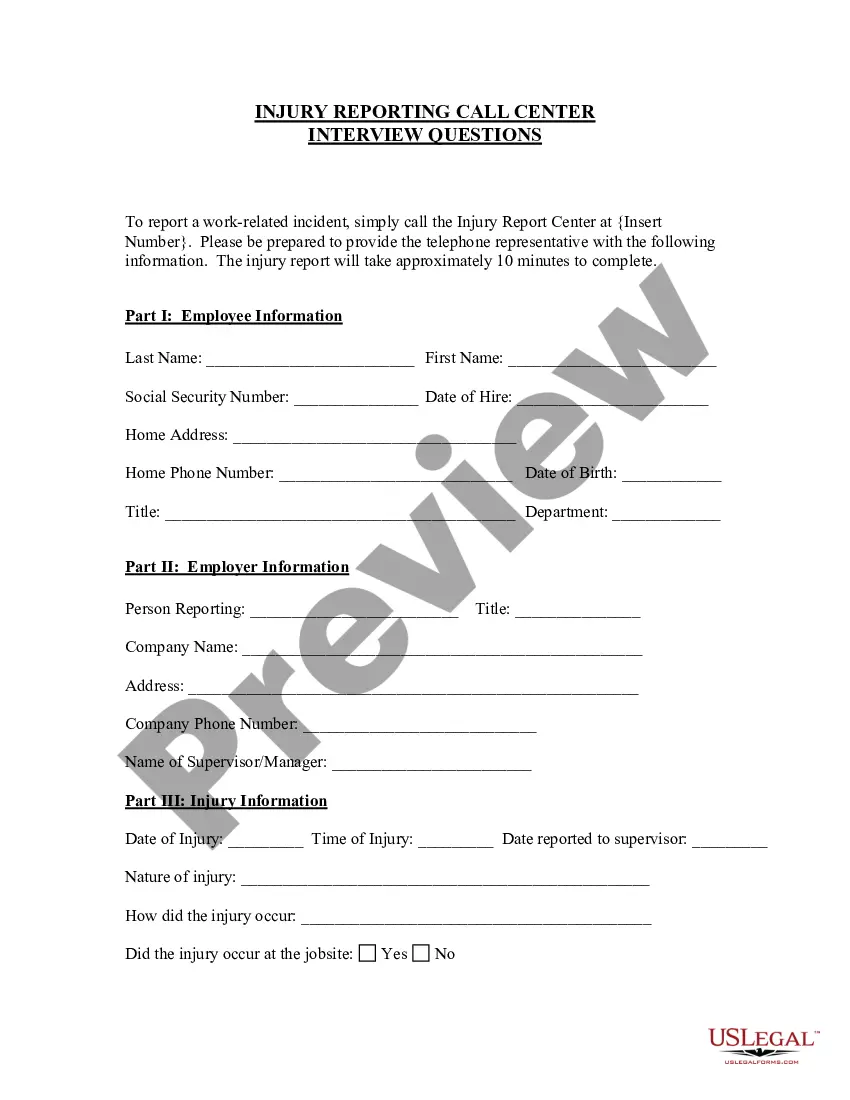

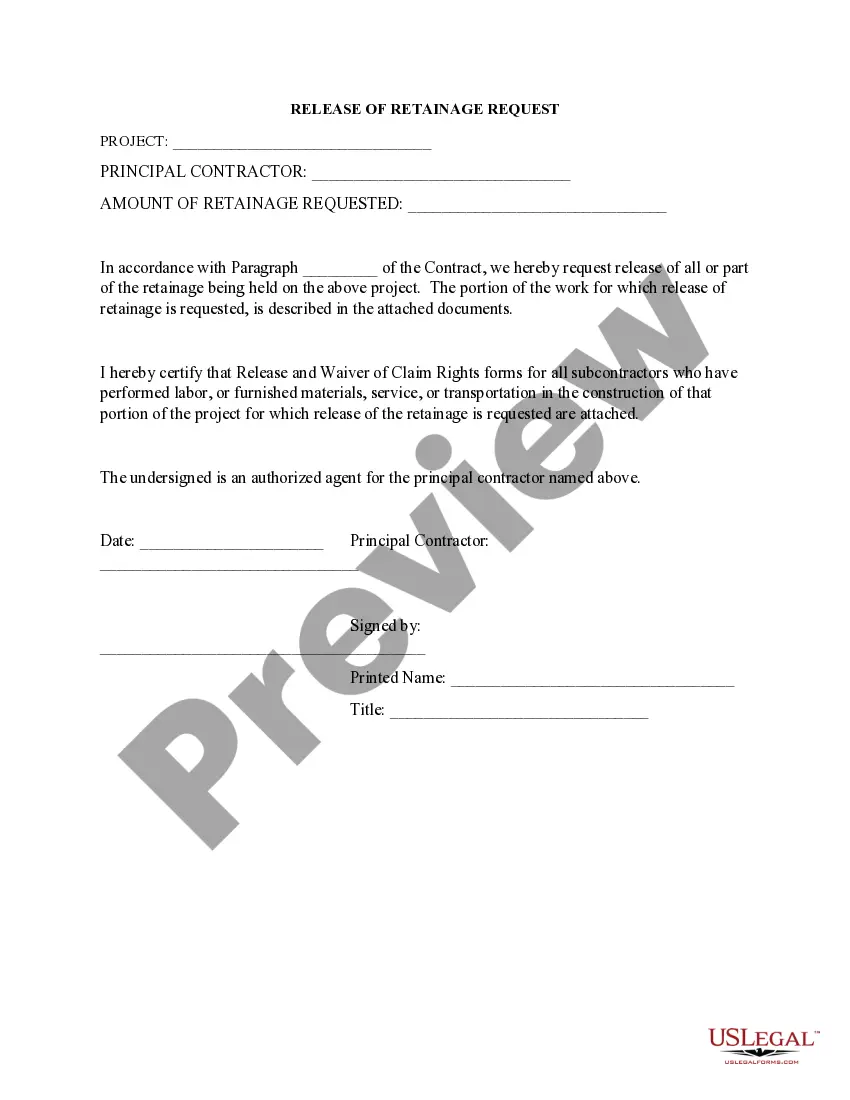

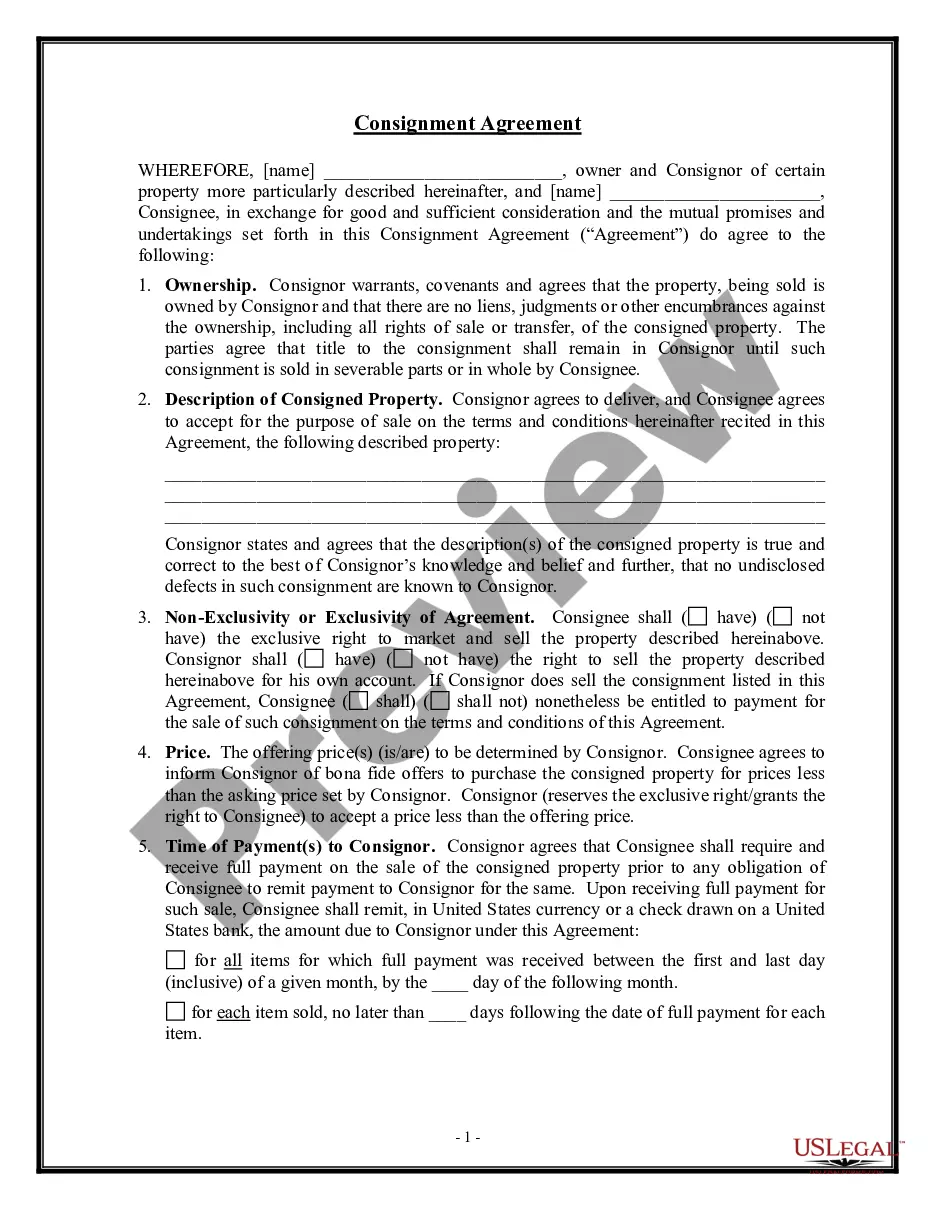

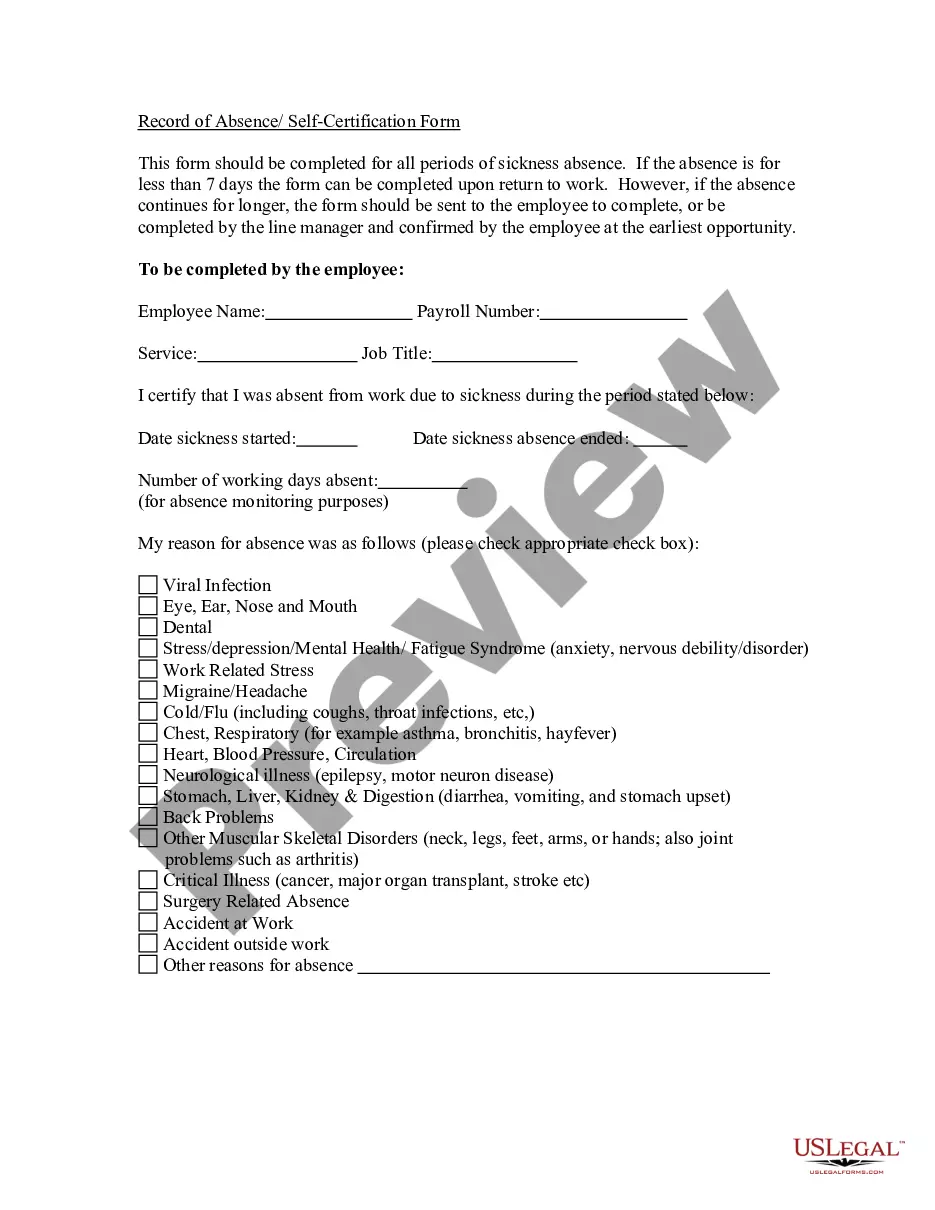

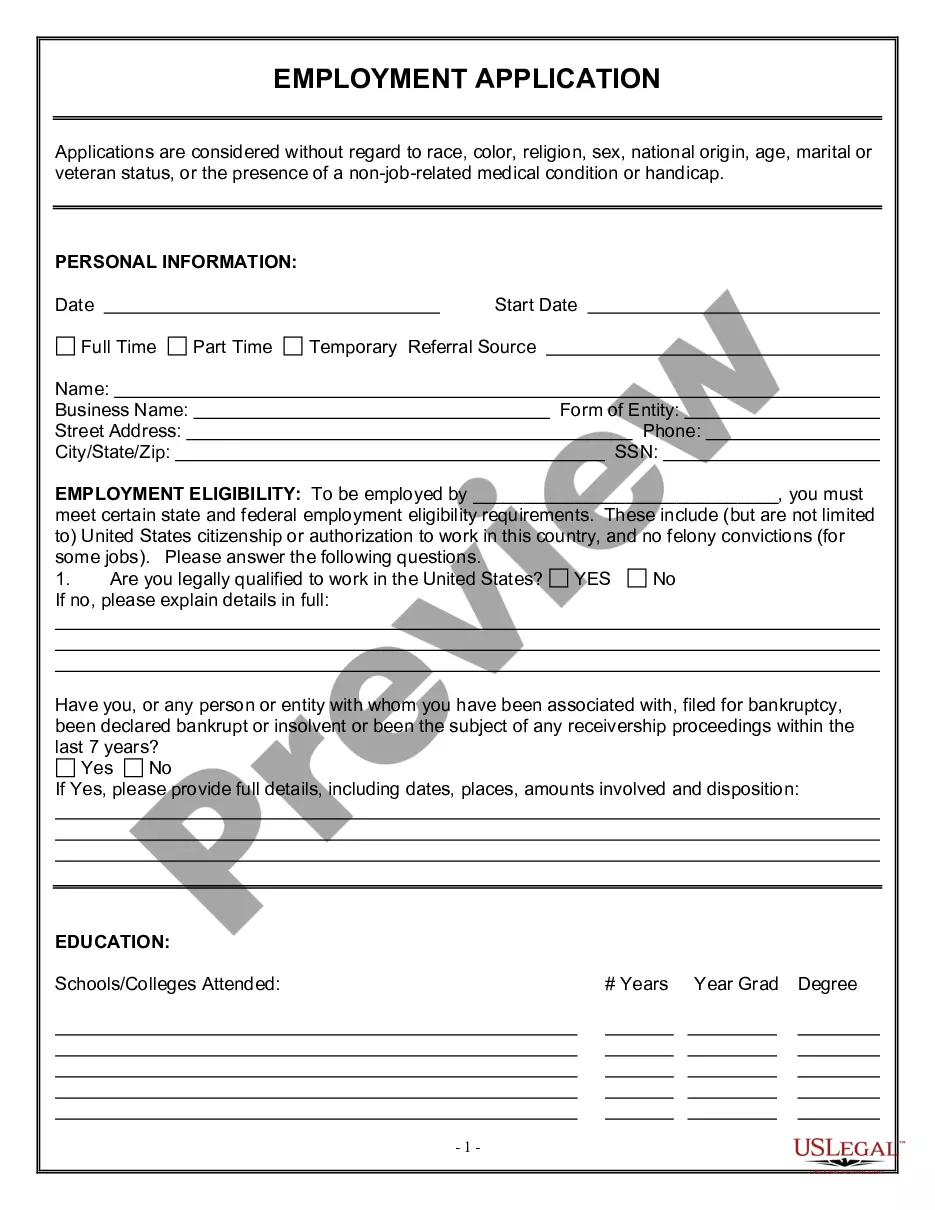

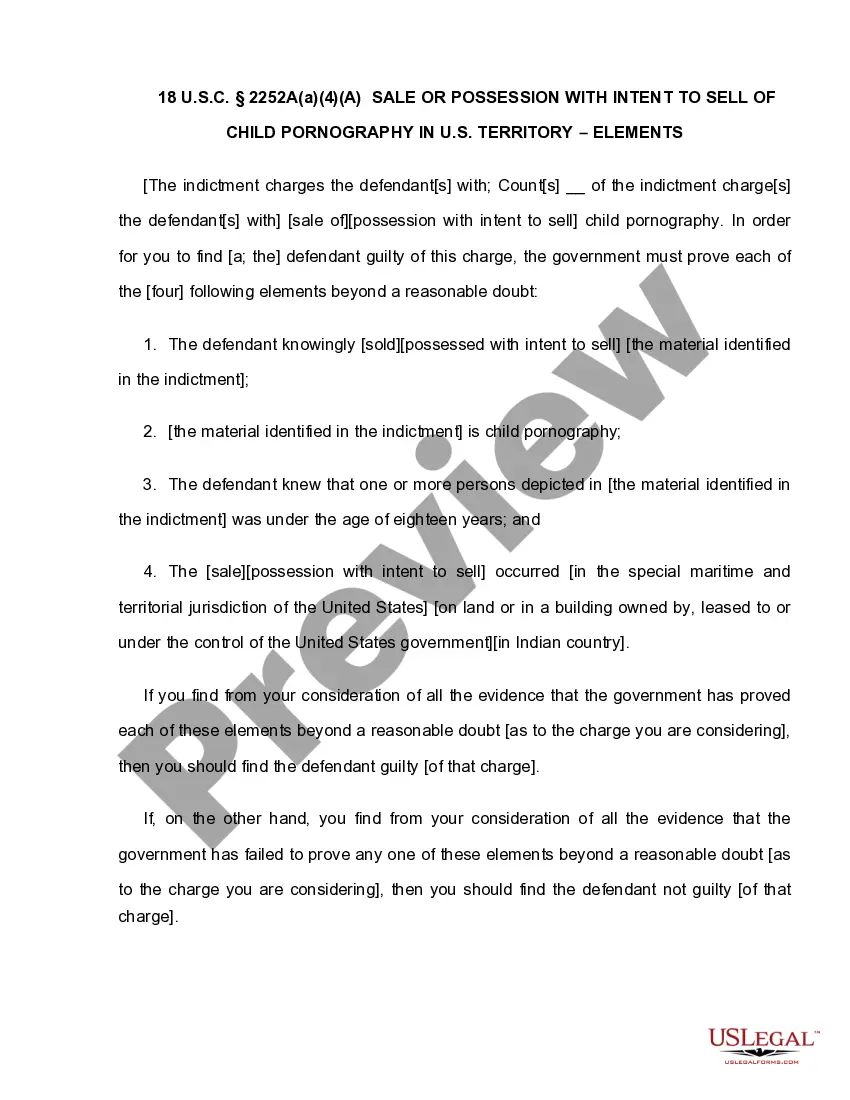

- Utilize the Preview option to review the form.

- Browse the outline to ensure that you have chosen the proper type.

- If the type isn`t what you`re searching for, make use of the Lookup area to obtain the type that fits your needs and requirements.

- Whenever you get the proper type, click Purchase now.

- Select the pricing program you desire, complete the necessary information and facts to make your money, and pay for an order making use of your PayPal or credit card.

- Choose a hassle-free file structure and acquire your duplicate.

Get all the file web templates you might have bought in the My Forms menus. You can aquire a more duplicate of Delaware Maintenance Assistance - Technician Checklist anytime, if necessary. Just go through the needed type to acquire or printing the file format.

Use US Legal Forms, one of the most considerable variety of authorized kinds, in order to save time and avoid faults. The service delivers expertly made authorized file web templates which you can use for a variety of functions. Create an account on US Legal Forms and start creating your way of life a little easier.