A Strategy for Research and Development

Research and development (R & D) needs to be carefully planned and managed to succeed. It is easy to waste money on developing ideas that go nowhere, but getting it right can lead to business stability, security and long-term profits.

Planning

R & D should be included in your overall business plan. The plan should illustrate the direction you want the business to take and how R & D fits in with your other business activities. Set out clear objectives, time frames and budgets. A clear plan can prevent the project straying from your business goals and wasting valuable resources and money.

You may need to involve staff with specific skills to draw up the plan, for example finance staff to set up budgets. You may also need outside help.

Your plan should set out the steps that need to be taken from the inception of the ideas to the product launch. You should allocate the necessary resources to the project, including funding, staff and time. You might decide to set up a specific team to work on the project.

Management

Good management is vital to reduce risk of failure and realize as many ideas as possible.

To manage R & D projects effectively you should:

" Make sure staff involved in R & D understand the business' overall strategy;

" Ensure these employees understand what is commercially realistic;

" Assess the changing risks and potential of projects as they progress, continually developing a rigorous business case;

" Ensure that intellectual property ownership issues are resolved;

" Recognize when a project isn't going to work; and

" Understand the relative importance of different projects to your business.

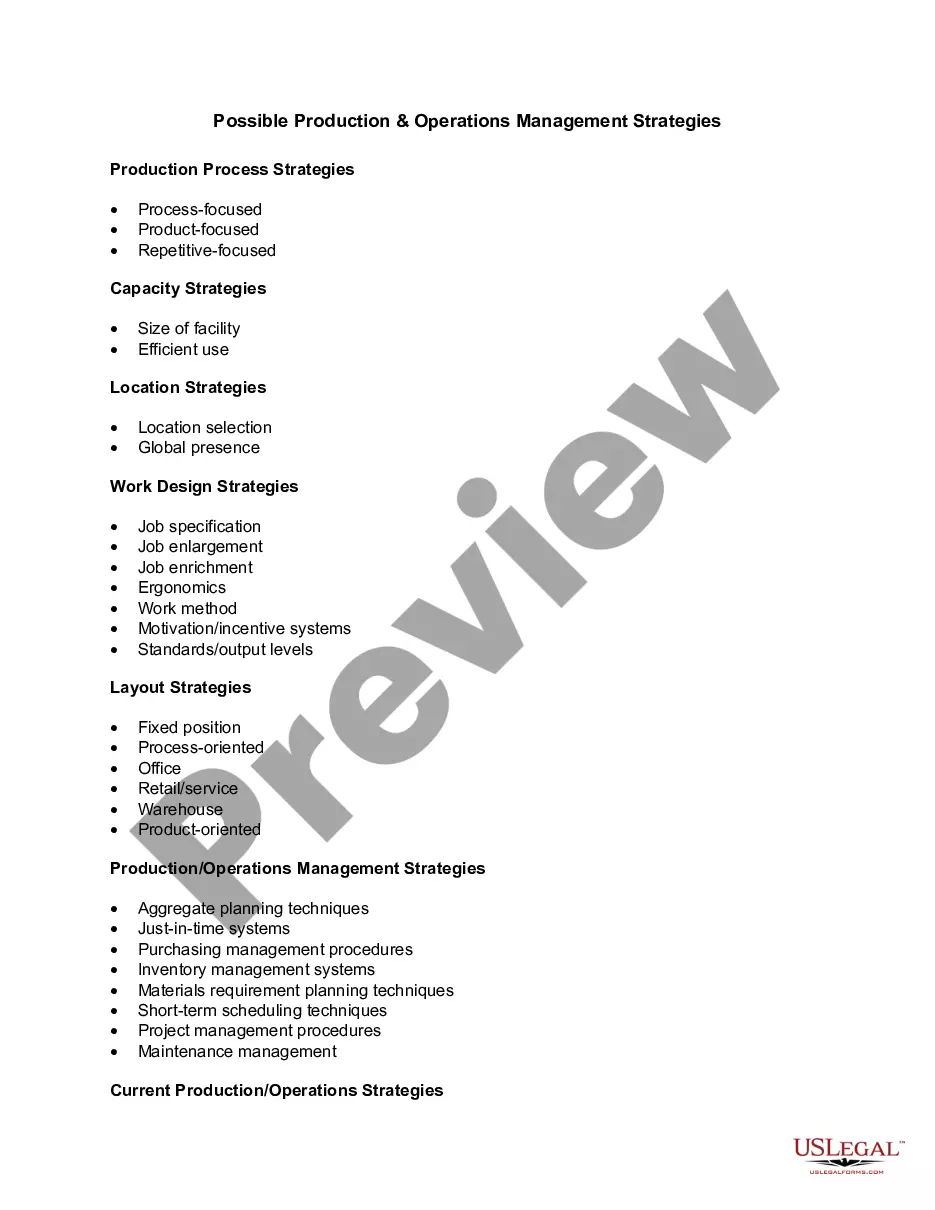

Florida Possible Production and Operations Management Strategies: An In-depth Overview Production and operations management strategies play a crucial role in enhancing efficiency, productivity, and profitability within organizations. In the context of Florida's possible production and operations management strategies, several key principles and approaches can be considered to optimize business operations and maximize outcomes. Let's delve into the detailed description of these strategies, incorporating relevant keywords to present a comprehensive picture. 1. Lean Manufacturing: Lean manufacturing utilizes a systematic approach to eliminate waste, minimize defects, and streamline processes. By focusing on continuous improvement, just-in-time production, and efficient resource utilization, lean manufacturing enables organizations in Florida to enhance productivity while reducing costs and lead times. 2. Six Sigma: Six Sigma is a data-driven approach aimed at minimizing process variation, defects, and errors. By focusing on process improvement through statistical analysis and rigorous problem-solving techniques, organizations can strive for near-perfect quality levels and consistent operations, leading to enhanced customer satisfaction and increased competitiveness in the Florida market. 3. Supply Chain Management: Supply chain management (SCM) strategies aim to optimize the flow of goods, services, and information across various stages of production and distribution. Through effective coordination and collaboration with suppliers, manufacturers, and distributors, organizations in Florida can minimize disruptions, improve delivery times, and reduce overall costs. 4. Just-in-Time (JIT) Manufacturing: JIT manufacturing emphasizes minimizing inventory and achieving real-time production based on customer demand. By closely synchronizing production with customer requirements, businesses in Florida can reduce inventory carrying costs, enhance responsiveness, and mitigate the risk of obsolete products. 5. Total Quality Management (TQM): TQM is a comprehensive approach that focuses on continuous improvement, customer satisfaction, and employee involvement. By integrating quality principles into every aspect of operations, organizations in Florida can ensure consistent high-quality output, higher customer loyalty, and improved business performance. 6. Agile Manufacturing: Agile manufacturing involves flexible production systems capable of responding swiftly to changing customer demands or market dynamics. By incorporating modularization, collaboration, and adaptability, organizations in Florida can better cope with uncertain conditions, reduce time to market, and stay competitive in dynamic market environments. 7. Sustainability and Green Operations: Sustainable production and operations management strategies aim to minimize environmental impact, reduce waste generation, and conserve resources. By implementing eco-friendly practices, organizations in Florida can enhance brand reputation, meet legal and regulatory requirements, and improve overall operational efficiency. 8. Automation and Technology Integration: Embracing automation and technology can significantly improve production and operations efficiency. By leveraging advanced technologies such as robotics, artificial intelligence (AI), and Internet of Things (IoT), businesses in Florida can automate repetitive tasks, improve accuracy, optimize resource allocation, and unlock new opportunities for growth. In conclusion, Florida Possible Production and Operations Management Strategies encompass a diverse range of approaches aimed at enhancing efficiency, quality, and competitiveness. By adopting these strategies, organizations in Florida can optimize their production and operations, improve customer satisfaction, and achieve sustainable growth.