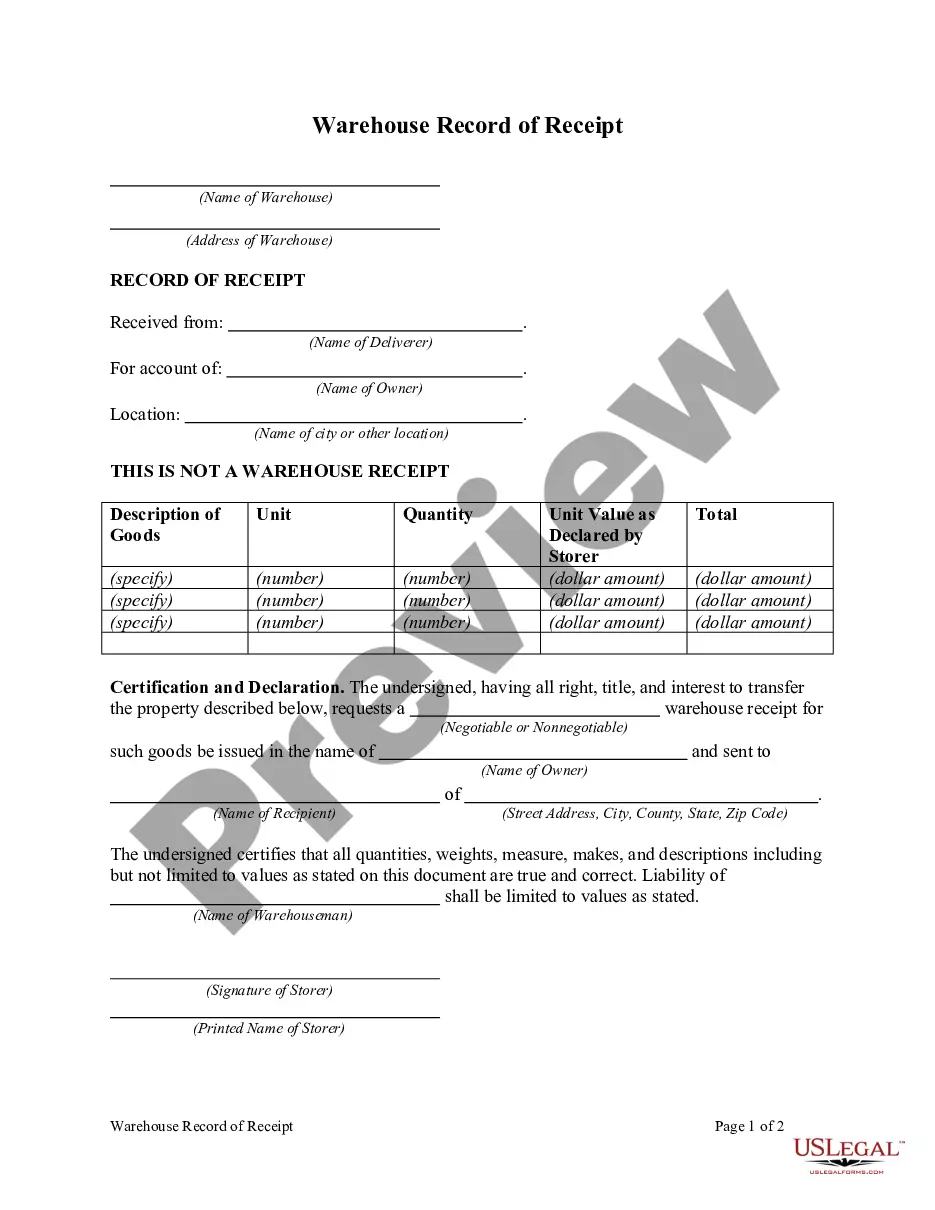

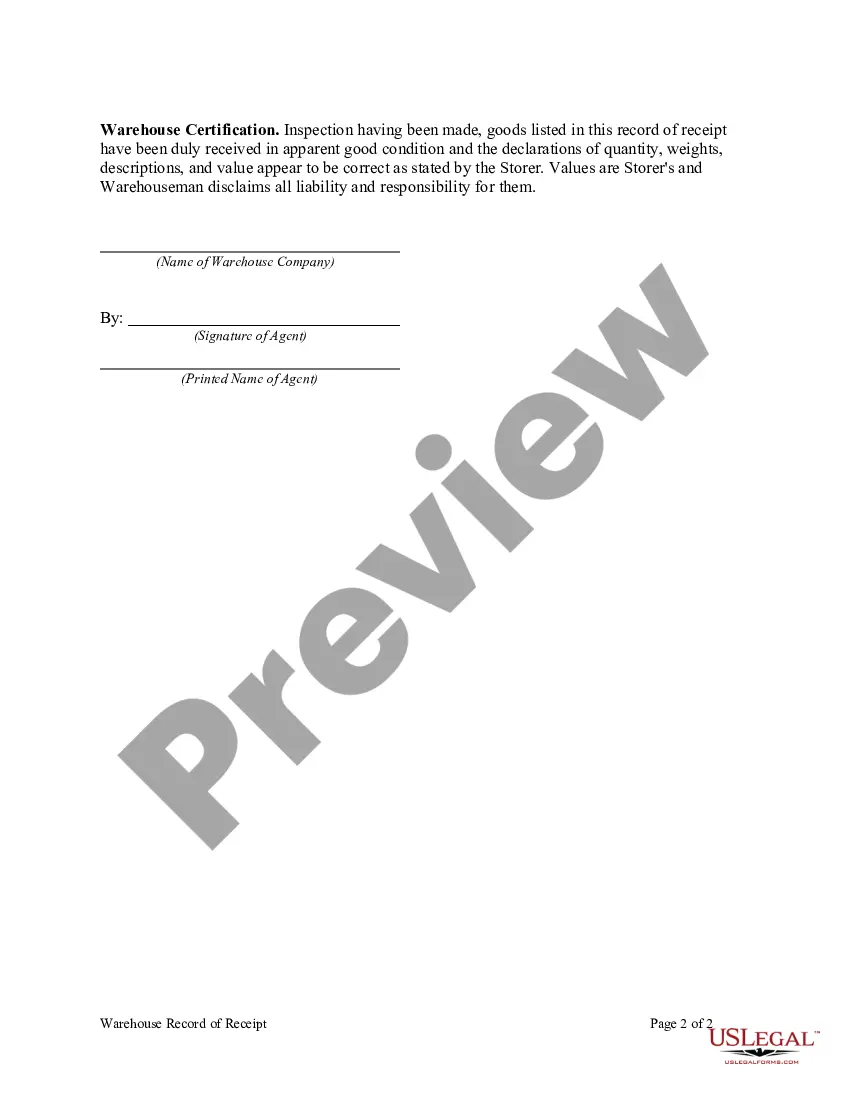

Guam Warehouse Record of Receipt is a crucial document utilized in the logistics industry for tracking and documenting goods received at a warehouse facility located in Guam. This record acts as a legal proof of receipt, providing a detailed account of the items received, their condition, and relevant information involved in the transfer of goods. The Guam Warehouse Record of Receipt typically includes essential keywords such as: 1. Warehouse: The physical location where goods are stored, managed, and distributed. 2. Receipt: Acknowledgment of receiving goods, indicating that the transfer has been successfully completed. 3. Guam: Referring to the specific geographic location of the warehouse, which is the territory of the United States in the western Pacific Ocean. 4. Goods: The physical items received, including their description, quantity, and any associated identification numbers (e.g., SKU, serial number, or batch number). 5. Condition: Documentation of the state of the goods upon receipt, noting any damages, defects, or discrepancies. 6. Shipping Information: Details about the shipment, such as the origin, date of delivery, carrier name, and tracking number. 7. Consignee: The individual, entity, or organization receiving the goods, including their name, address, and contact information. 8. Consignor: The sender or shipper of the goods, providing their details for reference. 9. Signature: Authorized signatures of both the consignor and the warehouse representative, ensuring the mutual agreement of the receipt's contents. 10. Date and Time: The exact date and timestamp of when the goods were received at the warehouse, establishing an accurate timeline. Different types of Guam Warehouse Records of Receipt could include specialized variations based on the nature of goods being received or the specific industry requirements. For instance: 1. General Merchandise Warehouse Record of Receipt: Used for tracking and documenting various consumer goods, including electronics, clothing, household products, and other non-perishable items. 2. Perishable Goods Warehouse Record of Receipt: Specifically designed for tracking and documenting goods with limited shelf life, such as fresh produce, frozen foods, pharmaceuticals, or flowers. 3. Hazardous Materials Warehouse Record of Receipt: Utilized when dealing with hazardous or dangerous substances, ensuring compliance with safety regulations and guidelines outlined by relevant authorities. 4. Automotive Parts Warehouse Record of Receipt: Focused on tracking and documenting incoming automotive components, spare parts, or accessories. 5. E-commerce Fulfillment Warehouse Record of Receipt: Tailored for e-commerce businesses, managing the receipt of goods from various suppliers and providing real-time inventory updates. These various types of Guam Warehouse Records of Receipt cater to the unique needs of different industries, ensuring accurate inventory management, accountability, and smooth operations within the warehouse facility.

Guam Warehouse Record of Receipt

Description

How to fill out Guam Warehouse Record Of Receipt?

If you have to total, download, or printing legitimate papers web templates, use US Legal Forms, the largest variety of legitimate forms, which can be found on the web. Utilize the site`s simple and hassle-free look for to find the documents you will need. Different web templates for business and specific functions are sorted by categories and states, or keywords and phrases. Use US Legal Forms to find the Guam Warehouse Record of Receipt with a couple of clicks.

When you are previously a US Legal Forms buyer, log in to your bank account and then click the Obtain key to find the Guam Warehouse Record of Receipt. You can also accessibility forms you previously downloaded in the My Forms tab of your respective bank account.

If you work with US Legal Forms the first time, refer to the instructions listed below:

- Step 1. Be sure you have selected the shape to the correct city/country.

- Step 2. Take advantage of the Preview option to examine the form`s information. Do not neglect to read the information.

- Step 3. When you are unsatisfied using the kind, make use of the Research industry at the top of the monitor to discover other versions from the legitimate kind template.

- Step 4. Upon having found the shape you will need, go through the Purchase now key. Pick the prices program you prefer and add your qualifications to sign up for the bank account.

- Step 5. Process the purchase. You should use your bank card or PayPal bank account to finish the purchase.

- Step 6. Choose the format from the legitimate kind and download it in your device.

- Step 7. Full, modify and printing or indication the Guam Warehouse Record of Receipt.

Every legitimate papers template you buy is yours eternally. You have acces to every single kind you downloaded inside your acccount. Go through the My Forms portion and pick a kind to printing or download once more.

Be competitive and download, and printing the Guam Warehouse Record of Receipt with US Legal Forms. There are many professional and express-distinct forms you can use for your personal business or specific requires.