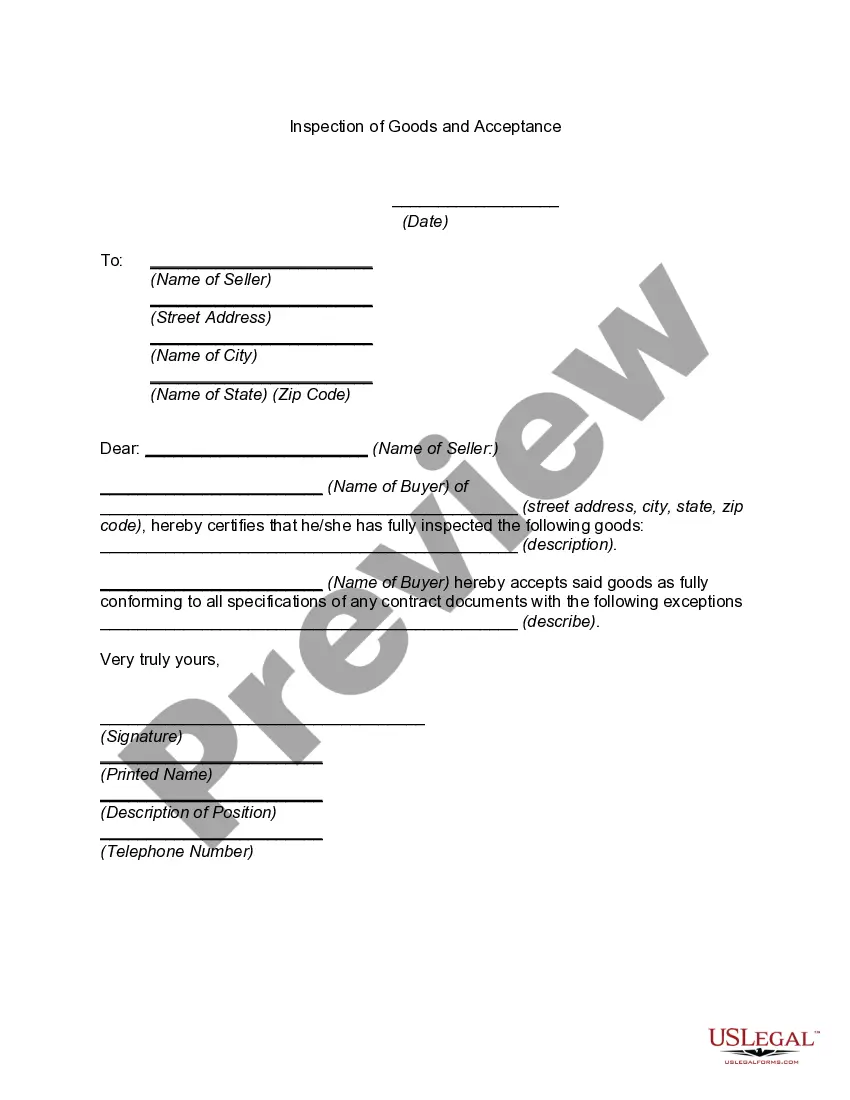

Hawaii Inspection of Goods and Acceptance refers to the process of evaluating and accepting goods received by a buyer from a seller in the state of Hawaii. This inspection is crucial to ensure that the goods meet the required specifications, quality standards, and quantity agreed upon. It serves to protect both the buyer and the seller by resolving any discrepancies, defects, or issues related to the purchased goods. The Hawaii Inspection of Goods and Acceptance can be categorized into two main types: 1. Pre-shipment inspection: This type of inspection takes place before the goods are shipped to Hawaii. It involves verifying the compliance of the goods with the provided specifications, packing requirements, labeling, and safety standards. The purpose of pre-shipment inspection is to detect any potential issues or discrepancies early on, allowing necessary corrections to be made before shipping the goods. 2. Post-shipment inspection: This inspection occurs after the goods have arrived in Hawaii and the buyer has taken physical possession. It aims to ensure that the goods have been delivered as agreed upon and are in satisfactory condition. The post-shipment inspection involves examining the goods for any damages, missing parts, or defects that may have occurred during transit. It also includes verifying the quantity received and comparing it to the purchase order or contract. The Hawaii Inspection of Goods and Acceptance process involves several key steps. Initially, the buyer and seller establish the inspection criteria and requirements in the purchase agreement or contract. These criteria may include specific quality standards, measurements, packaging, labeling, or any other relevant specifications. Once the goods arrive, the buyer, or their representative, will conduct a thorough inspection based on the agreed criteria. This inspection may involve visual checks, testing, sampling, or any other necessary procedures to ensure compliance. If any issues or discrepancies are found, they can be documented and reported to the seller for resolution. The Hawaii Inspection of Goods and Acceptance is especially important for businesses operating in various industries, including manufacturing, retail, import/export, and distribution. It helps maintain accountability, transparency, and trust between buyers and sellers, ensuring a smooth and efficient flow of goods in the marketplace. In conclusion, Hawaii Inspection of Goods and Acceptance is a critical process in the procurement and supply chain management. It ensures that goods received in Hawaii meet the required standards and specifications agreed upon between the buyer and seller. The two main types of inspections are reshipment and post-shipment inspections. Conducting these inspections helps protect both the buyer and the seller and promotes fair trade practices in the state of Hawaii.

Hawaii Inspection of Goods and Acceptance

Description

How to fill out Hawaii Inspection Of Goods And Acceptance?

You may spend time online searching for the lawful file web template that suits the state and federal needs you require. US Legal Forms gives a huge number of lawful types which are analyzed by specialists. You can actually obtain or print out the Hawaii Inspection of Goods and Acceptance from the assistance.

If you already have a US Legal Forms bank account, you are able to log in and then click the Acquire option. Following that, you are able to complete, modify, print out, or signal the Hawaii Inspection of Goods and Acceptance. Every lawful file web template you purchase is your own property eternally. To obtain yet another backup of any obtained type, check out the My Forms tab and then click the corresponding option.

If you work with the US Legal Forms web site for the first time, stick to the easy instructions under:

- Very first, make sure that you have chosen the proper file web template for the area/town of your liking. See the type outline to ensure you have picked the appropriate type. If available, utilize the Preview option to search through the file web template as well.

- If you would like locate yet another edition in the type, utilize the Search industry to obtain the web template that suits you and needs.

- When you have identified the web template you would like, simply click Purchase now to continue.

- Pick the costs strategy you would like, type your qualifications, and sign up for your account on US Legal Forms.

- Total the financial transaction. You can utilize your Visa or Mastercard or PayPal bank account to fund the lawful type.

- Pick the formatting in the file and obtain it to the system.

- Make modifications to the file if required. You may complete, modify and signal and print out Hawaii Inspection of Goods and Acceptance.

Acquire and print out a huge number of file templates utilizing the US Legal Forms site, which offers the most important variety of lawful types. Use professional and status-distinct templates to handle your organization or individual needs.