Hawaii Maintenance Engineer Checklist

Category:

State:

Multi-State

Control #:

US-381EM

Format:

Word;

Rich Text

Instant download

Description

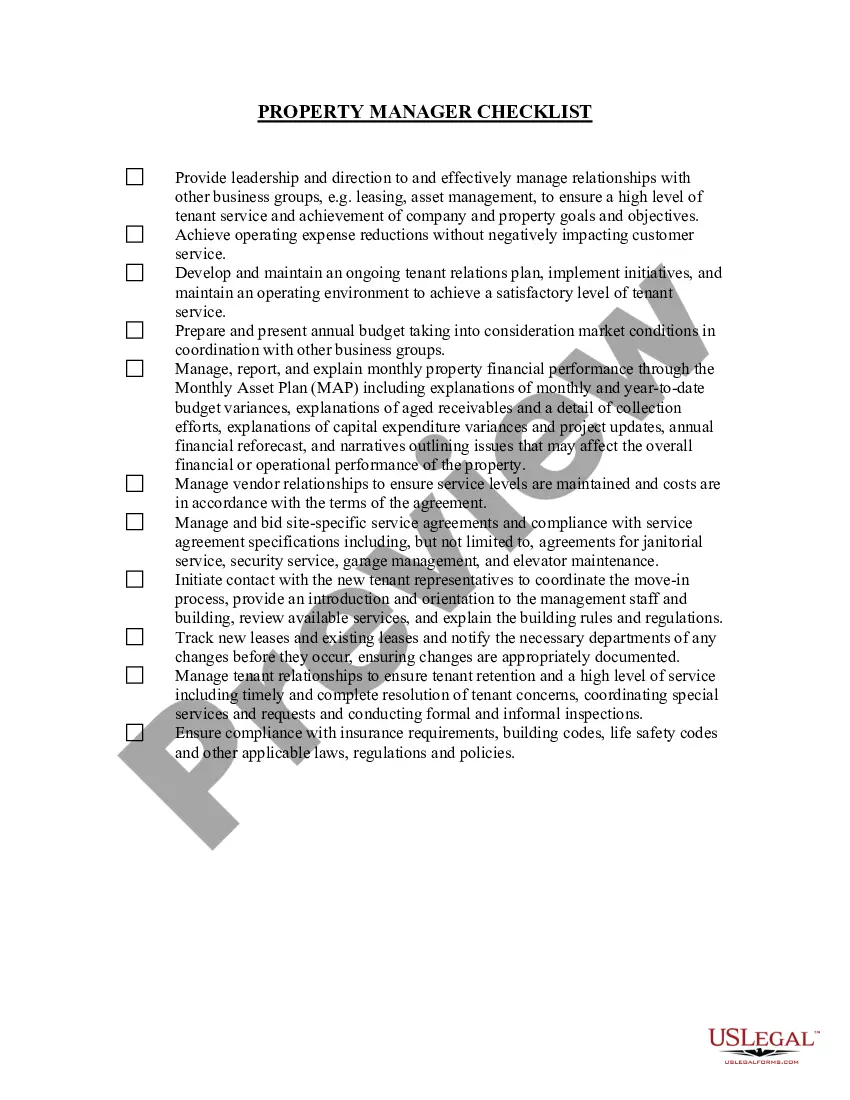

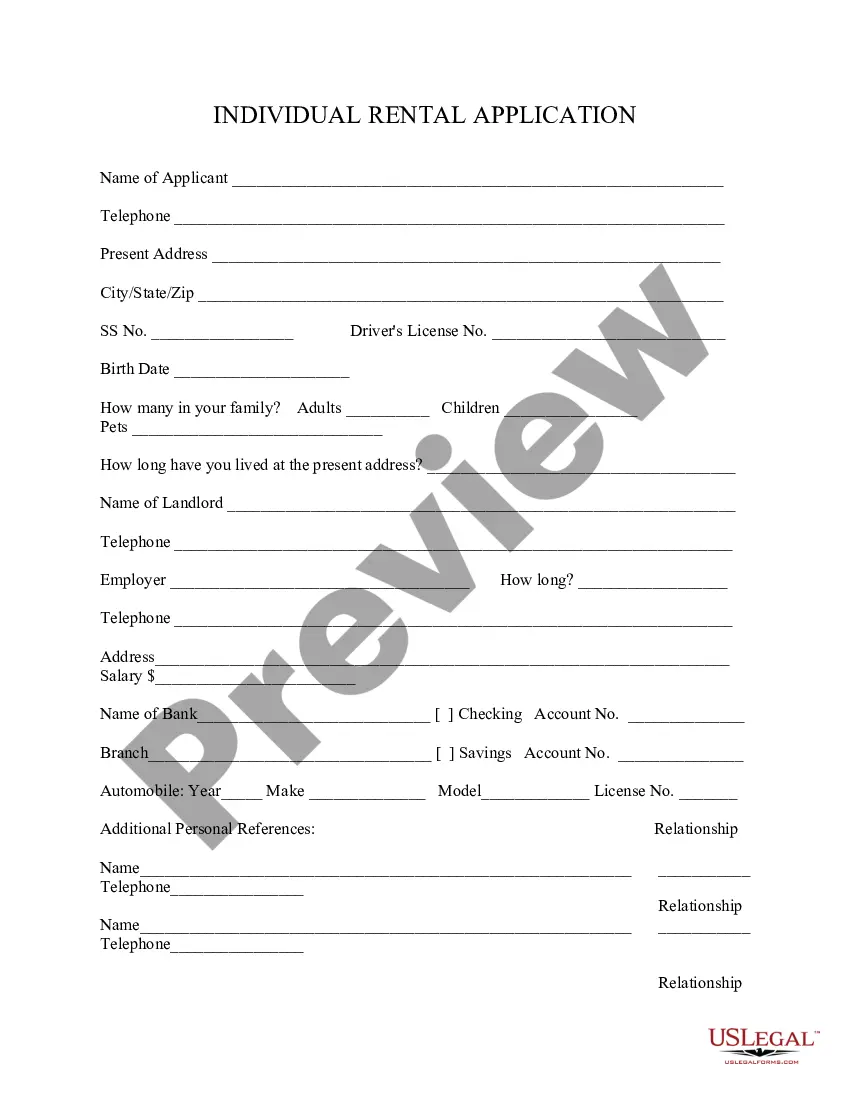

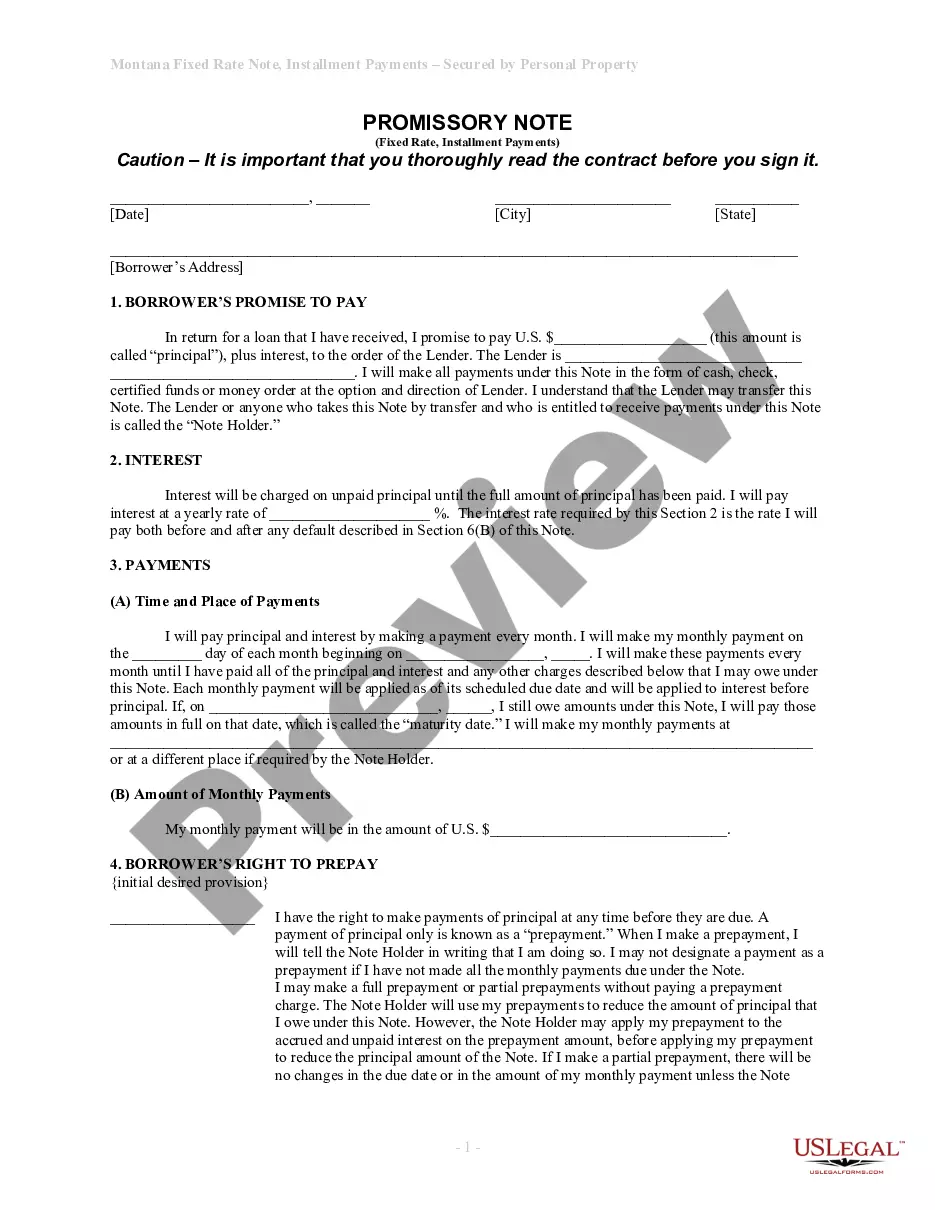

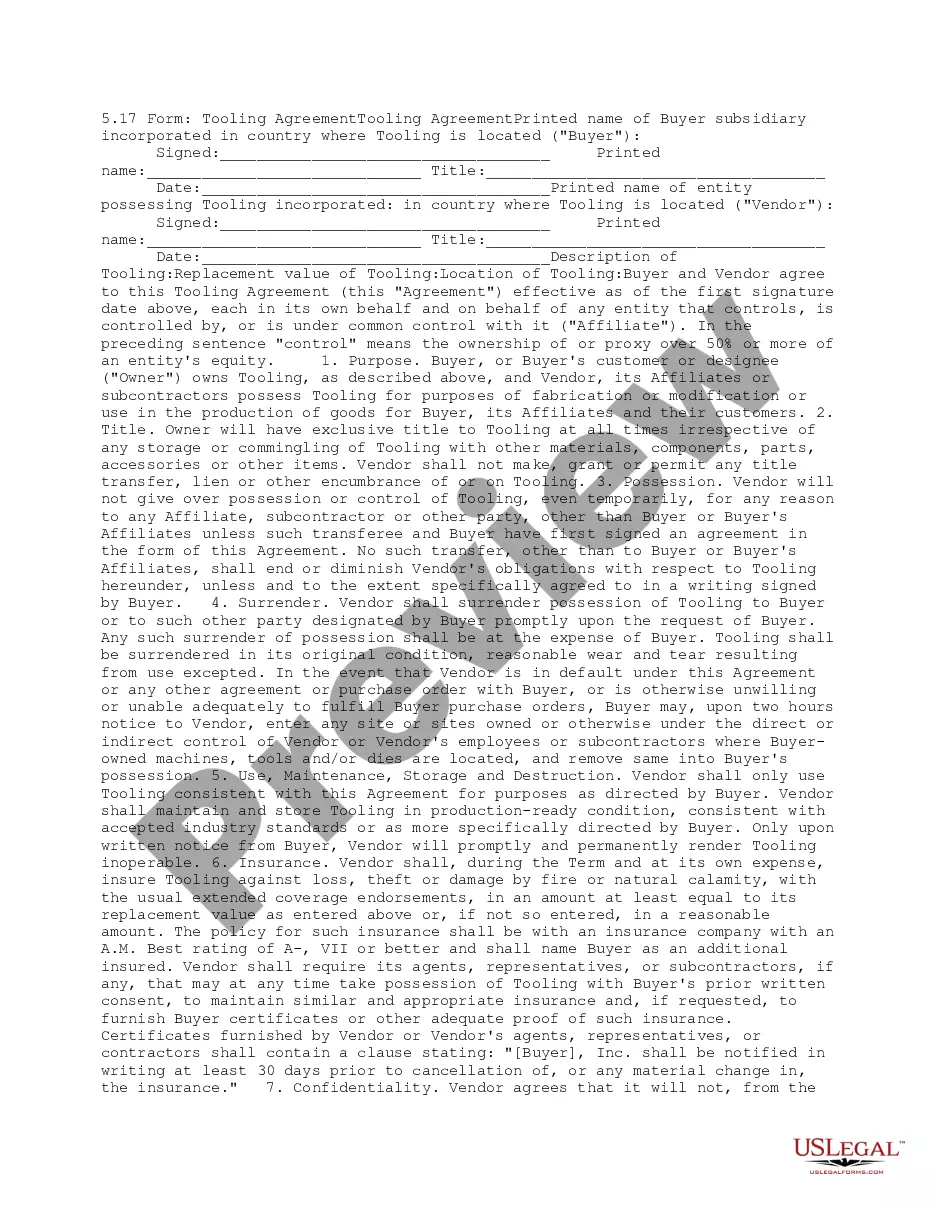

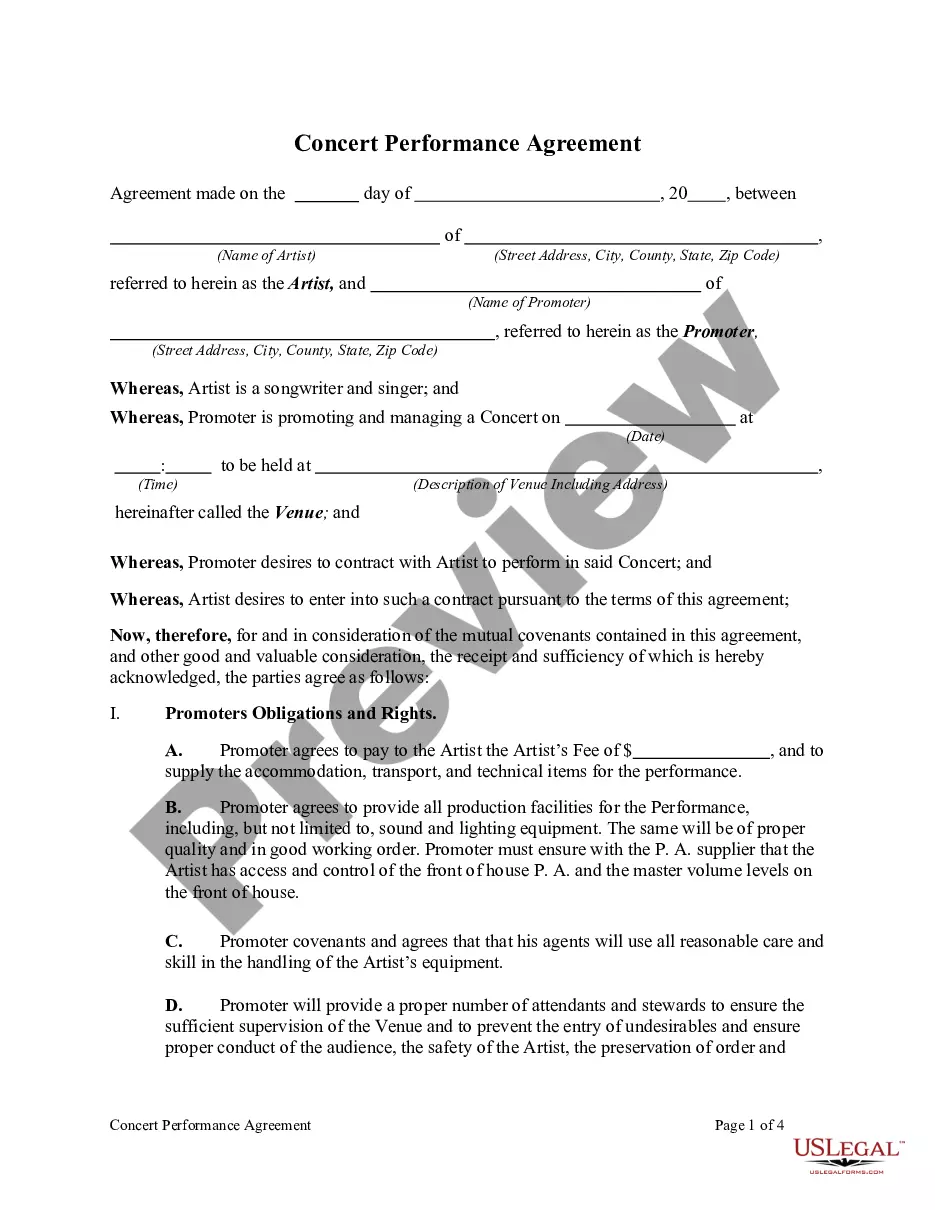

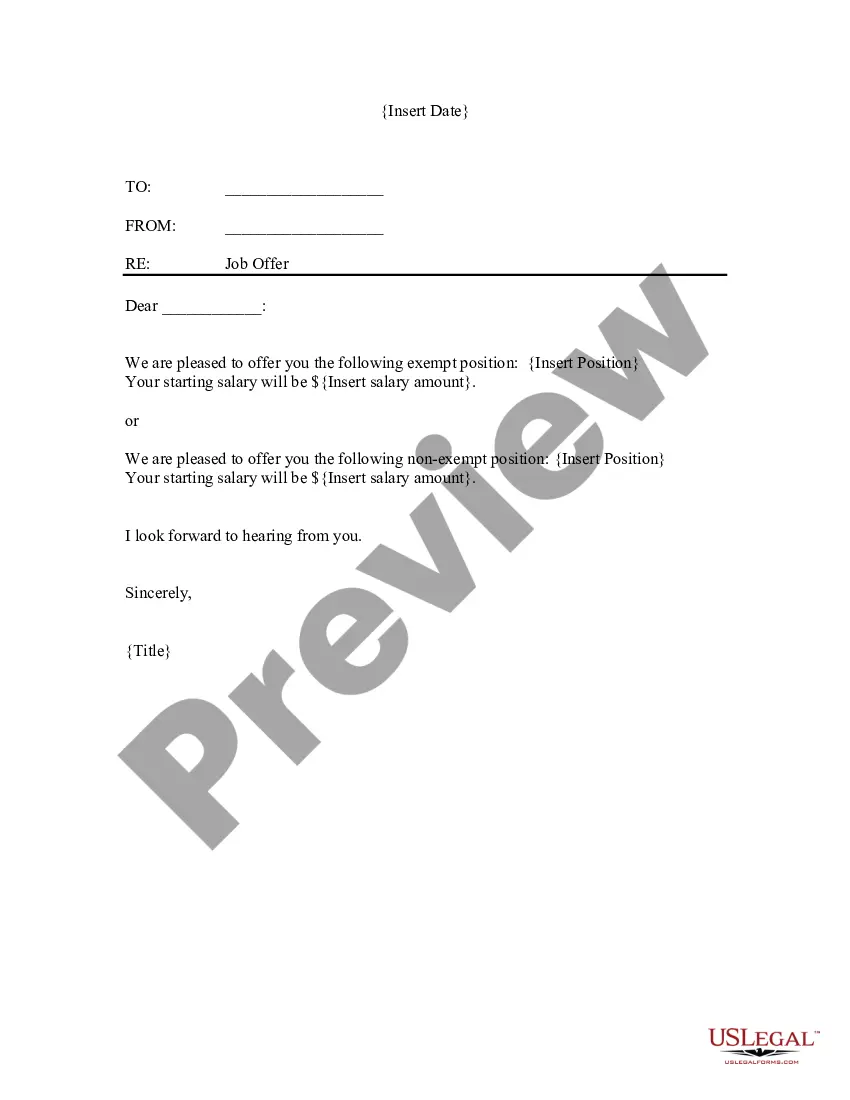

This form is used to list the potential duties of a maintenance engineer.

Free preview

How to fill out Maintenance Engineer Checklist?

Are you in a circumstance where you need documents for both professional or personal purposes almost every time.

There are numerous legal document templates available online, but finding reliable types isn't easy.

US Legal Forms offers thousands of document templates, including the Hawaii Maintenance Engineer Checklist, that are crafted to comply with state and federal regulations.

Choose the pricing plan you desire, provide the necessary information to create your account, and make the payment using your PayPal or credit card.

Select a preferred document format and download your version.

- If you are currently aware of the US Legal Forms website and have an account, simply Log In.

- Then, you can download the Hawaii Maintenance Engineer Checklist template.

- If you do not have an account and wish to start using US Legal Forms, follow these steps.

- Obtain the document you need and ensure it is for your correct jurisdiction/area.

- Utilize the Preview option to review the form.

- Check the details to ensure you have selected the right document.

- If the document isn't what you are seeking, use the Lookup field to find the form that suits your needs and requirements.

- Once you find the appropriate form, click Buy now.