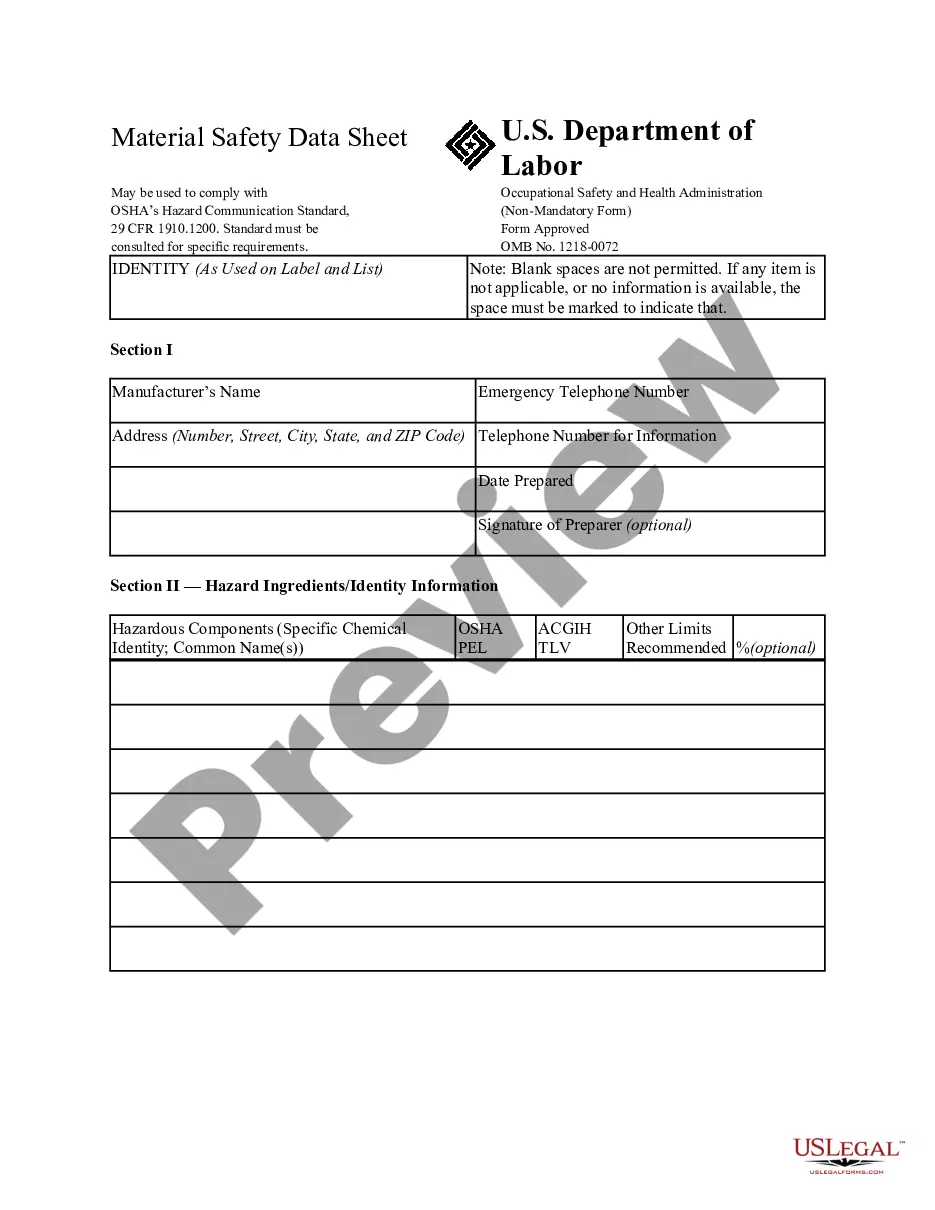

Hawaii Material Safety Data Sheet

Description

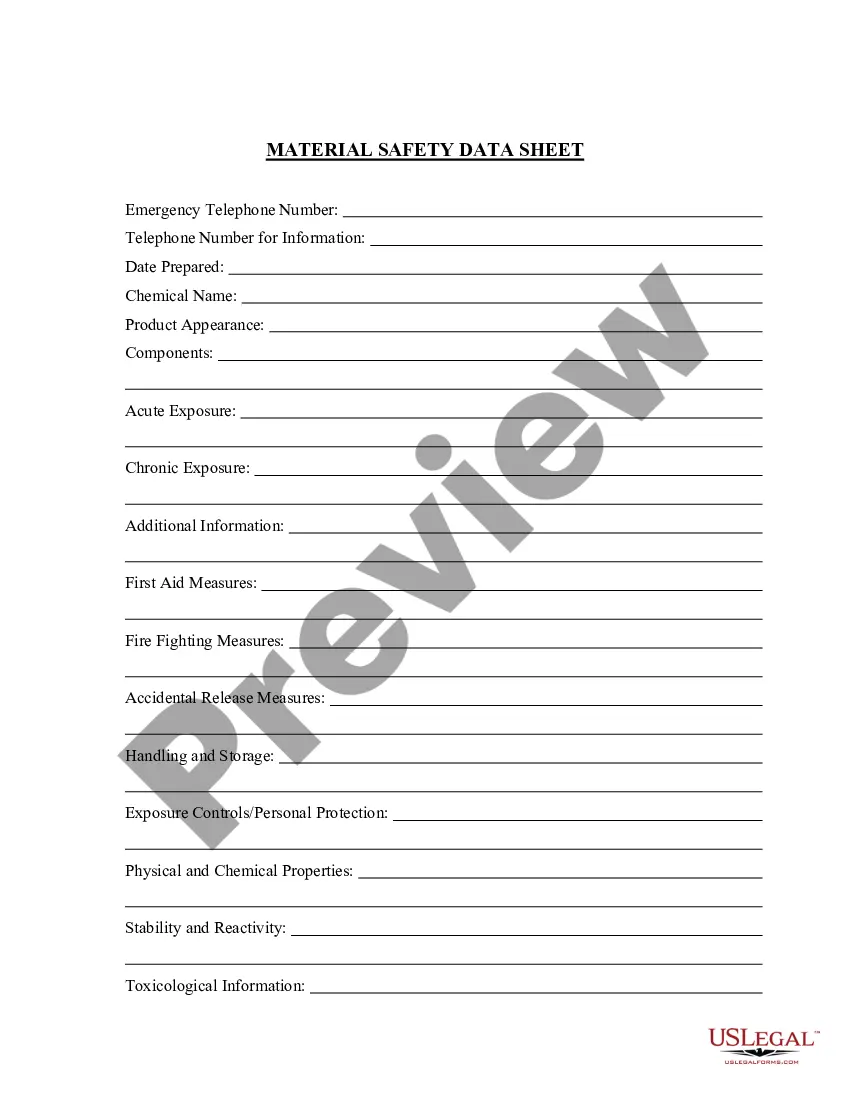

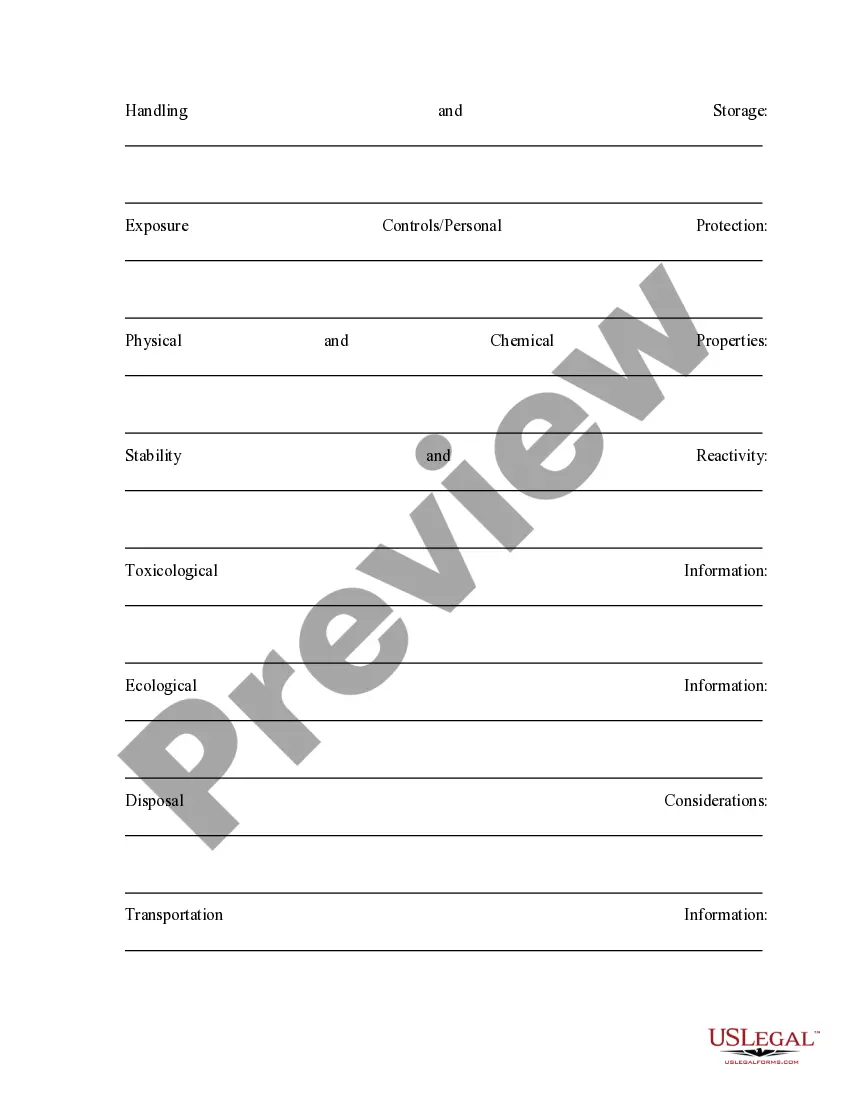

How to fill out Material Safety Data Sheet?

US Legal Forms - one of the largest collections of legal documents in the United States - offers a wide variety of legal document templates that you can download or print.

By using the website, you will find thousands of forms for business and personal use, categorized by types, states, or keywords. You can access the latest versions of forms such as the Hawaii Material Safety Data Sheet in moments.

If you already hold a subscription, Log In to download the Hawaii Material Safety Data Sheet from the US Legal Forms database. The Download button will appear on every form you view. You can find all previously saved forms in the My documents section of your account.

Complete the transaction. Use your credit card or PayPal account to finalize the purchase.

Choose the format and download the form to your device. Make modifications. Fill out, edit, print, and sign the downloaded Hawaii Material Safety Data Sheet. Every template you add to your account has no expiration date and is yours permanently. Therefore, if you wish to download or print another copy, simply go to the My documents section and click on the form you need. Access the Hawaii Material Safety Data Sheet with US Legal Forms, the most extensive collection of legal document templates. Utilize thousands of professional and state-specific templates that meet your business or personal requirements.

- To use US Legal Forms for the first time, here are basic instructions to get started.

- Ensure you have chosen the correct form for your region/area.

- Click the Preview button to review the form's content.

- Examine the form description to confirm you have selected the right form.

- If the form does not suit your needs, use the Search field at the top of the screen to find one that does.

- If you are satisfied with the form, confirm your choice by clicking the Get now button.

- Next, select the pricing plan you prefer and provide your details to register for an account.

Form popularity

FAQ

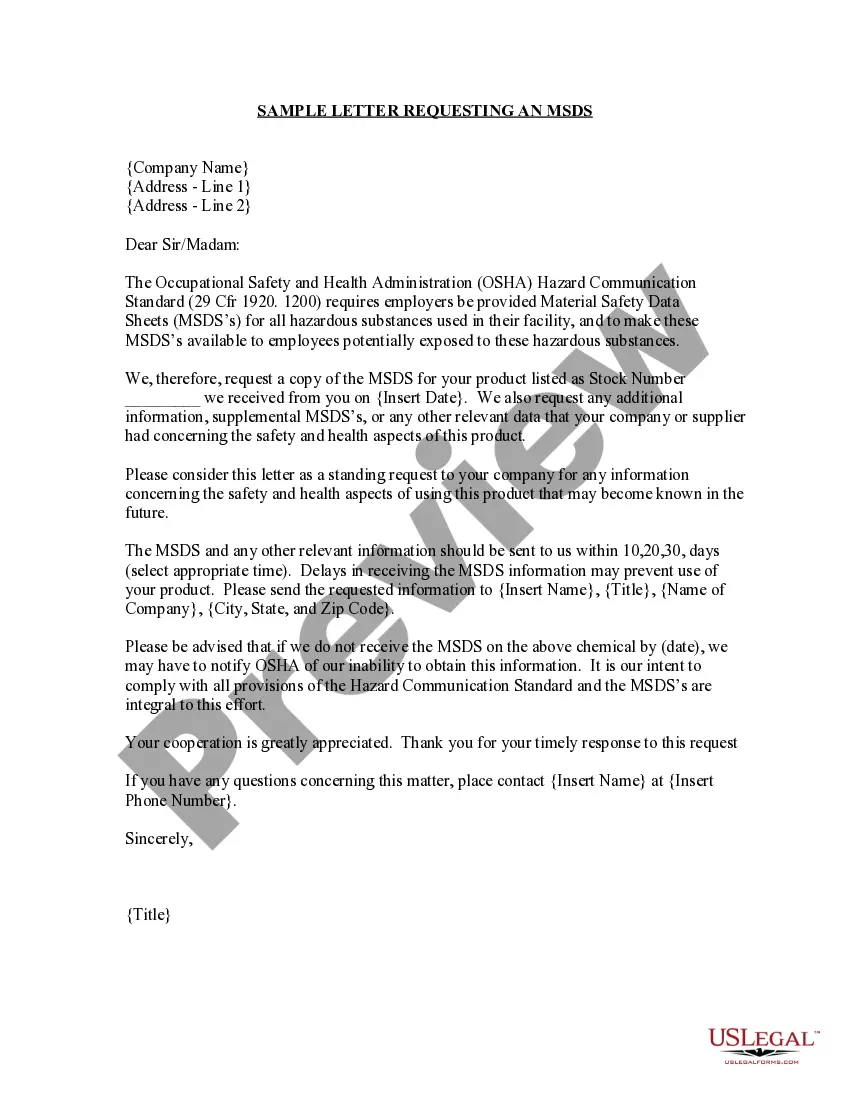

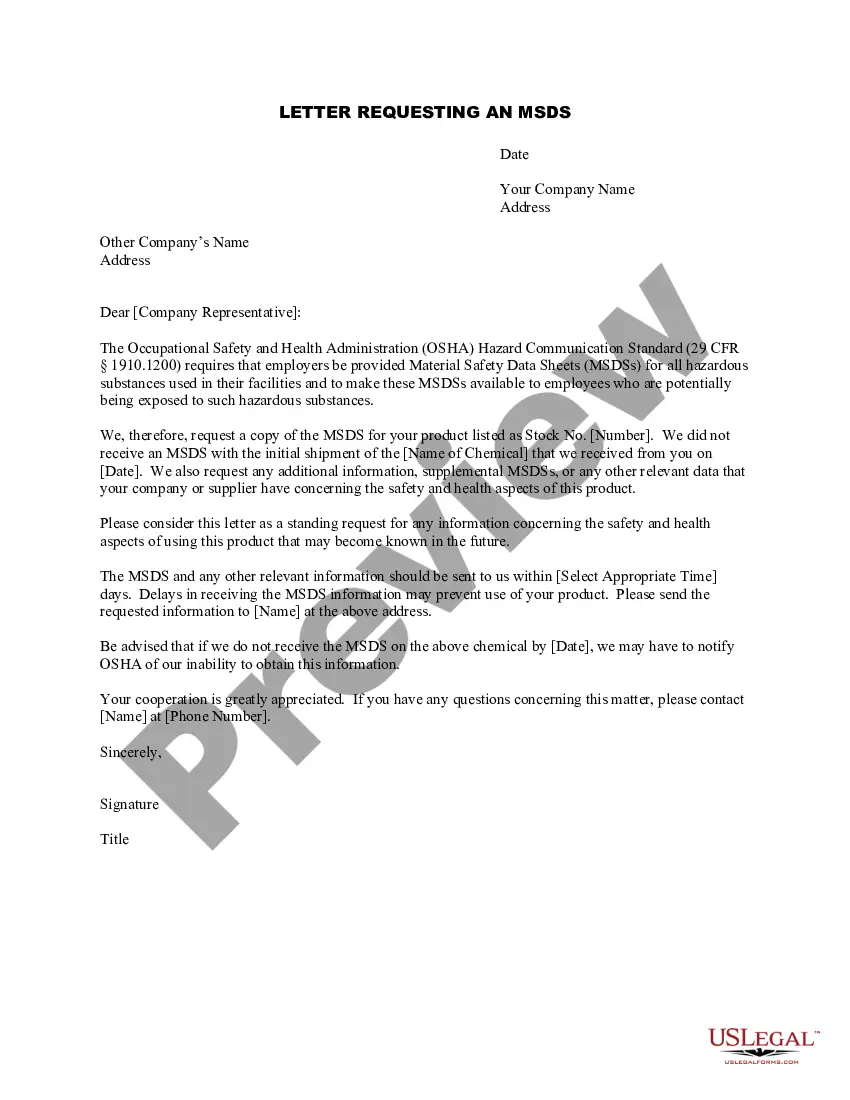

To obtain SDS, get them from the manufacturer.They may be sent with the chemical order (paper copy or e-mail attachment).Otherwise, go to the manufacturer's website and download it or request a copy.

Under its Hazard Communication Standard revision, OSHA has completely redone what used to be our familiar MSDS. The old Material Safety Data Sheet has been replaced by the Safety Data Sheet (SDS). The new Safety Data Sheet provides essentially the same information as the MSDS, but in a more user-friendly format.

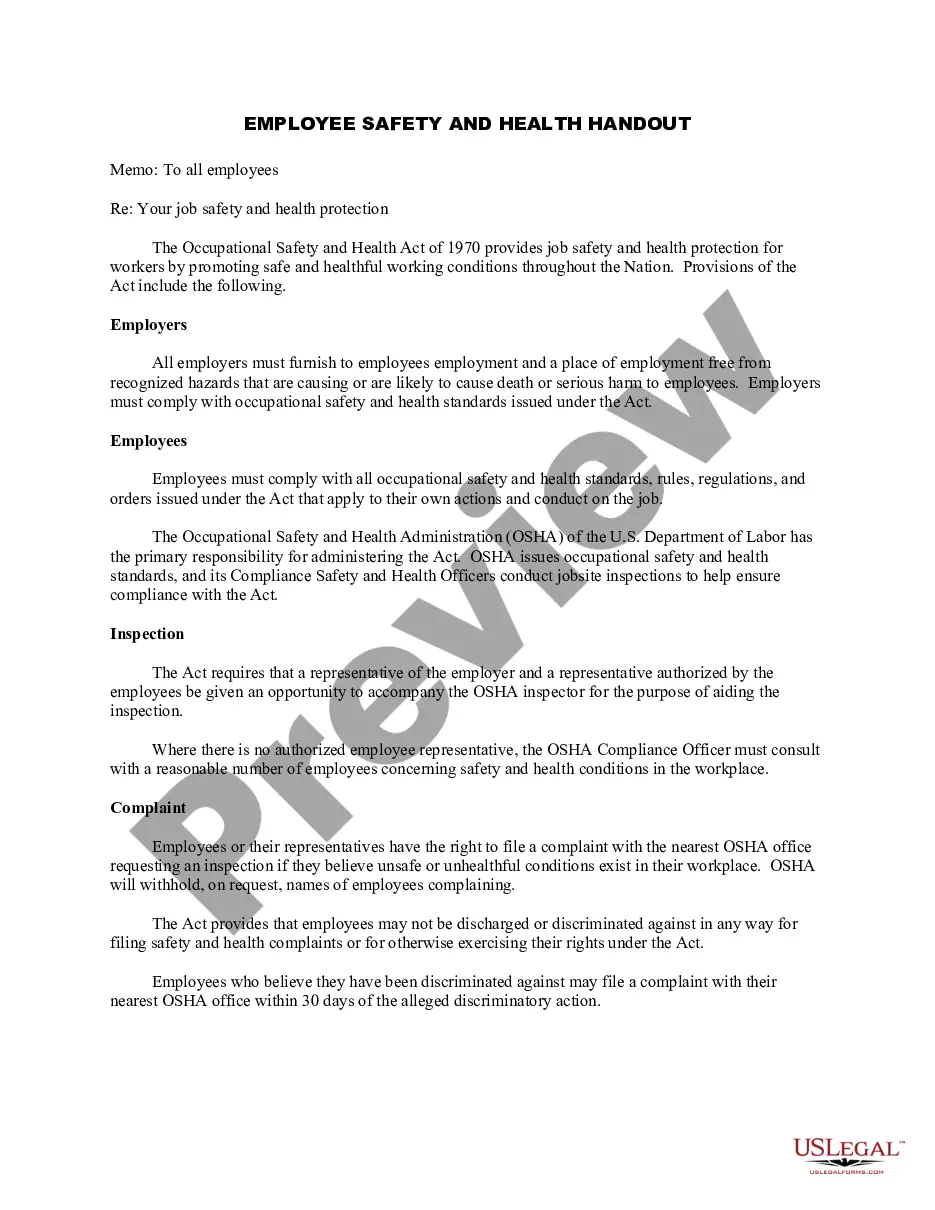

They are required as a part of any compliance obligation to be available and displayed prominently in the workplace. The public has a right to MSDS data upon request. They must be written in English and contain: the name of the chemical (same as on the label)

A Material Safety Data Sheet (MSDS) is a document that contains information on the potential hazards (health, fire, reactivity and environmental) and how to work safely with the chemical product. It is an essential starting point for the development of a complete health and safety program.

We often come across the myth that some information contained in the Safety Data Sheets (SDS) is confidential. A basic rule applies. No confidentiality may be imposed on information that should be included in the Safety Data Sheet. Only one thing can remain concealed in the SDS.

MSDS (Material Safety Data Sheet) is now called an SDS (Safety Data Sheet). Purpose of both MSDS and SDS documents remains unchanged and is to list the information pertaining to the occupational health and safety for the various uses of the substances and products.

Use Guidelines. Chemical Safety's SDS and GHS database is a free service available to organizations of all types. For-profit organizations are granted permission to access Chemical Safety's SDS Search from Chemical Safety's website.

The switch from MSDS to SDS format is expected to increase your workplace safety and make it easier for your business to properly use, store, and dispose of the chemicals you use. However, the transition will also require employers to update their chemical inventory management systems.

They are required as a part of any compliance obligation to be available and displayed prominently in the workplace. The public has a right to MSDS data upon request.

To obtain SDS, get them from the manufacturer.They may be sent with the chemical order (paper copy or e-mail attachment).Otherwise, go to the manufacturer's website and download it or request a copy.