Iowa Assessing the Primary and Support Activities in the Value Chain Approach

Description

How to fill out Assessing The Primary And Support Activities In The Value Chain Approach?

Selecting the appropriate legal document format can be a challenge.

Certainly, there are numerous formats available online, but how do you locate the legal type you require.

Utilize the US Legal Forms website. The platform offers thousands of formats, including the Iowa Evaluating the Core and Support Activities in the Value Chain Method, which can serve both business and personal purposes.

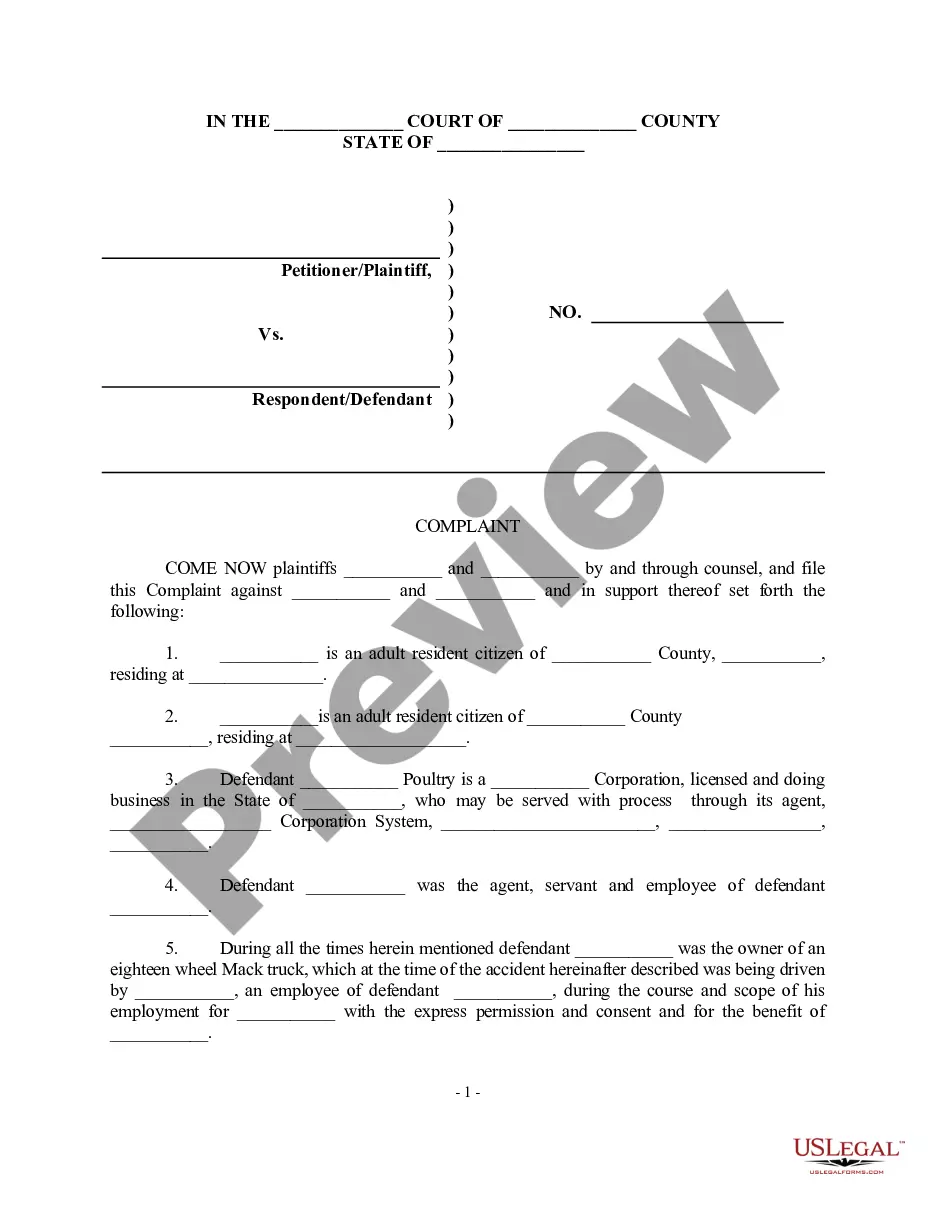

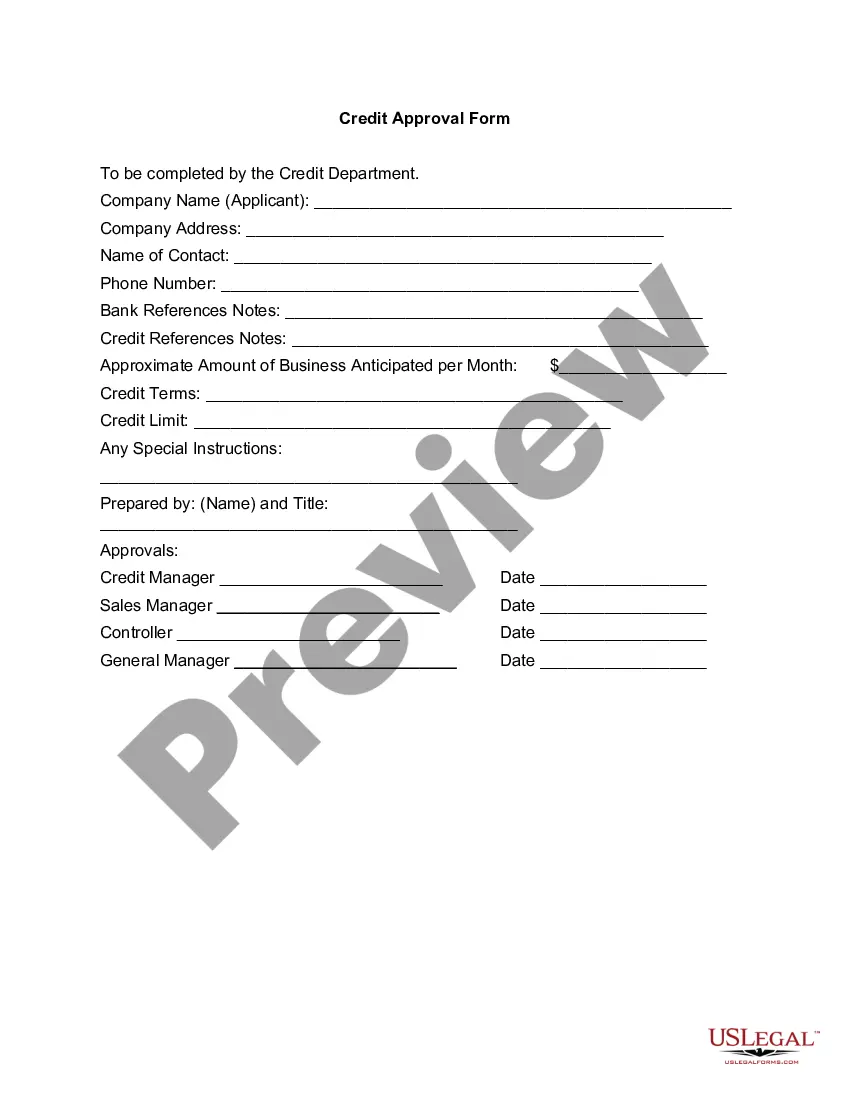

First, ensure you have chosen the correct form for your city/county. You can explore the form using the Review button and examine the form details to verify it is indeed the right one for you.

- All the documents are vetted by experts and adhere to state and federal regulations.

- If you are already registered, Log In to your account and click on the Download button to obtain the Iowa Evaluating the Core and Support Activities in the Value Chain Method.

- Use your account to browse through the legal documents you have purchased previously.

- Go to the My documents section of your account and download another copy of the document you require.

- If you are a new user of US Legal Forms, here are simple steps you can follow.

Form popularity

FAQ

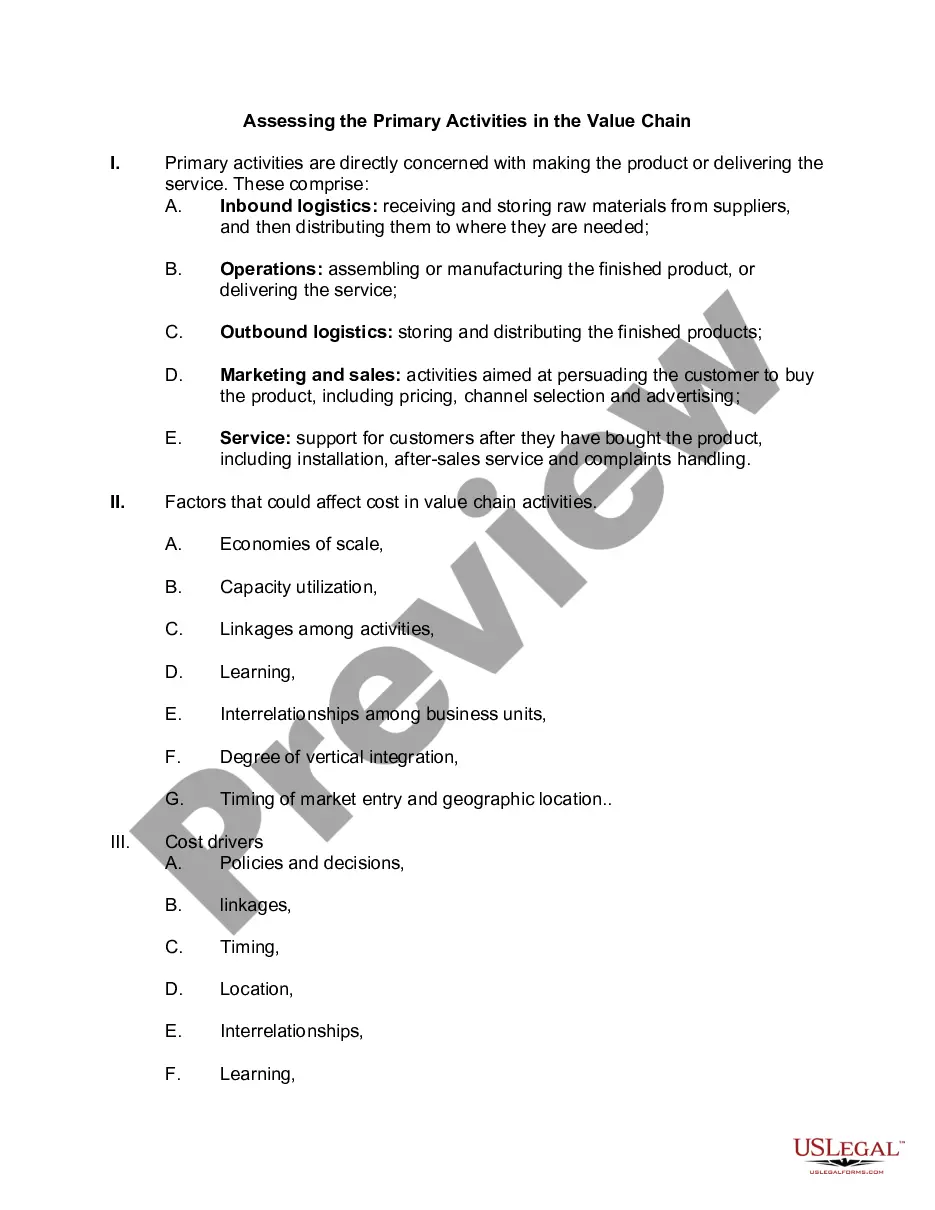

Primary activities in the value chain typically include inbound logistics, operations, outbound logistics, marketing and sales, and service. Each of these plays a critical role in delivering value to the customer. By applying Iowa Assessing the Primary and Support Activities in the Value Chain Approach, businesses can identify and enhance these activities to drive success.

An example of a value chain activity is marketing and sales. This activity directly connects a business with its customers, showing the importance of effectively positioning products in the market. In Iowa Assessing the Primary and Support Activities in the Value Chain Approach, understanding this activity can significantly impact your business's growth and competitiveness.

A primary activity in a value chain could include inbound logistics, which focuses on receiving and storing raw materials for production. This is essential in Iowa Assessing the Primary and Support Activities in the Value Chain Approach, as it sets the stage for efficient operations. Recognizing these activities helps businesses optimize their processes effectively.

The primary activities in a value chain include inbound logistics, operations, outbound logistics, marketing, and sales, all focused on delivering a product or service. In contrast, support activities enhance these primary functions through procurement, technology development, human resources, and company infrastructure. Understanding both sets of activities is crucial for Iowa Assessing the Primary and Support Activities in the Value Chain Approach, as it allows organizations to maximize efficiency and effectiveness.

Support activities are essential functions that help the primary activities to function smoothly. They include procurement, where materials and resources are acquired; technology development, which involves research to innovate; human resources management, focusing on employee recruitment and training; and firm infrastructure like finance and planning. Proper management of these support activities is important for Iowa Assessing the Primary and Support Activities in the Value Chain Approach.

Michael Porter defines primary activities as those directly linked to creating and delivering a product or service, including inbound logistics, operations, outbound logistics, marketing, and sales. Support activities, on the other hand, facilitate the primary activities and include functions like procurement, technology development, human resources, and company infrastructure. Understanding these activities is vital in Iowa Assessing the Primary and Support Activities in the Value Chain Approach.

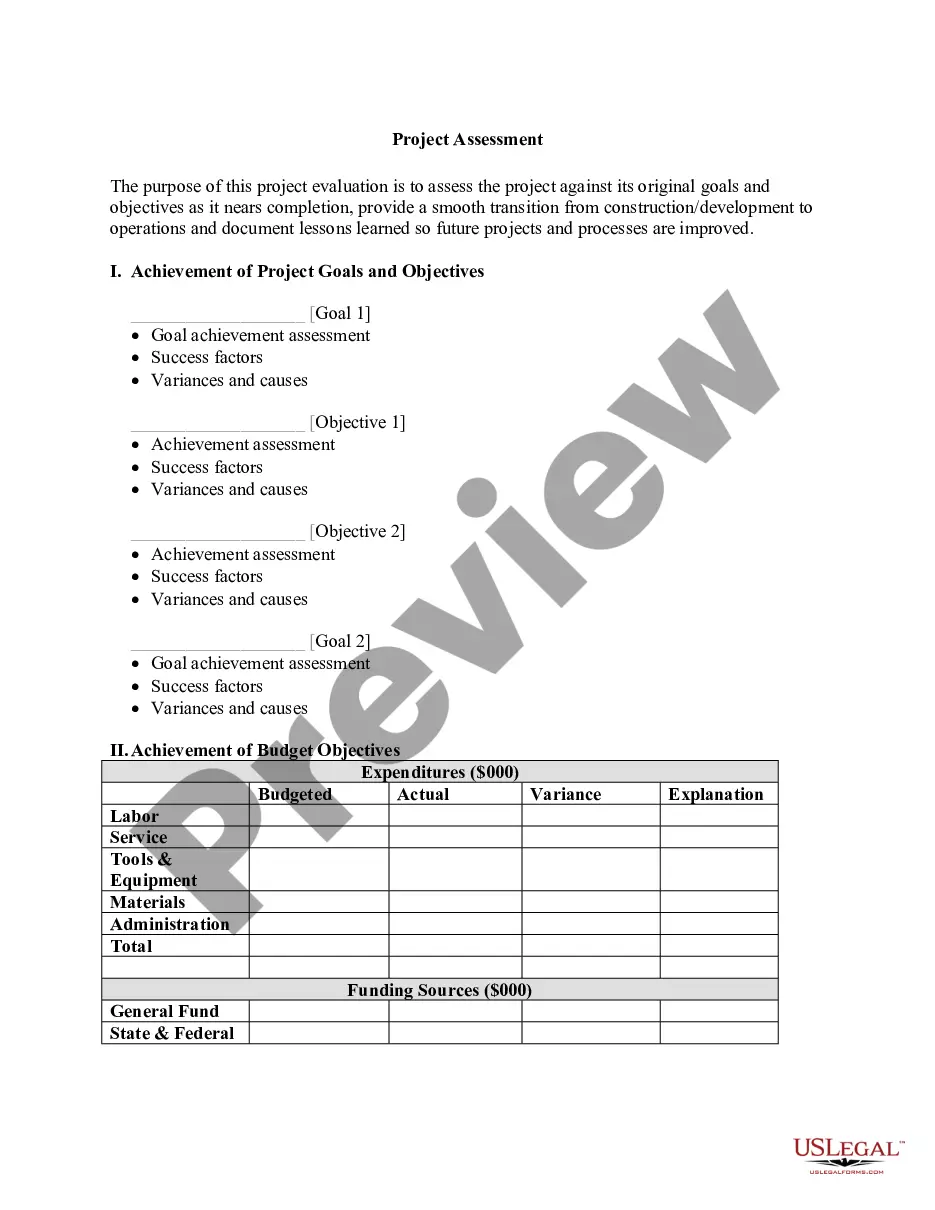

To conduct a value chain assessment, start by identifying your company's primary and support activities. Gather data on each activity's efficiency and effectiveness. Then, analyze how these activities interact to deliver value to customers. This process is crucial for Iowa Assessing the Primary and Support Activities in the Value Chain Approach as it highlights areas for improvement.

Value chain analysis supporting activities form the backbone of primary activities by providing the necessary resources and capabilities. These include functions like human resources management, which ensures a motivated workforce, and technological development, which drives innovation. Understanding these supporting activities is vital for effective Iowa assessing the primary and support activities in the value chain approach.

A value chain consists of a series of interrelated activities that create value through the production and delivery of goods or services. These activities include both primary activities, such as operations and marketing, and the supporting activities that enhance efficiency, like technology development and procurement. By concentrating on these areas, firms can leverage Iowa assessing the primary and support activities in the value chain approach.

In value chain analysis, support activities include functions like technology development, procurement, human resource management, and firm infrastructure. These activities enable the smooth operation of primary activities, leading to improved value creation. Iowa assessing the primary and support activities in the value chain approach highlights the importance of a strong support system for overall success.