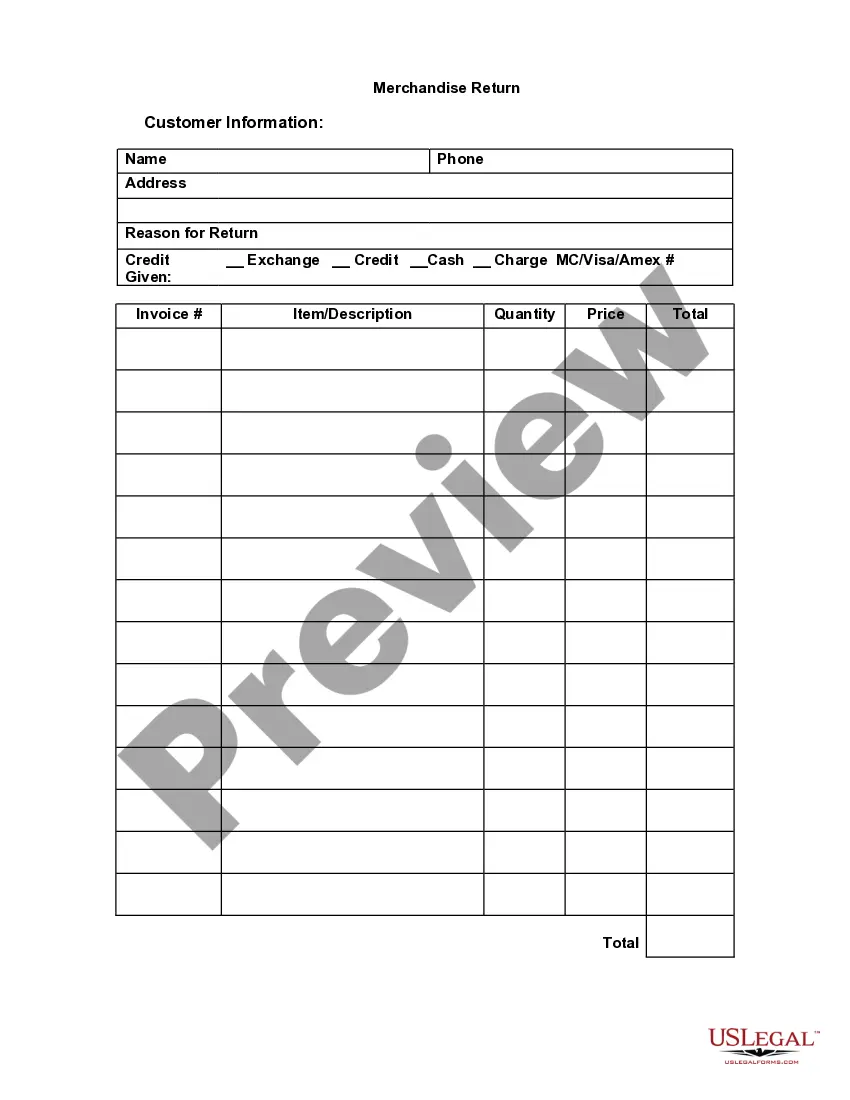

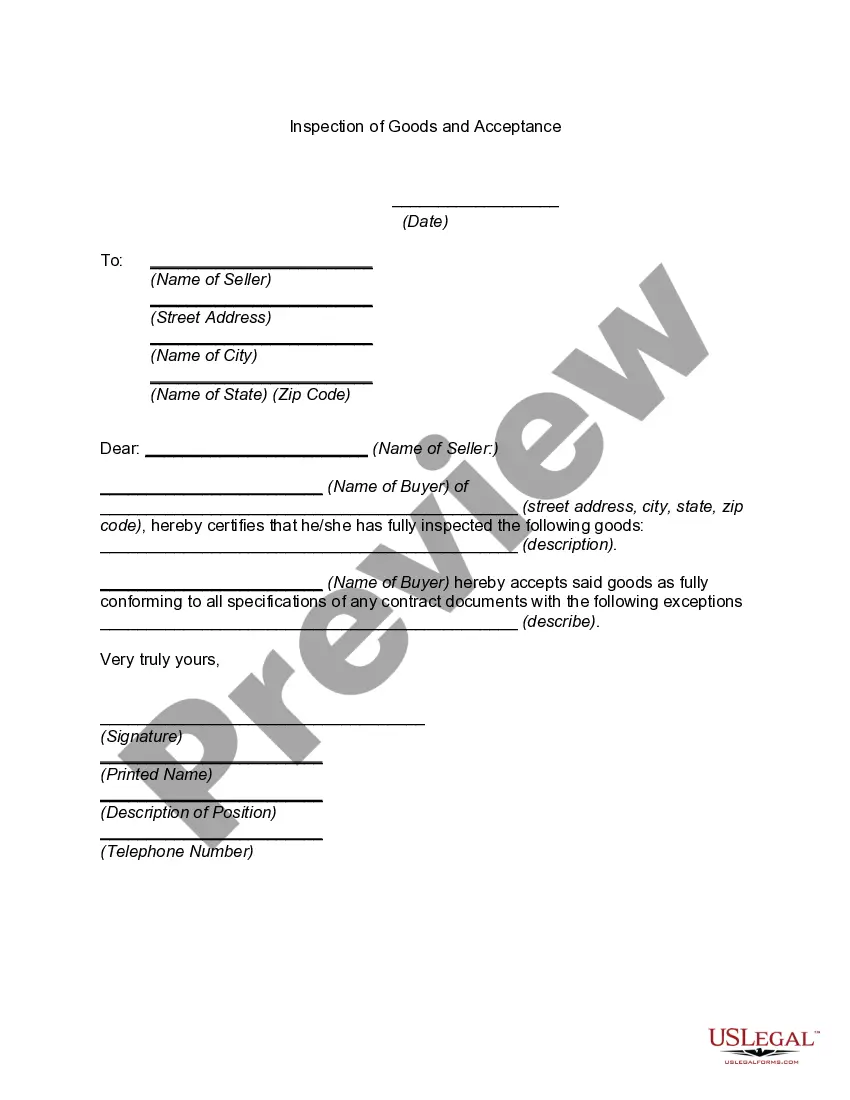

Iowa Inspection of Goods and Acceptance is a procurement process carried out to ensure the quality and conformity of goods delivered to a buyer. This inspection is crucial to determine whether the goods meet the buyer's specifications, standards, and expectations before accepting them. The inspection process involves a thorough examination of the goods based on predefined criteria such as quantity, quality, packaging, labeling, and overall compliance with the purchase agreement. Inspections are typically conducted by qualified inspectors or third-party inspection agencies to maintain objectivity and accuracy. Now, let's delve into different types of Iowa Inspection of Goods and Acceptance: 1. Pre-shipment inspection: This type of inspection is conducted before the goods are shipped from the supplier's location. It ensures that the goods are in compliance with the buyer's requirements and helps identify any discrepancies or defects that can be rectified before shipping. 2. In-process inspection: This inspection is performed during the manufacturing or production process to verify that the goods being produced meet the desired quality standards. It ensures that the manufacturing processes are following the agreed-upon specifications and that potential issues are detected and resolved at an early stage. 3. Post-arrival inspection: This type of inspection is carried out after the goods have been delivered to the buyer's location. It includes a comprehensive assessment of the goods to ensure they are free from any damages or defects that might have occurred during transportation. It also verifies if the goods match the purchase order and meet the agreed-upon quality standards. 4. Periodic inspection: Periodic inspections are conducted at regular intervals to maintain consistency in the quality of goods delivered over time. This type of inspection is particularly important for long-term contracts or when dealing with suppliers that frequently provide goods. 5. Random inspection: Random inspections involve selecting goods for inspection based on a random sampling method. It aims to prevent bias or manipulation and ensure that all goods have an equal chance of being thoroughly examined. Random inspections contribute to fair trade practices and promote transparency. 6. Special inspection: Special inspections are conducted when specific circumstances or concerns arise. These inspections may be carried out due to suspected quality issues, changes in manufacturing techniques or materials, or when there is a need for additional scrutiny. Special inspections cater to unique requirements, providing tailored evaluations to mitigate risks and maintain quality. In summary, Iowa Inspection of Goods and Acceptance is an essential process that safeguards the interests of buyers by ensuring the delivered goods comply with specifications, quality standards, and purchase agreements. Different types of inspections, such as reshipment, in-process, post-arrival, periodic, random, and special inspections, contribute to an effective quality assurance system, promoting transparency and fair trade practices.

Iowa Inspection of Goods and Acceptance

Description

How to fill out Inspection Of Goods And Acceptance?

Discovering the right authorized file format might be a struggle. Needless to say, there are a lot of web templates available on the net, but how will you obtain the authorized form you want? Use the US Legal Forms site. The services delivers thousands of web templates, including the Iowa Inspection of Goods and Acceptance, which you can use for enterprise and private requires. All the kinds are inspected by pros and satisfy federal and state demands.

In case you are currently listed, log in in your profile and then click the Down load switch to obtain the Iowa Inspection of Goods and Acceptance. Use your profile to check through the authorized kinds you may have bought earlier. Go to the My Forms tab of your profile and get another copy of your file you want.

In case you are a whole new consumer of US Legal Forms, listed here are easy guidelines that you should follow:

- Initial, make sure you have selected the proper form for your metropolis/county. You may examine the shape using the Preview switch and look at the shape outline to ensure this is basically the right one for you.

- In case the form does not satisfy your requirements, take advantage of the Seach discipline to find the correct form.

- When you are positive that the shape is proper, click the Buy now switch to obtain the form.

- Choose the pricing plan you desire and enter in the needed info. Design your profile and pay for the order using your PayPal profile or bank card.

- Choose the document file format and acquire the authorized file format in your system.

- Full, edit and produce and indicator the attained Iowa Inspection of Goods and Acceptance.

US Legal Forms will be the greatest library of authorized kinds in which you will find a variety of file web templates. Use the service to acquire expertly-produced files that follow condition demands.