A Strategy for Research and Development

Research and development (R & D) needs to be carefully planned and managed to succeed. It is easy to waste money on developing ideas that go nowhere, but getting it right can lead to business stability, security and long-term profits.

Planning

R & D should be included in your overall business plan. The plan should illustrate the direction you want the business to take and how R & D fits in with your other business activities. Set out clear objectives, time frames and budgets. A clear plan can prevent the project straying from your business goals and wasting valuable resources and money.

You may need to involve staff with specific skills to draw up the plan, for example finance staff to set up budgets. You may also need outside help.

Your plan should set out the steps that need to be taken from the inception of the ideas to the product launch. You should allocate the necessary resources to the project, including funding, staff and time. You might decide to set up a specific team to work on the project.

Management

Good management is vital to reduce risk of failure and realize as many ideas as possible.

To manage R & D projects effectively you should:

" Make sure staff involved in R & D understand the business' overall strategy;

" Ensure these employees understand what is commercially realistic;

" Assess the changing risks and potential of projects as they progress, continually developing a rigorous business case;

" Ensure that intellectual property ownership issues are resolved;

" Recognize when a project isn't going to work; and

" Understand the relative importance of different projects to your business.

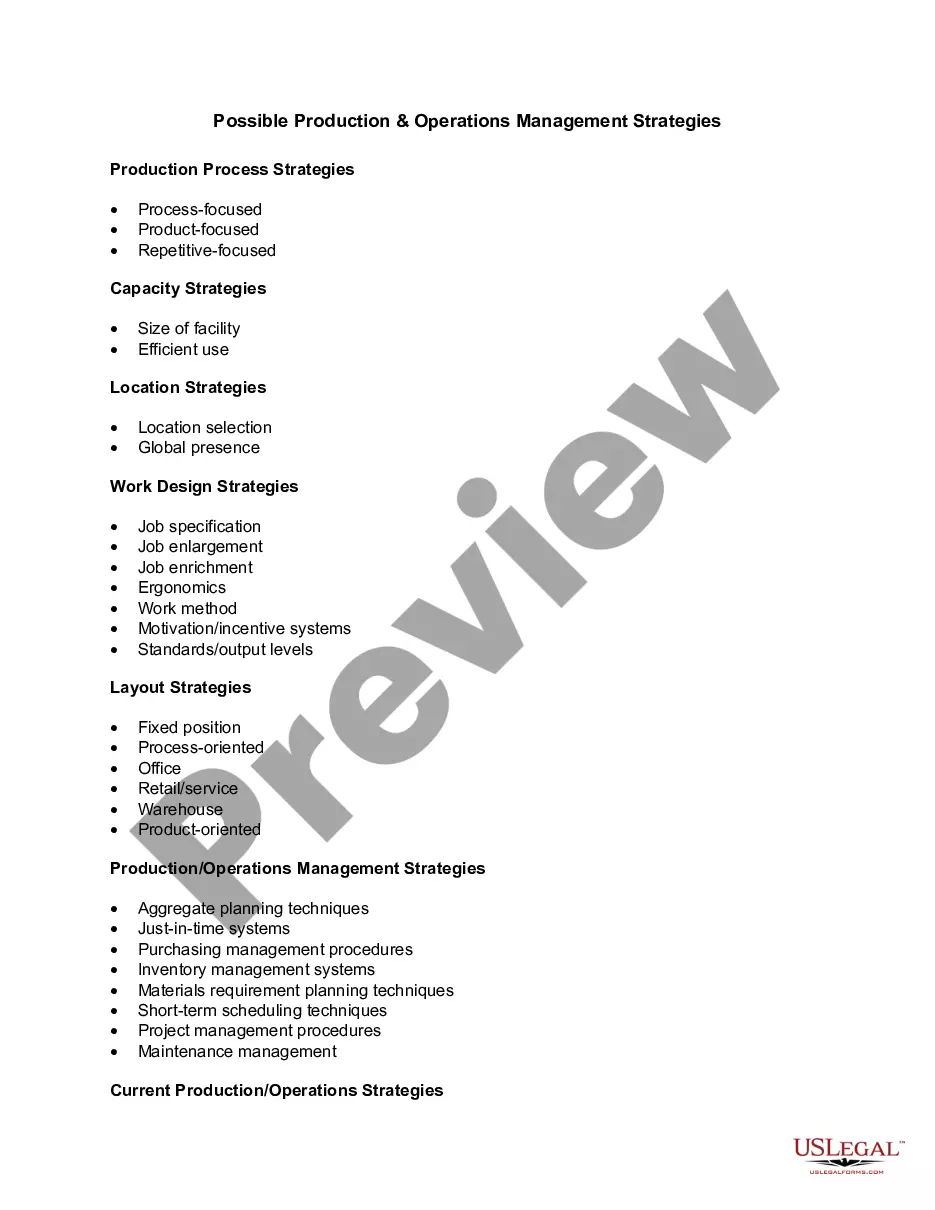

Idaho Possible Production and Operations Management Strategies are a set of techniques and approaches used by businesses in the state of Idaho to effectively manage their production processes and optimize overall operational efficiency. This includes various strategies aimed at planning, organizing, and controlling the resources and activities involved in producing goods or delivering services. The key focus of these strategies is to ensure smooth operations, minimize costs, improve productivity, meet customer demands, and ultimately maximize profitability. By implementing the right production and operations management strategies, businesses in Idaho can gain a competitive edge in their respective industries. Here are some relevant keywords related to Idaho Possible Production and Operations Management Strategies: 1. Lean Manufacturing: This strategy aims to eliminate waste and increase efficiency in the production process by constantly improving operations, reducing costs, and delivering high-quality products consistently. 2. Just-in-Time (JIT): This approach involves minimizing inventory levels by supplying materials and components "just-in-time" for production. JIT helps reduce carrying costs, improve cash flow, and eliminate waste due to excess inventory. 3. Total Quality Management (TQM): TQM is a management philosophy that focuses on meeting customer expectations by continuously improving quality at all levels of the production process. It involves a strong emphasis on employee involvement, process improvement, and customer satisfaction. 4. Six Sigma: A data-driven approach to eliminate defects and errors in the production process. Six Sigma aims to achieve near-perfect quality levels by systematically analyzing and improving processes, reducing variation, and increasing customer satisfaction. 5. Supply Chain Management: This strategy involves the coordination and integration of all activities involved in the procurement, production, and distribution of goods or services. It aims to optimize the flow of materials, information, and finances across the entire supply chain, from suppliers to customers. 6. Outsourcing: Some businesses in Idaho may adopt outsourcing strategies to delegate specific tasks or processes to external vendors or partners. This can help reduce costs, access specialized expertise, improve flexibility, and focus on core competencies. 7. Continuous Improvement: This strategy revolves around constantly seeking opportunities for enhancements throughout the production and operational processes. It involves employee engagement, gathering feedback, making incremental changes, and adopting new technologies or practices staying competitive. 8. Capacity Planning: Effective capacity planning ensures that resources, including labor, machinery, and facilities, are aligned with the demand forecasted in the market. It helps businesses avoid bottlenecks, manage seasonal variations, and maximize production efficiency. 9. Sustainability: Idaho-based businesses may also incorporate sustainable production and operations management strategies to reduce their environmental impact. This includes energy-efficient manufacturing processes, waste reduction initiatives, and responsible sourcing practices. 10. Technology Integration: Leveraging technology such as automation, artificial intelligence (AI), and data analytics can enhance production and operational capabilities. This includes implementing Enterprise Resource Planning (ERP) systems, cloud-based software, and Internet of Things (IoT) devices to optimize processes, track performance, and facilitate decision-making. Overall, Idaho Possible Production and Operations Management Strategies encompass a wide range of approaches aimed at improving efficiency, reducing costs, ensuring quality, and staying competitive in the business landscape. Successful implementation of these strategies allows Idaho-based businesses to thrive and contribute to the state's overall economic growth.