Idaho Aeseptic Techniques

Description

How to fill out Aeseptic Techniques?

US Legal Forms - one of the largest collections of legal documents in the United States - provides a variety of legal document templates available for download or printing.

By using the website, you can access thousands of forms for commercial and personal purposes, organized by categories, states, or keywords. You can obtain the latest forms of documents like the Idaho Aseptic Techniques within moments.

If you already have an account, Log In and download Idaho Aseptic Techniques from the US Legal Forms library. The Download button will appear on every form you view. You can access all previously saved forms from the My documents section of your account.

Process the payment. Use your credit card or PayPal account to complete the transaction.

Choose the format and download the form to your device. Make edits. Fill out, modify, print, and sign the saved Idaho Aseptic Techniques. Each template you add to your account has no expiration date and is yours permanently. Therefore, if you wish to download or print another copy, simply go to the My documents section and click on the form you want. Access the Idaho Aseptic Techniques with US Legal Forms, one of the most comprehensive libraries of legal document templates. Utilize thousands of professional and state-specific templates that meet your business or personal needs.

- If you are new to US Legal Forms, here are easy steps to get started.

- Make sure to select the correct form for your city/county.

- Click the Review button to examine the document's content.

- Check the form description to confirm that you have picked the right form.

- If the form doesn't meet your needs, use the Search field at the top of the screen to find one that does.

- If you are satisfied with the form, confirm your choice by clicking the Get now button.

- Then, select the pricing plan you prefer and enter your details to register for an account.

Form popularity

FAQ

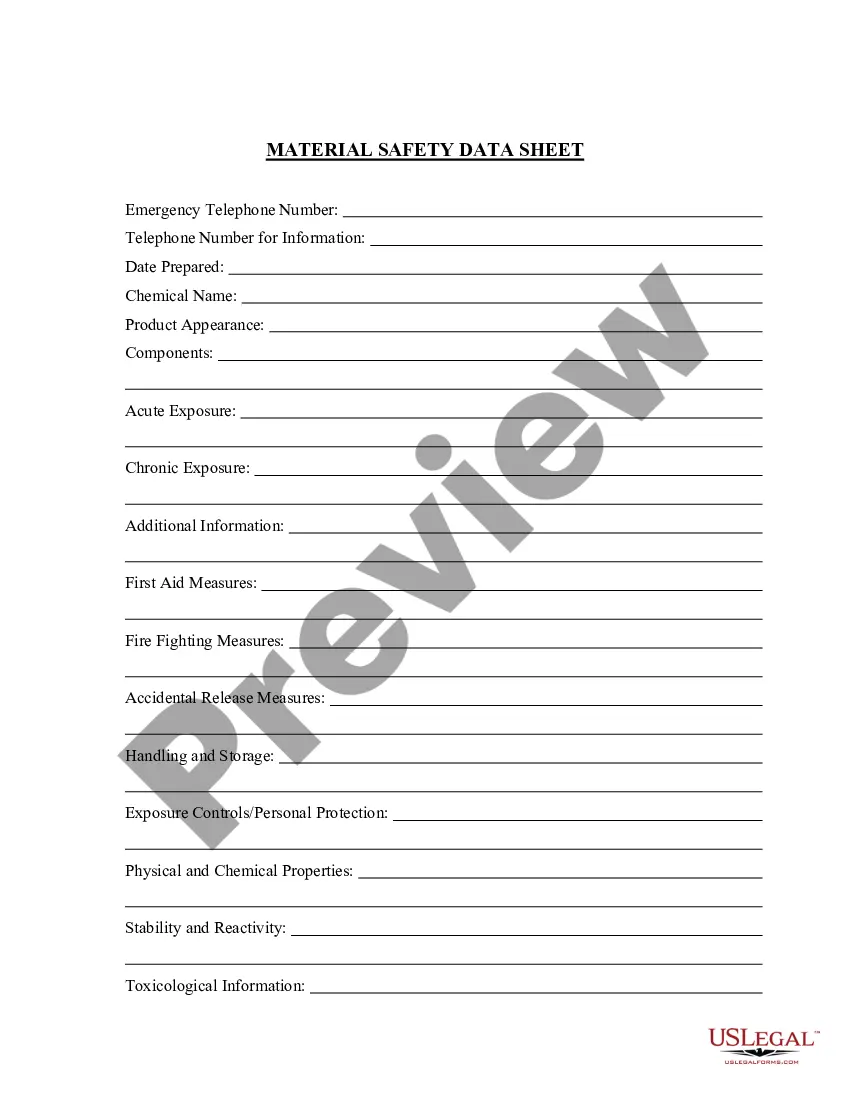

Under federal law, prescription records should typically be maintained for at least two years after the last date of dispensing. This requirement helps ensure compliance and supports the implementation of best practices, such as Idaho Aeseptic Techniques, in medication management. Pharmacies that need a structured method for record retention can benefit from the services provided by uslegalforms.

Types of Aseptic TechniquesSterile technique. The strictest form of aseptic technique, sterile technique is intended to provide a space that has no germs whatsoever.Surgical aseptic technique. This is a strict form of aseptic technique that can be used outside the operating room.Standard aseptic technique.

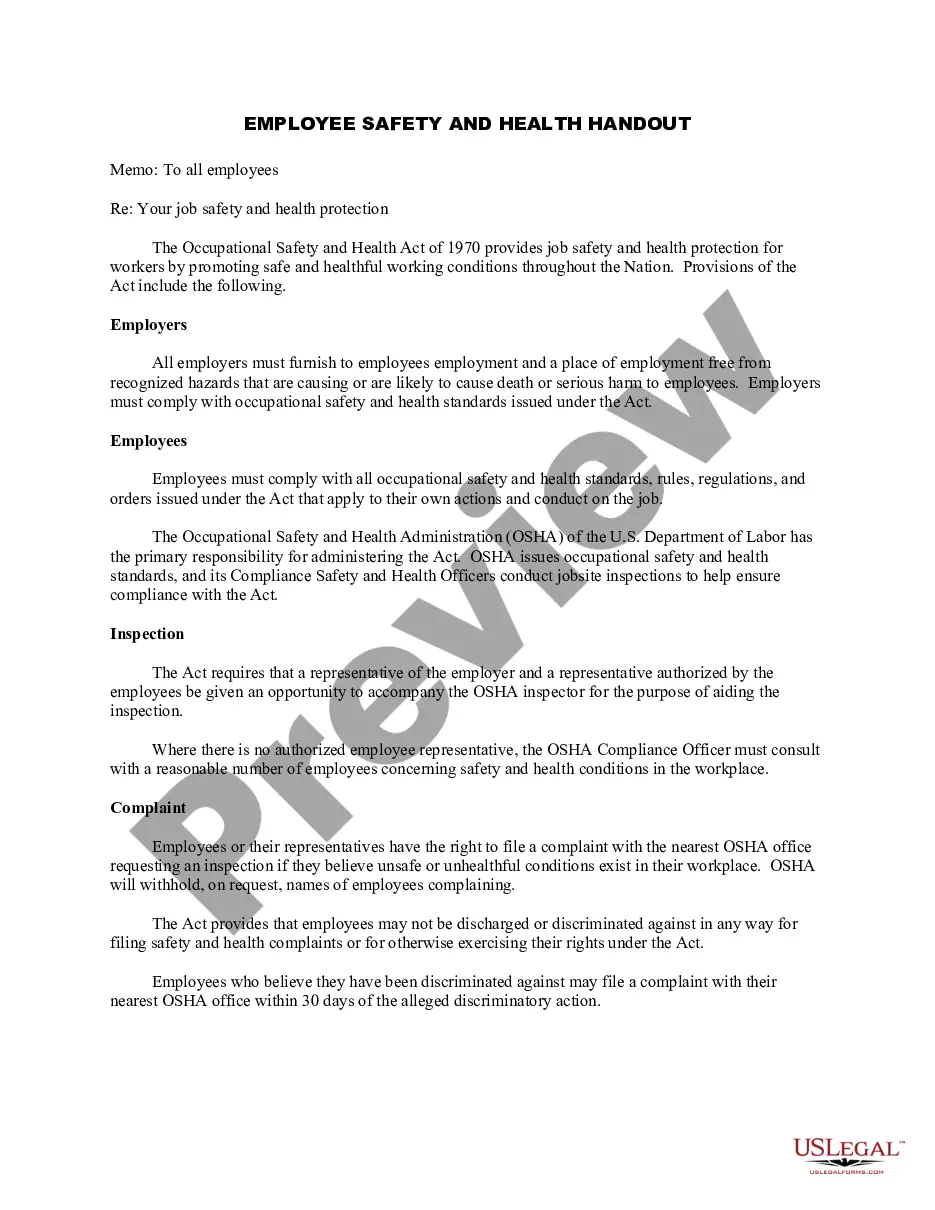

Healthcare professionals use aseptic technique when they are:performing surgical procedures.performing biopsies.dressing surgical wounds or burns.suturing wounds.inserting a urinary catheter, wound drain, intravenous line, or chest tube.administering injections.using instruments to conduct a vaginal examination.More items...?08-Nov-2018

Aseptic technique is a method that involves target-specific practices and procedures under suitably controlled conditions to reduce the contamination from microbes. It is a compulsory laboratory skill to conduct research related in the field of microbiology.

Aseptic techniques range from simple practices, such as using alcohol to sterilize the skin, to full surgical asepsis, which involves the use of sterile gowns, gloves, and masks. Healthcare professionals use aseptic technique practices in hospitals, surgery rooms, outpatient care clinics, and other healthcare settings.

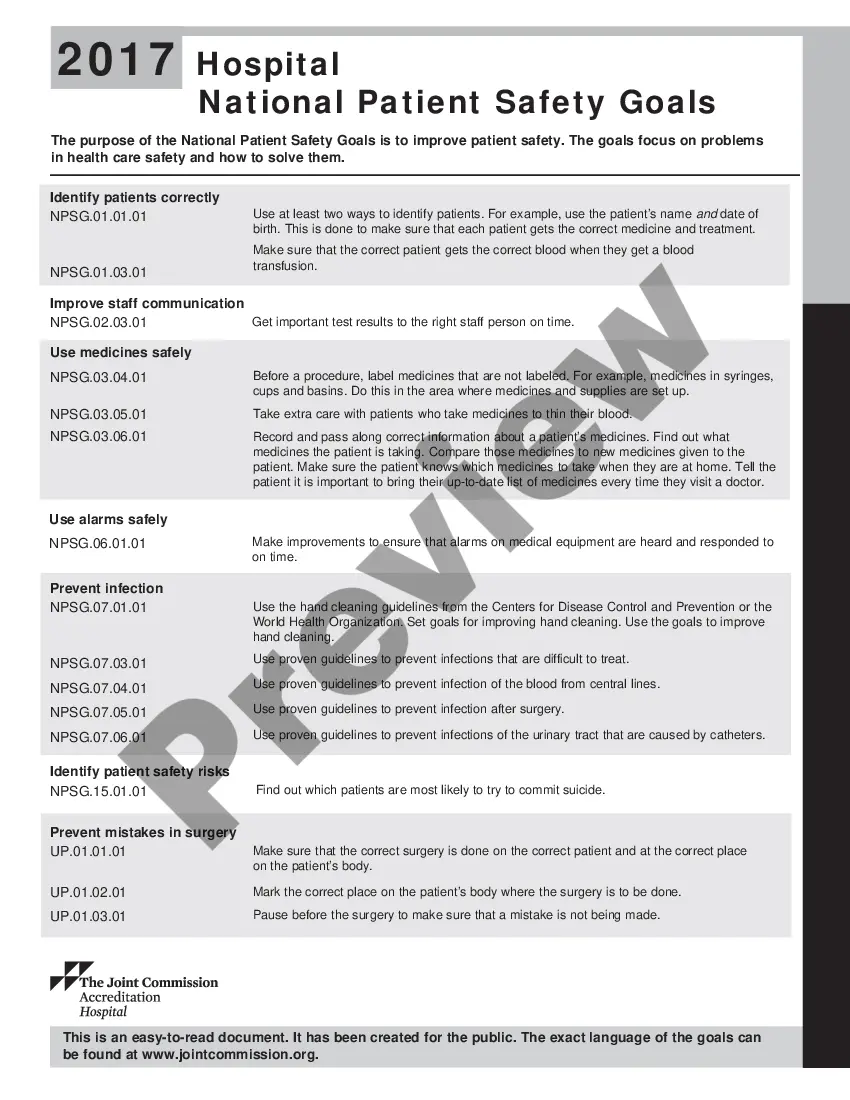

According to The Joint Commission, there are four chief aspects of the aseptic technique: barriers, patient equipment and preparation, environmental controls, and contact guidelines. Each plays an important role in infection prevention during a medical procedure.

These principles include the following: (1) use only sterile items within a sterile field; (2) sterile (scrubbed) personnel are gowned and gloved; (3) sterile personnel operate within a sterile field (sterile personnel touch only sterile items or areas, unsterile personnel touch only unsterile items or areas); (4)

Terms in this set (25) 1) Remove the cap from the culture tube. 2) Reheat the mouth of the culture tube and replace the cap. 3) Get a loopful of the culture. 4) Sterilize the loop by heating it red-hot.

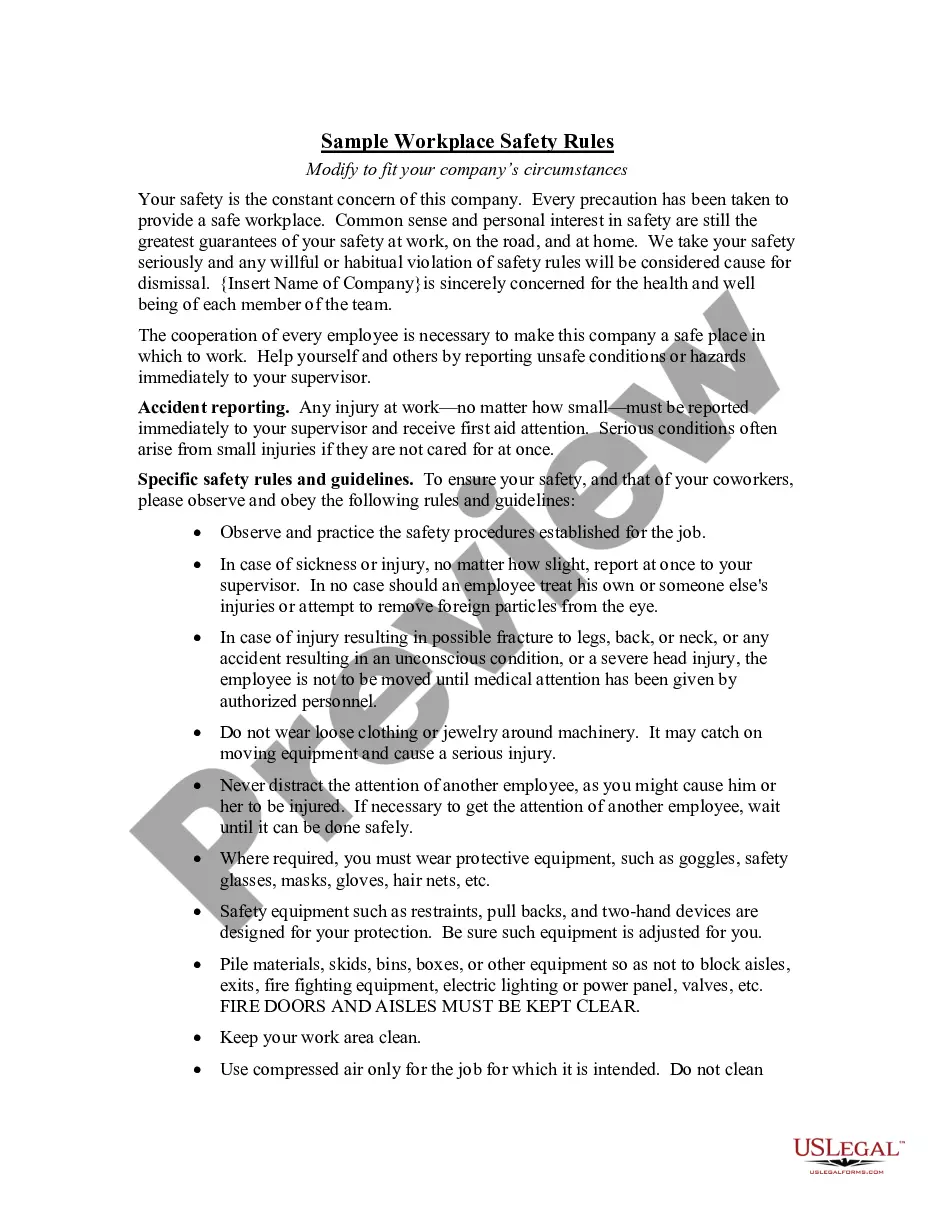

Stages of medical aseptic techniqueHand hygiene.Storage of equipment.Preparing equipment.Consent.Environment.Use of gloves and aprons.Maintaining a sterile field.Equipment disposal.