Idaho Maintenance Assistance — Technician Checklist: A Comprehensive Guide to Efficient Maintenance Processes The Idaho Maintenance Assistance — Technician Checklist is a structured and comprehensive guide aimed at assisting maintenance technicians in carrying out their tasks effectively. This checklist serves as a valuable tool to ensure efficient and systematic maintenance practices, resulting in optimized operational performance and enhanced equipment reliability. It encompasses various key areas of maintenance, covering a wide range of industries such as manufacturing, construction, transportation, and more. Key Keywords: 1. Idaho Maintenance Assistance: This refers to a specialized program or resource available in Idaho that aims to support and provide assistance to maintenance technicians in improving their maintenance processes. 2. Technician Checklist: A systematic list of tasks, procedures, or guidelines that maintenance technicians follow to ensure proper and efficient execution of their duties. 3. Efficient maintenance: Refers to accomplishing maintenance tasks in a timely and cost-effective manner, minimizing downtime and maximizing equipment functionality. 4. Operational performance: The effectiveness and efficiency of equipment, systems, or processes in achieving desired outcomes within specific operational parameters. 5. Equipment reliability: The degree to which equipment can perform its intended function without failure, breakdowns, or unexpected downtime. Types of Idaho Maintenance Assistance — Technician Checklists: 1. Preventive Maintenance Checklist: This type of checklist outlines routine maintenance tasks to be performed at scheduled intervals. It aims to prevent equipment failure, extend equipment lifespan, and reduce the occurrence of unexpected breakdowns. 2. Corrective Maintenance Checklist: This checklist focuses on addressing equipment malfunctions or failures that have already occurred. Maintenance technicians refer to this checklist to troubleshoot and repair equipment efficiently, minimizing downtime. 3. Safety Maintenance Checklist: Safety is of paramount importance in maintenance work. This checklist ensures that maintenance technicians follow safety protocols, use proper protective equipment, and adhere to established safety guidelines while performing maintenance tasks. 4. Facility Maintenance Checklist: Facilities like buildings, grounds, and infrastructure require regular maintenance to ensure a safe and functional environment. This checklist covers tasks such as cleaning, repairs, inspections, and general upkeep. 5. Equipment-specific Maintenance Checklist: Different types of equipment demand specific maintenance requirements. This checklist focuses on equipment-specific tasks, such as lubrication, calibration, filter replacements, and inspections, to ensure optimal performance and longevity. By utilizing the Idaho Maintenance Assistance — Technician Checklist, maintenance technicians can streamline their processes, reduce errors, improve equipment reliability, and ultimately contribute to the overall efficiency and productivity of the organization. With the flexibility to adapt and customize the checklist as per specific industry requirements, this resource serves as an indispensable tool for maintenance professionals across various sectors in Idaho.

Idaho Maintenance Assistance - Technician Checklist

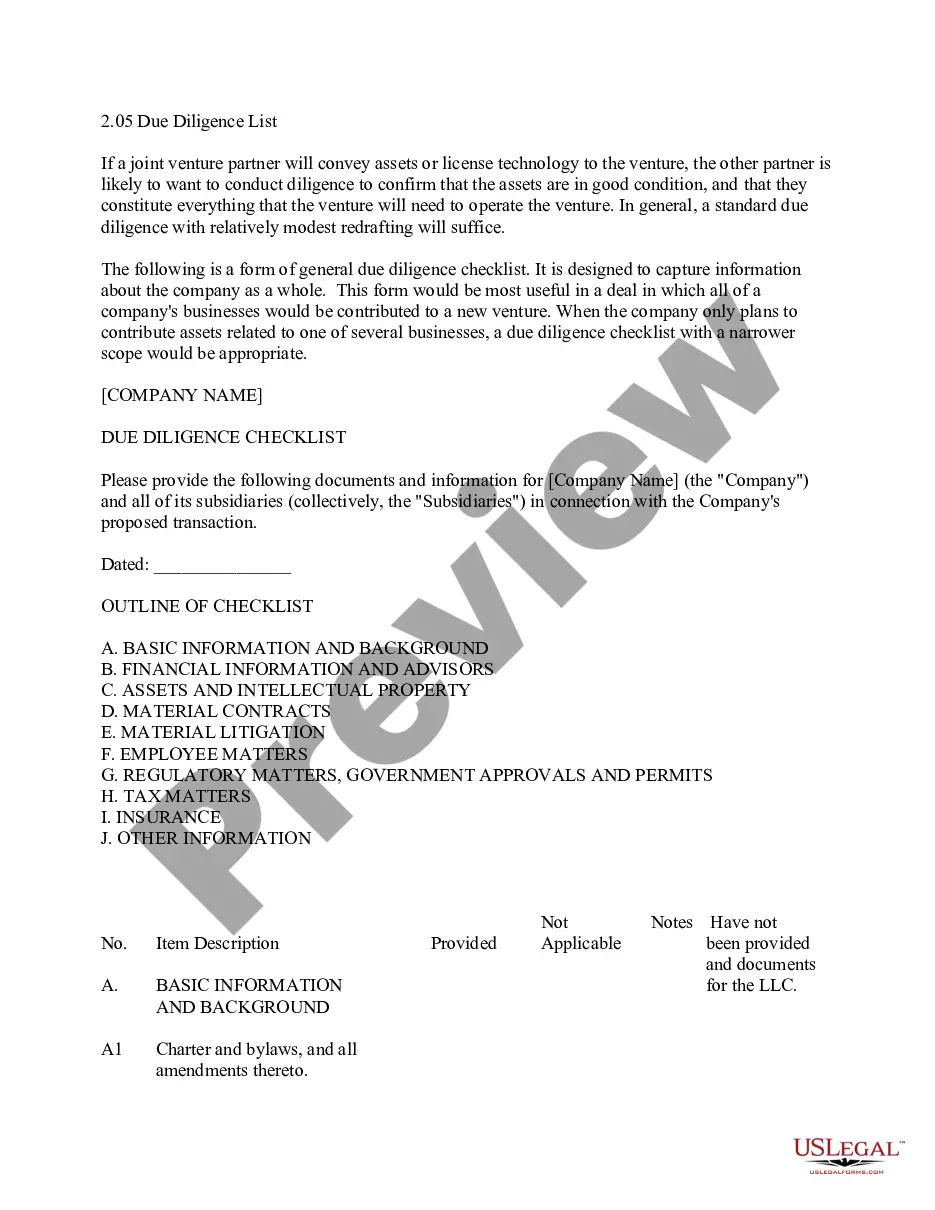

Description

How to fill out Idaho Maintenance Assistance - Technician Checklist?

Choosing the right legitimate papers format could be a battle. Obviously, there are a lot of layouts accessible on the Internet, but how do you obtain the legitimate type you want? Take advantage of the US Legal Forms internet site. The service gives thousands of layouts, like the Idaho Maintenance Assistance - Technician Checklist, that can be used for company and personal requirements. Every one of the forms are checked by pros and meet federal and state specifications.

Should you be presently signed up, log in to your account and then click the Down load key to find the Idaho Maintenance Assistance - Technician Checklist. Use your account to appear through the legitimate forms you have ordered in the past. Visit the My Forms tab of your respective account and acquire another backup of your papers you want.

Should you be a fresh customer of US Legal Forms, listed below are straightforward directions so that you can adhere to:

- Initial, make certain you have selected the right type to your metropolis/area. You are able to look over the shape using the Preview key and look at the shape explanation to make sure it will be the right one for you.

- In case the type fails to meet your needs, make use of the Seach discipline to get the correct type.

- When you are positive that the shape is suitable, select the Acquire now key to find the type.

- Select the rates plan you desire and enter the required information and facts. Create your account and buy the transaction using your PayPal account or charge card.

- Opt for the document file format and obtain the legitimate papers format to your gadget.

- Total, modify and produce and signal the attained Idaho Maintenance Assistance - Technician Checklist.

US Legal Forms will be the greatest library of legitimate forms for which you can find a variety of papers layouts. Take advantage of the service to obtain appropriately-manufactured papers that adhere to express specifications.