Idaho Maintenance Supervisor Checklist

Category:

State:

Multi-State

Control #:

US-382EM

Format:

Word;

Rich Text

Instant download

Description

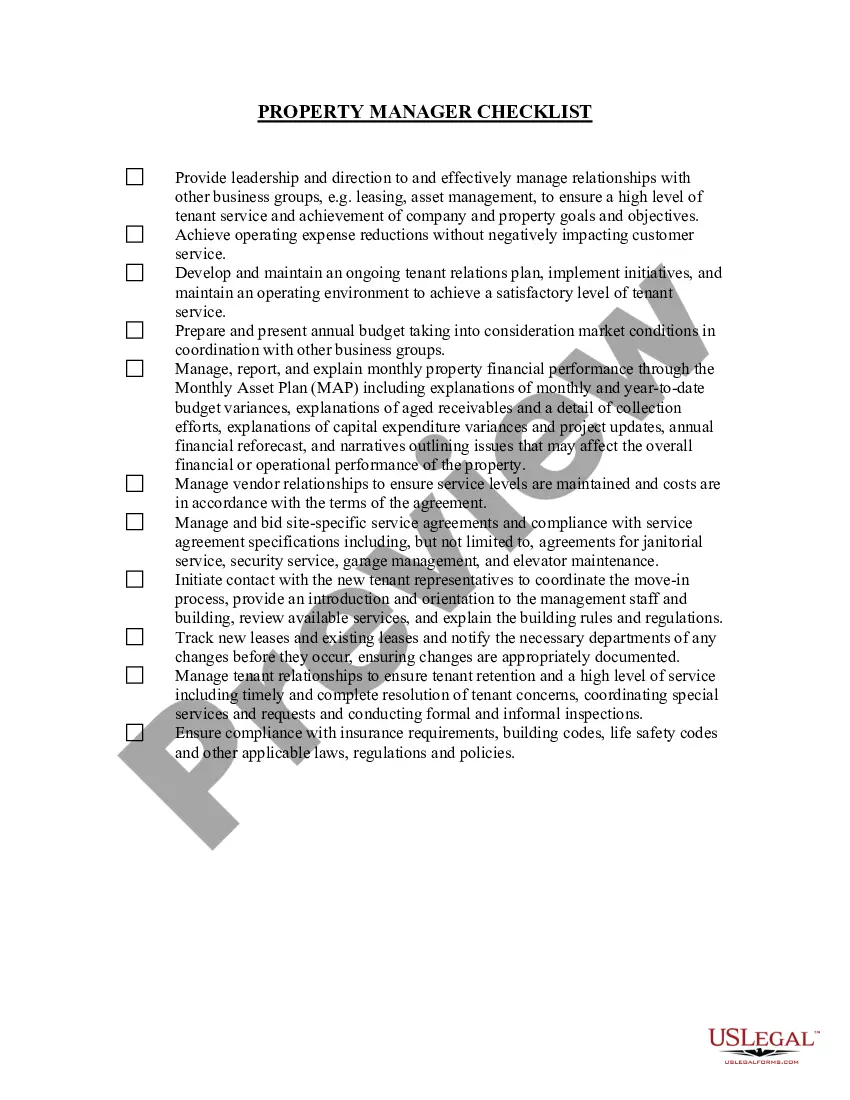

This form is used to list the potential duties of a maintenance supervisor.

How to fill out Maintenance Supervisor Checklist?

You can invest time online looking for the legal document format that satisfies the state and federal requirements you need.

US Legal Forms provides a vast array of legal templates that are vetted by professionals.

You can retrieve or print the Idaho Maintenance Supervisor Checklist from my support.

If available, utilize the Preview button to view the document format as well.

- If you possess a US Legal Forms account, you may sign in and then click the Obtain button.

- After that, you may complete, modify, print, or sign the Idaho Maintenance Supervisor Checklist.

- Every legal document format you purchase is yours permanently.

- To acquire another copy of the purchased form, go to the My documents tab and click the corresponding button.

- If you are using the US Legal Forms website for the first time, follow the straightforward instructions below.

- First, ensure that you have selected the correct document format for your state/city of choice.

- Check the form description to verify you have chosen the accurate form.