This is a tooling agreement between the buyer and vendor. The document describes the description of tooling, the replacement value of tooling, location of tooling, and the relationship of the parties in all their dealings.

Idaho Tooling Agreement

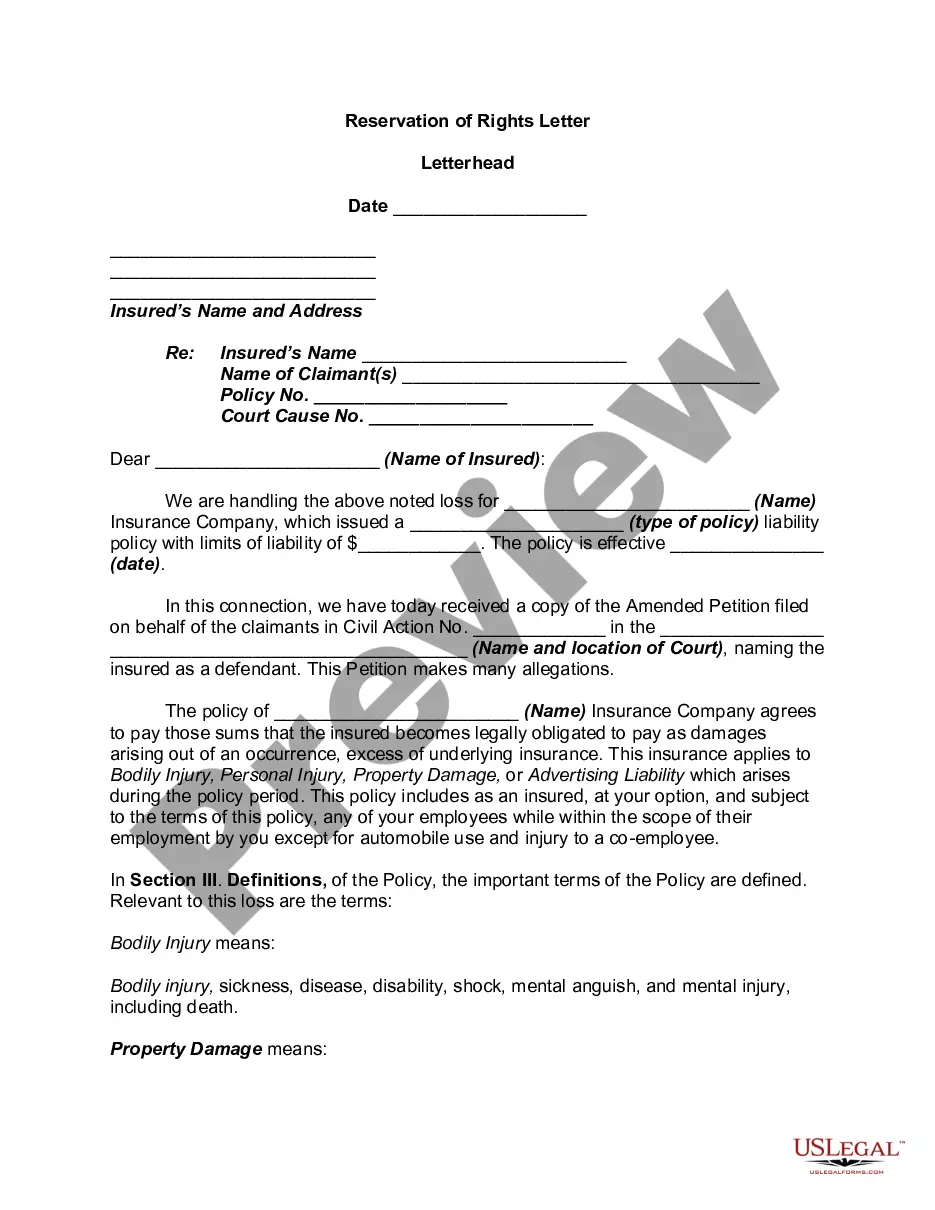

Description

How to fill out Tooling Agreement?

If you want to complete, download, or print out legitimate record templates, use US Legal Forms, the largest collection of legitimate varieties, that can be found on the Internet. Use the site`s easy and convenient lookup to obtain the documents you want. A variety of templates for company and specific reasons are sorted by categories and claims, or keywords and phrases. Use US Legal Forms to obtain the Idaho Tooling Agreement in a couple of mouse clicks.

When you are presently a US Legal Forms client, log in in your accounts and then click the Obtain key to get the Idaho Tooling Agreement. You can even gain access to varieties you in the past delivered electronically within the My Forms tab of your own accounts.

If you work with US Legal Forms initially, refer to the instructions below:

- Step 1. Ensure you have chosen the shape for your correct town/country.

- Step 2. Take advantage of the Preview method to look through the form`s content. Do not overlook to see the explanation.

- Step 3. When you are not satisfied with all the kind, use the Look for area near the top of the monitor to find other types of your legitimate kind web template.

- Step 4. When you have identified the shape you want, go through the Acquire now key. Choose the costs program you like and put your accreditations to sign up to have an accounts.

- Step 5. Process the transaction. You should use your credit card or PayPal accounts to finish the transaction.

- Step 6. Select the formatting of your legitimate kind and download it on your device.

- Step 7. Comprehensive, revise and print out or sign the Idaho Tooling Agreement.

Each legitimate record web template you purchase is yours eternally. You have acces to each and every kind you delivered electronically in your acccount. Click on the My Forms portion and select a kind to print out or download again.

Contend and download, and print out the Idaho Tooling Agreement with US Legal Forms. There are millions of professional and status-particular varieties you may use for your company or specific requirements.

Form popularity

FAQ

(1) An action for breach of any contract for sale must be commenced within four (4) years after the cause of action has accrued. By the original agreement the parties may reduce the period of limitation to not less than one (1) year but may not extend it.

For collection of a debt on an account, where there is an agreement in writing, the statute of limitations is five years. (Refer to §5-216.) For collection of a debt on an account, where there is an oral agreement, the statute of limitations is four years. (Refer to §5-217.)

(a) Any person calling the number "911" for the purpose of making a false alarm or complaint and reporting false information which could or does result in the emergency response of any firefighting, police, medical or other emergency services shall be guilty of a misdemeanor and upon conviction thereof shall be ...

Search Idaho Statutes Contracts may be oral. All contracts may be oral except such as are specially required by statute to be in writing.

For written contracts, the statute of limitations is five years. (Refer to §5-216.) For oral contracts, the statute of limitations is four years. (Refer to §5-217.)

In Idaho, whether your potential case involves damage to real property (your house or your land, for example) or personal property (including damage to vehicles), it must be filed within three years, ing to Idaho Code section 5-218.

28-2-607. Effect of acceptance ? Notice of breach ? Burden of establishing breach after acceptance ? Notice of claim or litigation to person answerable over. (1) The buyer must pay at the contract rate for any goods accepted.

5-216. Action on written contract. Within five (5) years: An action upon any contract, obligation or liability founded upon an instrument in writing.