Illinois Inspection of Goods and Acceptance is a crucial step in the business transaction process, aimed at ensuring the quality, quantity, and conformance of goods received by buyers or clients. This inspection serves as a protection mechanism for individuals or businesses involved in the purchasing or receiving of products, as it allows them to inspect the goods thoroughly before accepting them. The purpose of the Illinois Inspection of Goods and Acceptance is to verify that the goods received match the specifications, description, and quality standards agreed upon in the contract or purchase order. This inspection can be performed by the buyer or a designated inspector who examines the goods for any defects, damages, or non-compliance issues. Key aspects covered during the Illinois Inspection of Goods and Acceptance include: 1. Quality Assurance: The inspection focuses on confirming that the received goods meet the required quality standards. This involves checking for any visible defects in material, workmanship, or performance. 2. Quantity Verification: The inspector ensures that the received quantity matches what was ordered. This includes counting individual units, measuring bulk goods, or weighing as applicable. 3. Packaging and Labeling Compliance: The inspection ensures that the goods are packaged and labeled correctly, adhering to any specific requirements mentioned in the order or relevant regulations. 4. Documentation Review: The inspector may review relevant documents, such as invoices, packing slips, certificates, or test reports, to ensure accuracy and compliance. 5. Non-Conformance Identification: If any deviations or non-compliance issues are found during the inspection, they are documented, and appropriate actions, such as rejection, replacement, or negotiation, are initiated. Different types of Illinois Inspection of Goods and Acceptance may include: 1. Reshipment Inspection: This inspection occurs before the goods are shipped from the supplier's location. It provides an opportunity for the buyer to verify the goods' quality, quantity, and compliance with specifications agreed upon. 2. Receiving Inspection: This inspection is performed upon receipt of the goods at the buyer's premises. It allows the buyer to ensure that the goods delivered match the order and are in acceptable condition. 3. In-Process Inspection: This inspection takes place during the manufacturing or assembly process of the goods. It aims to identify and rectify any quality issues before the final product is completed. In conclusion, the Illinois Inspection of Goods and Acceptance plays a vital role in protecting the rights of buyers and ensuring the quality and compliance of received goods. By conducting thorough inspections, individuals and businesses can mitigate risks, minimize disputes, and maintain high standards in their procurement processes.

Illinois Inspection of Goods and Acceptance

Description

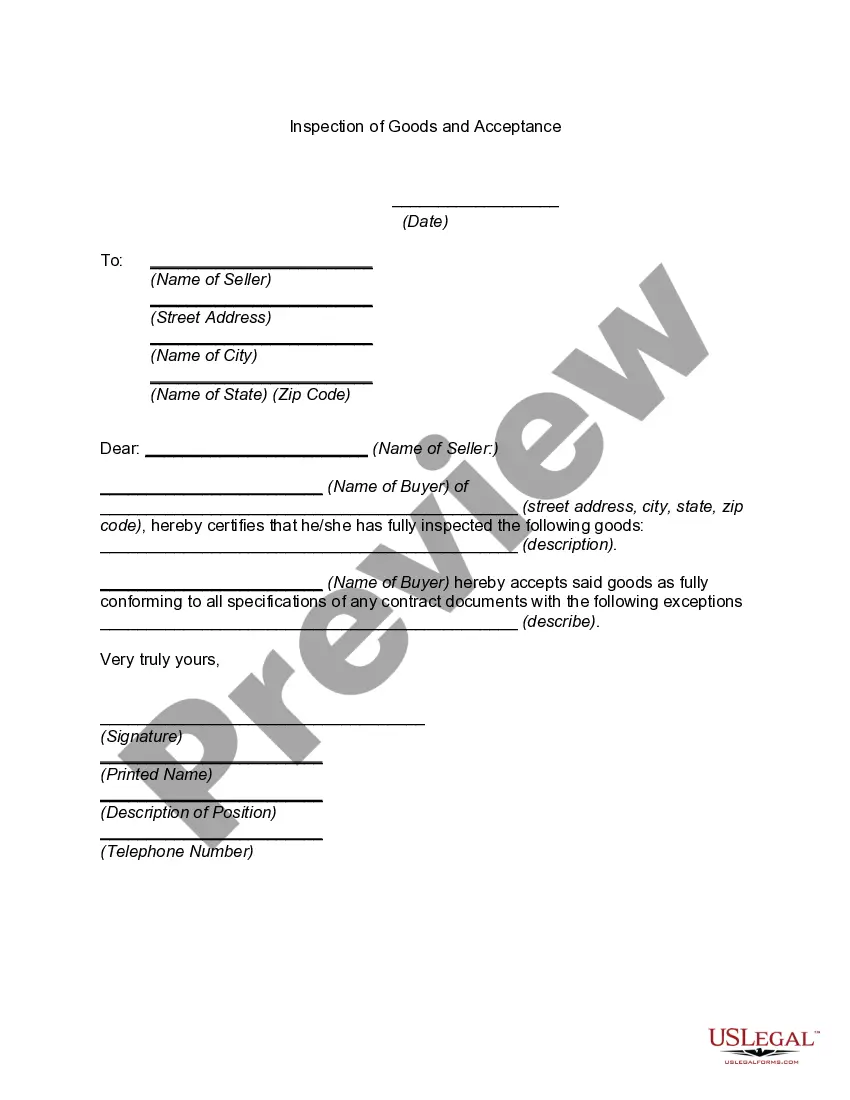

How to fill out Inspection Of Goods And Acceptance?

Finding the right lawful document web template might be a struggle. Naturally, there are plenty of layouts accessible on the Internet, but how will you discover the lawful form you need? Make use of the US Legal Forms site. The service delivers thousands of layouts, for example the Illinois Inspection of Goods and Acceptance, which you can use for business and personal demands. All of the types are examined by professionals and meet state and federal requirements.

If you are presently registered, log in for your profile and then click the Obtain key to get the Illinois Inspection of Goods and Acceptance. Utilize your profile to look throughout the lawful types you might have bought earlier. Proceed to the My Forms tab of your profile and acquire an additional duplicate from the document you need.

If you are a whole new customer of US Legal Forms, listed here are easy instructions for you to follow:

- Very first, ensure you have selected the appropriate form for your metropolis/region. You are able to examine the form using the Preview key and study the form explanation to make sure this is the right one for you.

- In case the form fails to meet your expectations, make use of the Seach area to discover the appropriate form.

- Once you are positive that the form is proper, click the Acquire now key to get the form.

- Select the prices prepare you desire and type in the essential information and facts. Build your profile and pay money for the transaction with your PayPal profile or charge card.

- Select the file format and acquire the lawful document web template for your product.

- Complete, edit and produce and indication the obtained Illinois Inspection of Goods and Acceptance.

US Legal Forms may be the most significant catalogue of lawful types for which you can discover various document layouts. Make use of the company to acquire professionally-manufactured papers that follow condition requirements.

Form popularity

FAQ

Under the UCC, the primary obligation of a buyer of goods is to pay for the goods. The general rule is that the buyer must accept and pay for the goods when the seller has deliveredor, to use more technical language, tendered delivery ofthe goods.

An express act or implication by conduct that manifests assent to the terms of an offer in a manner invited or required by the offer so that a binding contract is formed.

(1) Acceptance of goods occurs when the buyer. (a) after a reasonable opportunity to inspect the goods signifies to the seller that the goods are conforming or that he will take or retain them in spite of their nonconformity; or.

Rejection of non conforming goods should be made by a buyer in a reasonable time after the goods are delivered. If the goods are non conforming and the buyer has rejected the goods, the buyer has no liability to pay for the goods.

The Seller's Primary Obligation Under the UCC, a seller's primary obligation is "tender of delivery." In other words, delivering the goods to the buyer. In some cases, tender of delivery will involve the seller shipping or otherwise transporting goods to the buyer.

When the person to whom a proposal is made signifies their assent, it is an "acceptance" of their offer, also called an agreement. For example, if someone gives a gift and another receives it, then they have accepted the gift; therefore, having acceptance.

(1) Acceptance of goods occurs when the buyer (a) after a reasonable opportunity to inspect the goods signifies to the seller that the goods are conforming or that he will take or retain them in spite of their nonconformity; or (b) fails to make an effective rejection as provided by subsection (1) of section 42a-2-602,

In a shipment contract, the seller has four duties: (1) to deliver the goods to a carrier; (2) to deliver the goods with a reasonable contract for their transportation; (3) to deliver them with proper documentation for the buyer; and (4) to promptly notify the buyer of the shipment (UCC, Section 2-504).

Duties of sellerHe should give a proper title to the goods which he has to pass to the buyer. He should deliver the goods according to the terms of the agreement. He should ensure that the goods supplied should be agreed to the implied condition and warranties.

The general duty of the seller is this: to make a timely delivery of conforming goods. Uniform Commercial Code, Sections 2-301and 2-309.