Title: Indiana Manufacturer Analysis Checklist: A Comprehensive Evaluation Tool for Manufacturing Businesses Introduction: The Indiana Manufacturer Analysis Checklist is an extensive evaluation tool designed specifically for manufacturing businesses operating in the state of Indiana. This checklist aims to assess various aspects of a manufacturer's operations, identify potential areas of improvement, and ensure compliance with state regulations. By employing this checklist, manufacturers can gain valuable insights into their performance, enhance efficiency, and streamline their operations to thrive in Indiana's highly competitive manufacturing industry. Keywords: Indiana manufacturer, analysis checklist, manufacturing businesses, evaluation tool, areas of improvement, state regulations, performance, efficiency, operations, competitive industry. Types of Indiana Manufacturer Analysis Checklists: 1. Compliance and Regulatory Checklist: This type of checklist focuses on ensuring that manufacturers adhere to all relevant state regulations governing areas such as environmental protection, health and safety, labor laws, and product quality standards. It covers key aspects like permits and licenses, workplace safety protocols, waste management, and compliance with quality certifications. The compliance and regulatory checklist ensures that manufacturers meet legal requirements, avoiding penalties and fostering responsible business practices. Keywords: compliance, regulatory checklist, state regulations, environmental protection, health and safety, labor laws, product quality standards, permits and licenses, workplace safety protocols, waste management, quality certifications, responsible business practices. 2. Operational Efficiency Checklist: Manufacturers often face challenges related to operational inefficiencies, which can hinder profitability and growth. This checklist evaluates various operational aspects, including production processes, supply chain management, inventory control, equipment maintenance, and workforce optimization. It helps identify bottlenecks, streamline workflows, reduce production costs, and improve overall operational efficiency. Keywords: operational efficiency, production processes, supply chain management, inventory control, equipment maintenance, workforce optimization, bottlenecks, workflows, production costs. 3. Quality Control Checklist: Quality control is crucial for manufacturers to deliver products that meet customer expectations and comply with industry standards. This checklist focuses on ensuring that manufacturers implement robust quality control measures across their production lines. It covers areas like raw material inspection, product testing, quality assurance protocols, documentation practices, and customer feedback analysis. By adhering to this checklist, manufacturers can enhance product quality and customer satisfaction. Keywords: quality control, raw material inspection, product testing, quality assurance protocols, documentation practices, customer feedback analysis, product quality, customer satisfaction. 4. Sustainability and Environmental Checklist: With increasing emphasis on sustainable practices, this checklist helps manufacturers evaluate their environmental impact and adopt eco-friendly strategies. It assesses areas such as energy consumption, waste minimization, recycling initiatives, water usage, emissions reduction, and responsible sourcing. By integrating sustainable practices into their operations, manufacturers can reduce their carbon footprint, enhance reputation, and attract eco-conscious consumers. Keywords: sustainability, environmental checklist, eco-friendly strategies, energy consumption, waste minimization, recycling initiatives, water usage, emissions reduction, responsible sourcing, carbon footprint, reputation, eco-conscious consumers. Conclusion: The Indiana Manufacturer Analysis Checklist is a valuable resource for manufacturers operating in Indiana, enabling them to assess their compliance with state regulations, improve operational efficiency, enhance product quality, and embrace sustainable practices. By leveraging the appropriate type of checklist, manufacturers can gain a competitive edge in Indiana's thriving manufacturing industry and pave the way for long-term success. Keywords: Indiana Manufacturer Analysis Checklist, compliance, efficiency, quality control, sustainability, manufacturing industry, operational aspects, state regulations, Indiana, inventory control, compliance with quality certifications.

Indiana Manufacturer Analysis Checklist

Description

How to fill out Indiana Manufacturer Analysis Checklist?

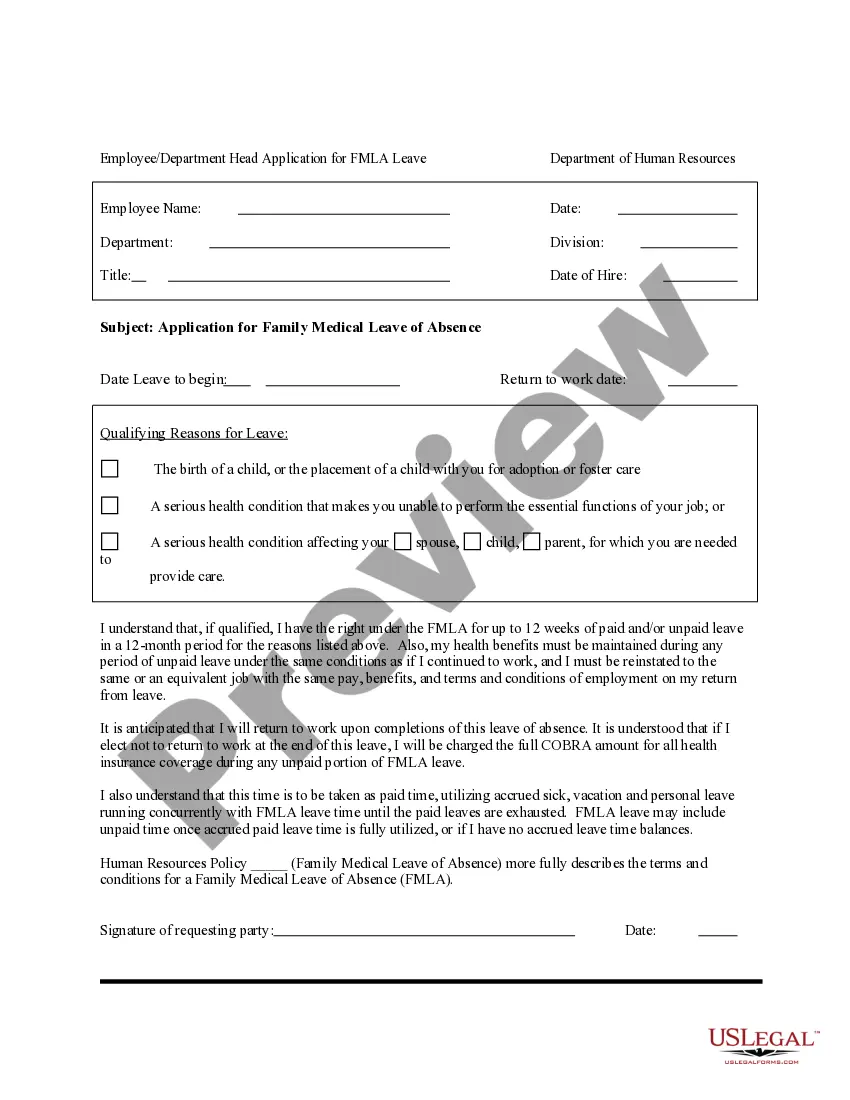

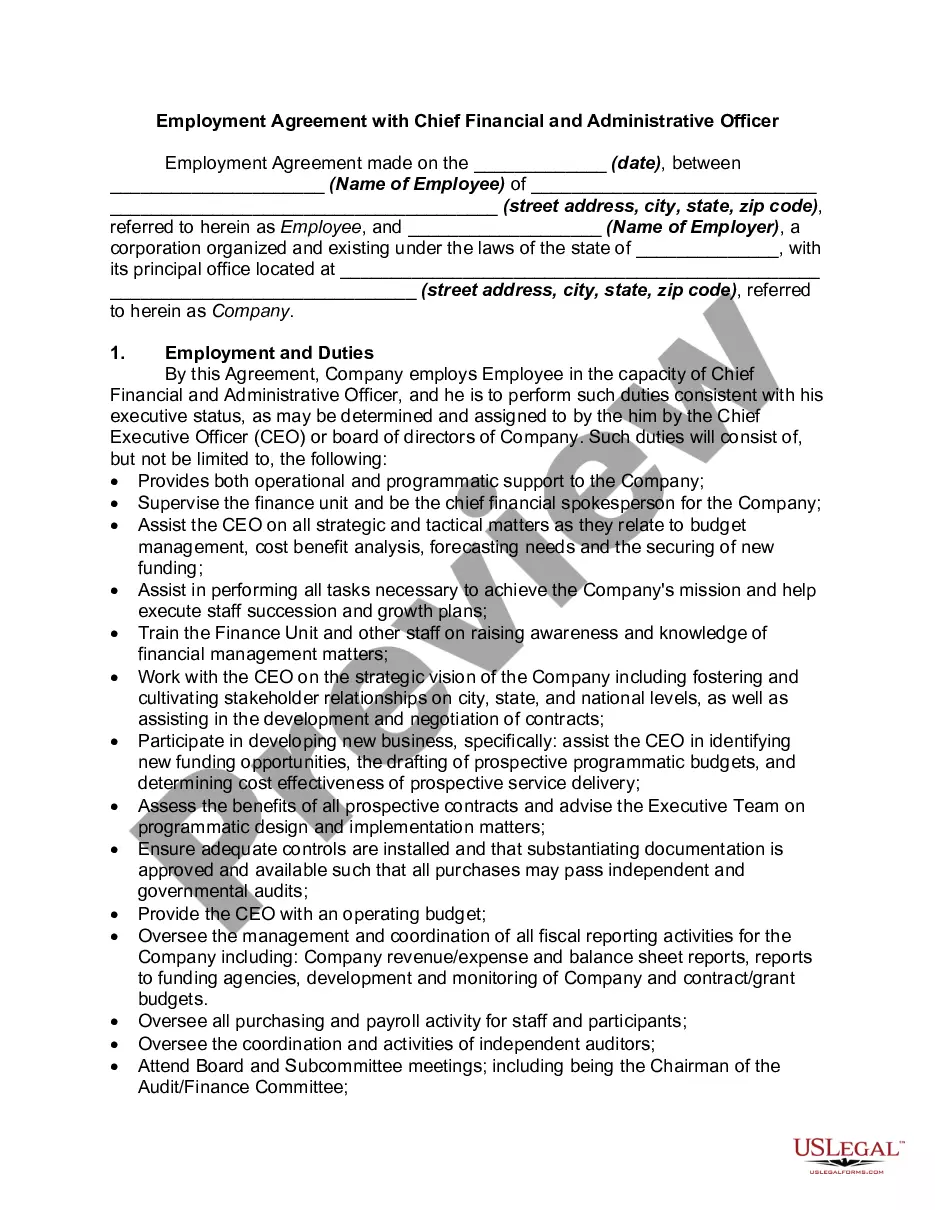

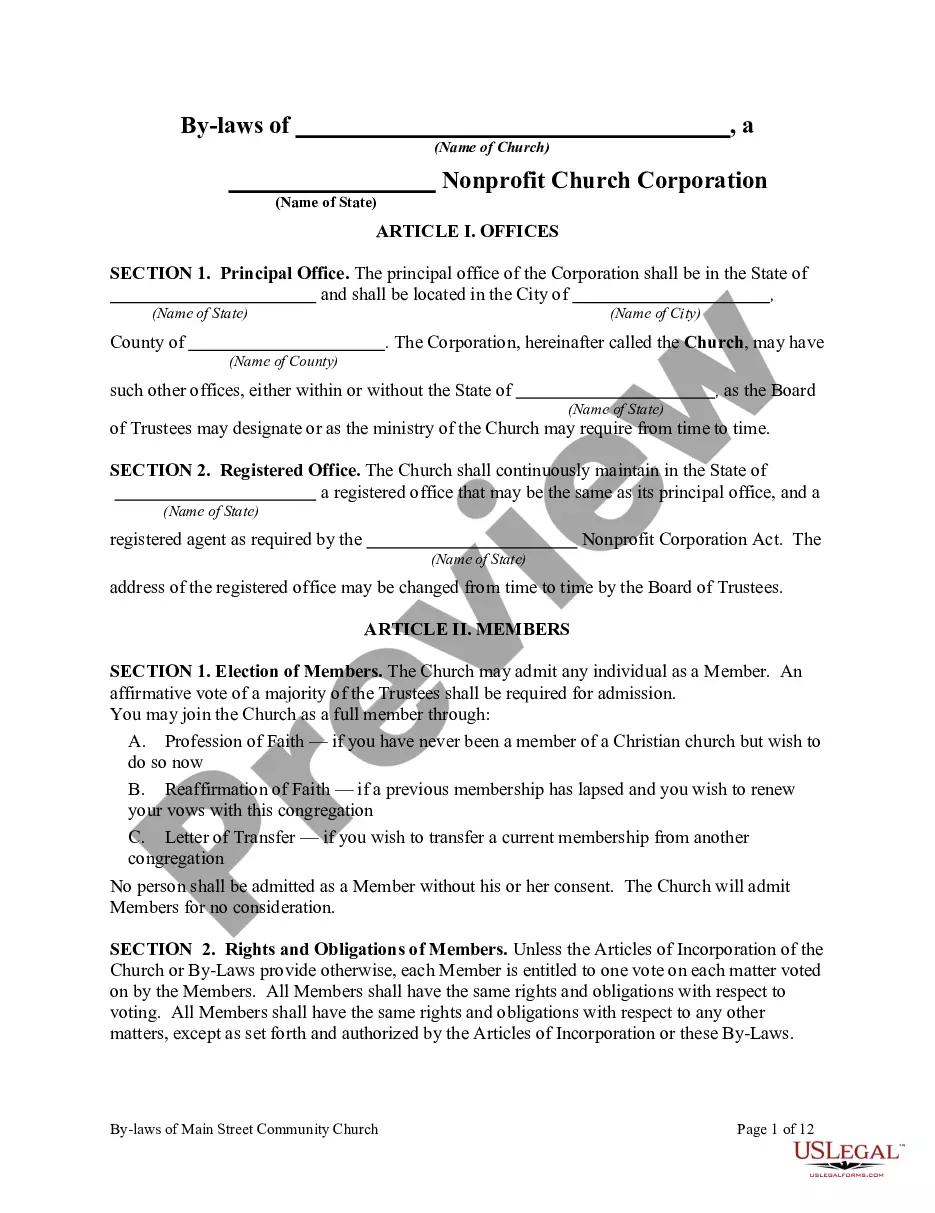

Choosing the best legitimate papers format can be a battle. Obviously, there are tons of web templates available on the net, but how can you find the legitimate develop you want? Make use of the US Legal Forms internet site. The services offers 1000s of web templates, like the Indiana Manufacturer Analysis Checklist, which you can use for company and private demands. Every one of the varieties are inspected by pros and satisfy state and federal specifications.

In case you are presently listed, log in in your account and click the Down load key to find the Indiana Manufacturer Analysis Checklist. Make use of your account to appear throughout the legitimate varieties you have bought formerly. Visit the My Forms tab of your respective account and get another backup from the papers you want.

In case you are a whole new user of US Legal Forms, listed here are easy instructions that you should follow:

- Initially, ensure you have selected the proper develop to your town/area. You are able to look over the form while using Preview key and read the form outline to make sure this is the right one for you.

- In case the develop will not satisfy your expectations, use the Seach area to find the appropriate develop.

- Once you are sure that the form would work, go through the Buy now key to find the develop.

- Choose the rates plan you would like and type in the required information and facts. Build your account and pay for the order using your PayPal account or Visa or Mastercard.

- Pick the document format and download the legitimate papers format in your device.

- Total, revise and printing and indicator the obtained Indiana Manufacturer Analysis Checklist.

US Legal Forms will be the biggest library of legitimate varieties for which you can discover numerous papers web templates. Make use of the service to download appropriately-manufactured files that follow state specifications.