Kansas 21 Things to do for a Safe Workplace

Description

How to fill out 21 Things To Do For A Safe Workplace?

Are you in a situation where you require documents for either a company or specific roles almost every time.

There are numerous legal document templates accessible online, but finding reliable ones can be challenging.

US Legal Forms offers a vast array of templates, such as the Kansas 21 Things to do for a Safe Workplace, designed to meet state and federal requirements.

Choose the pricing plan you prefer, complete the required information to create your account, and pay for the transaction with your PayPal or credit card.

Select a convenient document format and download your copy.

- If you are already familiar with the US Legal Forms website and have an account, simply Log In.

- Next, you can download the Kansas 21 Things to do for a Safe Workplace template.

- If you don't have an account and wish to start using US Legal Forms, follow these steps.

- Obtain the template you need and ensure it is for the correct city/area.

- Utilize the Review button to examine the template.

- Check the details to confirm you have selected the correct document.

- If the template is not what you are looking for, use the Search field to find the one that meets your needs and specifications.

- Once you find the correct template, simply click Acquire now.

Form popularity

FAQ

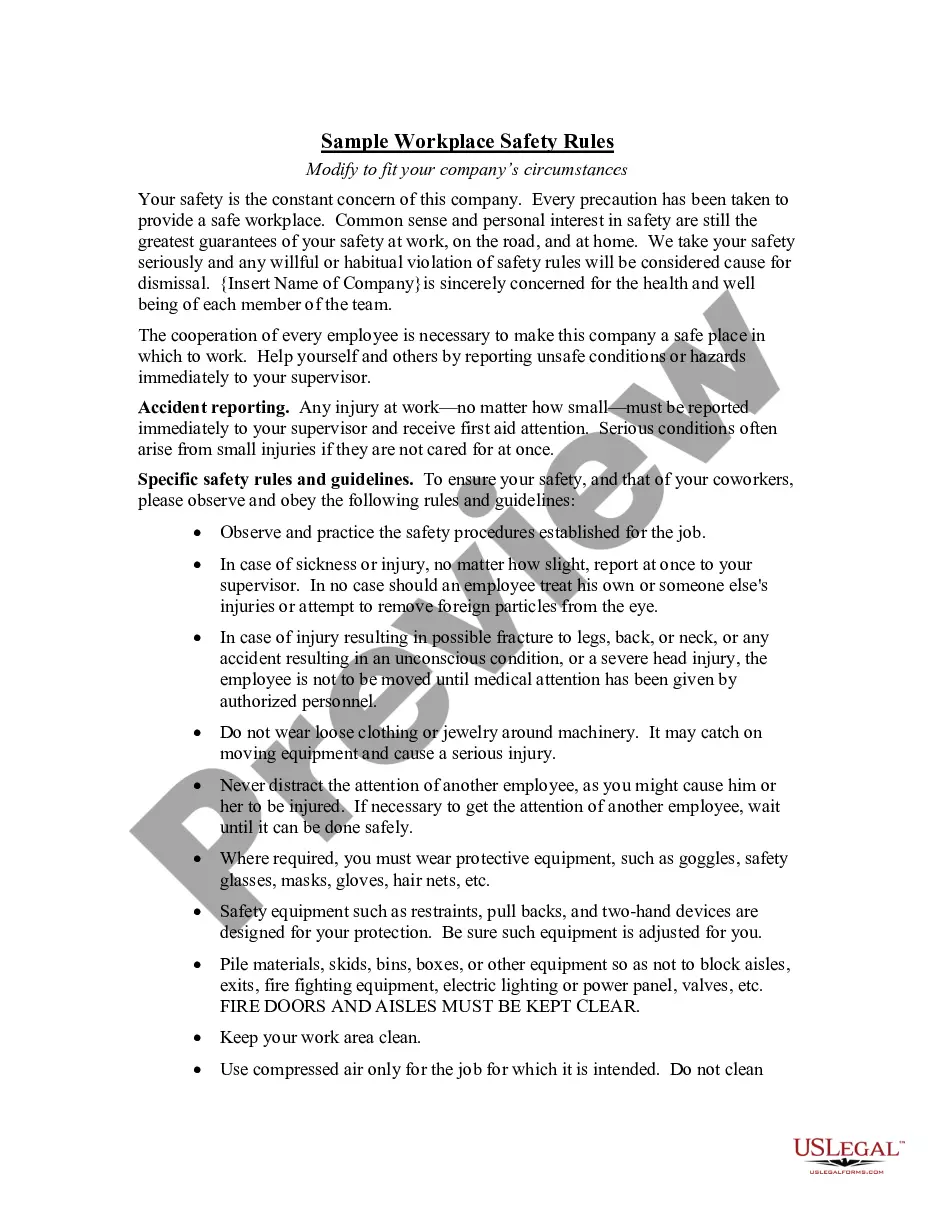

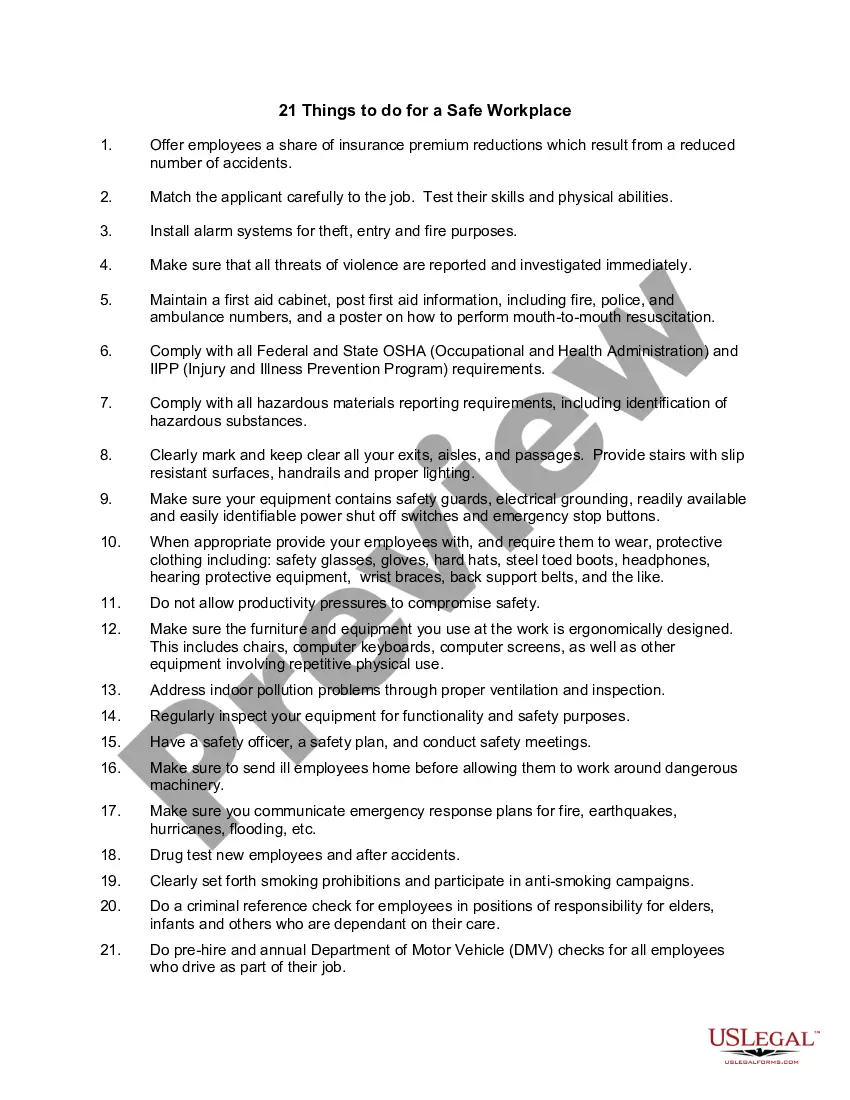

To enhance the safety culture at your workplace, start by encouraging open dialogue about safety issues. Recognizing and rewarding safe behaviors motivates employees to prioritize safety. Incorporating the Kansas 21 Things to do for a Safe Workplace can provide actionable steps to cultivate a positive safety culture, ultimately benefiting everyone.

Employers are legally obligated to offer a safe workplace under several federal and state regulations. This includes implementing safety measures to protect employees from accidents and health risks. Leveraging the Kansas 21 Things to do for a Safe Workplace can guide employers in fulfilling their responsibilities and ensuring a secure environment.

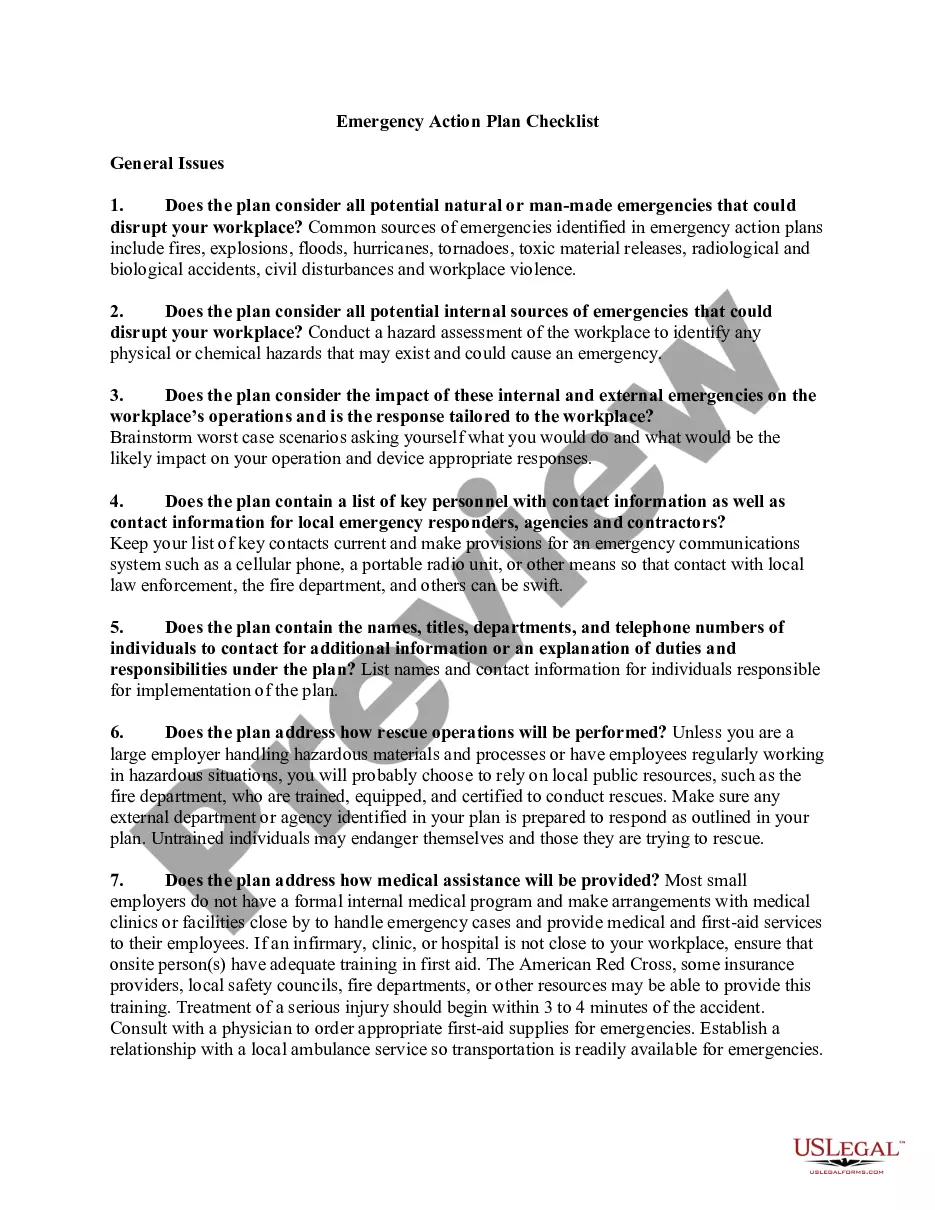

The Occupational Safety and Health Administration (OSHA) outlines that employers must provide safe and healthful working conditions. Additionally, the law requires employers to investigate every workplace accident thoroughly. By following the guidelines from the Kansas 21 Things to do for a Safe Workplace, employers can address safety proactively and mitigate risks effectively.

Promoting safety awareness begins with comprehensive training programs. Regular workshops, safety drills, and open communication about safety concerns create a culture of safety. Integrating the Kansas 21 Things to do for a Safe Workplace into routine discussions can significantly enhance awareness and participation among employees.

Employers must comply with the Occupational Safety and Health Act, which mandates that they provide a safe workplace for their employees. This includes addressing potential hazards and ensuring that safety standards are met consistently. By implementing the Kansas 21 Things to do for a Safe Workplace, employers can foster a safer environment.

A good safety topic for work includes mental health awareness, which plays a vital role in overall workplace safety. Addressing mental well-being can reduce stress-related accidents and promote a supportive work environment. You can also incorporate the Kansas 21 Things to do for a Safe Workplace to provide a framework for discussing how to create a safer workplace, both physically and mentally.

Good safety meeting topics include discussing recent near misses, reviewing safety protocols, and sharing best practices. You may also focus on specific hazards related to your industry or significant changes in safety regulations. Additionally, consider integrating the Kansas 21 Things to do for a Safe Workplace to foster a comprehensive understanding of safety among your team. Such discussions can create a culture of safety and awareness.

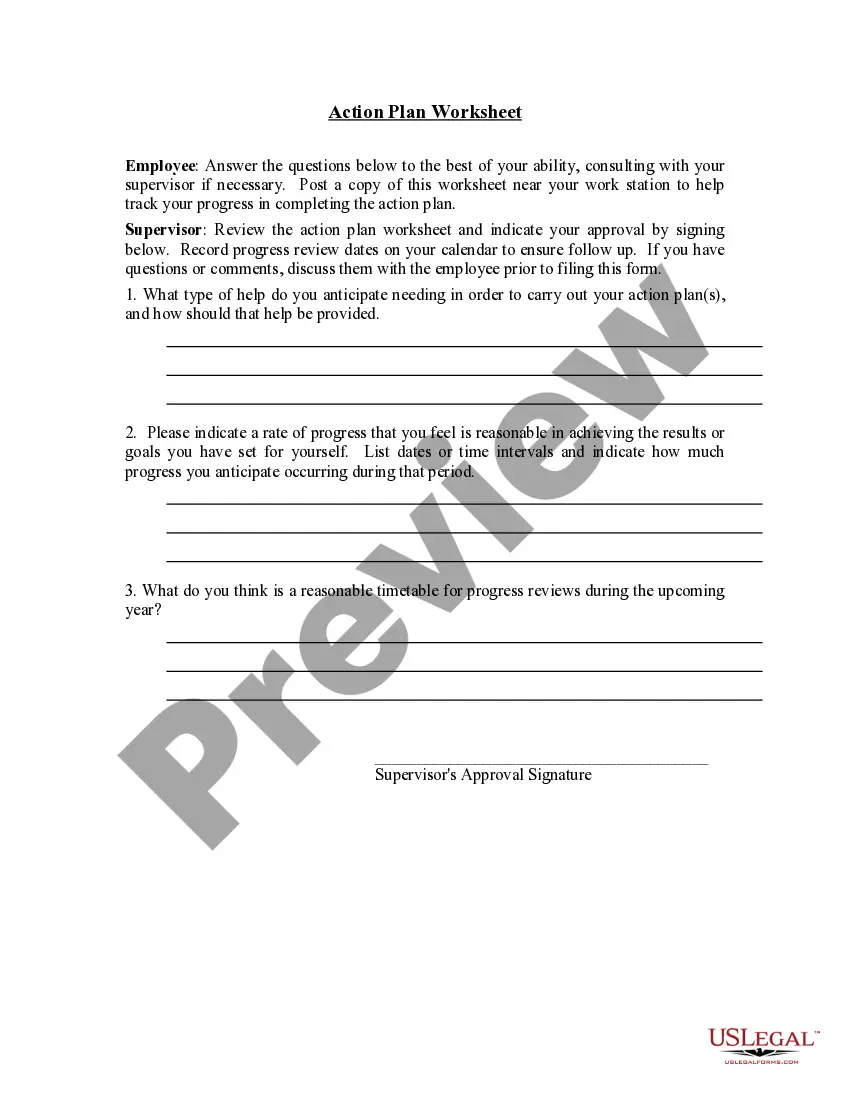

To ensure a safe work area, begin with a complete hazard assessment of your environment. Encourage regular safety audits, promote open communication about safety concerns, and provide the necessary training for all employees. Furthermore, you can develop a safety plan that incorporates the Kansas 21 Things to do for a Safe Workplace, establishing a proactive approach to maintaining safety standards.

The take 5 topics for safety focus on key areas that every workplace should address. These include hazard identification, risk assessment, safe work practices, emergency procedures, and ongoing training. By engaging your team in these areas, you can significantly enhance your workplace safety. Consider integrating Kansas 21 Things to do for a Safe Workplace into your safety training sessions to reinforce these important topics.

Creating a workplace safety plan starts with a thorough hazard assessment and the inclusion of policies tailored to specific workplace needs. Engage employees in discussions about safety practices and ensure that training programs are comprehensive. Aligning your strategy with the Kansas 21 Things to do for a Safe Workplace will help you design a robust plan.