Kansas Aeseptic Techniques

Description

How to fill out Aeseptic Techniques?

Selecting the finest authentic document template can be challenging.

Of course, there are numerous templates accessible online, but how do you find the genuine form you require.

Utilize the US Legal Forms website. This service offers a vast selection of templates, including the Kansas Aseptic Techniques, suitable for both business and personal use.

If the form does not fulfill your requirements, use the Search field to find the appropriate document.

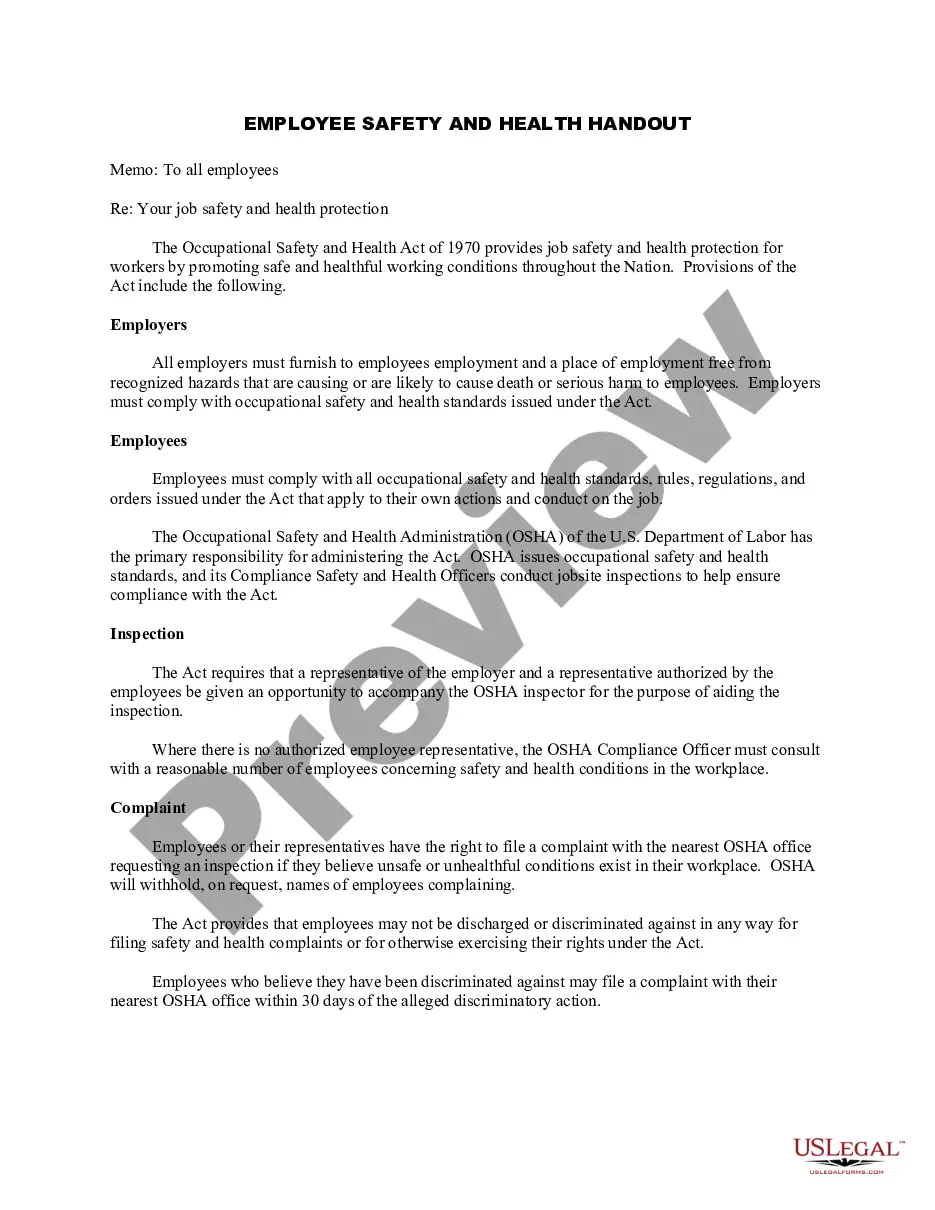

- All forms are reviewed by experts and comply with state and federal regulations.

- If you are already registered, Log In to your account and click the Download button to obtain the Kansas Aseptic Techniques.

- Use your account to view the legal forms you have previously purchased.

- Go to the My documents section in your account to get another copy of the document you need.

- If you are a new user of US Legal Forms, here are simple steps to follow.

- First, ensure you have selected the correct form for your city/state. You can preview the form using the Review option and read the form summary to ensure it is suitable for you.

Form popularity

FAQ

Passing sterile processing technician training may present challenges, but with the right resources, it's achievable. Engaging with comprehensive study materials, like those offered on platforms such as USLegalForms, can enhance your learning experience. Kansas aseptic techniques are thoroughly covered in training, equipping you for success.

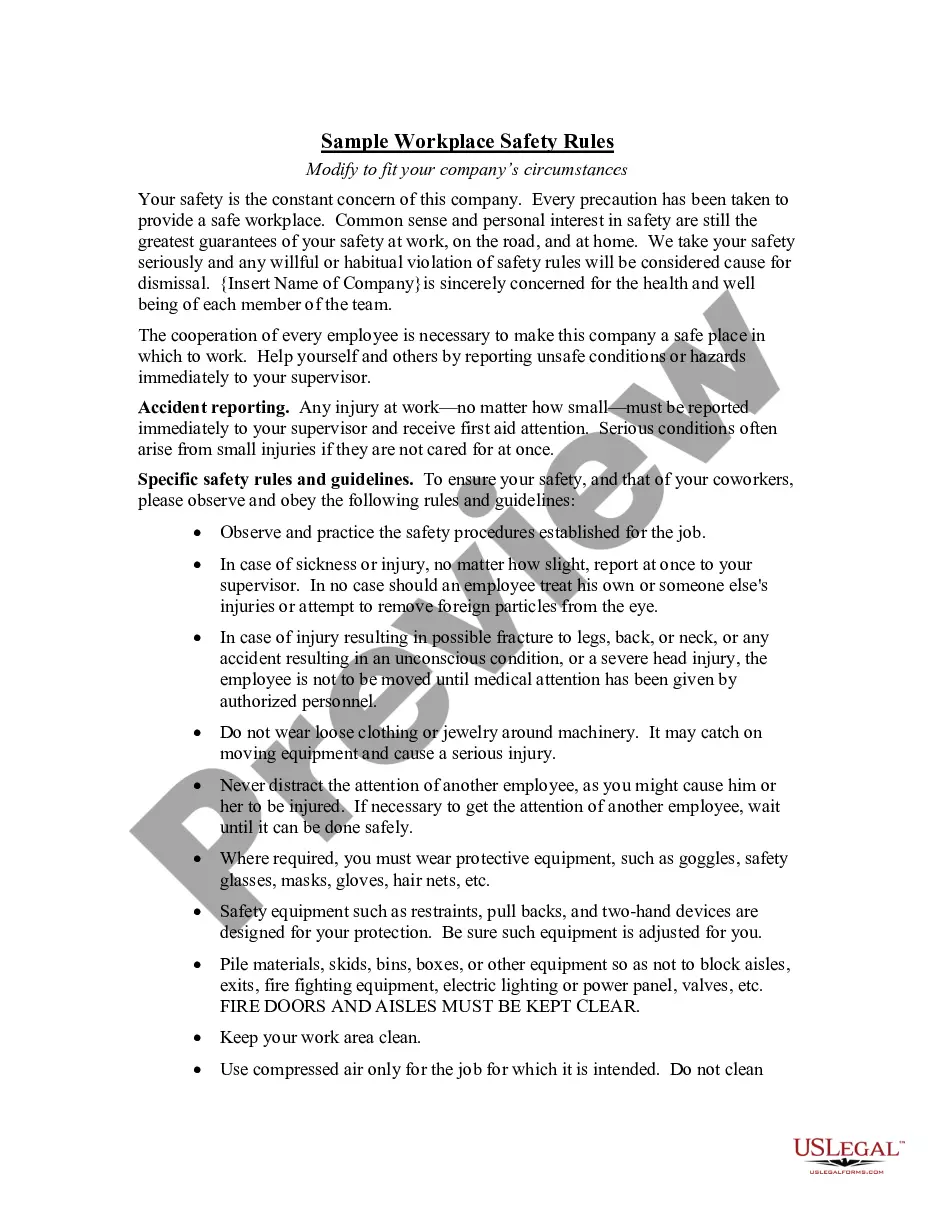

Procedures that involve aseptic technique include:200cInserting PICC lines.200cPerforming dialysis.200cInserting catheters.200cRunning IVs.200cInserting chest tubes.200cPerforming surgeries.200cDressing wounds.

Types of Aseptic TechniquesSterile technique. The strictest form of aseptic technique, sterile technique is intended to provide a space that has no germs whatsoever.Surgical aseptic technique. This is a strict form of aseptic technique that can be used outside the operating room.Standard aseptic technique.

ANTT is supported by evidence and highlights the key components involved in maintaining asepsis and aims to standardise practice.The underlying principles of ANTT are:Always wash hands effectively;Never contaminate key parts;Touch non-key parts with confidence;Take appropriate infective precautions.

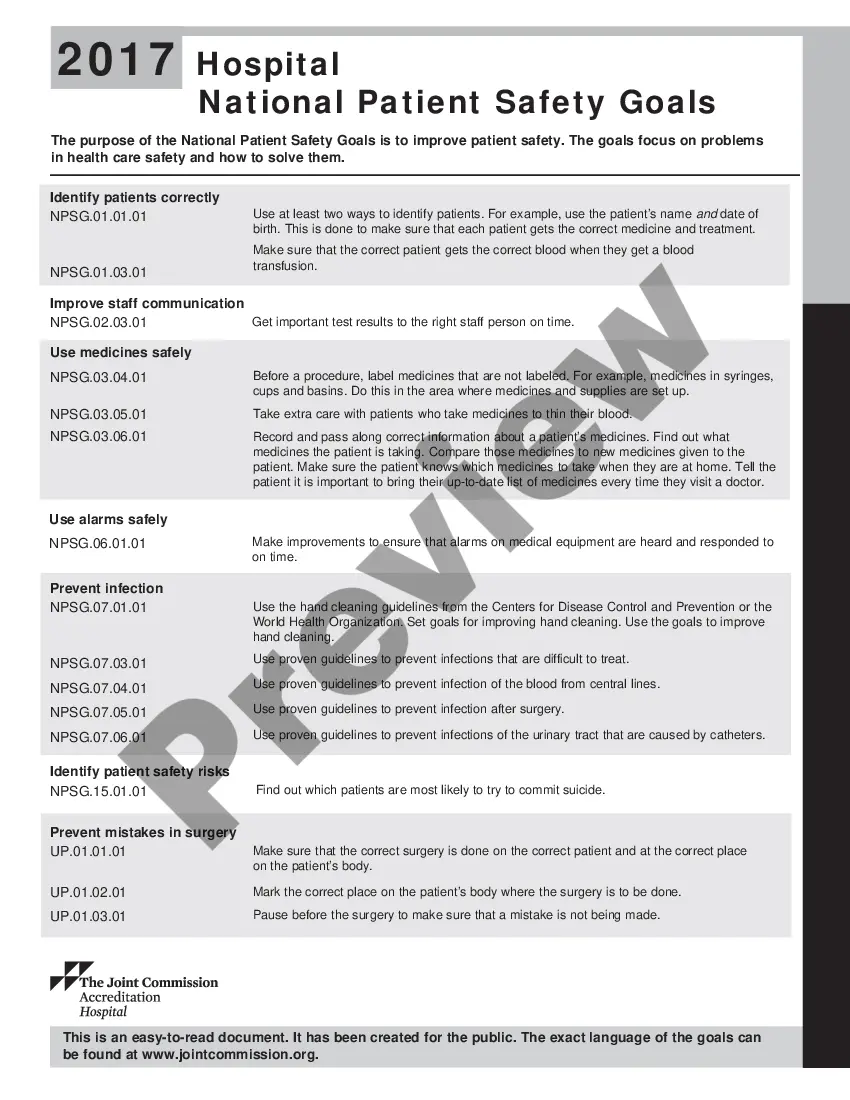

According to The Joint Commission, there are four chief aspects of the aseptic technique: barriers, patient equipment and preparation, environmental controls, and contact guidelines. Each plays an important role in infection prevention during a medical procedure.

According to The Joint Commission, there are four chief aspects of the aseptic technique: barriers, patient equipment and preparation, environmental controls, and contact guidelines. Each plays an important role in infection prevention during a medical procedure.

These principles include the following: (1) use only sterile items within a sterile field; (2) sterile (scrubbed) personnel are gowned and gloved; (3) sterile personnel operate within a sterile field (sterile personnel touch only sterile items or areas, unsterile personnel touch only unsterile items or areas); (4)

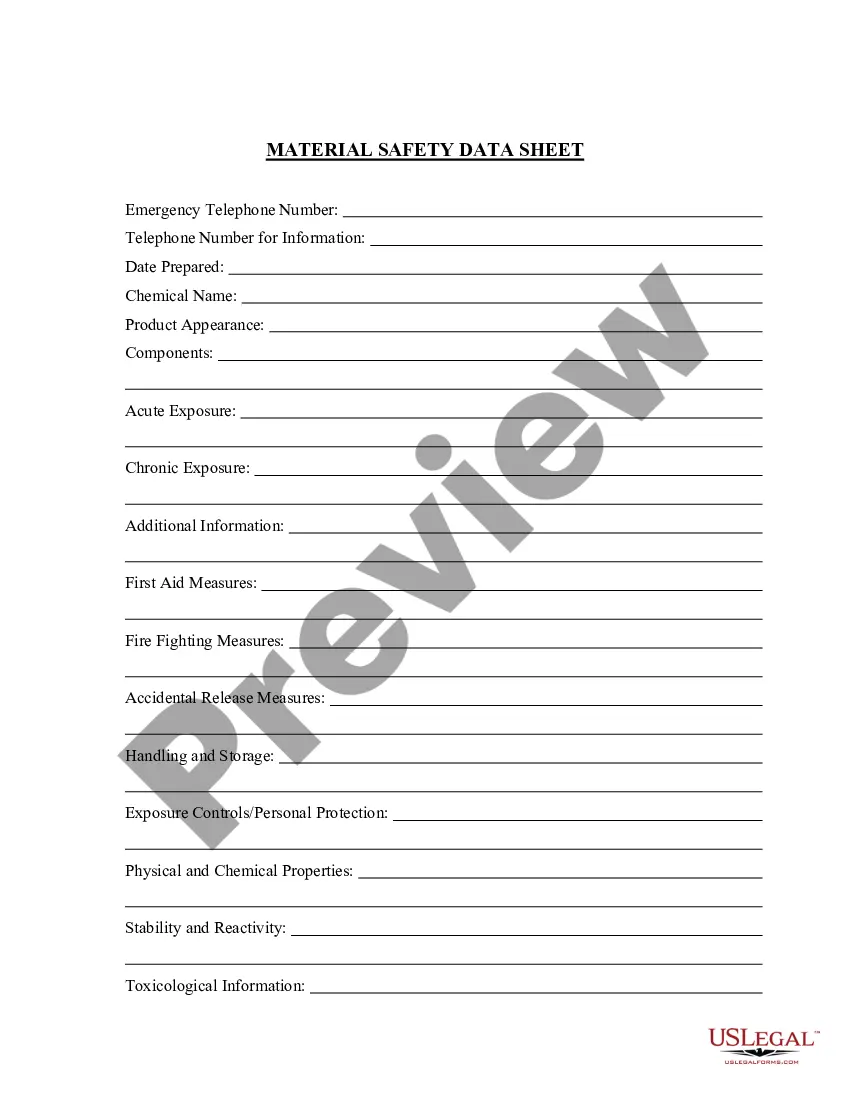

Aseptic technique is a method that involves target-specific practices and procedures under suitably controlled conditions to reduce the contamination from microbes. It is a compulsory laboratory skill to conduct research related in the field of microbiology.

Aseptic techniques include:Wiping bench with disinfectant/alcohol. Not growing microorganisms at body temperature. Using sterile loops when transferring cultures . Flaming culture bottle necks to prevent contamination. Sterilising (using an autoclave ) or disposing of all used equipment.