Kansas Sample Sharps Injury Log is a crucial document that helps organizations in Kansas to maintain a comprehensive record of all sharps-related injuries that occur within their facility. This log serves as a vital tool in monitoring and tracking sharps injuries, ensuring compliance with safety regulations, and taking necessary measures to prevent future incidents. The Kansas Sample Sharps Injury Log provides a standardized format for recording detailed information about each sharps' injury. It contains fields to capture essential details such as the date and time of the incident, location within the facility where the injury occurred, the specific type of sharp instrument involved (e.g., needles, lancets, scalpel blades), and the actions taken immediately after the incident. In addition to basic information, this log also includes space to record other relevant data such as the job title of the injured individual, their department or unit, the nature and severity of the injury, and any medical treatment administered. This comprehensive documentation aids in identifying trends, evaluating the effectiveness of safety measures, and formulating targeted strategies to minimize future sharps injuries. There are different types of Kansas Sample Sharps Injury Logs tailored to specific industries or settings. Some examples include: 1. Healthcare Setting Sample Sharps Injury Log: This log is designed for hospitals, clinics, nursing homes, and other healthcare facilities where sharps injuries are more prevalent due to the nature of the work and the frequent use of needles, syringes, and other sharp instruments. 2. Laboratory Setting Sample Sharps Injury Log: Laboratories dealing with biological samples, chemicals, and various laboratory equipment utilize this type of log to document sharps injuries that may occur while handling or disposing of sharp objects. 3. Industrial Setting Sample Sharps Injury Log: In industries such as manufacturing, construction, and agriculture, where workers come into contact with machinery and equipment with sharps components, this type of log aids in tracking and preventing workplace-related sharps injuries. Regardless of the specific type, the Kansas Sample Sharps Injury Log is an essential tool for maintaining a safe working environment and meeting regulatory requirements. It promotes a culture of safety and helps organizations identify areas of improvement to minimize sharps-related incidents and protect the well-being of their employees.

Kansas Sample Sharps Injury Log

Description

How to fill out Kansas Sample Sharps Injury Log?

US Legal Forms - one of the greatest libraries of legitimate forms in the United States - provides a variety of legitimate file web templates you may down load or produce. While using internet site, you may get a huge number of forms for enterprise and person uses, categorized by categories, claims, or keywords and phrases.You can find the most recent variations of forms just like the Kansas Sample Sharps Injury Log in seconds.

If you already possess a monthly subscription, log in and down load Kansas Sample Sharps Injury Log through the US Legal Forms library. The Download switch will show up on each and every develop you see. You get access to all earlier delivered electronically forms from the My Forms tab of the accounts.

If you wish to use US Legal Forms the very first time, here are simple recommendations to obtain began:

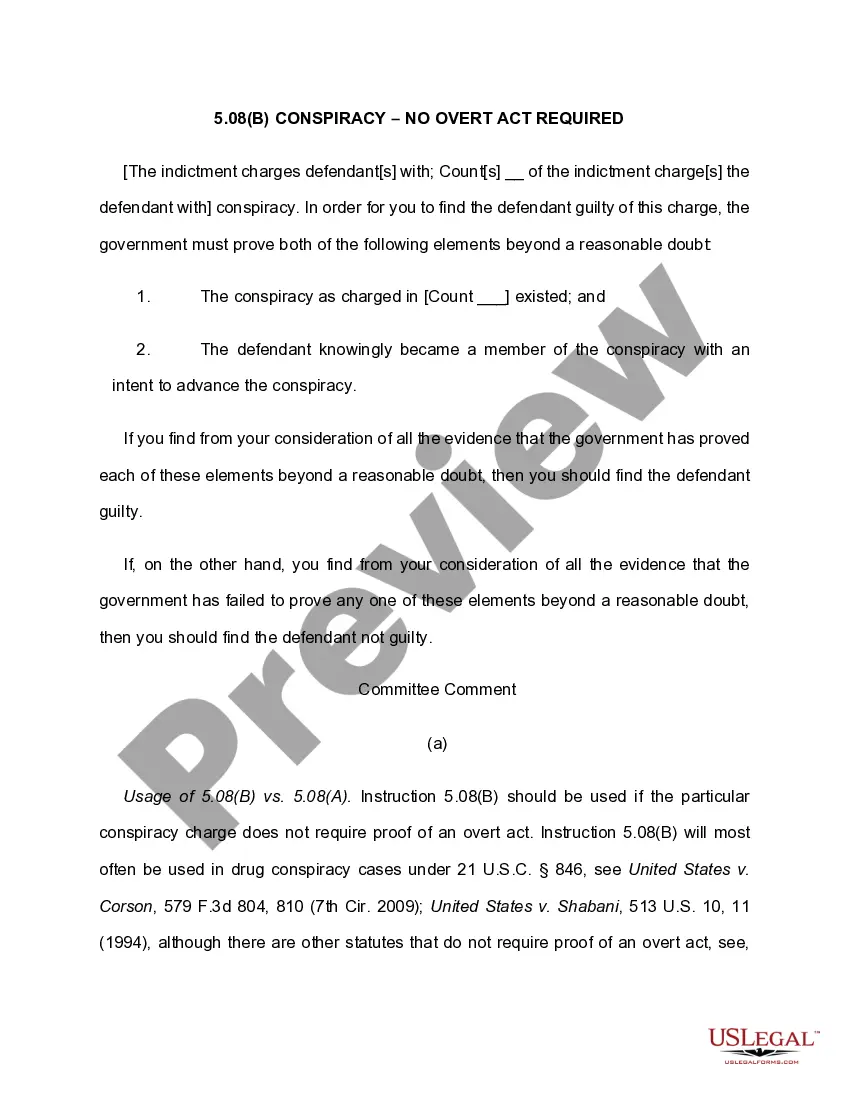

- Be sure you have picked out the proper develop for your personal city/area. Select the Preview switch to check the form`s content material. Browse the develop description to ensure that you have chosen the proper develop.

- If the develop does not match your needs, use the Lookup area towards the top of the monitor to obtain the one which does.

- When you are pleased with the form, affirm your selection by visiting the Purchase now switch. Then, opt for the rates program you prefer and give your credentials to sign up for the accounts.

- Method the deal. Use your charge card or PayPal accounts to complete the deal.

- Choose the structure and down load the form in your device.

- Make modifications. Fill up, change and produce and indicator the delivered electronically Kansas Sample Sharps Injury Log.

Every web template you added to your bank account lacks an expiry date which is the one you have for a long time. So, in order to down load or produce an additional duplicate, just visit the My Forms section and click on in the develop you need.

Gain access to the Kansas Sample Sharps Injury Log with US Legal Forms, probably the most considerable library of legitimate file web templates. Use a huge number of expert and express-specific web templates that satisfy your business or person demands and needs.