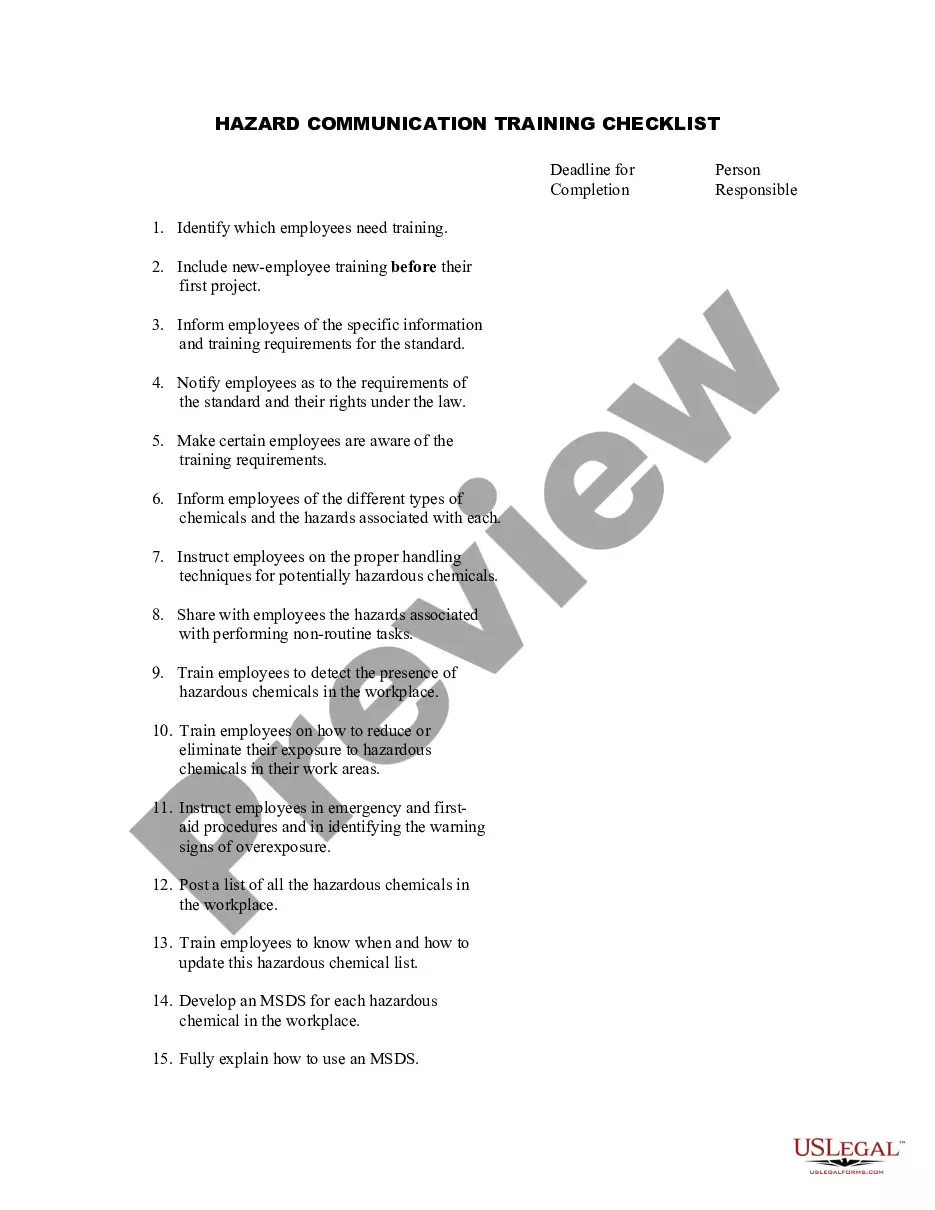

Kansas Hazard Communication Training Checklist for Individual Employees

Description

How to fill out Hazard Communication Training Checklist For Individual Employees?

Have you found yourself in a situation where you require documentation for both business or specific purposes almost every day.

There are numerous legitimate document templates accessible online, but finding forms you can trust isn't simple.

US Legal Forms offers a vast selection of template documents, such as the Kansas Hazard Communication Training Checklist for Individual Employees, which are designed to comply with federal and state regulations.

Choose a convenient file format and download your copy.

Access all the document templates you have purchased from the My documents menu. You can retrieve another copy of the Kansas Hazard Communication Training Checklist for Individual Employees at any time if necessary. Click on the desired form to download or print the template. Utilize US Legal Forms, one of the largest collections of legitimate documents, to save time and reduce errors. The service provides professionally crafted legal document templates that can be used for various purposes. Create your account on US Legal Forms and start making your life easier.

- If you are already familiar with the US Legal Forms website and have an account, simply Log In.

- Afterwards, you can download the Kansas Hazard Communication Training Checklist for Individual Employees template.

- If you do not have an account and want to start using US Legal Forms, follow these steps.

- Find the form you need and ensure it is for your specific city/state.

- Utilize the Preview button to review the document.

- Check the description to confirm you have chosen the correct form.

- If the form isn't what you are looking for, use the Lookup field to find the form that suits your needs and requirements.

- Once you find the correct form, click on Buy now.

- Select the pricing plan you want, fill in the required details to create your account, and finalize your order using your PayPal or credit card.

Form popularity

FAQ

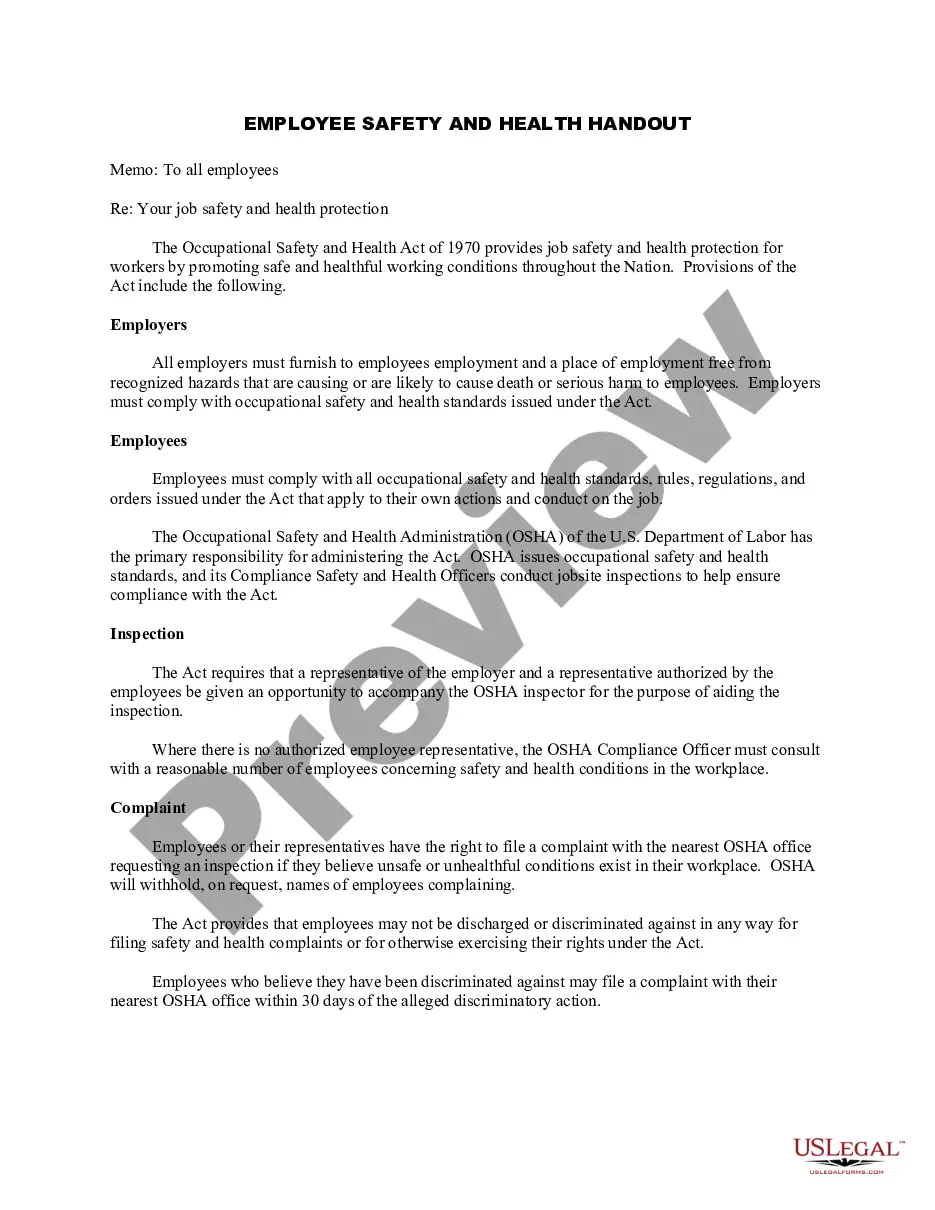

Yes, employers must have a written hazard communication program. This program outlines how they will communicate hazards associated with chemicals to their employees. It must include details on labeling and safety data sheets, ensuring all staff understand potential dangers. By using the Kansas Hazard Communication Training Checklist for Individual Employees, employers can fulfill this requirement effectively.

The OSHA HAZCOM standard has been in place for many years, and OSHA's general requirements for employers include concessioners. Concessioners must: Develop and implement a written HAZCOM program that meets OSHA requirements. Maintain an inventory of chemicals used and stored in the workplace.

The program must include labels on containers of hazardous chemicals, safety data sheets (SDSs) for hazardous chemicals, and training for workers. Each employer must also describe in a written program how it will meet the requirements of the HCS in each of these areas.

Although OSHA doesn't require training for workers who encounter hazardous chemicals in non-routine, isolated instances, employers tend to provide hazcom training to a broad array of employees to cover their bases, according to Shannon Gainey, technical and regulatory director for consulting firm REACH24H USA.

These are the Five elements of the Hazard Communication Standard. They are: Chemical Inventory, Written Program, Labels, Material Safety Data Sheets, and Training. The first element of the Hazard Communication Standard is for employers to develop inventories of all the hazardous chemicals they have at their worksite.

Employers in all industries of all sizes must provide training when hazardous chemicals are present in the workplace. This includes health care, dental, labs, construction, manufacturing, cleaning services, etc. Only workers who have potential exposure to the hazardous chemicals need to be trained.

You must provide "effective" HazCom training to your employees at the time of their initial assignment and whenever a new physical or health hazard the employees have not previously been trained about is introduced into their work area.

The Hazard Communication Standard (HCS), 29 CFR 1910.1200 (h), requires all employers to provide information and training to their employees about the hazardous chemicals to which they may be exposed at the time of their initial assignment and whenever a new hazard is introduced into their work area.

The Hazard Communication Standard (HCS), 29 CFR 1910.1200 (h), requires all employers to provide information and training to their employees about the hazardous chemicals to which they may be exposed at the time of their initial assignment and whenever a new hazard is introduced into their work area.

The Hazard Communication Regulation (Cal/OSHA, section 5194; Federal OSHA 29 CFR 1910.1200) requires that the chemical manufacturer, distributor, or importer provide safety data sheets (SDSs) (formerly MSDSs or material safety data sheets) for each hazardous chemical to downstream users to communicate information on