Kansas Hazard Communication Training Checklist for Company Policies

Description

How to fill out Hazard Communication Training Checklist For Company Policies?

If you need to obtain, acquire, or print legal document templates, utilize US Legal Forms, the largest compilation of legal forms available online.

Make use of the site's simple and convenient search to find the documents you require.

Various templates for business and personal applications are organized by categories and states, or keywords.

Step 4. After locating the form you need, click the Get Now button. Select your preferred pricing plan and enter your details to create an account.

Step 5. Complete the payment process. You can use your credit card or PayPal account to finalize the payment.Step 6. Choose the format of the legal document and download it to your device.Step 7. Fill out, modify, and print or sign the Kansas Hazard Communication Training Checklist for Company Policies.

- Employ US Legal Forms to access the Kansas Hazard Communication Training Checklist for Company Policies with just a few clicks.

- If you are already a US Legal Forms user, Log In to your account and click the Download button for the Kansas Hazard Communication Training Checklist for Company Policies.

- You can also find previously downloaded forms in the My documents section of your account.

- If you're new to US Legal Forms, follow the steps below.

- Step 1. Make sure you have selected the form for the appropriate jurisdiction.

- Step 2. Use the Review option to examine the form's details. Always remember to read the information.

- Step 3. If you are not satisfied with the form, use the Search field at the top of the screen to find other versions of the legal form template.

Form popularity

FAQ

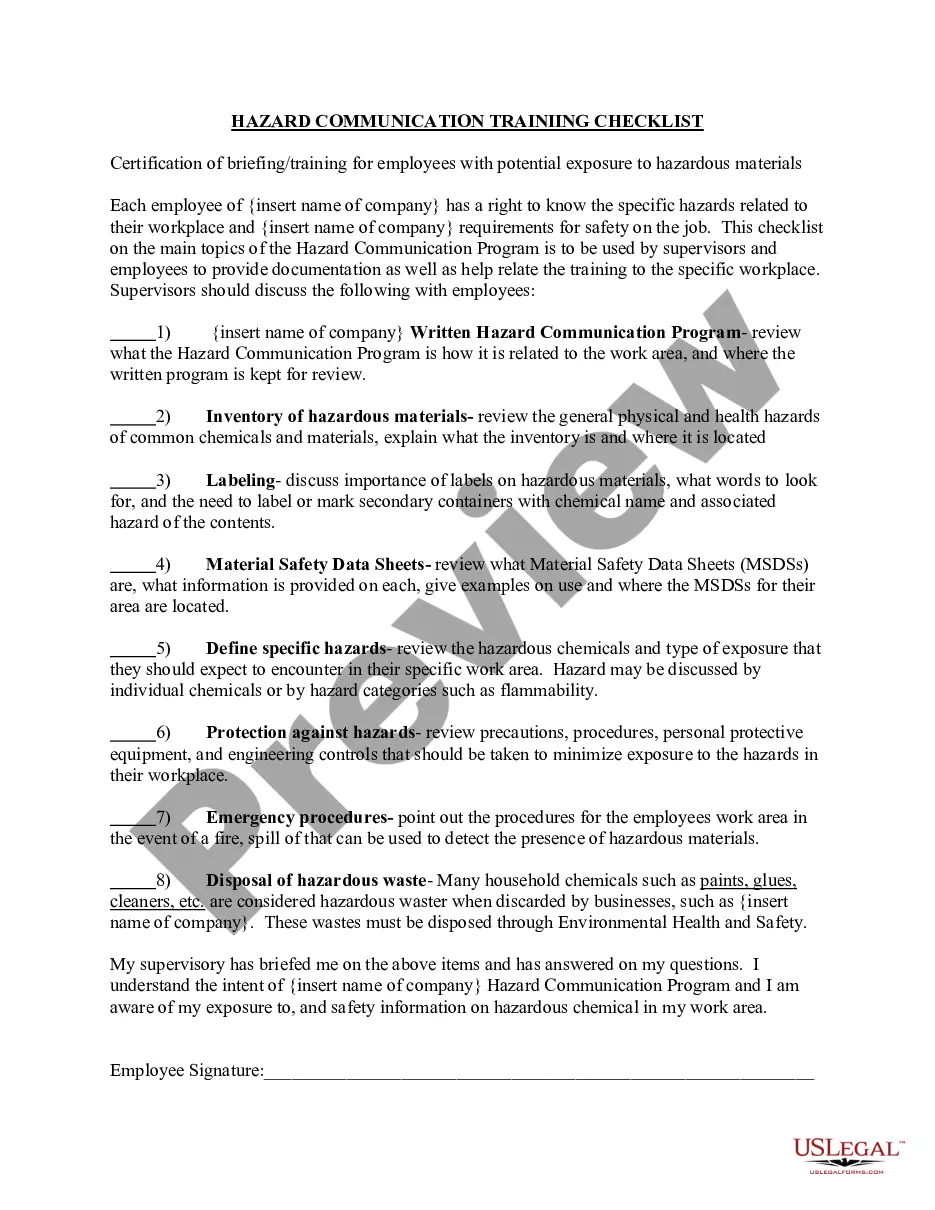

Yes, employers are required to have a written hazard communication program that outlines how they will inform and protect their employees. This program should include details on the use of labels, safety data sheets, and training protocols. The Kansas Hazard Communication Training Checklist for Company Policies can guide you in creating a thorough and compliant program tailored for your workplace's unique needs.

The Hazard Communication Regulation (Cal/OSHA, section 5194; Federal OSHA 29 CFR 1910.1200) requires that the chemical manufacturer, distributor, or importer provide safety data sheets (SDSs) (formerly MSDSs or material safety data sheets) for each hazardous chemical to downstream users to communicate information on

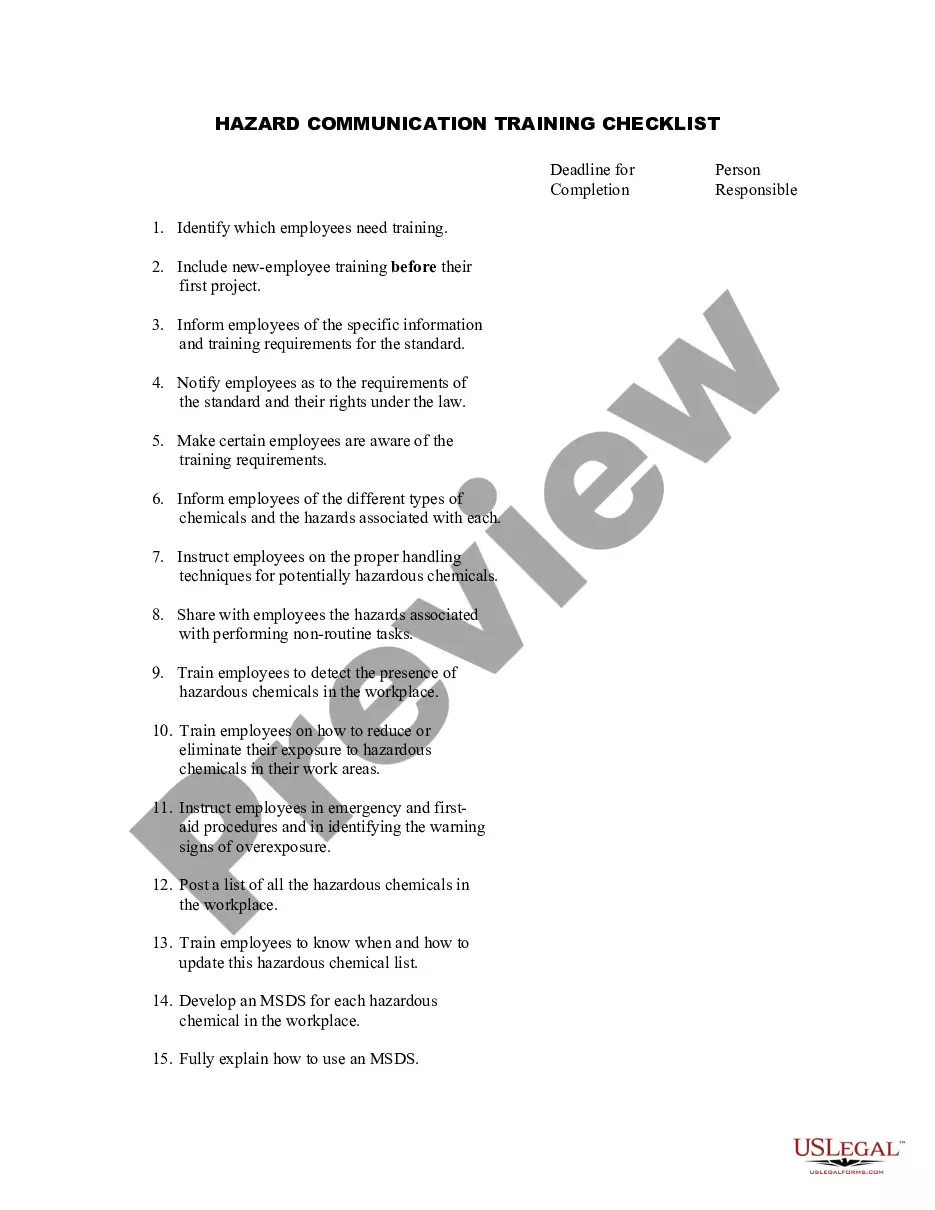

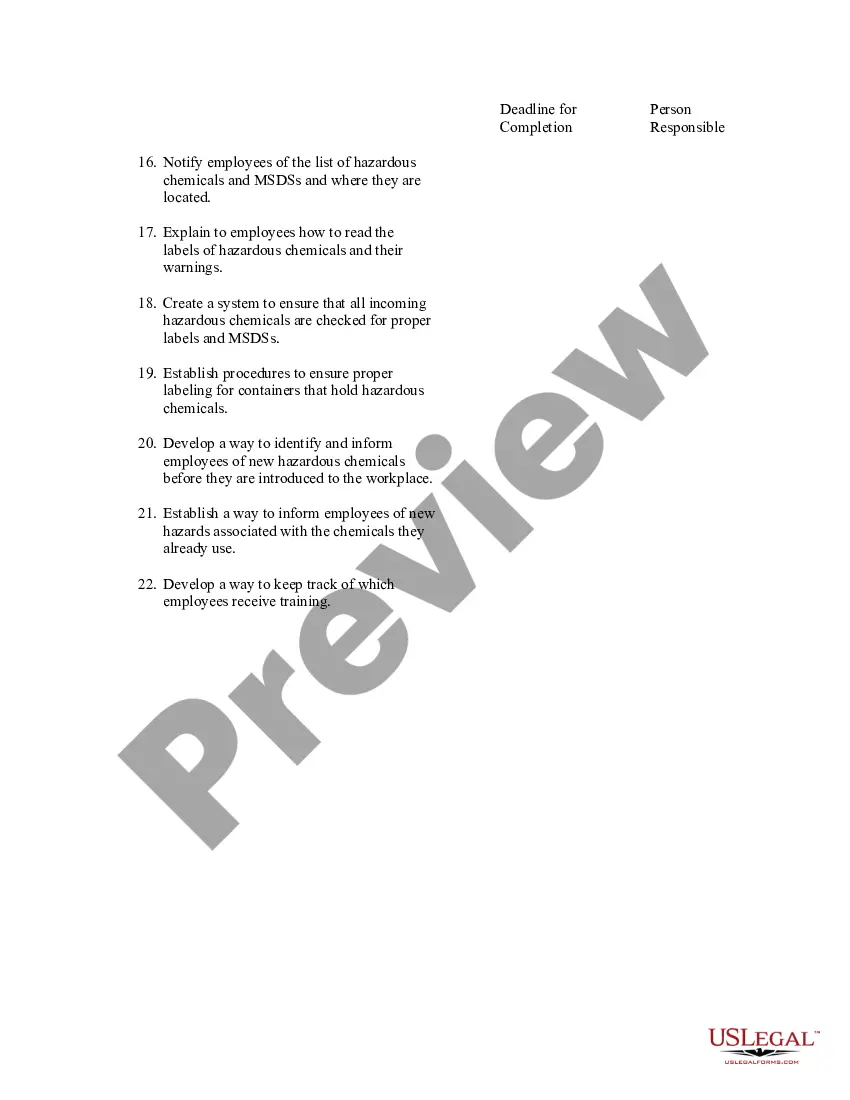

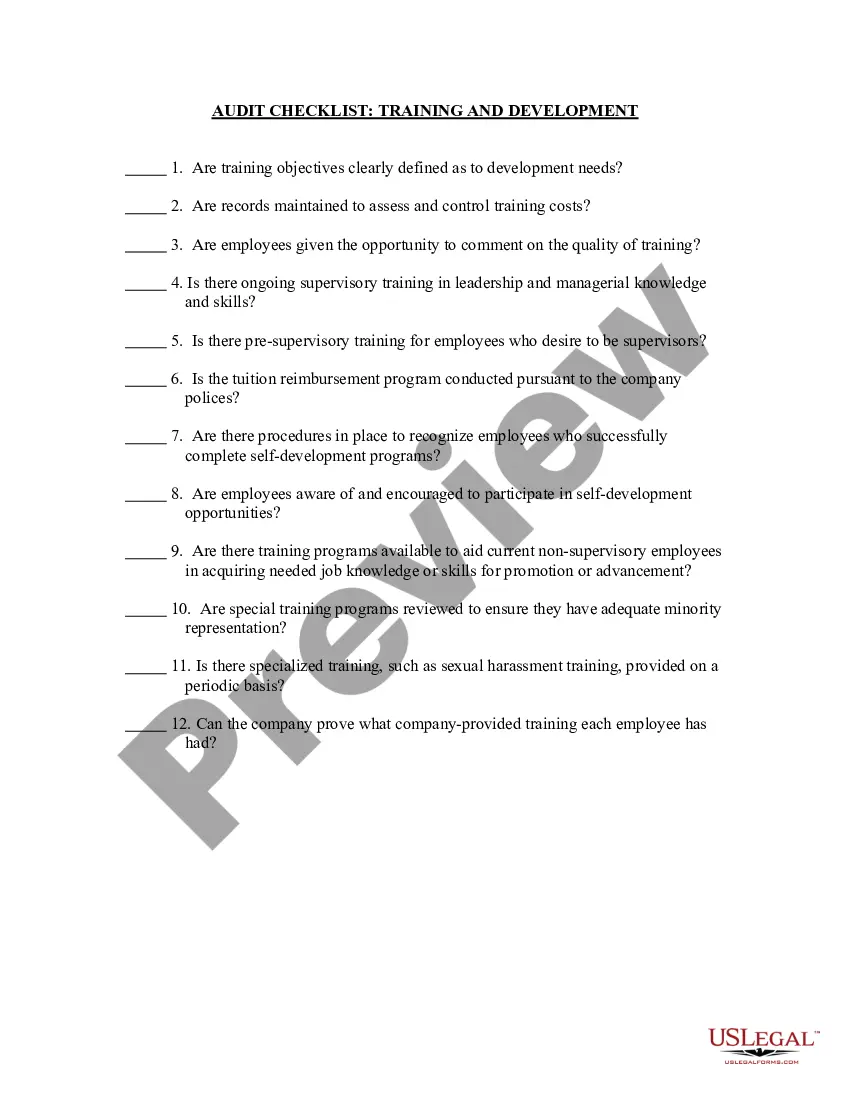

HCS was developed to protect employees from exposure to hazardous products and chemicals. This standard requires all employers to develop a written program addressing labeling and warning requirements, material safety data sheets (MSDSs) and employee training on hazardous materials.

These are the Five elements of the Hazard Communication Standard. They are: Chemical Inventory, Written Program, Labels, Material Safety Data Sheets, and Training. The first element of the Hazard Communication Standard is for employers to develop inventories of all the hazardous chemicals they have at their worksite.

The Hazard Communication Standard (HCS), 29 CFR 1910.1200 (h), requires all employers to provide information and training to their employees about the hazardous chemicals to which they may be exposed at the time of their initial assignment and whenever a new hazard is introduced into their work area.

These are the Five elements of the Hazard Communication Standard. They are: Chemical Inventory, Written Program, Labels, Material Safety Data Sheets, and Training. The first element of the Hazard Communication Standard is for employers to develop inventories of all the hazardous chemicals they have at their worksite.

The following general industry tasks require initial training (new employee orientation) and periodic/new hazard training:Accident Prevention Signs and Tags 1910.145.Aerial Lifts 1910.67(c)Arc Welding & Cutting 1915.252.Chainsaw Safety 1910.266.Compressed Gas Safety 1910.101.More items...?

The program must include labels on containers of hazardous chemicals, safety data sheets (SDSs) for hazardous chemicals, and training for workers. Each employer must also describe in a written program how it will meet the requirements of the HCS in each of these areas.

The Hazard Communication Standard (HCS), 29 CFR 1910.1200 (h), requires all employers to provide information and training to their employees about the hazardous chemicals to which they may be exposed at the time of their initial assignment and whenever a new hazard is introduced into their work area.

A log or file should be kept of all the documents that pertain to any safety training sessions or safety meetings. Employee medical records must be kept for the duration of employment plus 30 years and employee exposure records must be kept for at least 30 years. Communication Standard.