This lease rider form may be used when you are involved in a lease transaction, and have made the decision to utilize the form of Oil and Gas Lease presented to you by the Lessee, and you want to include additional provisions to that Lease form to address specific concerns you may have, or place limitations on the rights granted the Lessee in the “standard” lease form.

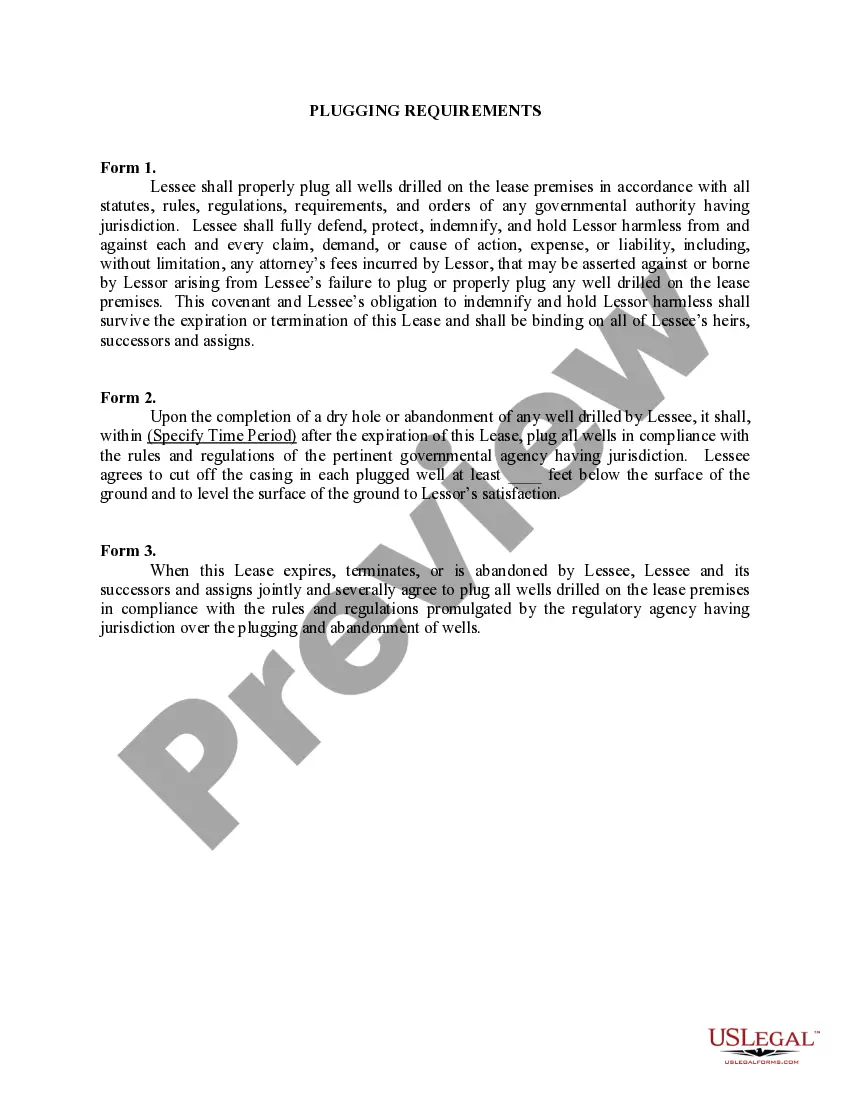

Kansas Plugging Requirements

Description

How to fill out Plugging Requirements?

If you have to comprehensive, down load, or print legal record themes, use US Legal Forms, the biggest variety of legal kinds, that can be found on the Internet. Make use of the site`s simple and easy hassle-free lookup to discover the papers you need. Different themes for organization and specific reasons are sorted by classes and states, or search phrases. Use US Legal Forms to discover the Kansas Plugging Requirements in a couple of click throughs.

When you are presently a US Legal Forms buyer, log in to the bank account and click on the Download key to get the Kansas Plugging Requirements. You can even entry kinds you earlier downloaded inside the My Forms tab of your own bank account.

Should you use US Legal Forms the first time, refer to the instructions beneath:

- Step 1. Ensure you have selected the form for your appropriate town/nation.

- Step 2. Utilize the Preview method to examine the form`s content. Do not neglect to learn the information.

- Step 3. When you are not happy with the develop, use the Look for industry near the top of the monitor to get other variations of the legal develop web template.

- Step 4. Upon having discovered the form you need, go through the Get now key. Pick the rates plan you favor and add your references to sign up to have an bank account.

- Step 5. Procedure the deal. You may use your charge card or PayPal bank account to finish the deal.

- Step 6. Find the structure of the legal develop and down load it in your gadget.

- Step 7. Comprehensive, change and print or indicator the Kansas Plugging Requirements.

Every single legal record web template you buy is yours forever. You have acces to each and every develop you downloaded in your acccount. Click on the My Forms area and decide on a develop to print or down load yet again.

Contend and down load, and print the Kansas Plugging Requirements with US Legal Forms. There are millions of professional and condition-specific kinds you can use for your personal organization or specific needs.

Form popularity

FAQ

Hand-dug wells are usually are lined with material such as brick or fieldstone. To plug a hand-dug well, carefully push in the upper 2 feet of the lining. Fill the well to within 2 feet of the surface with clean fill or soil. The remainder of the well should be filled with clay or clay-rich soil. PLUGGING YOUR ABANDONED WELL mo.gov ? dnr ? files ? vfc ? 2020/06 ? main mo.gov ? dnr ? files ? vfc ? 2020/06 ? main

For both primary and secondary protection, most large-diameter wells can be plugged effectively by filling with a combination of sand and gravel, native clay and topsoil (Figure 1A in Appendix IV). A mixture of sand and gravel is shoveled into the well up to a depth of 15 feet below the surface. A Guide to Plugging Abandoned Wells | NDSU Agriculture ndsu.edu ? agriculture ? ag-hub ? publications ndsu.edu ? agriculture ? ag-hub ? publications

Kansas regulations for water well construction require an approved, watertight casing from at least one foot above the finished ground surface to at least 20 feet below ground surface. Proper drainage at the well must be provided to prevent ponding of surface water within 50 feet (Figure 3). Kansas Department of Health and Environment k-state.edu ? docs ? Wells-Construction k-state.edu ? docs ? Wells-Construction

Fill the well with bentonite chips to a depth of 6 feet below the surface. Three feet of neat cement grout then should be added above the bentonite. The plug of neat cement grout over the bentonite will ensure that the bentonite will not dry out and lose its seal.