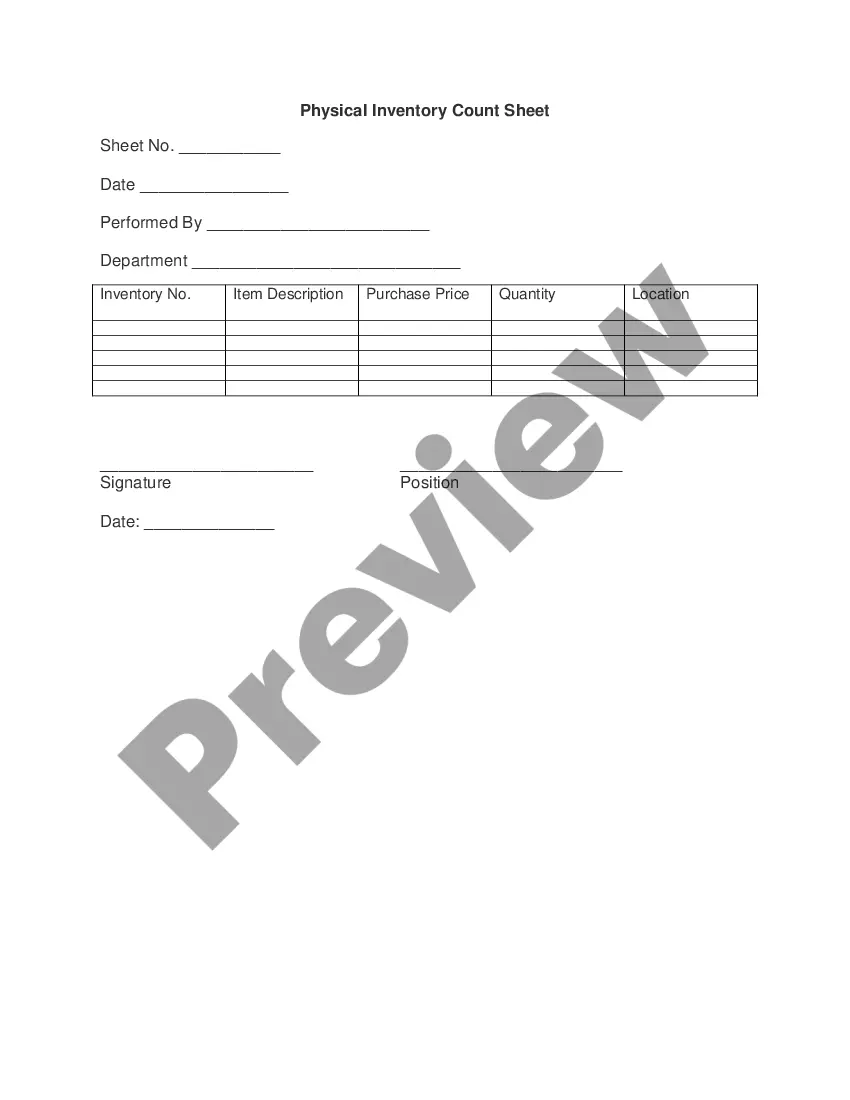

Kentucky Physical Inventory Count Sheet

Description

How to fill out Physical Inventory Count Sheet?

Are you currently in a situation where you require documents for both business or personal purposes almost every day.

There are many legal document templates accessible online, but finding ones you can rely on isn’t simple.

US Legal Forms offers a vast array of form templates, including the Kentucky Physical Inventory Count Sheet, that are crafted to meet state and federal requirements.

Once you find the correct form, simply click Purchase now.

Choose the payment plan you prefer, fill in the necessary information to create your account, and pay for the transaction using your PayPal or credit card.

- If you are already acquainted with the US Legal Forms website and possess an account, simply Log In.

- Then, you can download the Kentucky Physical Inventory Count Sheet template.

- If you do not have an account and wish to start using US Legal Forms, follow these steps.

- Identify the form you need and ensure it is for the correct city/area.

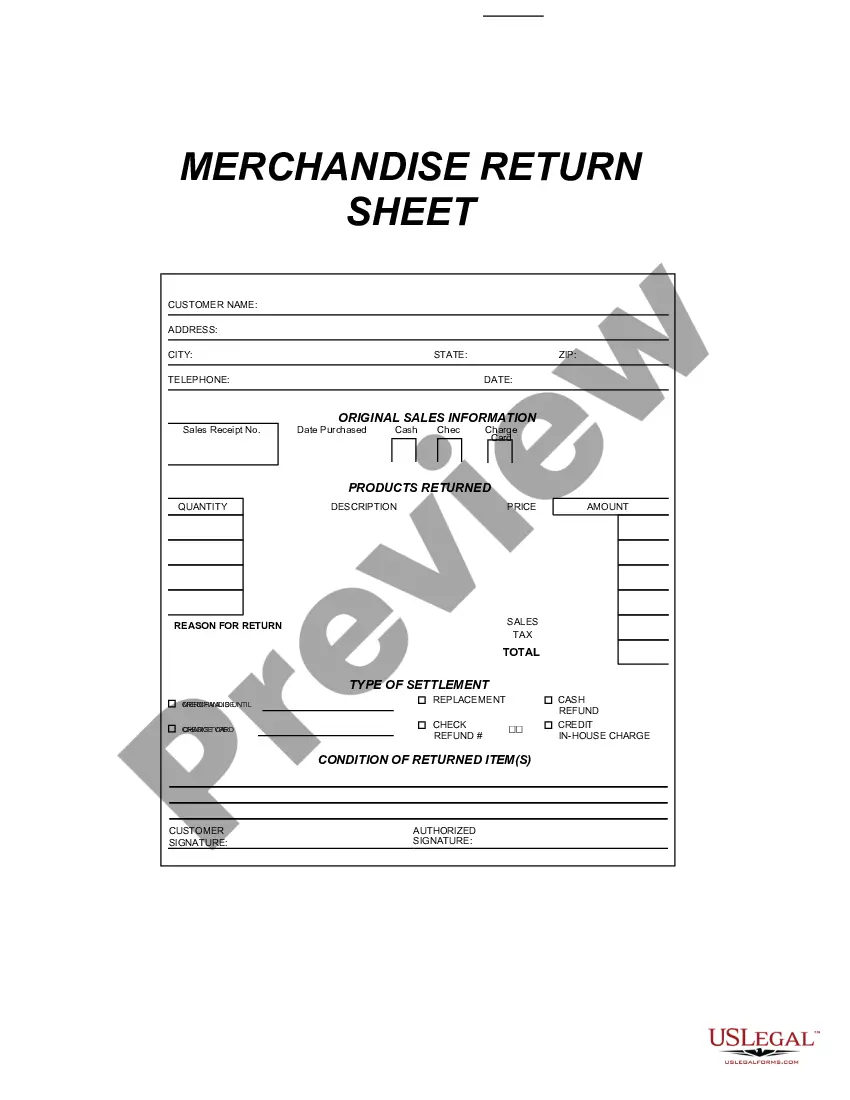

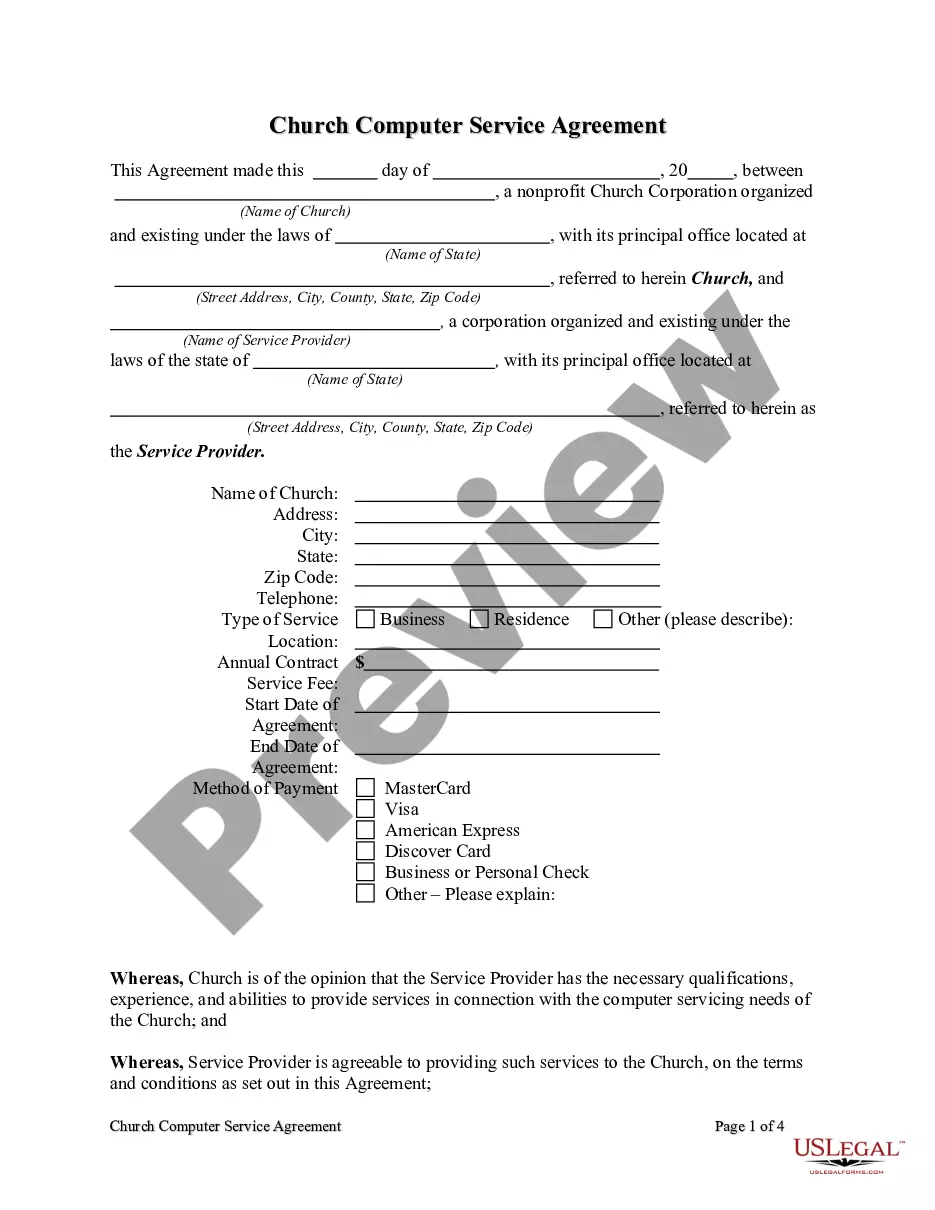

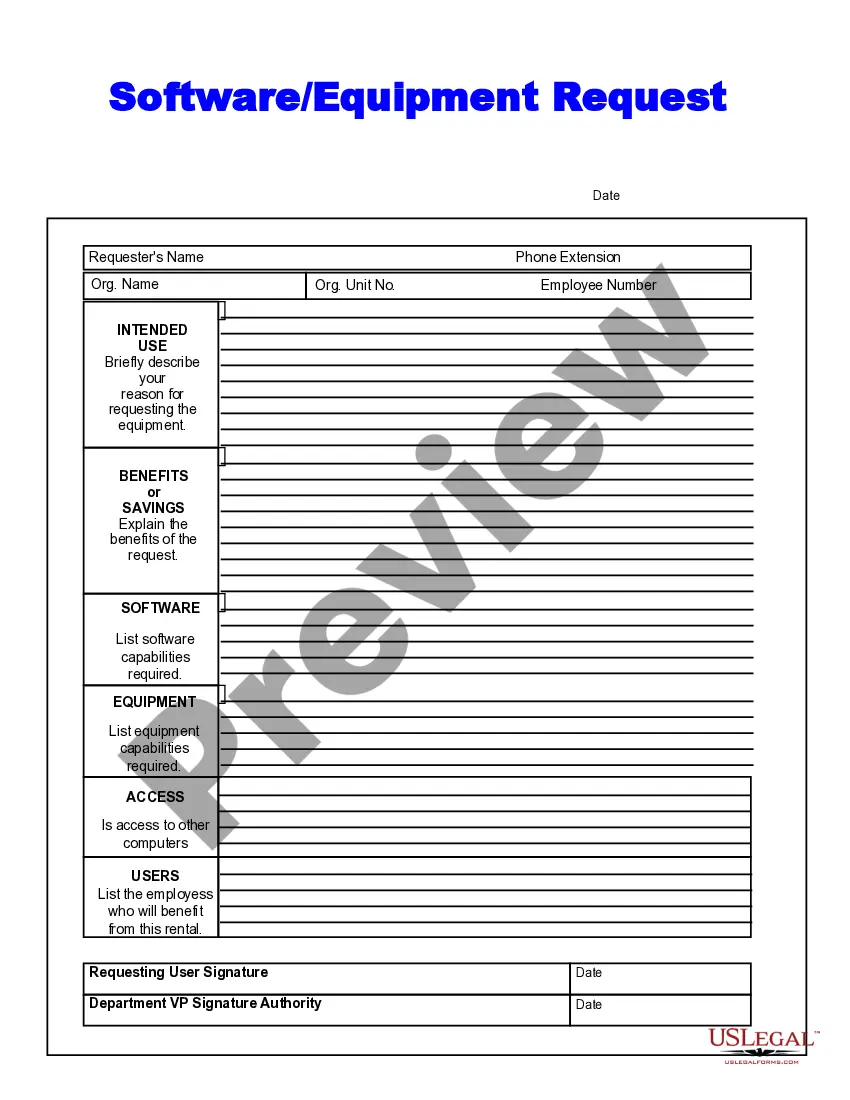

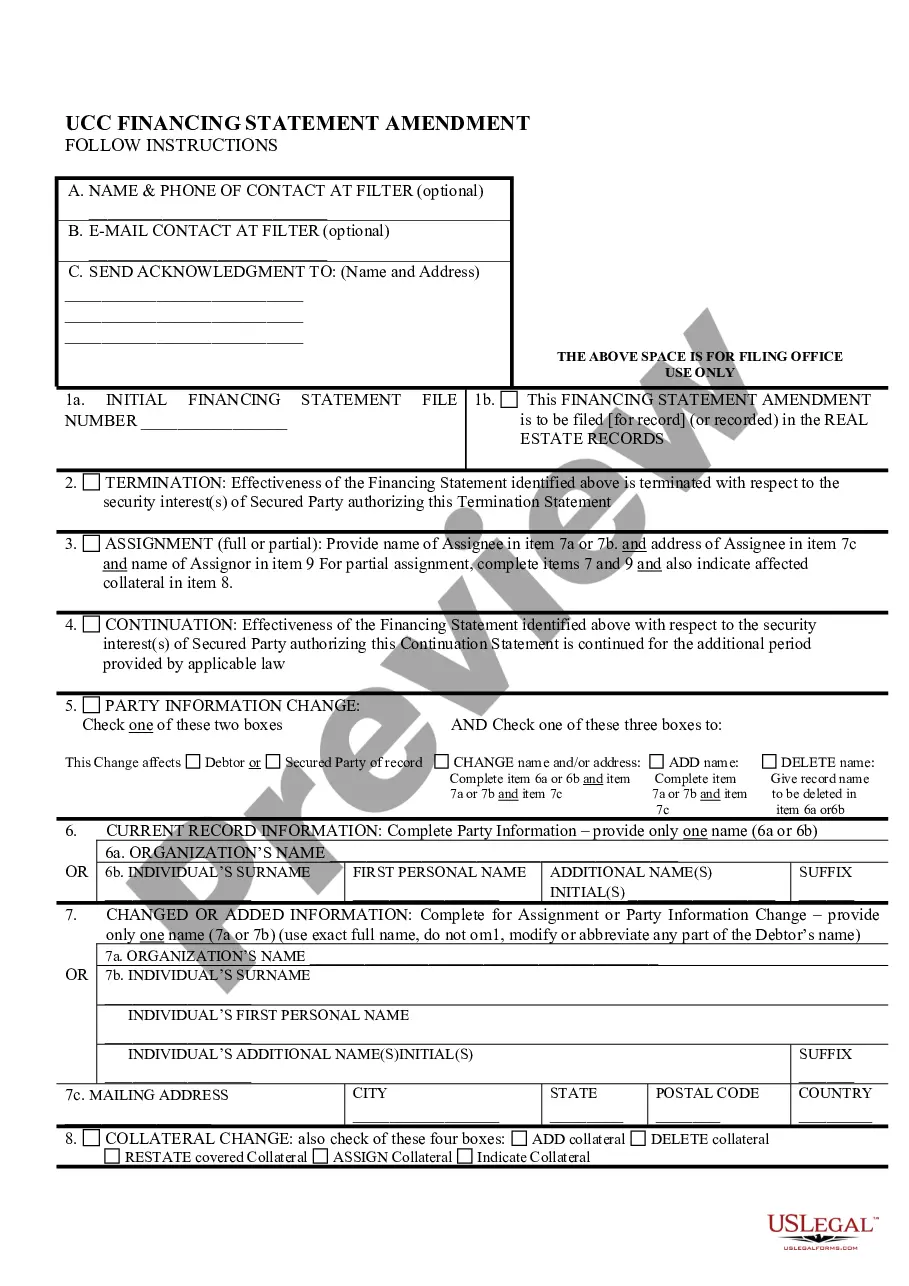

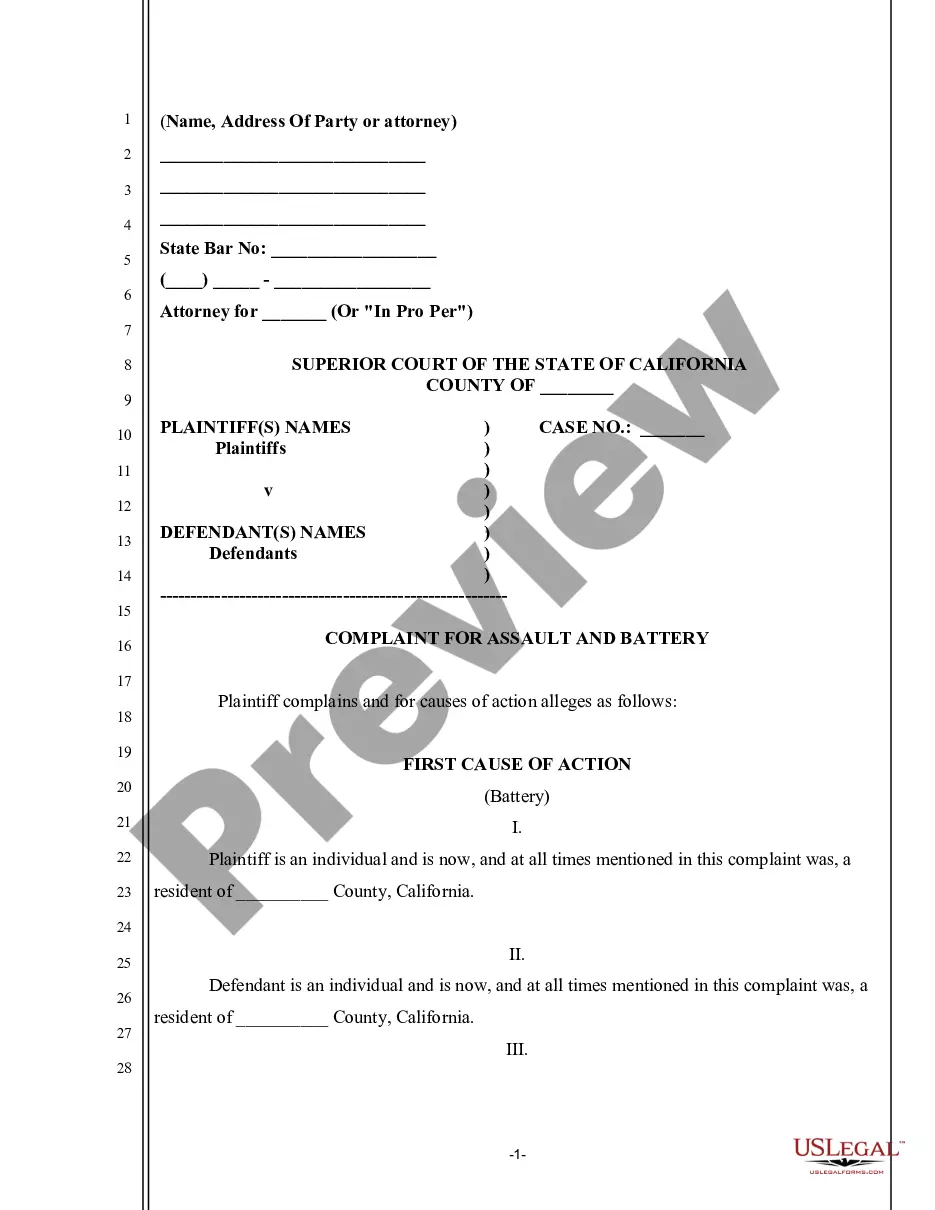

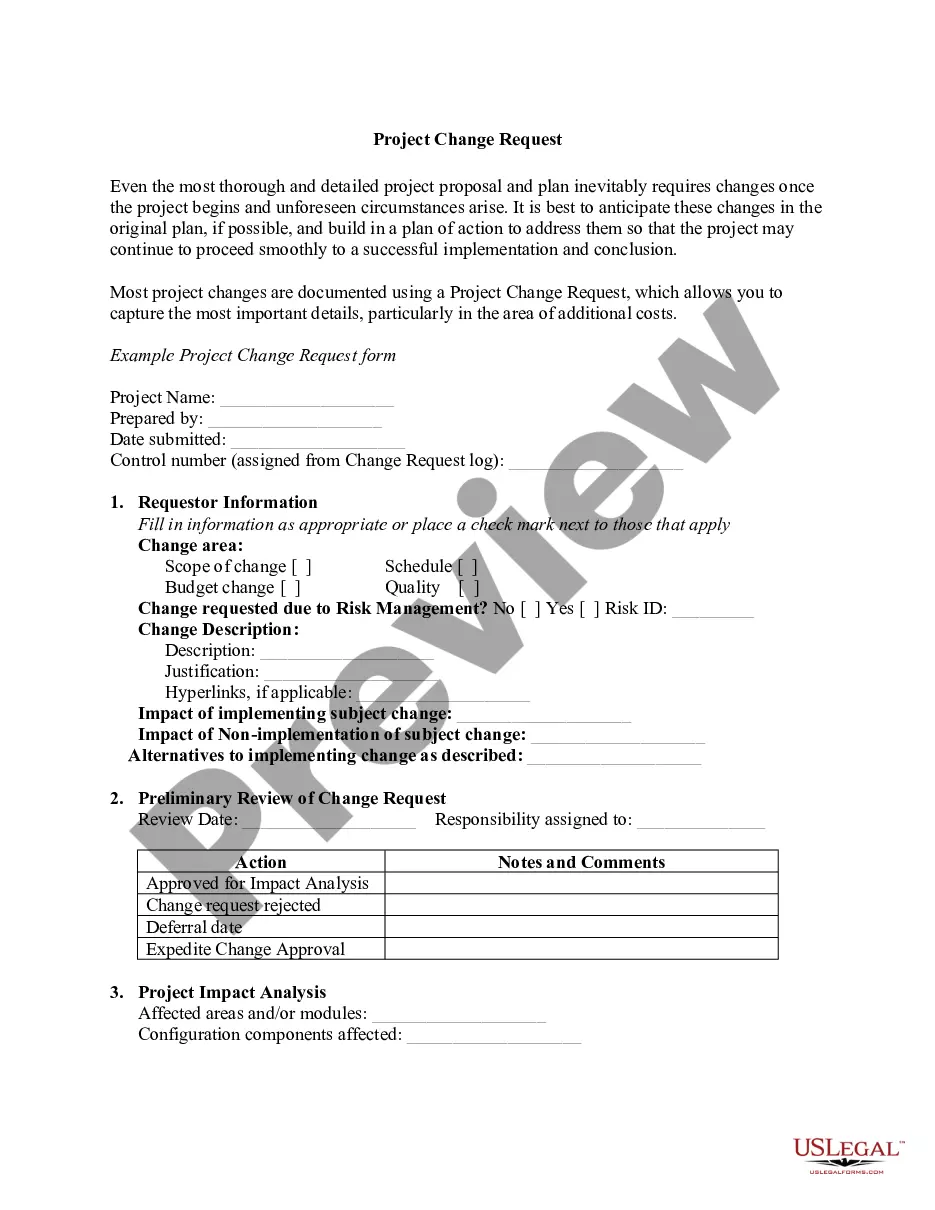

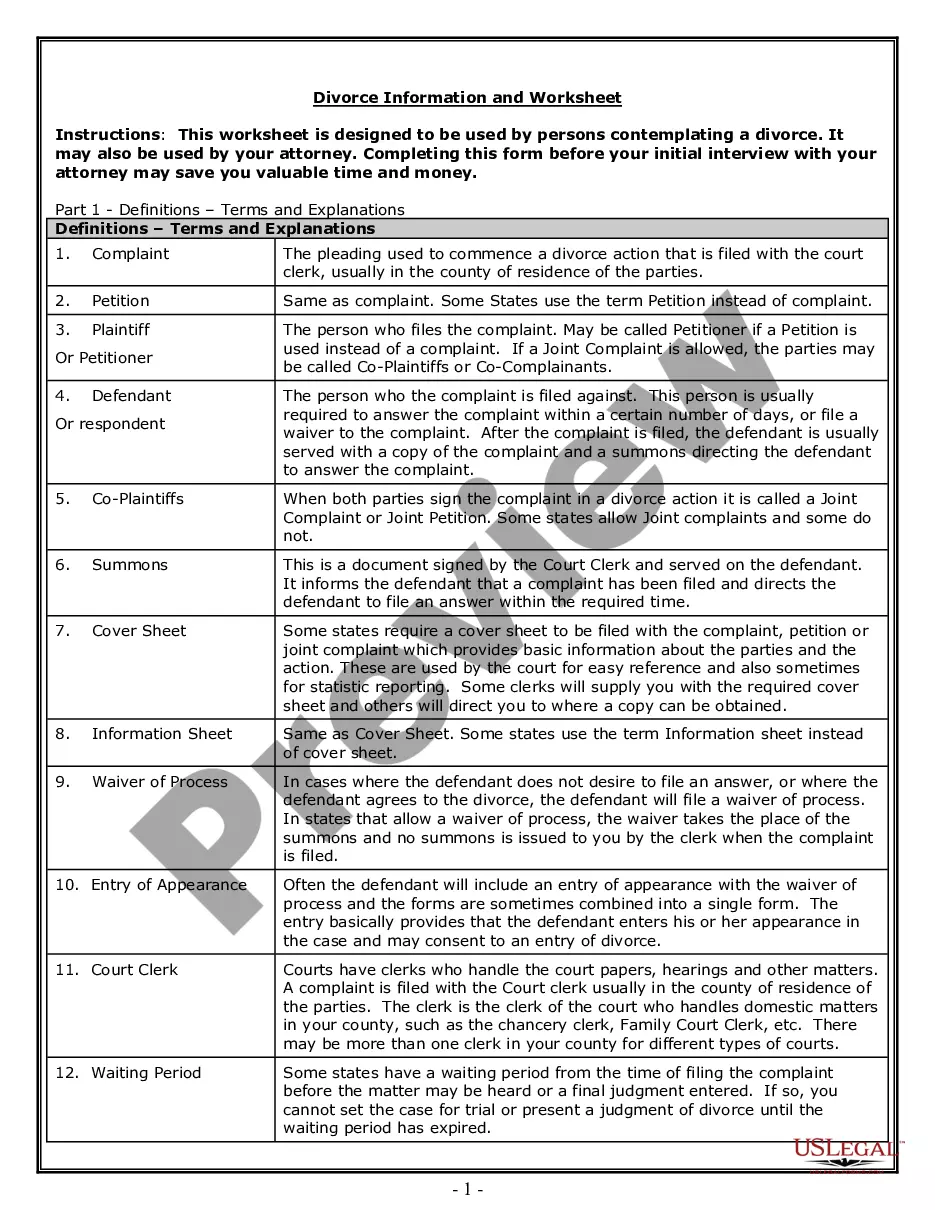

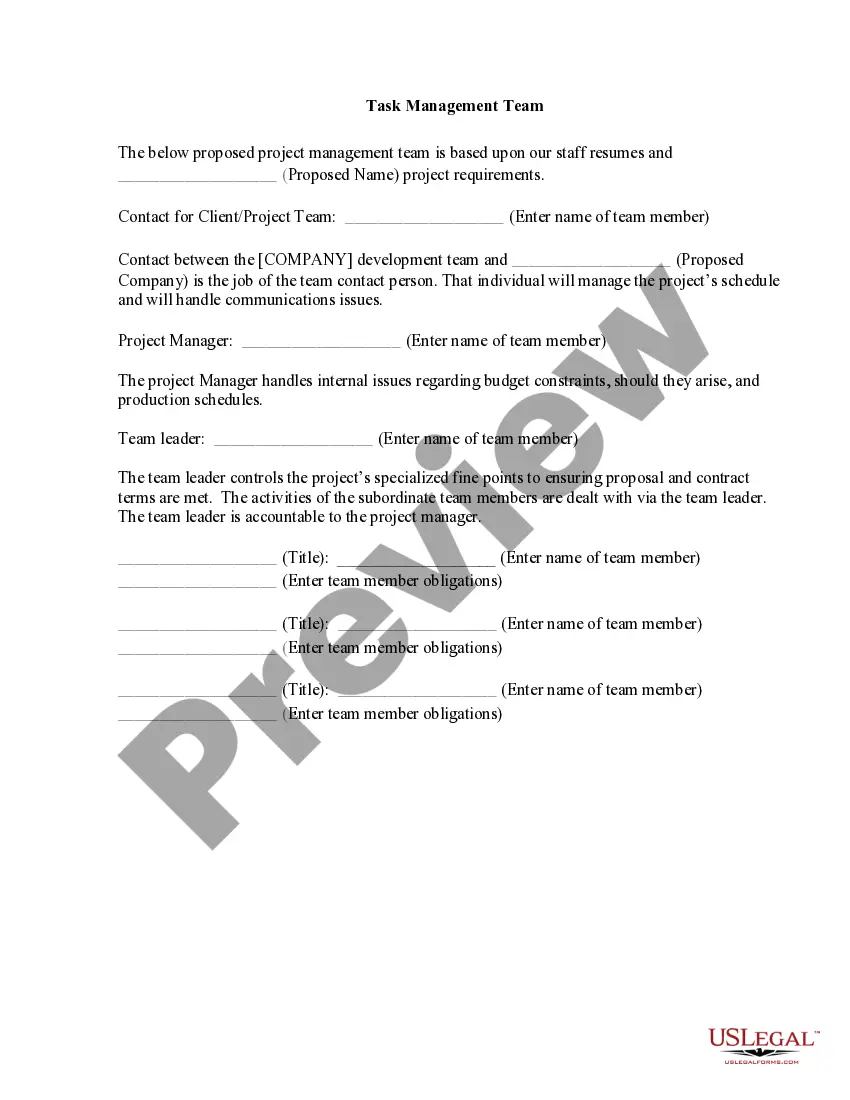

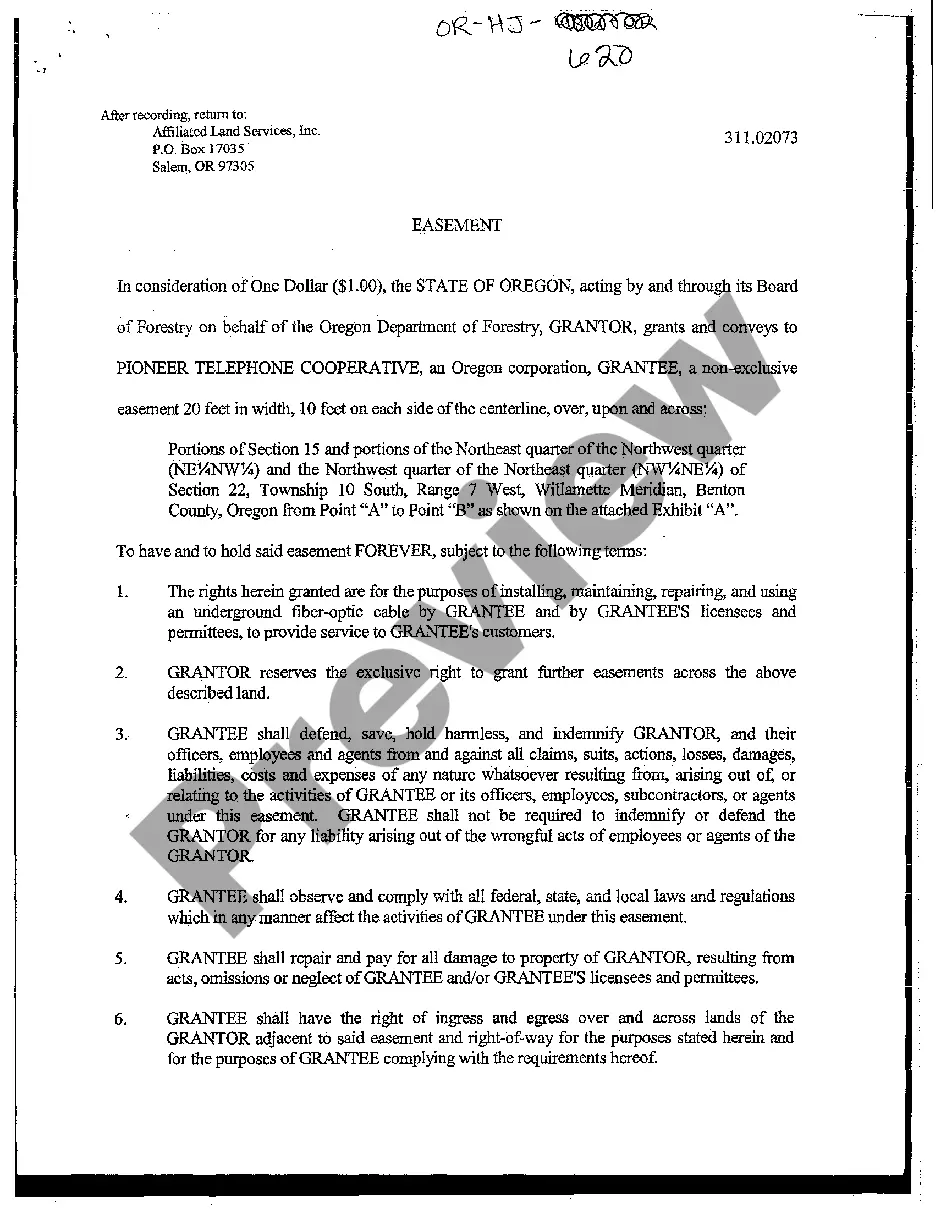

- Utilize the Review function to examine the document.

- Read the description to confirm you have selected the appropriate form.

- If the form isn’t what you’re looking for, use the Search field to find the one that meets your needs.

Form popularity

FAQ

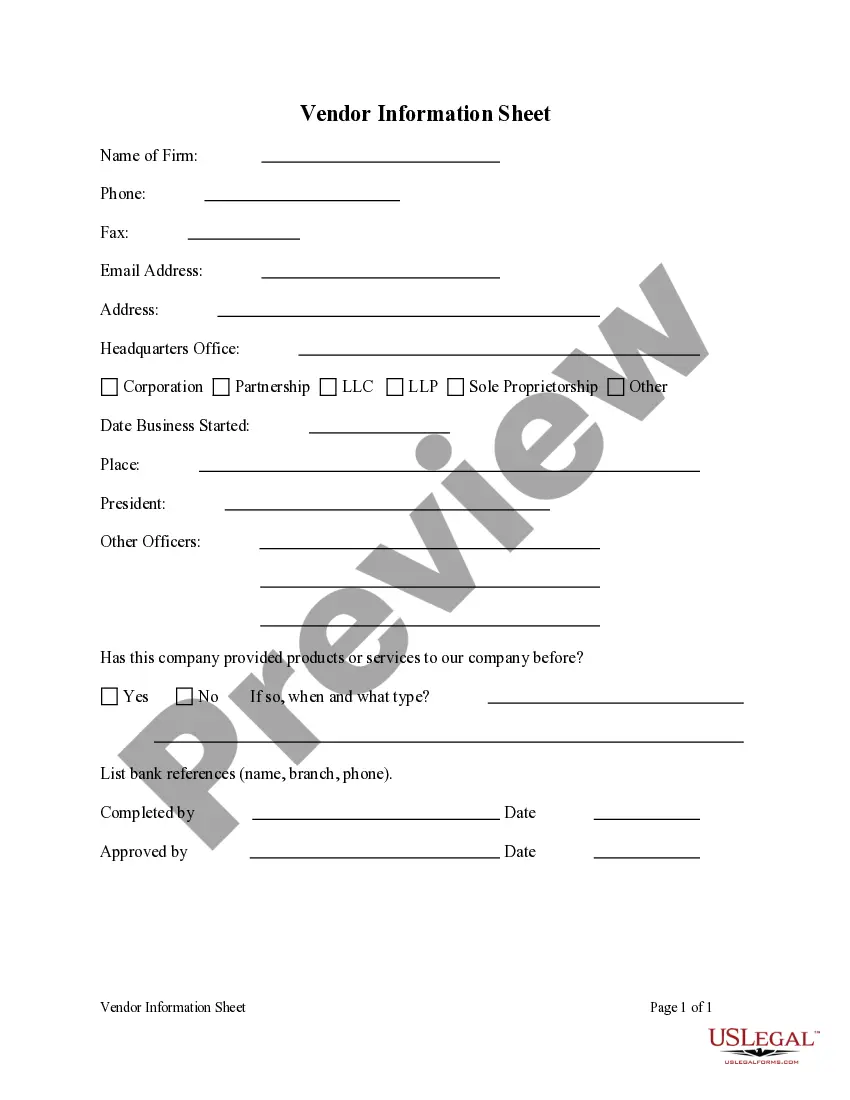

Inventory responsibility often lies with several key personnel, including inventory managers, warehouse staff, and sometimes, the financial department. Their collaboration is essential for maintaining accurate inventory records and ensuring those records reflect actual stock levels. Utilizing a Kentucky Physical Inventory Count Sheet promotes teamwork and communication among these roles, ensuring everyone is on the same page.

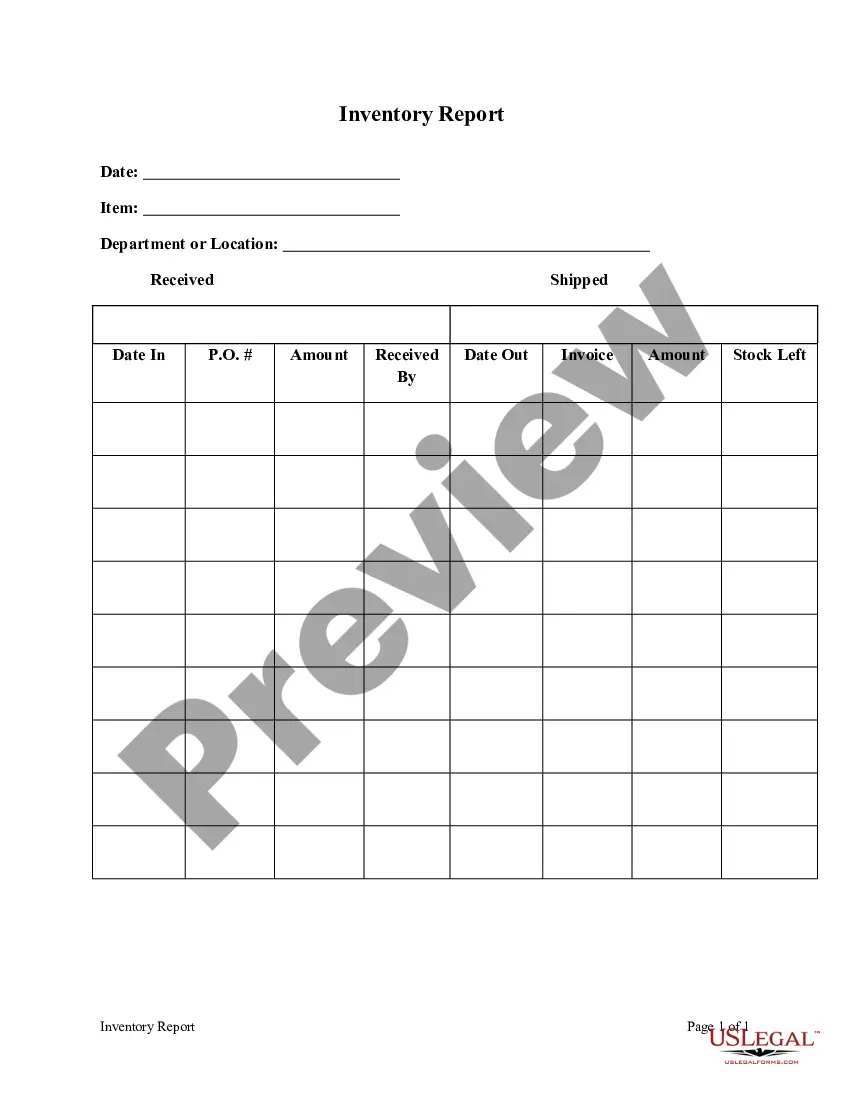

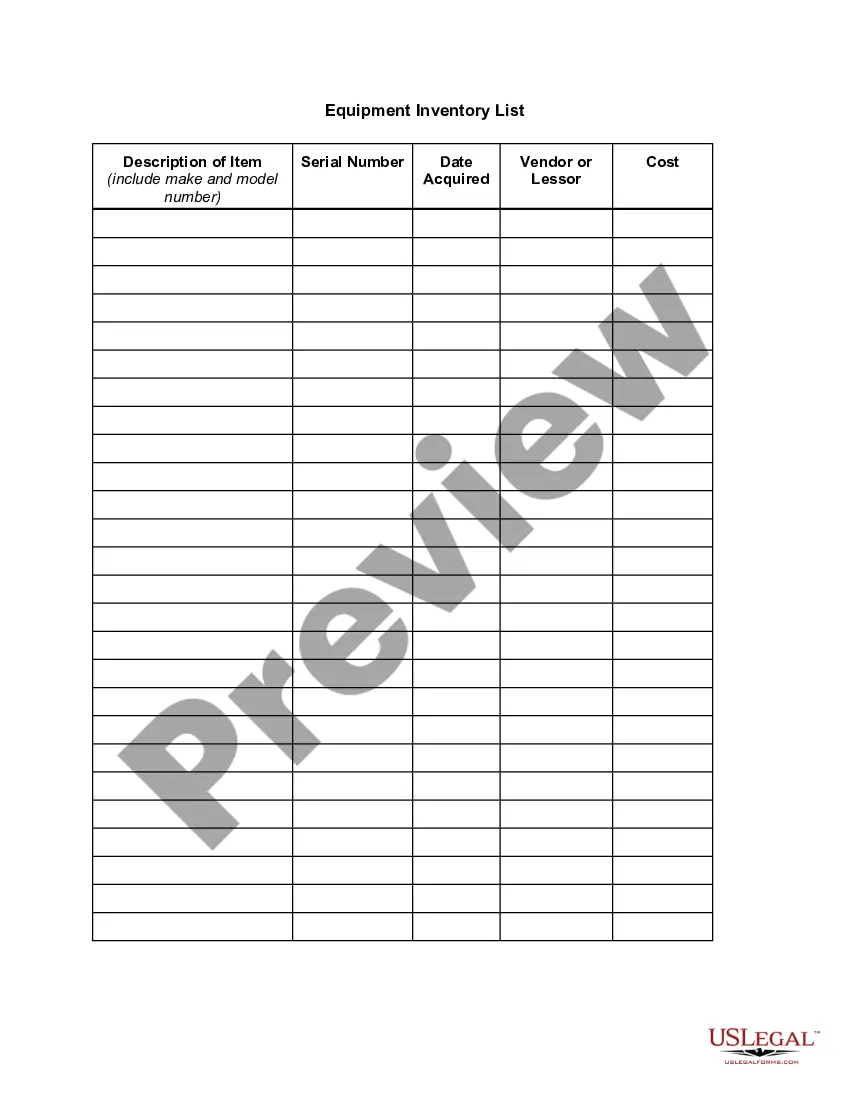

A physical inventory worksheet is a tool designed to help businesses log and track inventory during a physical count. It organizes information, helping to ensure no items are overlooked and providing a clear reference for future counts. Implementing a Kentucky Physical Inventory Count Sheet can enhance the effectiveness of this worksheet by ensuring updates and accuracy.

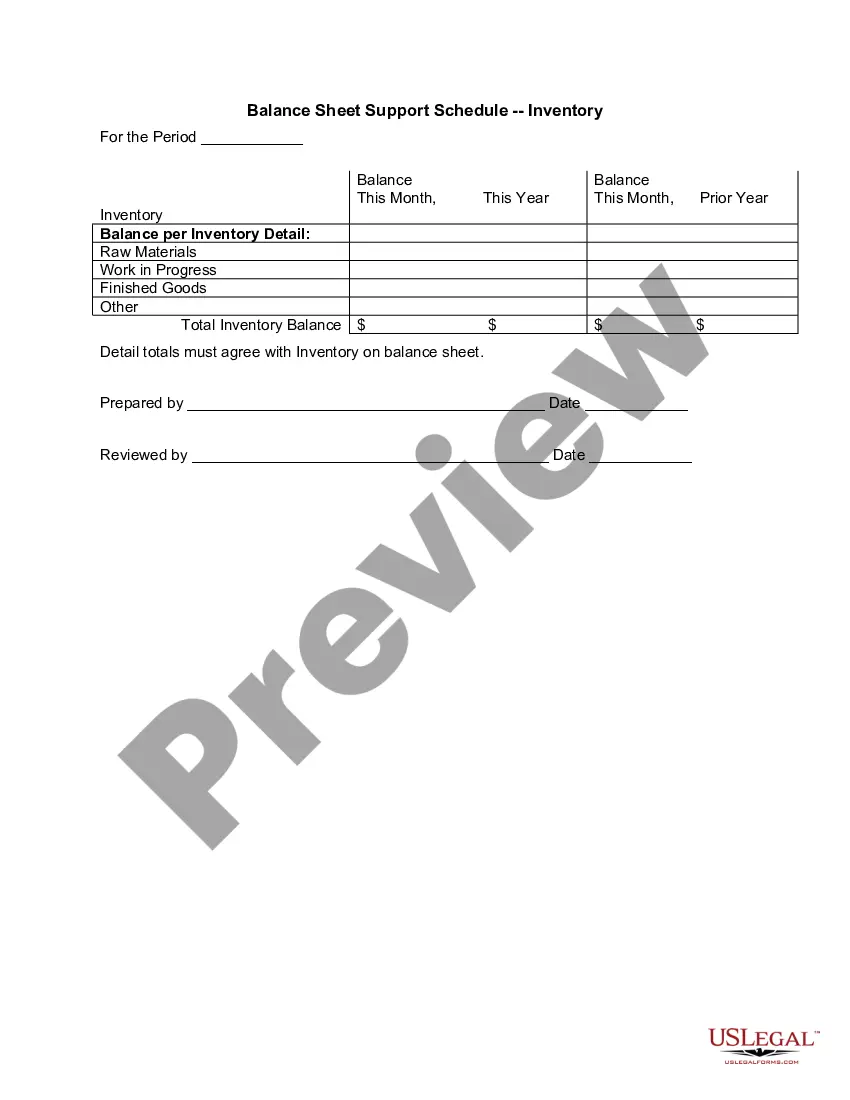

A physical inventory count is generally managed by the finance or audit team, with support from operations staff. The goal is to verify that physical stock matches recorded inventory levels. A Kentucky Physical Inventory Count Sheet can facilitate this verification process by providing a structured method to document findings.

The stock count is primarily the responsibility of the inventory control team, often led by an inventory supervisor. This role ensures that stock levels are accurately recorded and discrepancies are addressed. By employing a Kentucky Physical Inventory Count Sheet, teams can enhance their accountability and provide a clear framework for stock assessments.

Physical stock counting is usually performed by a dedicated inventory team, which can include employees from various departments. They coordinate to ensure accuracy and integrity during the counting process. Utilizing a Kentucky Physical Inventory Count Sheet streamlines this task, making it easier to track and record counts systematically.

The responsibility for inventory count typically falls on the inventory manager or the operations manager, but it can also involve staff members who manage specific inventory categories. Keeping an accurate count is crucial for effective business management. Using a Kentucky Physical Inventory Count Sheet can help delineate responsibilities and ensure clarity in the counting process.

A physical inventory number represents a unique identifier assigned to your inventory during the counting process. When using the Kentucky Physical Inventory Count Sheet, this number distinguishes each item counted. It aids in tracking and managing your inventory effectively, providing a clear reference for future checks.

Checking physical inventory involves a careful comparison of physical stock with inventory records. Using the Kentucky Physical Inventory Count Sheet, you can document each count clearly. This not only ensures accuracy but also facilitates easier audits and reconciliations in the future.

You can check physical inventory by comparing the actual counts against reported inventory in your system. Use the Kentucky Physical Inventory Count Sheet to systematically record your counts and identify any discrepancies. This process allows for timely adjustments and helps maintain accurate inventory levels.

To perform a physical inventory count, first gather your team and prepare your workspace. Equip your team with the Kentucky Physical Inventory Count Sheet, which should include item descriptions and spaces for recording counts. As you count each item, write down the quantities directly on the sheet, ensuring to double-check for accuracy.