Kentucky Aeseptic Techniques

Description

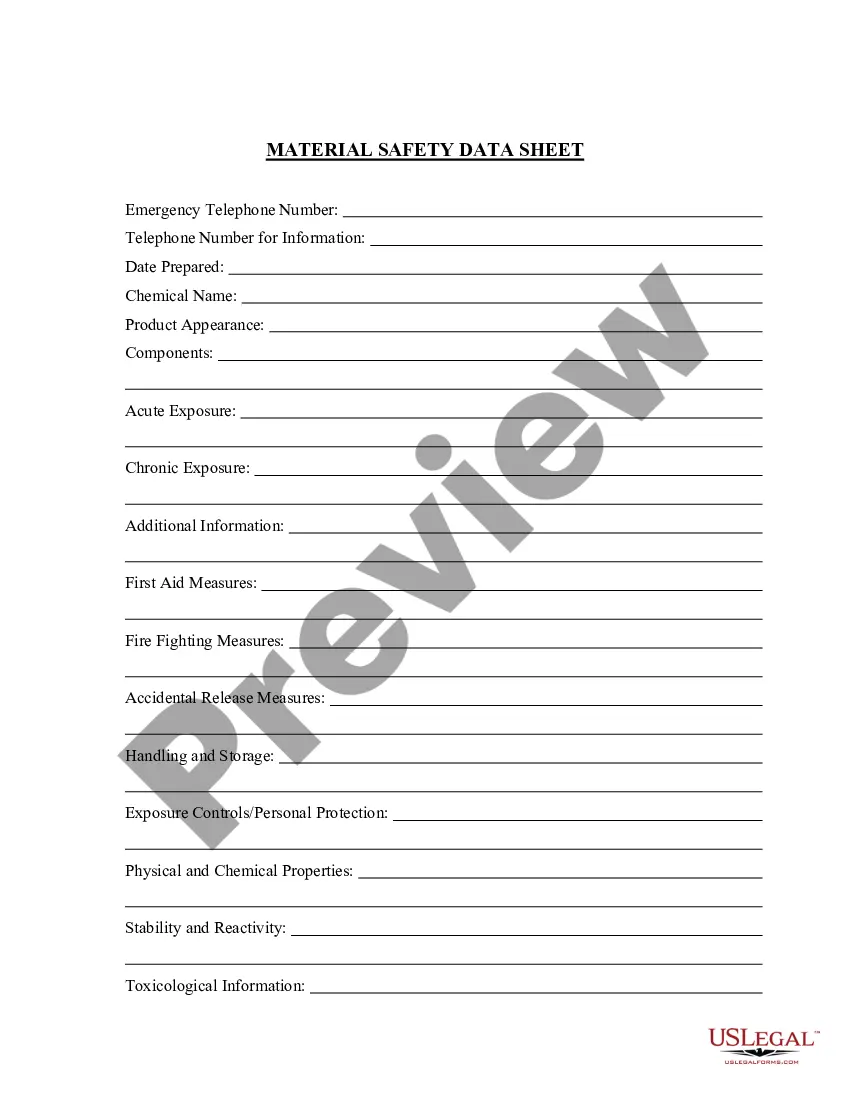

How to fill out Aeseptic Techniques?

If you are looking for thorough, obtain, or print legal document templates, utilize US Legal Forms, the largest selection of legal documents available online.

Employ the site’s user-friendly and convenient search function to locate the paperwork you need.

Various templates for business and personal use are categorized by types and tags, or keywords.

Step 4. Once you have found the form you need, click the Purchase now button. Choose the pricing plan you prefer and enter your details to register for an account.

Step 5. Complete the payment process. You can use your credit card or PayPal account to finalize the transaction.

- Use US Legal Forms to discover the Kentucky Aseptic Techniques with just a few clicks.

- If you are a current US Legal Forms customer, Log In to your account and click the Download button to access the Kentucky Aseptic Techniques.

- You can also retrieve forms you have previously saved in the My documents section of your account.

- If you are using US Legal Forms for the first time, follow the steps below.

- Step 1. Ensure you have chosen the form for the correct city/state.

- Step 2. Use the Preview option to view the form’s content. Be sure to understand the information.

- Step 3. If you are not satisfied with the form, utilize the Search area at the top of the screen to find other versions of the legal form template.

Form popularity

FAQ

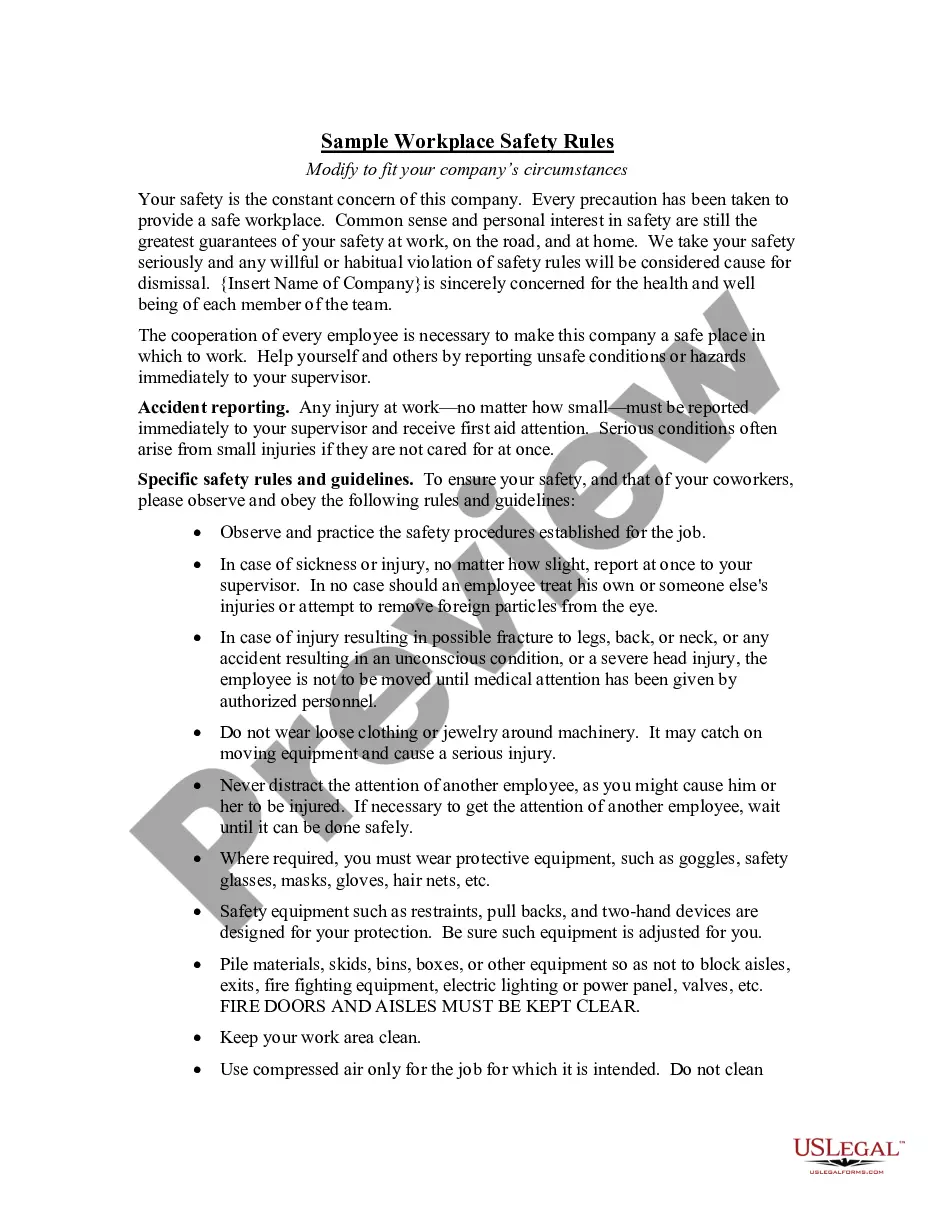

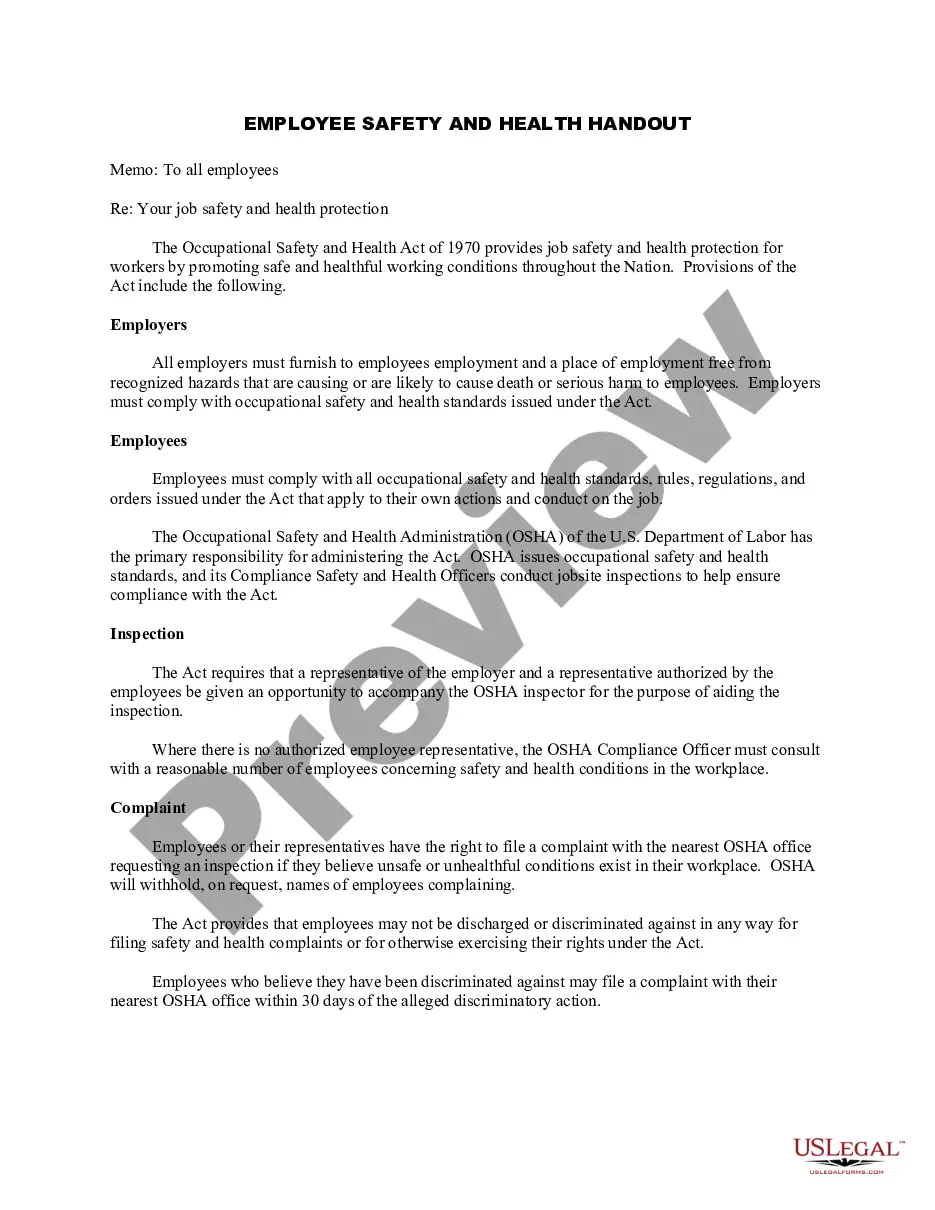

Aseptic techniques aim to minimize contamination, while non-sterile practices do not ensure any control over microbial presence. Aseptic methods are crucial in healthcare and laboratory settings, where the risk of infection or contamination is high. By adopting Kentucky Aseptic Techniques, you ensure that your processes maintain high safety standards.

Aseptic techniques include:Wiping bench with disinfectant/alcohol. Not growing microorganisms at body temperature. Using sterile loops when transferring cultures . Flaming culture bottle necks to prevent contamination. Sterilising (using an autoclave ) or disposing of all used equipment.

Aseptic technique is classified into two different categories: standard aseptic technique and surgical aseptic technique.

Principles of Sterile TechniqueFace to face or back to back.Turn back to a non-sterile person or when passing.Face a sterile area when passing the area.Ask a non-sterile person to step aside rather than trying to crowd past him.Step back away from the sterile field to sneeze or cough.More items...?

Do not sneeze, cough, laugh, or talk over the sterile field. Maintain a safe space or margin of safety between sterile and non-sterile objects and areas. Refrain from reaching over the sterile field. Keep operating room (OR) traffic to a minimum, and keep doors closed.

PRINCIPLES OF THE ASEPTIC TECHNIQUECreating a microorganism-free environment (sterile field)Use of sterilized instruments and dressings.Maintaining sterility of sterile field and instruments by preventing microbial contaminationby contact with non-sterile objects; such as:More items...

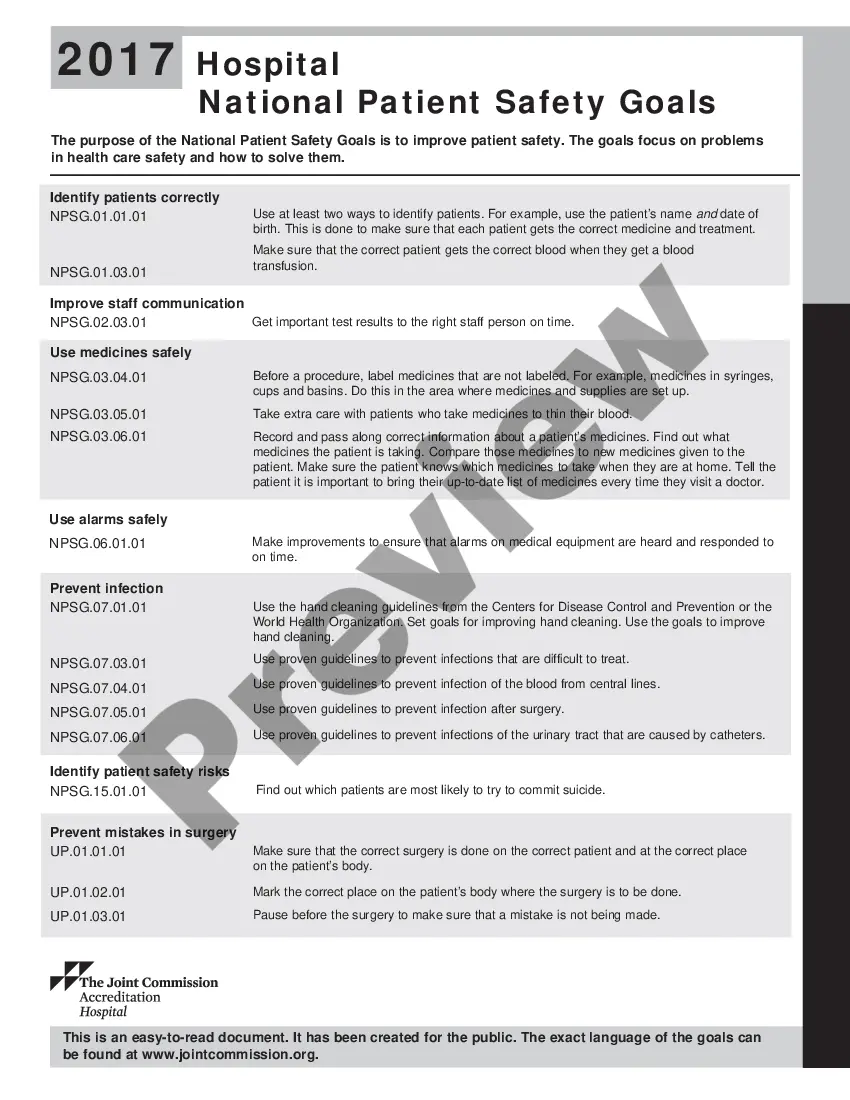

According to The Joint Commission, there are four chief aspects of the aseptic technique: barriers, patient equipment and preparation, environmental controls, and contact guidelines. Each plays an important role in infection prevention during a medical procedure.

Procedures that involve aseptic technique include:200cInserting PICC lines.200cPerforming dialysis.200cInserting catheters.200cRunning IVs.200cInserting chest tubes.200cPerforming surgeries.200cDressing wounds.

These principles include the following: (1) use only sterile items within a sterile field; (2) sterile (scrubbed) personnel are gowned and gloved; (3) sterile personnel operate within a sterile field (sterile personnel touch only sterile items or areas, unsterile personnel touch only unsterile items or areas); (4)