Kentucky Hazard Communication Training Checklist for Company Policies

Description

How to fill out Hazard Communication Training Checklist For Company Policies?

You might spend hours online attempting to locate the legal document template that fulfills the federal and state criteria you require.

US Legal Forms offers a vast array of legal documents that have been evaluated by experts.

You can download or print the Kentucky Hazard Communication Training Checklist for Company Policies from our platform.

If available, utilize the Preview button to browse the document template as well.

- If you possess a US Legal Forms account, you can sign in and click the Download button.

- After that, you can complete, modify, print, or sign the Kentucky Hazard Communication Training Checklist for Company Policies.

- Every legal document template you purchase is yours indefinitely.

- To obtain another copy of a purchased form, navigate to the My documents tab and click the corresponding button.

- If you are using the US Legal Forms website for the first time, follow the straightforward instructions below.

- Firstly, ensure that you have selected the correct document template for your region/area of choice.

- Review the form description to confirm you have selected the appropriate document.

Form popularity

FAQ

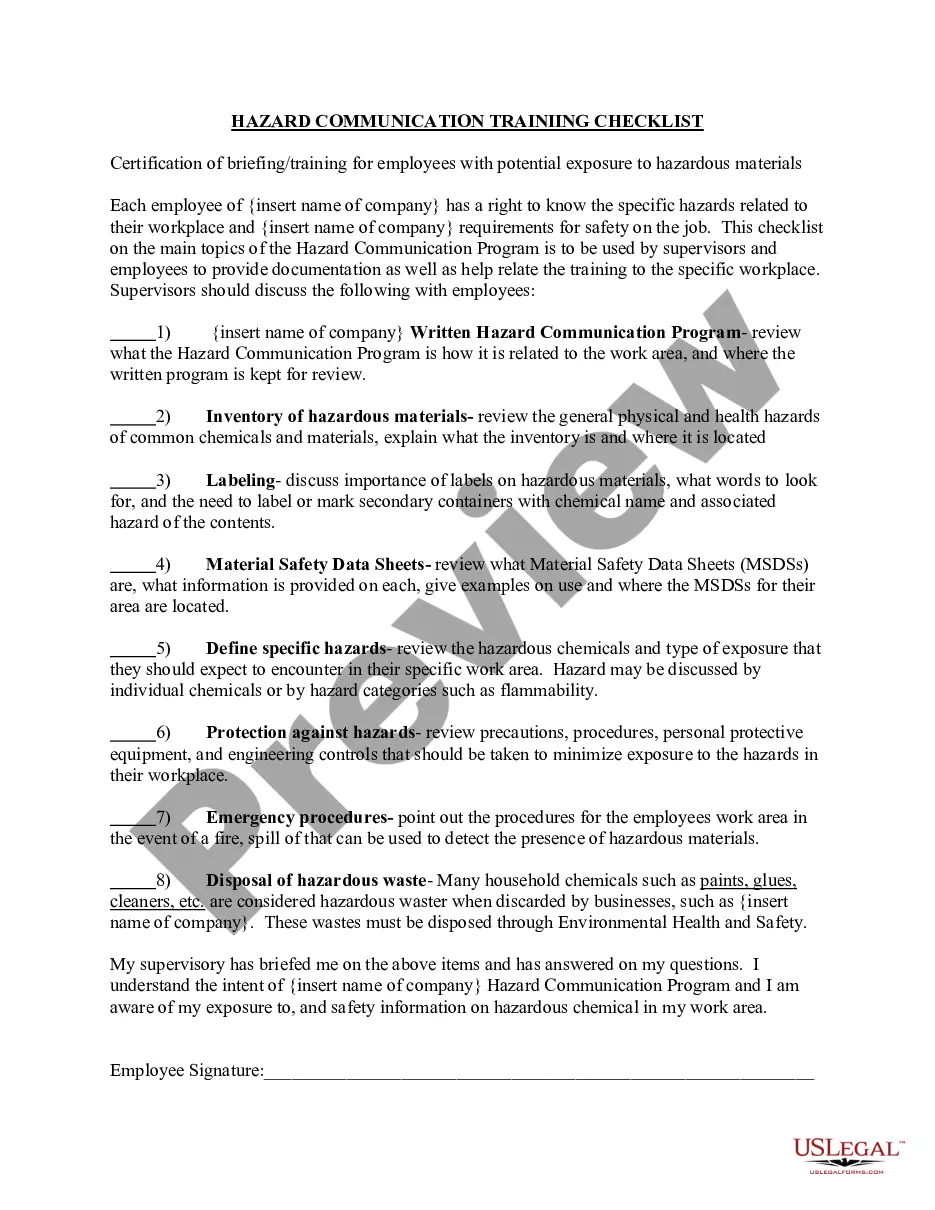

Yes, employers are required to maintain a written hazard communication program that outlines how they will meet OSHA's requirements. This program should detail how hazards will be communicated to employees, including training protocols and labeling systems. By utilizing the Kentucky Hazard Communication Training Checklist for Company Policies, businesses can streamline the development of their written program, ensuring compliance while enhancing employee safety and awareness.

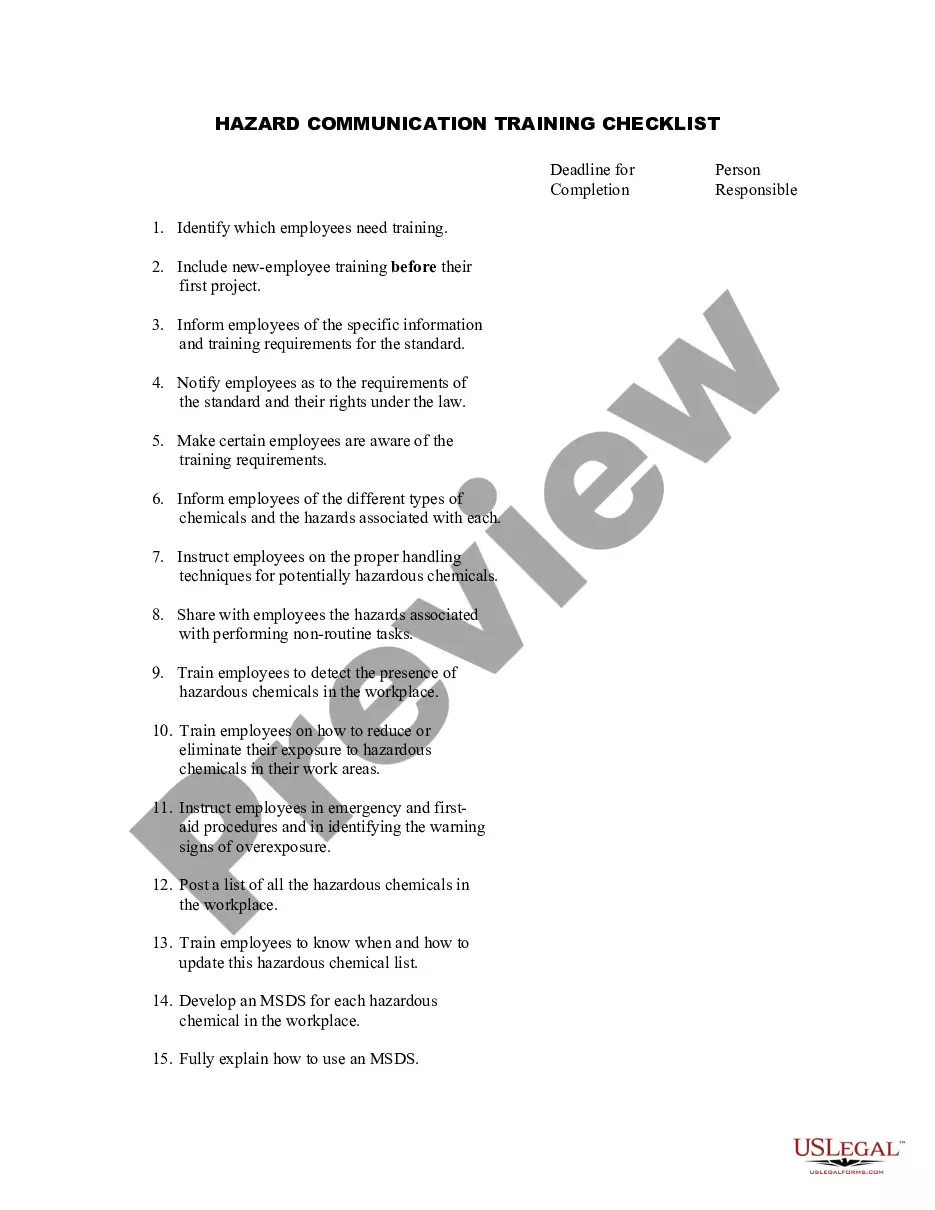

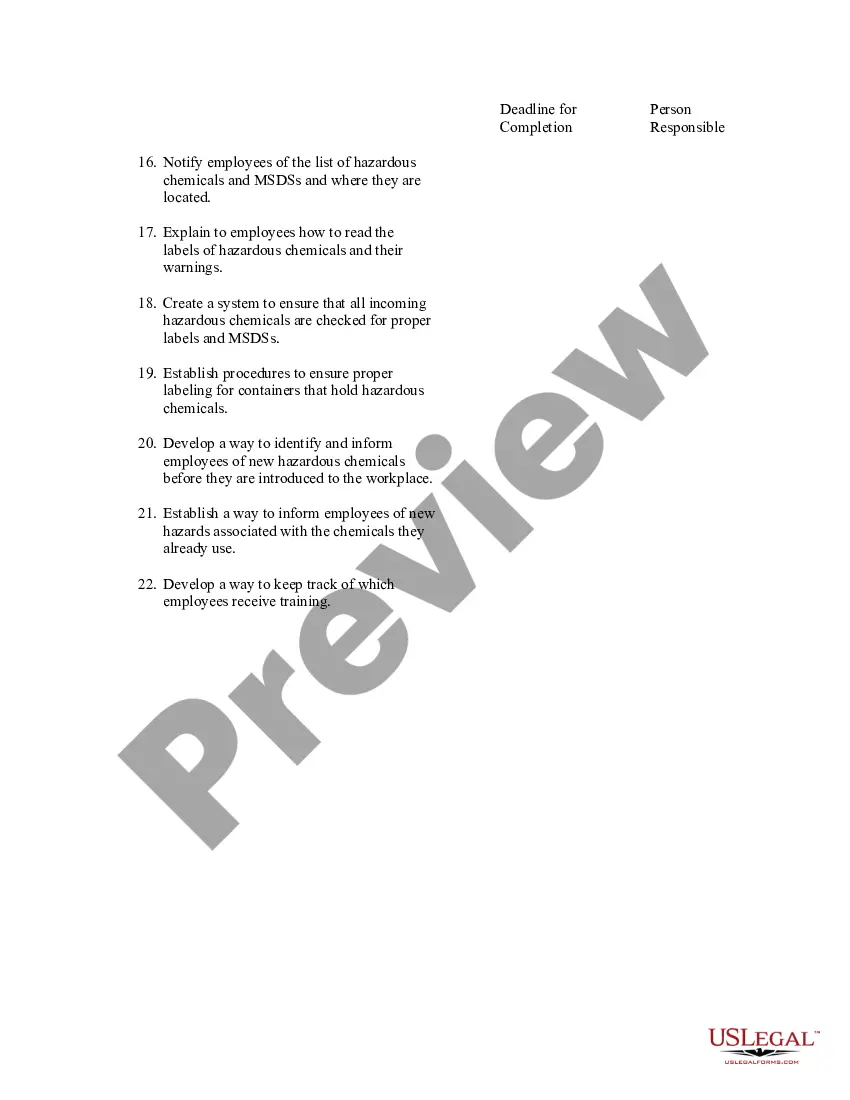

They are: Chemical Inventory, Written Program, Labels, Material Safety Data Sheets, and Training. The first element of the Hazard Communication Standard is for employers to develop inventories of all the hazardous chemicals they have at their worksite.

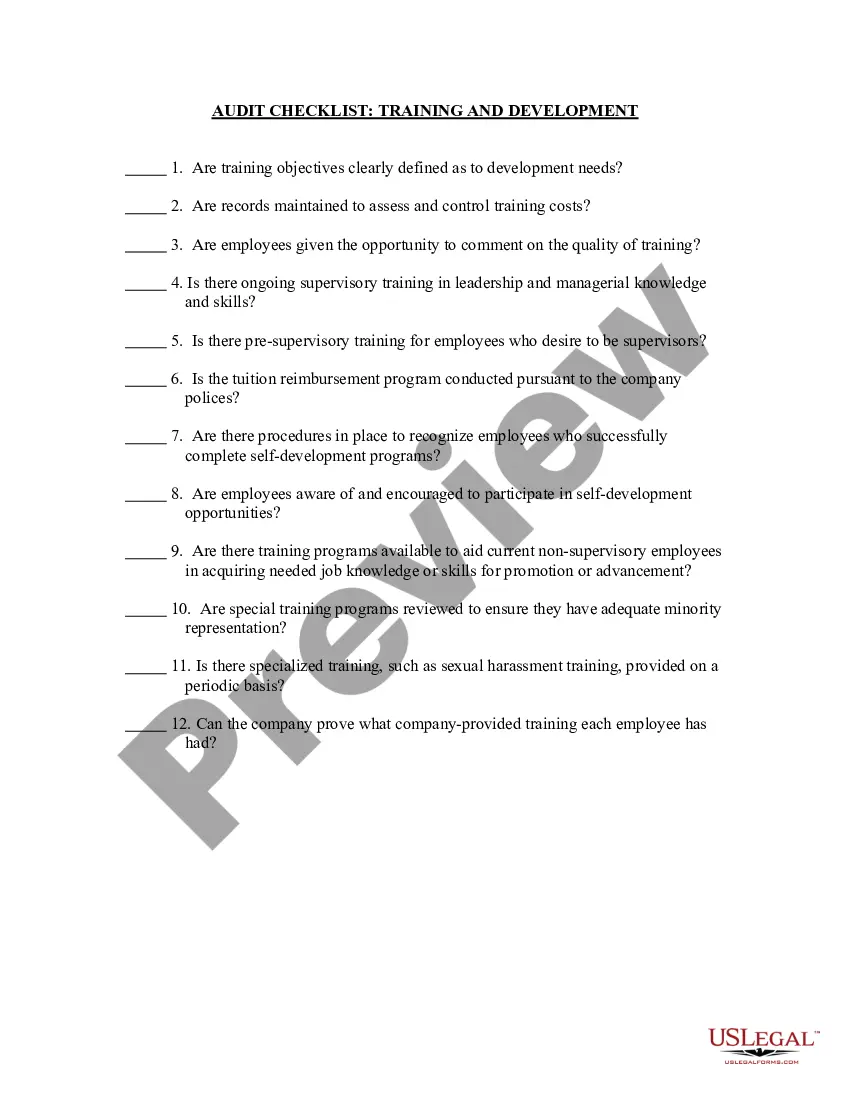

When working with hazardous chemicals, employees must have the proper information and training regarding handling the chemicals, protecting themselves against risk, and understanding any outstanding safety concerns.

The Hazard Communication Standard (HCS), 29 CFR 1910.1200 (h), requires all employers to provide information and training to their employees about the hazardous chemicals to which they may be exposed at the time of their initial assignment and whenever a new hazard is introduced into their work area.

All employees must be provided with information and training on hazardous chemicals in their work area at the time of their initial assignment (prior to being exposed to a chemical), and whenever a new chemical hazard they have not previously been trained about is introduced into their work area.

The program must include labels on containers of hazardous chemicals, safety data sheets (SDSs) for hazardous chemicals, and training for workers. Each employer must also describe in a written program how it will meet the requirements of the HCS in each of these areas.

Updated: Learn the standard and identify responsible staff for particular activities such as training.Prepare and implement a written hazard communication program.Ensure that containers are labeled.Maintain safety data sheets.Inform and train employees.Evaluate and reassess.27-Jul-2017

These are the Five elements of the Hazard Communication Standard. They are: Chemical Inventory, Written Program, Labels, Material Safety Data Sheets, and Training. The first element of the Hazard Communication Standard is for employers to develop inventories of all the hazardous chemicals they have at their worksite.

The Hazard Communication Regulation (Cal/OSHA, section 5194; Federal OSHA 29 CFR 1910.1200) requires that the chemical manufacturer, distributor, or importer provide safety data sheets (SDSs) (formerly MSDSs or material safety data sheets) for each hazardous chemical to downstream users to communicate information on

The Hazard Communication Standard (HCS), 29 CFR 1910.1200 (h), requires all employers to provide information and training to their employees about the hazardous chemicals to which they may be exposed at the time of their initial assignment and whenever a new hazard is introduced into their work area.